Automatic clearing device of shield segment mold

A technology for automatic cleaning and shield segments, which is applied in the direction of cleaning methods using tools, manufacturing tools, cleaning methods and utensils, etc., can solve problems such as low efficiency, shield segment defects, and reduced accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

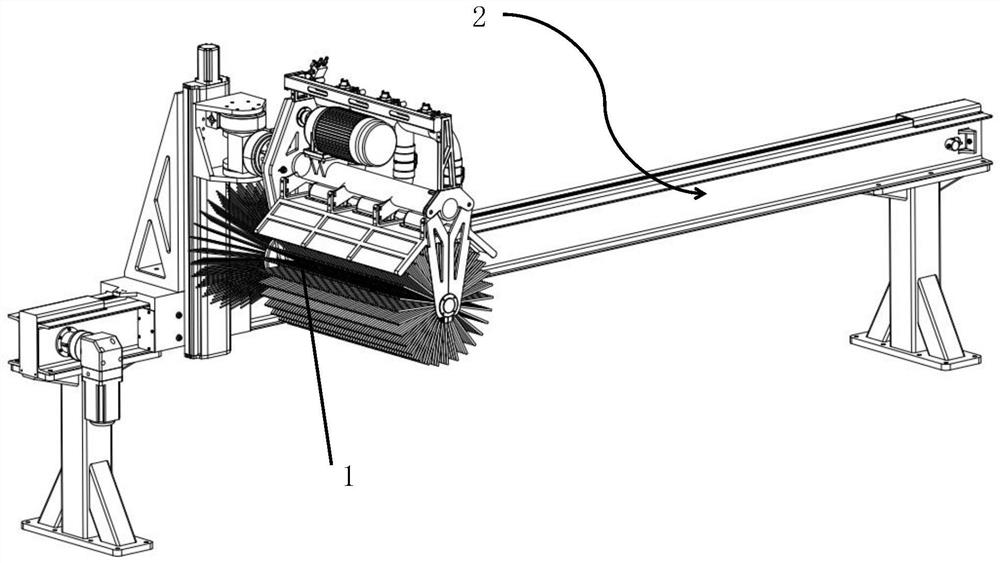

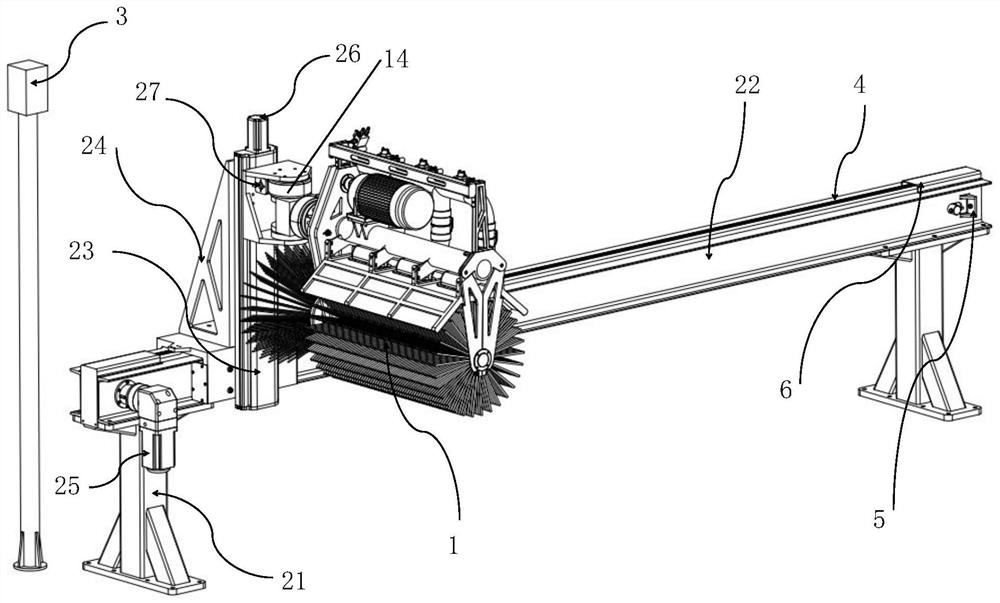

[0024] see Figure 1 to Figure 4 , an automatic cleaning device for shield segment molds, the key technology of which is to include a control system, a cleaning mechanism 1 and a moving mechanism 2 for providing multi-dimensional actions, the cleaning mechanism 1 is installed on the moving mechanism 2, and the control systems are respectively Connect with the cleaning mechanism 1 and the moving mechanism 2, and realize the automatic cleaning of the shield segment mold by controlling the cleaning mechanism 1 and the moving mechanism 2;

[0025] Such as figure 2 As shown, the moving mechanism 2 includes a bracket 21, a moving module 22 in the X direction and a moving module 23 in the Z direction. 23 is connected with the X-direction mobile module 22 through the XZ connecting plate 24, and the rotary driver 14 is installed on the Z-direction mobile module 23;

