Patents

Literature

35results about How to "Meet the needs of processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

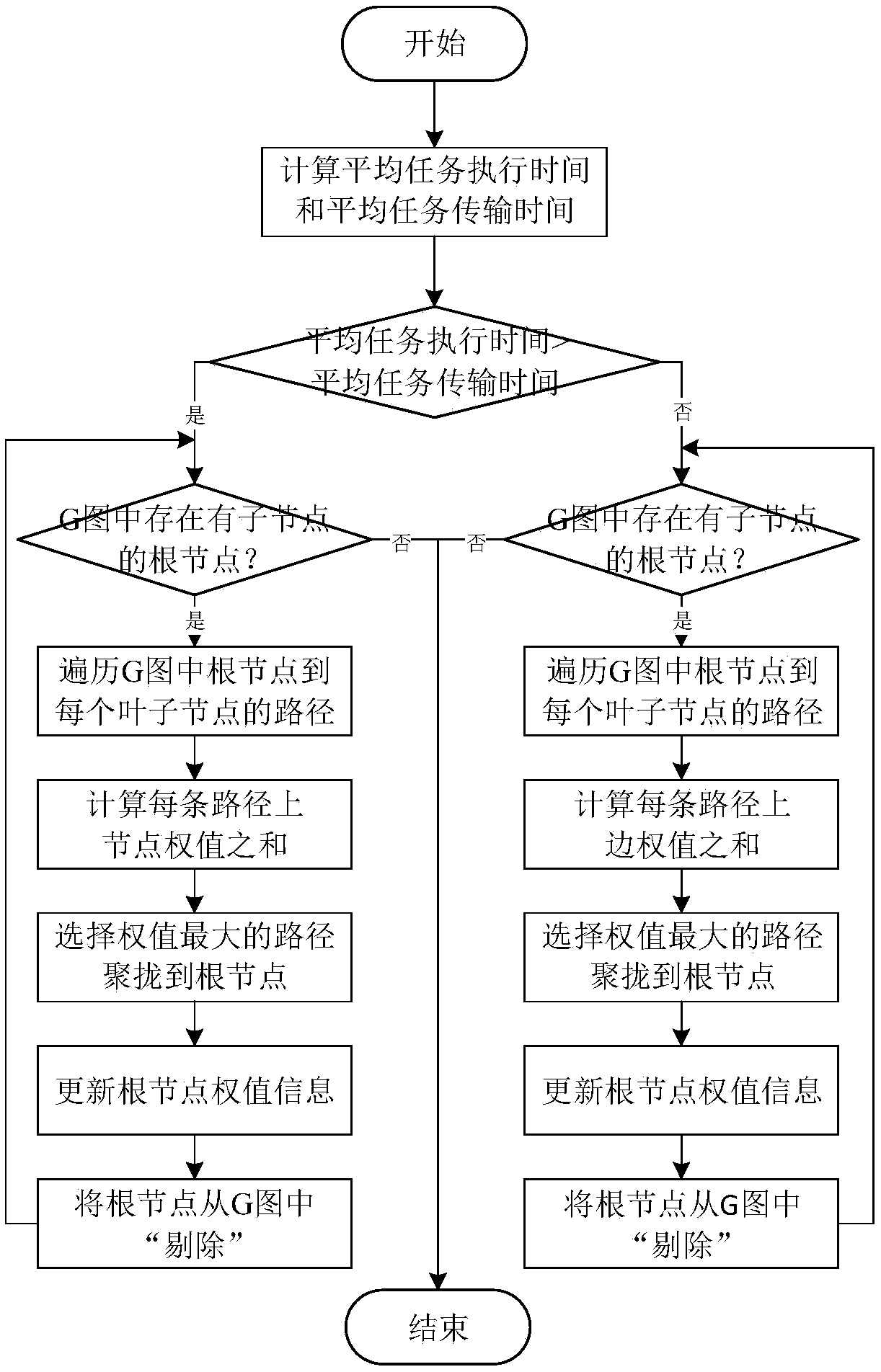

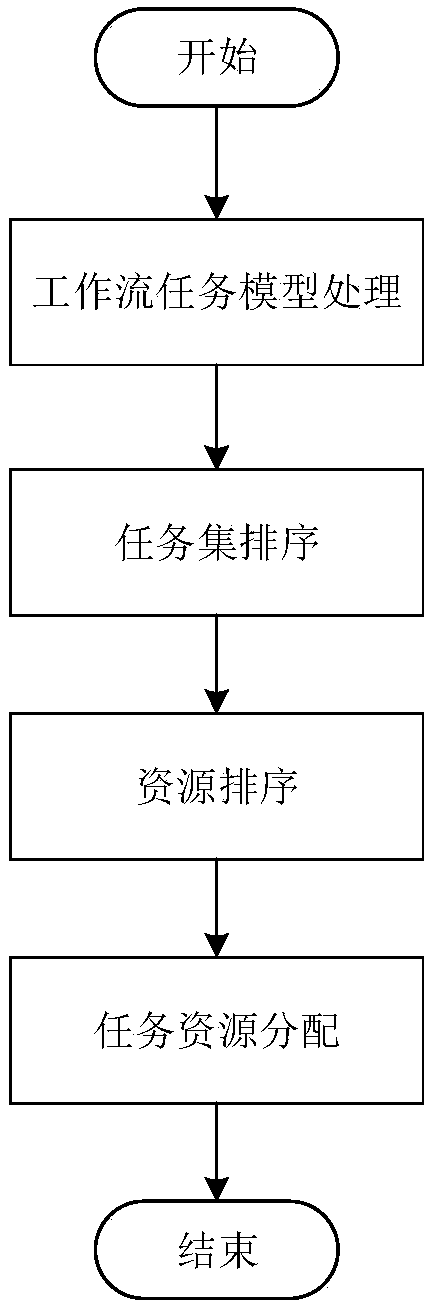

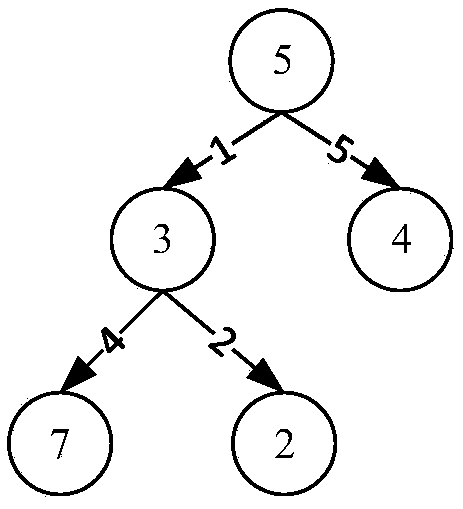

Workflow task scheduling method under distributed environment

ActiveCN106155791AReduce the number of tasksImprove scheduling abilityProgram initiation/switchingDistributed Computing EnvironmentData transmission

