Piston engine valve timing and variable lift driving system

A piston engine, valve timing technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as many fault points, insufficient linearity of power output, poor linearity of power output, etc., to prevent damage to parts and failure, reduction of mechanical vibration and stress, effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

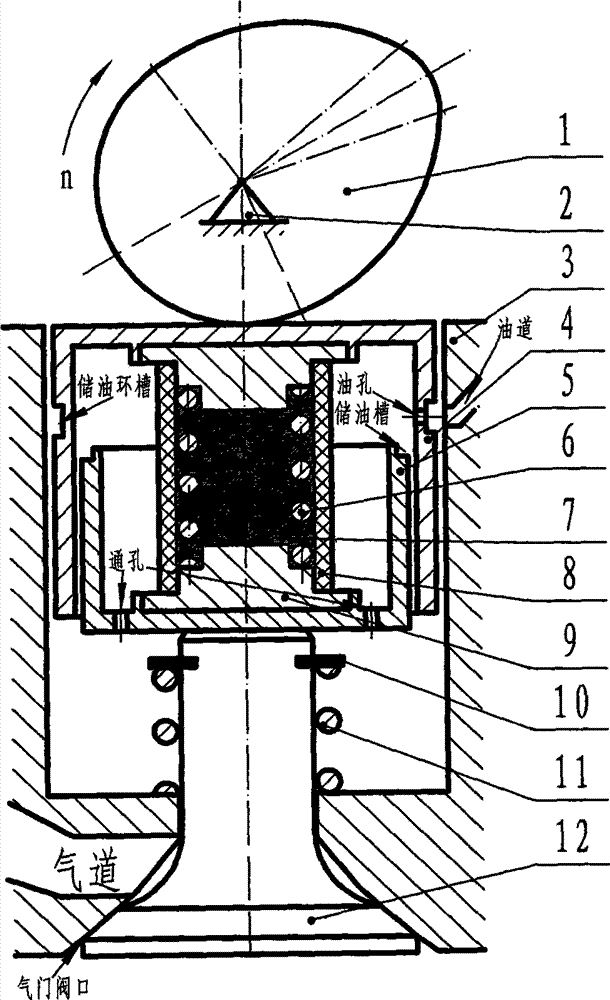

[0035] 1. Structure description

[0036] Such as figure 1 As shown, the technical solution structure of the present invention is made up of cam (1), frame (2), body (3), shear thickening tappet, valve spring seat (10), valve spring (11) and valve (12) . Among them: the shear thickening tappet consists of a large piston (4), a small piston (5), a piston return spring (6), a shear thickening liquid (7), a rubber sleeve (8) and an upper and lower base (9) composition.

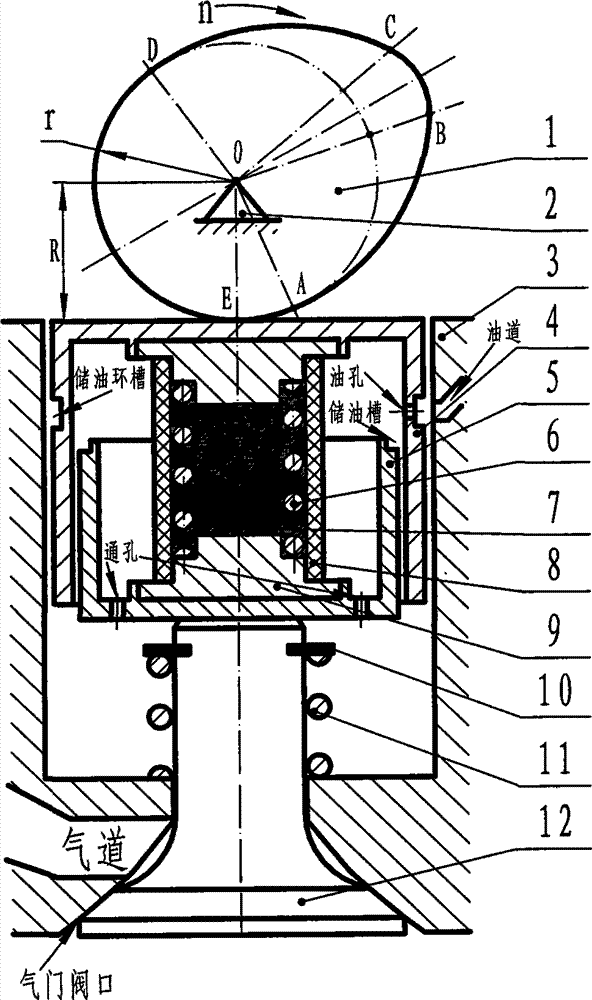

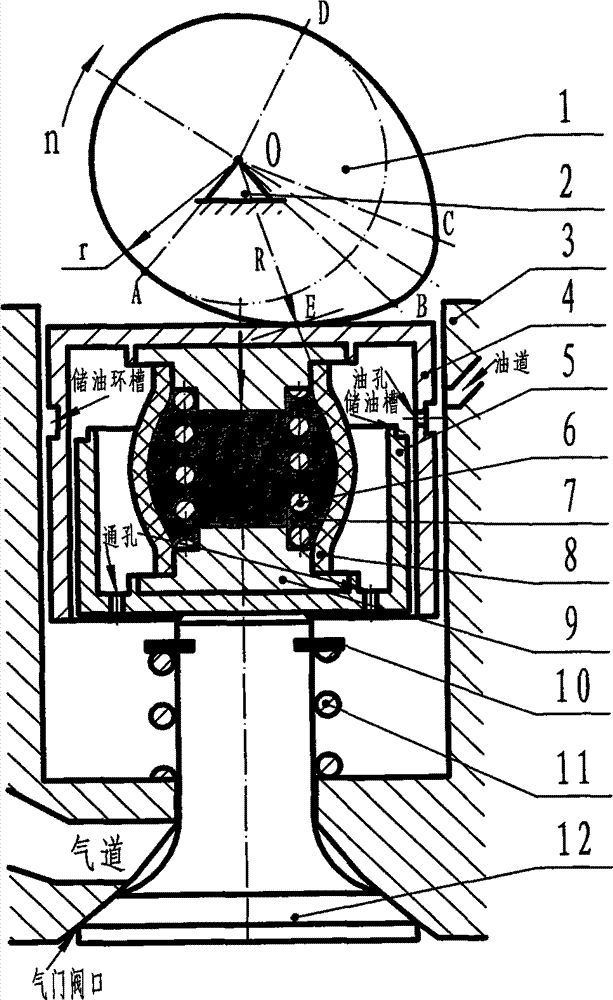

[0037] Two, technical scheme system working process analysis of the present invention

[0038] 1. If figure 2 As shown, the driving process of the cam base circle arc: as the cam (1) rotates around the rotation center O on the frame (2) at a speed n, the driving point E is within the base circle arc DA of the cam (1), along the The direction D→A is gradually changed to A, and the driving radius R is equal to the radius r of the base circle and remains unchanged. During this process, ① the shear thickening l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com