Multi-load hydraulic sensing system for single-power source and multi-system working

A single power source, hydraulic system technology, applied in the direction of lifting device, fluid steering mechanism, control device, etc., can solve the problems of inability to drive in two directions and omnidirectional steering, multi-pump oil supply for explosion-proof forklifts, complex structure, etc., and achieve explosion-proof costs. Low cost, reduced explosion-proof cost and technical difficulty, and multi-functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

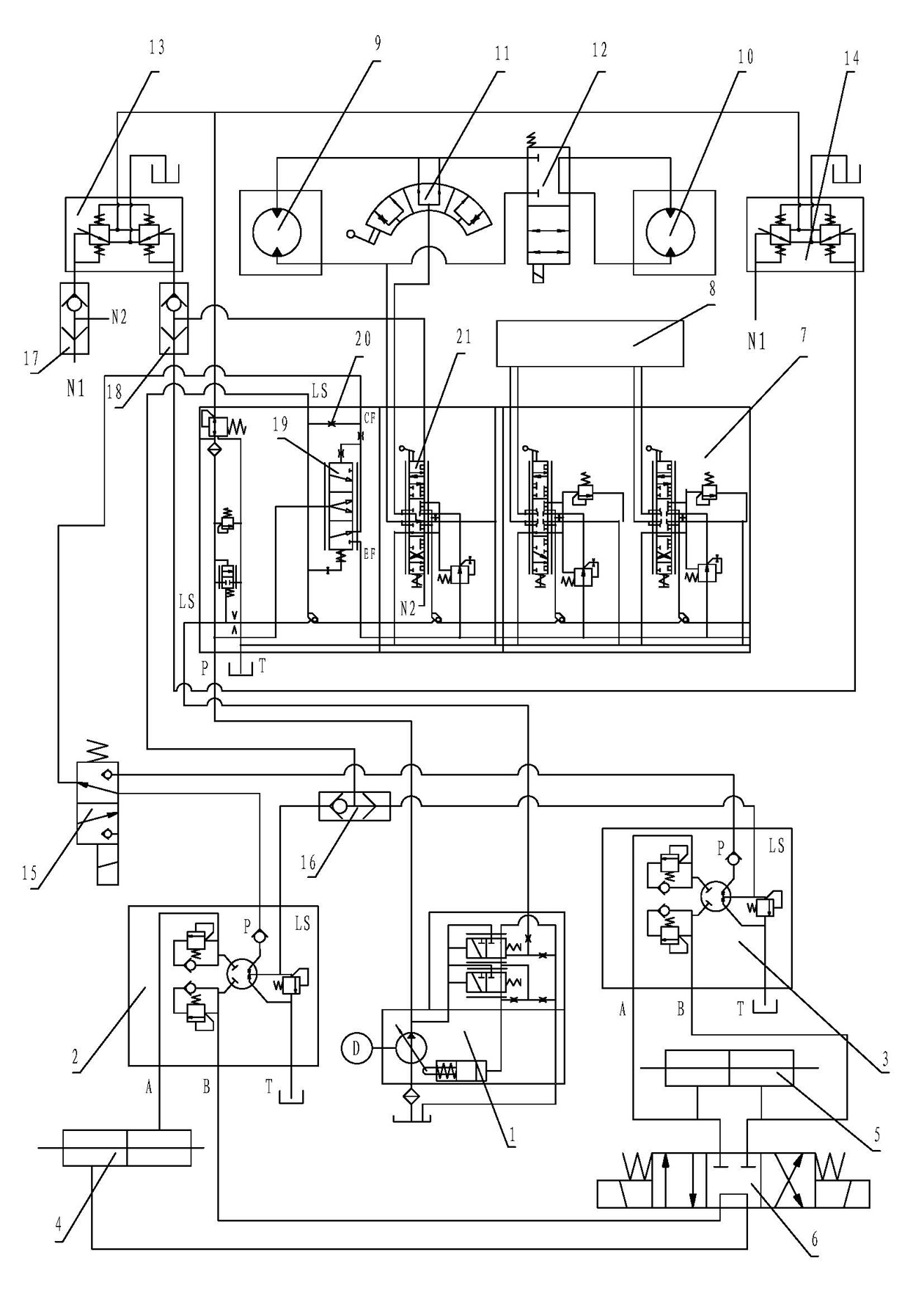

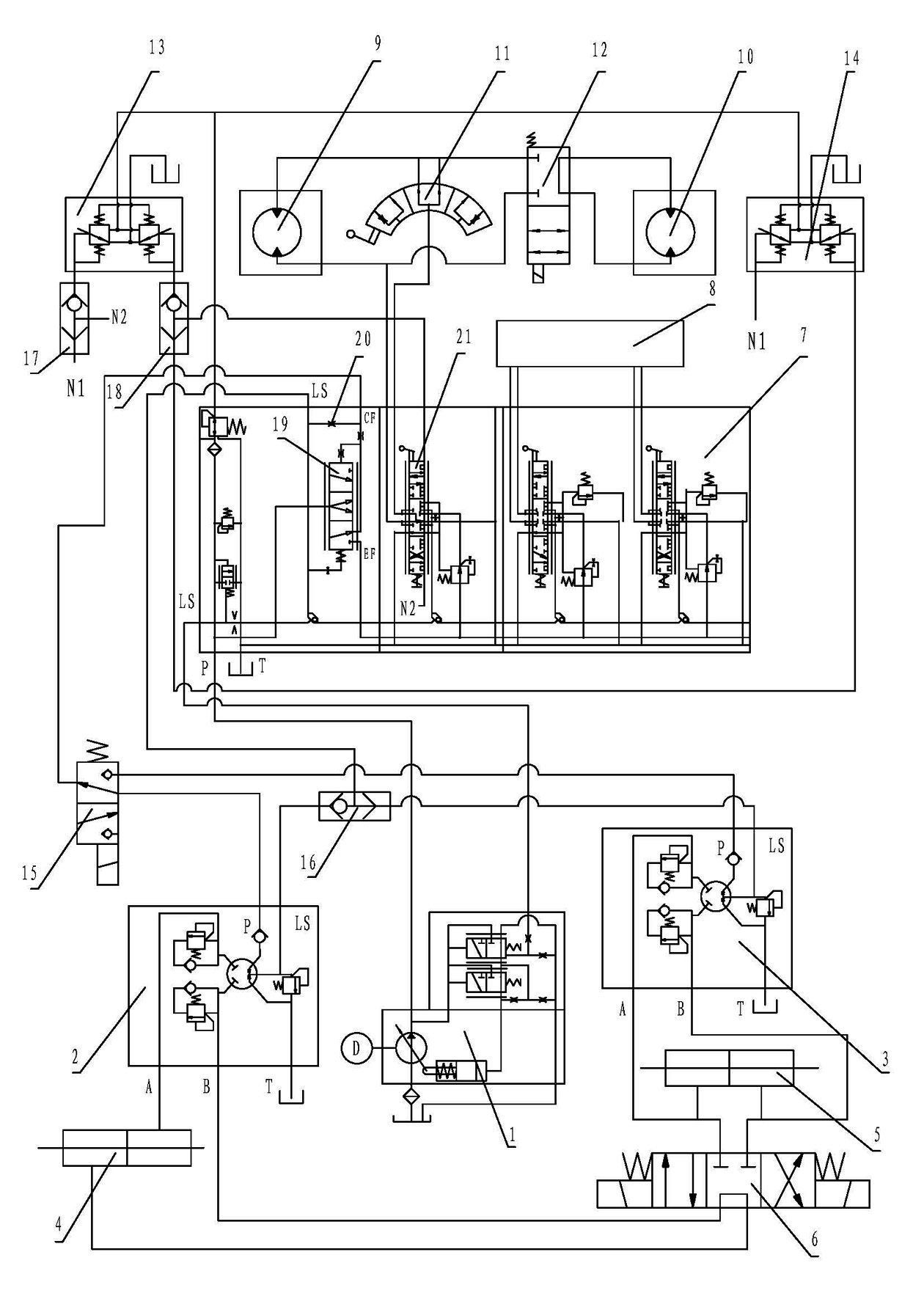

[0018] like figure 1 As shown, the multi-load sensing hydraulic system of the present invention includes a main hydraulic control handle 13, an auxiliary hydraulic control handle 14, a load sensitive variable pump 1, a load sensing main steering gear 2, a load sensing auxiliary steering gear 3, and a front wheel steering cylinder 4. Rear wheel steering oil cylinder 5, front wheel hydraulic motor 9, rear wheel hydraulic motor 10, working actuator 8 and other parts.

[0019] A shuttle valve and three three-position seven-way reversing valves 21 (the number of three-position seven-way reversing valves can be increased or decreased as required) are arranged in the PVG multi-way integrated valve 7 in a conventional manner. The entry and exit of the working actuator 8 The oil circuit is tapped on the two three-position seven-way reversing valves 21 on the right. A priority valve 19 as a preceding mechanism of the PVG manifold valve is also built in the PVG manifold valve 7 . Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com