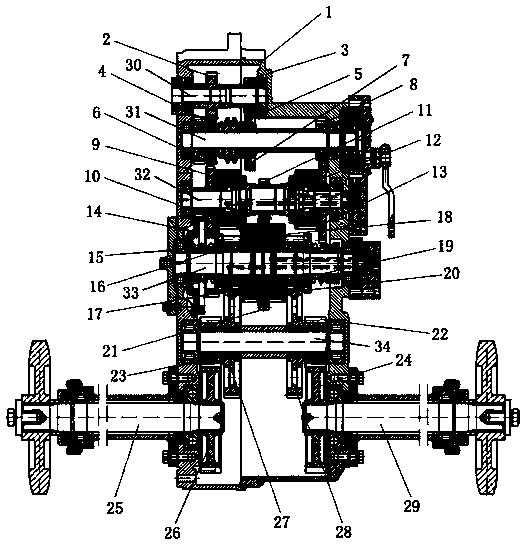

Continuously variable transmission adopting hydraulic control and flexible steering

A continuously variable transmission, hydraulic control system technology, applied in transmission control, gear transmission, multi-way valve, etc., can solve the problems of broken shaft, damaged steering gear, and high load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

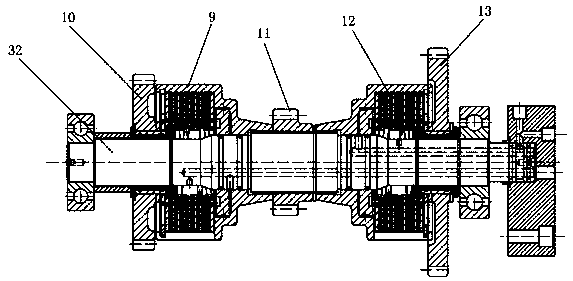

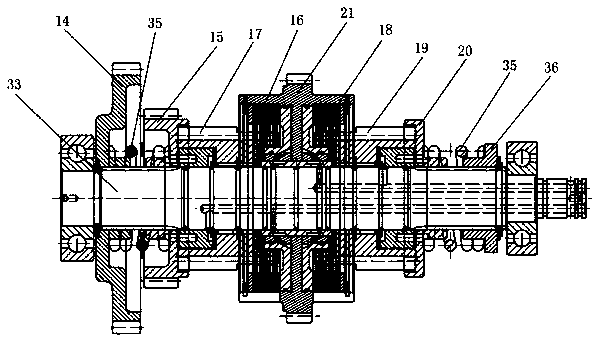

[0050] Going straight: the small holes in the oil passages of the first steering shaft and the second steering shaft do not emit oil, the friction plates of the first friction clutch and the second friction clutch are loosened, and are in a natural state, and the teeth of gear M and gear L are engaged.

[0051]

Embodiment 2

[0053] Left reverse and right positive: the friction plate of the first friction clutch of the steering axis is loosened, the friction plate of the second friction clutch is pressed, the friction plate of the third friction clutch of the second steering axis is pressed, and the friction plate of the fourth friction clutch is loosened , the gear M is disengaged and moves to the left, and the gear L is locked in place and does not move.

[0054]

Embodiment 3

[0056] The left is positive and the right is slow: the friction plate of the first friction clutch of the steering axis is pressed tightly, the friction plate of the second friction clutch is pressed and released, the friction plate of the third friction clutch of the second steering axis is loosened, and the friction plate of the fourth friction clutch is released. The friction discs are pressed tightly, the gear M's cogging engagement remains in place, and the gear L's cogging is disengaged and moves to the right.

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com