Automatic cutter deformation regulating device for ultra-large plate shearing machine

A technology of cutting tool deformation and automatic adjustment, applied in the direction of shearing devices, shearing machine accessories, manufacturing tools, etc., can solve the problems of large manual adjustment errors, inability to achieve flexible feeding, heavy workload, etc., and achieve the goal of operation Increased accuracy, accelerated blade deformation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

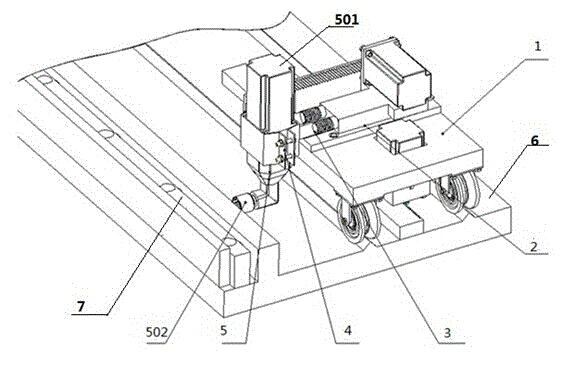

[0022] like figure 1 As shown, the automatic adjustment device for the deformation amount of the super large shearing machine tool of the present invention includes a rail car 1, a wrench feeding mechanism 2, a wrench connecting mechanism 3, a clamping device 4, a wrench mechanism 5, a feeding platform 6 and a tool deformation amount top, Pull bolt assembly 7.

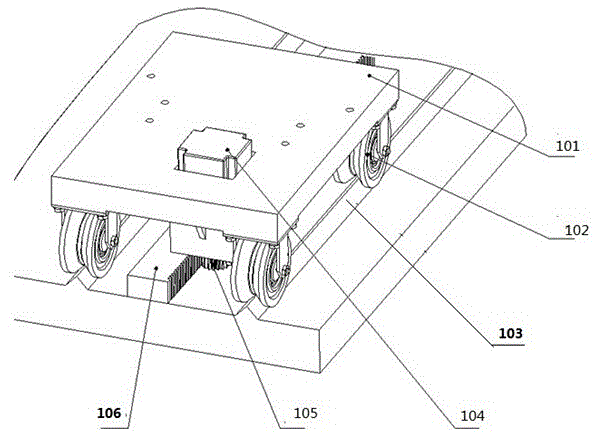

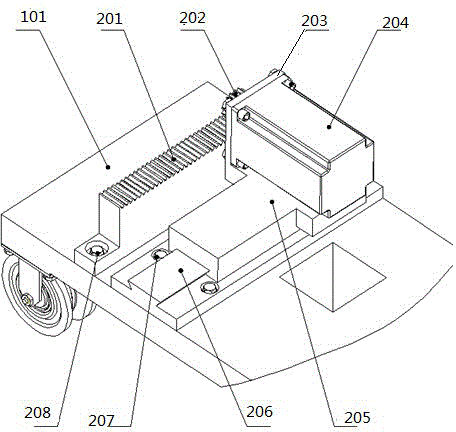

[0023] like figure 1 and 2 As shown, the rail car 1 includes a car body 101, four V-shaped sheaves 102, two V-shaped guide rails 103, a car body servo motor 104, a car body drive spur gear 105 and a car body drive rack 106; the The bottom of the vehicle body 101 is provided with four bosses, the four V-shaped sheaves 102 are respectively fixed on the four said bosses by bolts, and the four said V-shaped sheaves 102 are installed symmetrically in pairs; The body 101 is further provided with a sunken platform, and the body servo motor 104 is fixed on the sunken platform; the body servo motor 104 is coaxially connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com