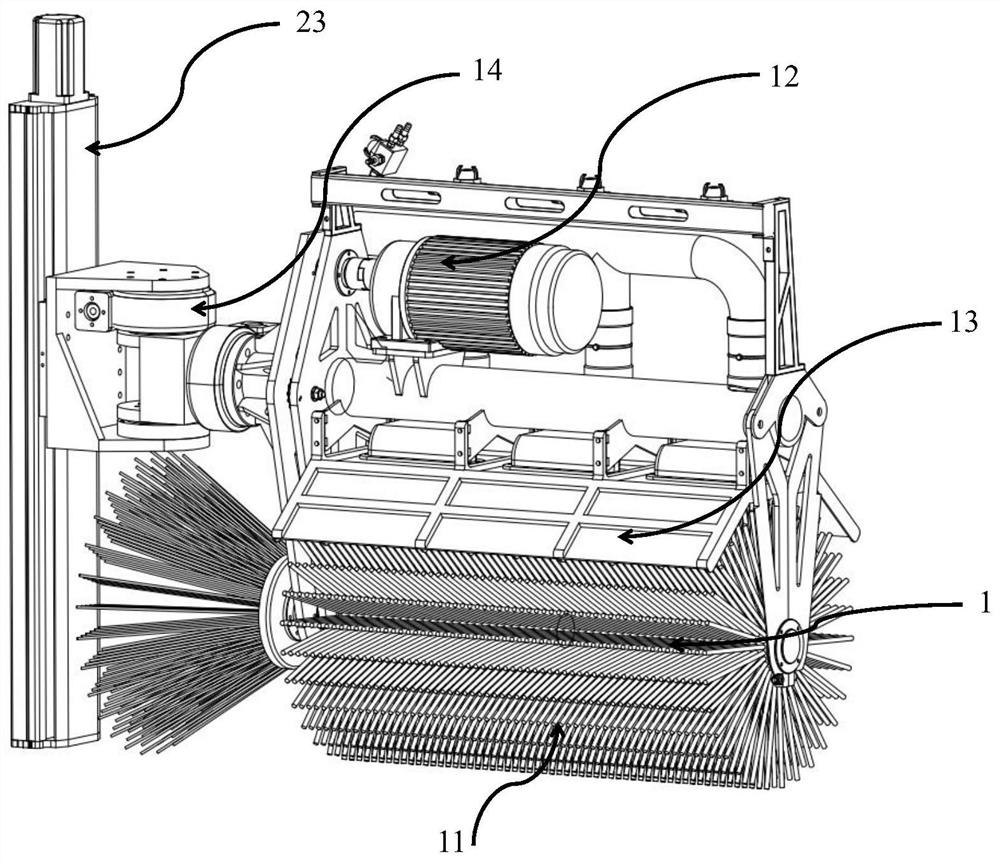

[0026] Such as image 3 As shown, the cleaning mechanism 1 is connected with a rotary drive 14 , and the cleaning me...

Embodiment 2

[0034] see Figure 1 to Figure 4 , an automatic cleaning device for shield segment molds, the key technology of which is to include a control system, a cleaning mechanism 1 and a moving mechanism 2 for providing multi-dimensional actions, the cleaning mechanism 1 is installed on the moving mechanism 2, and the control systems are respectively Connect with the cleaning mechanism 1 and the moving mechanism 2, and realize the automatic cleaning of the shield segment mold by controlling the cleaning mechanism 1 and the moving mechanism 2;

[0035] Such as figure 2 As shown, the moving mechanism 2 includes a bracket 21, a moving module 22 in the X direction and a moving module 23 in the Z direction. 23 is connected with the X-direction mobile module 22 through the XZ connecting plate 24, and the rotary driver 14 is installed on the Z-direction mobile module 23;

[0036] Such as image 3As shown, the cleaning mechanism 1 is connected with a rotary drive 14 , and the cleaning mec...

Embodiment 3

[0043] see Figure 1 to Figure 4 , an automatic cleaning device for shield segment molds, the key technology of which is to include a control system, a cleaning mechanism 1 and a moving mechanism 2 for providing multi-dimensional actions, the cleaning mechanism 1 is installed on the moving mechanism 2, and the control systems are respectively Connect with the cleaning mechanism 1 and the moving mechanism 2, and realize the automatic cleaning of the shield segment mold by controlling the cleaning mechanism 1 and the moving mechanism 2;

[0044] Such as figure 2 As shown, the moving mechanism 2 includes a bracket 21, a moving module 22 in the X direction and a moving module 23 in the Z direction. 23 is connected with the X-direction mobile module 22 through the XZ connecting plate 24, and the rotary driver 14 is installed on the Z-direction mobile module 23;

[0045] Such as image 3 As shown, the cleaning mechanism 1 is connected with a rotary drive 14 , and the cleaning me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com