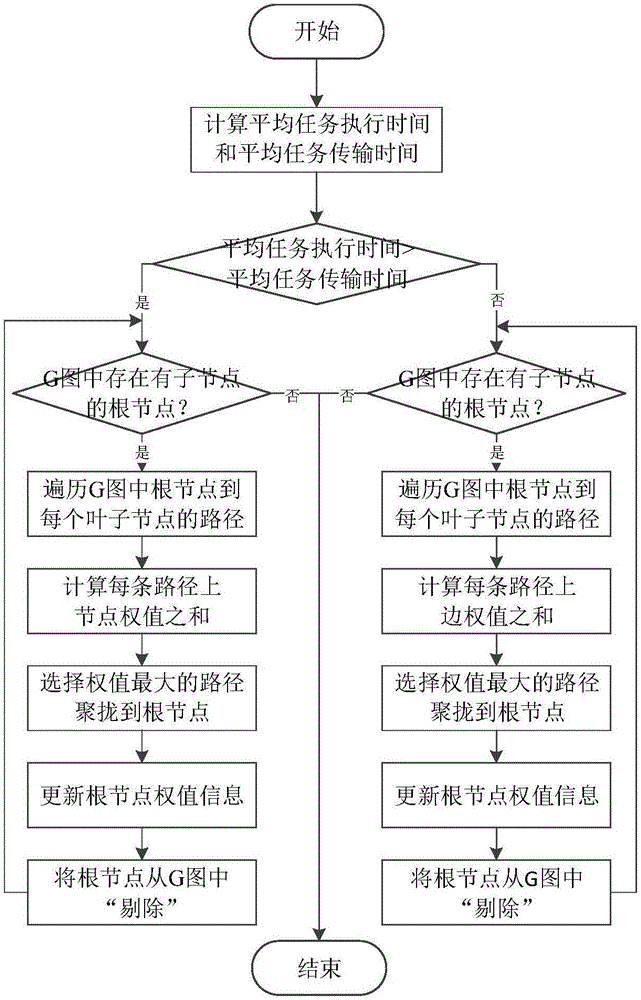

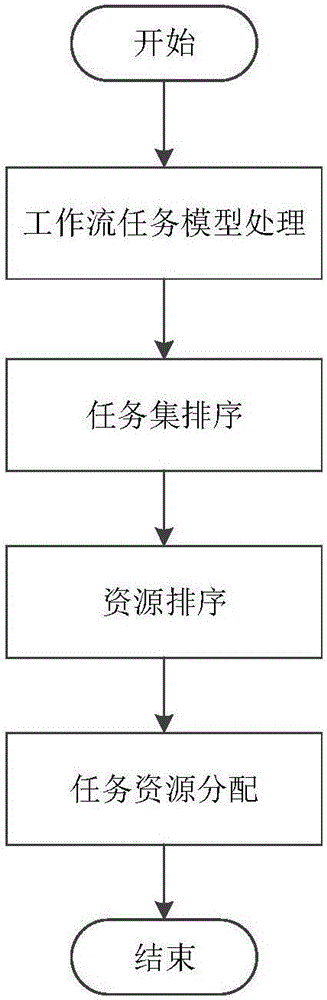

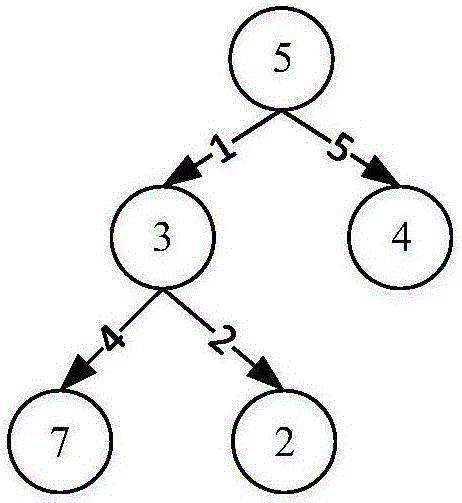

The invention discloses a workflow task scheduling method under the distributed computing environment. A directed acyclic graph is used for describing workflow tasks and resources, the average task execution time and the average task transmission time are calculated on the basis of node weight information and edge weight information so as to judge the type of a workflow task and perform classified model processing, the task with the data dependency is cut into a plurality of independent task sets, each task set contains one or more tasks, the multiple tasks in each task set have the data dependency, and therefore the workflow tasks are converted into independent tasks. The task sets gather the tasks with the large data size or the large data transmission quantity together, meanwhile, the number of tasks needing to be independently distributed is decreased, and the post-task scheduling performance is improved on the whole. In addition, when the number of workflow tasks is increased, the gathering operation of the tasks just needs to be enhanced, all tasks do not need to be processed any more, and the better expansibility is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

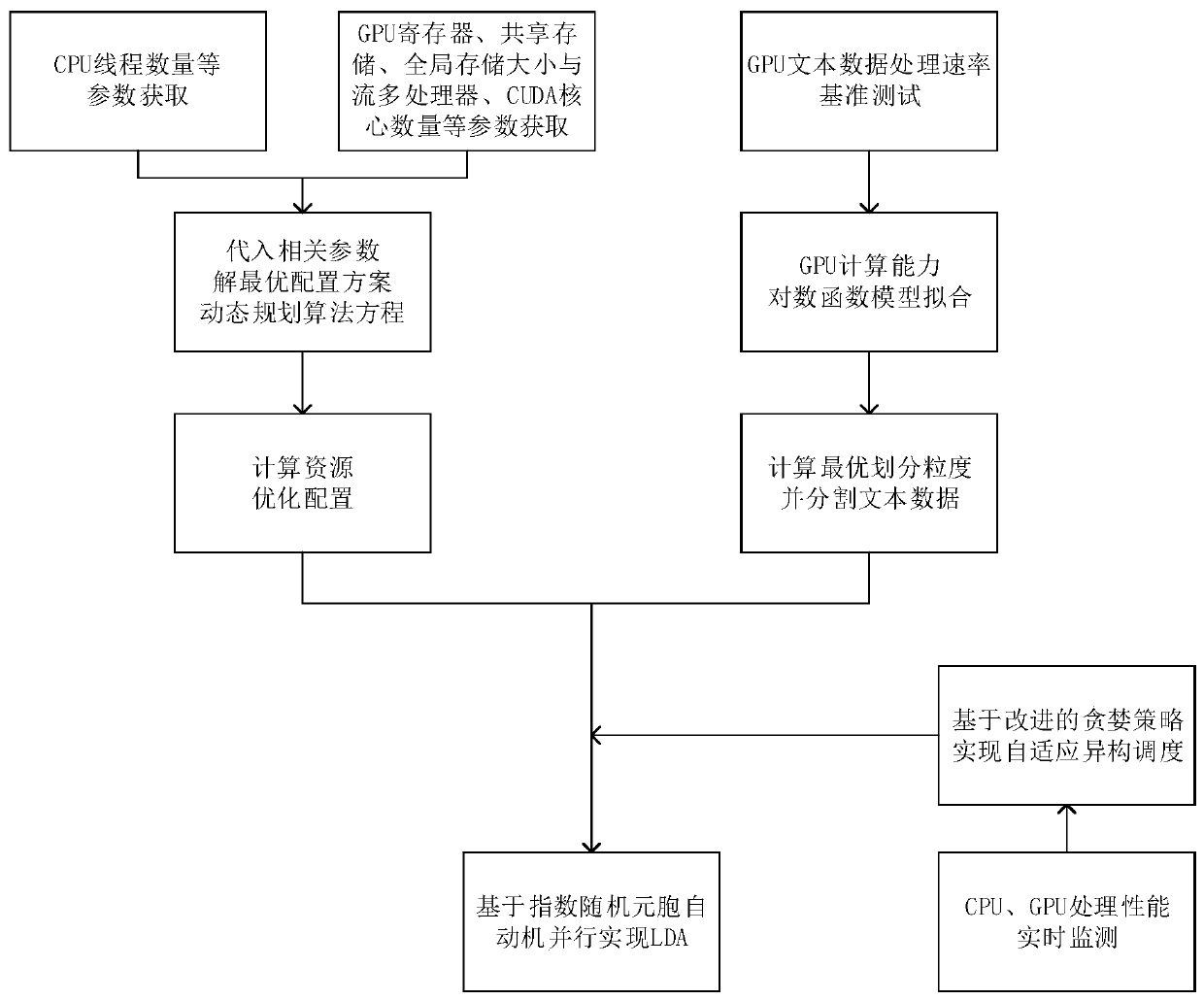

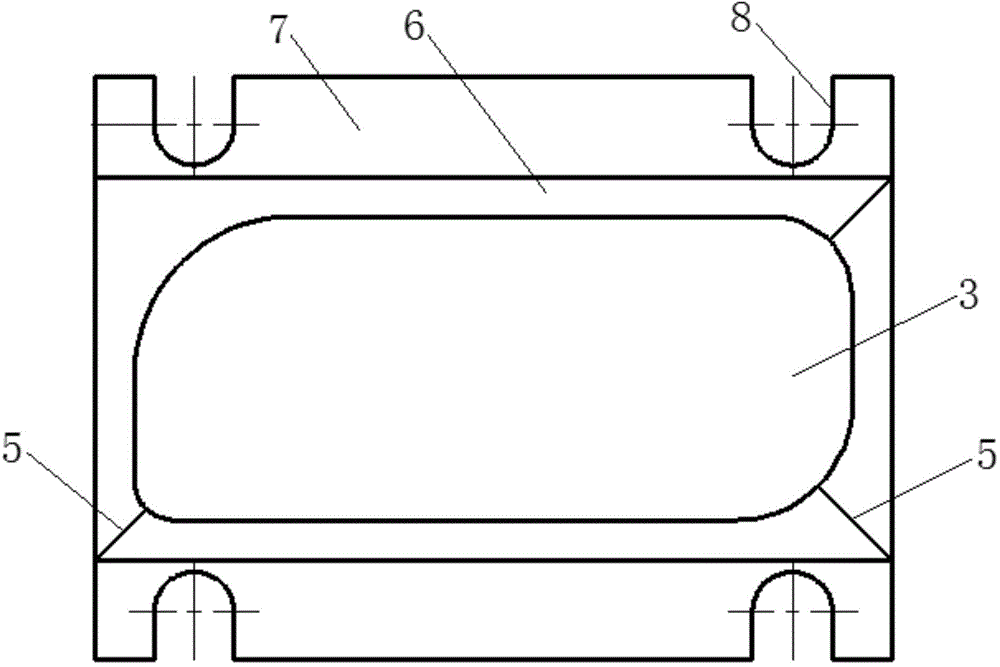

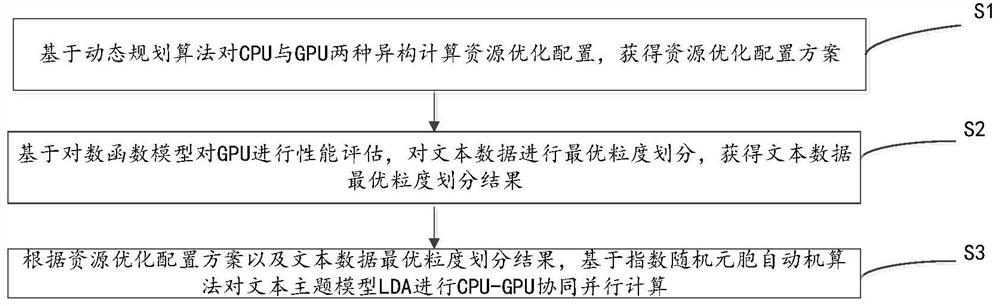

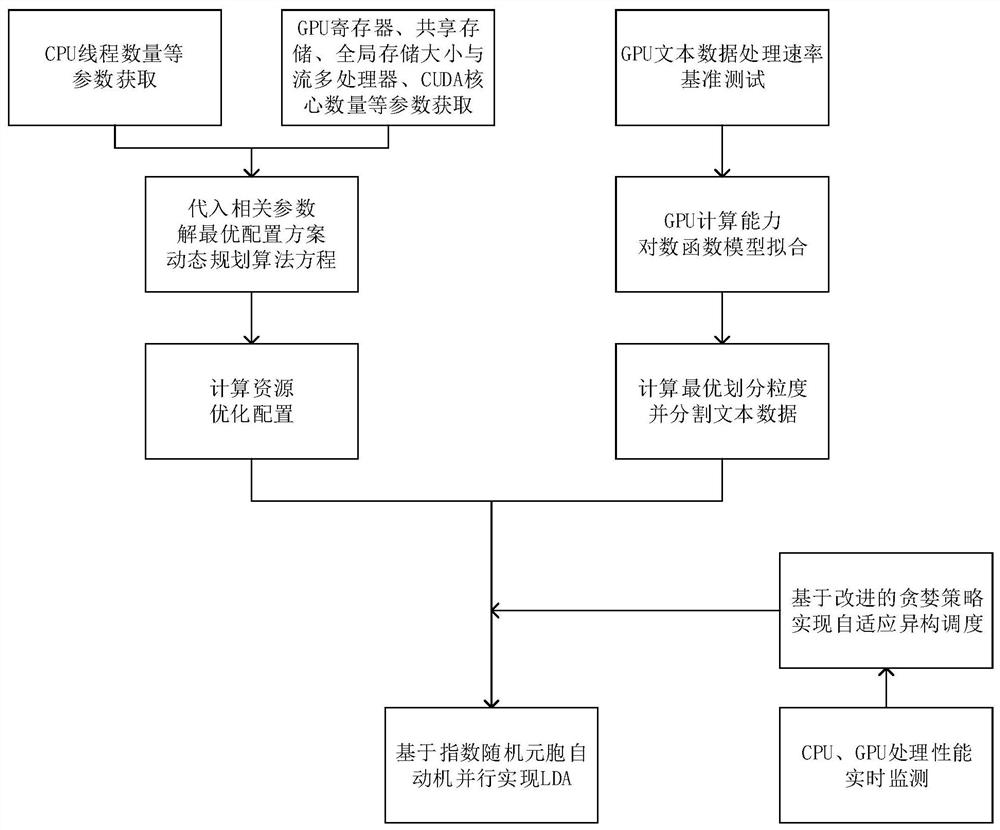

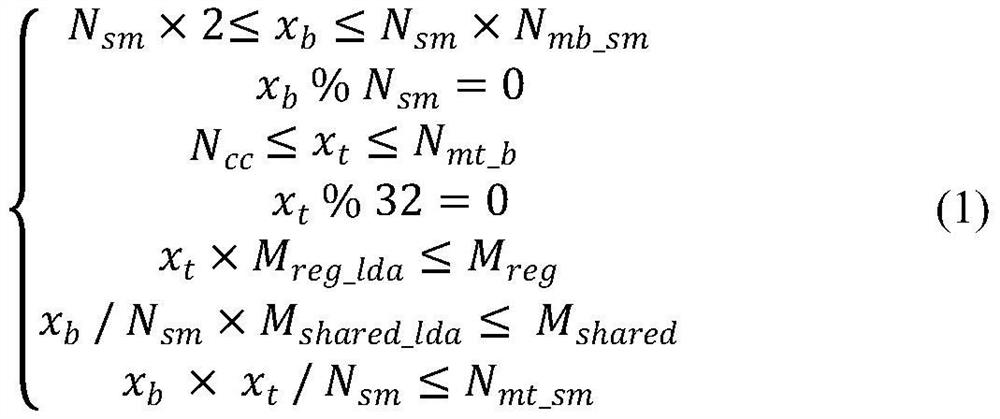

Text topic model LDA high-performance computing method based on CPU-GPU collaborative parallelism

ActiveCN110413776AEnable high-performance modelingQuick discoveryProgram initiation/switchingResource allocationCellular automationPerformance computing

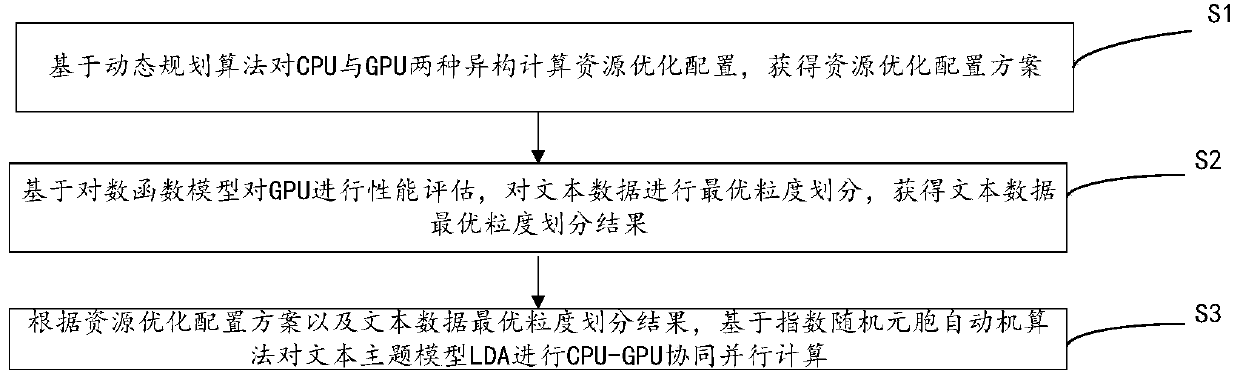

The invention discloses a text topic model LDA high-performance computing method based on CPU-GPU collaborative parallelism, and the method comprises the steps: firstly achieving the optimal configuration of two types of heterogeneous computing resources: a CPU and a GPU then, completing GPU performance evaluation based on the logarithm function model, and completing text data optimal granularitydivision; realizing CPU-GPU cooperative parallel computing of the hidden Dirichlet allocation model based on an exponential random cellular automaton algorithm; and furthermore, carrying out self-adaptive heterogeneous scheduling between the CPU and the GPU based on an improved greedy strategy to realize load balancing. According to the method, high-performance modeling of the text topic model isachieved, topic information implied in the text can be found quickly, and therefore the efficient processing requirements of applications such as massive document set classification and text data streaming computing are met.

Owner:WUHAN UNIV

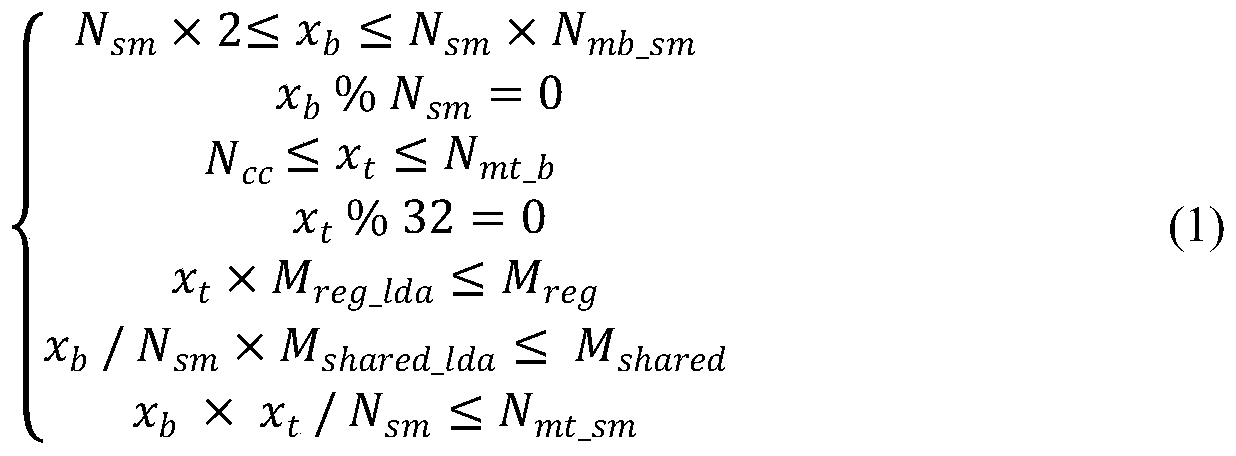

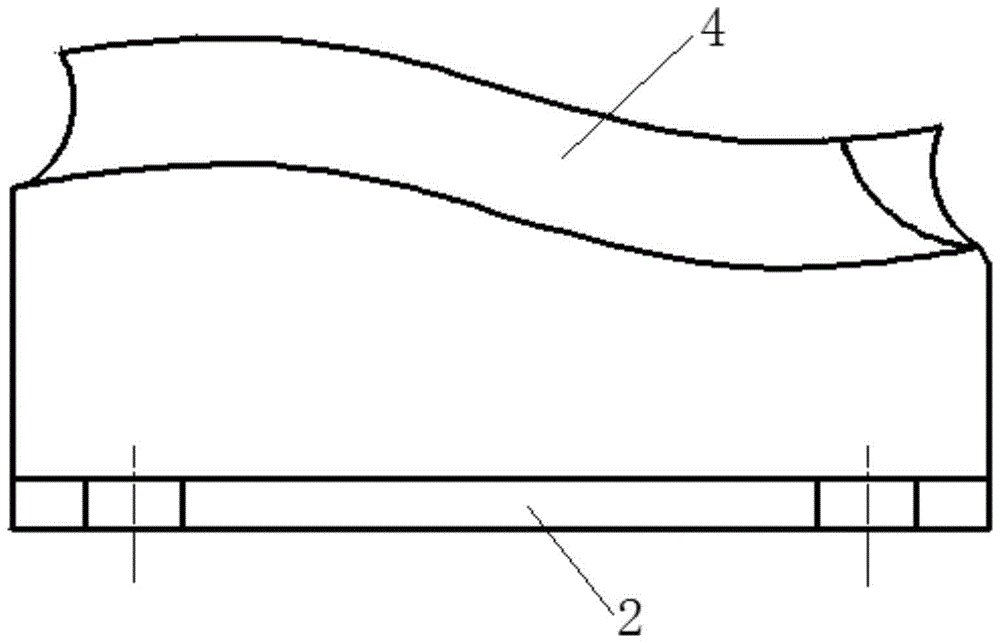

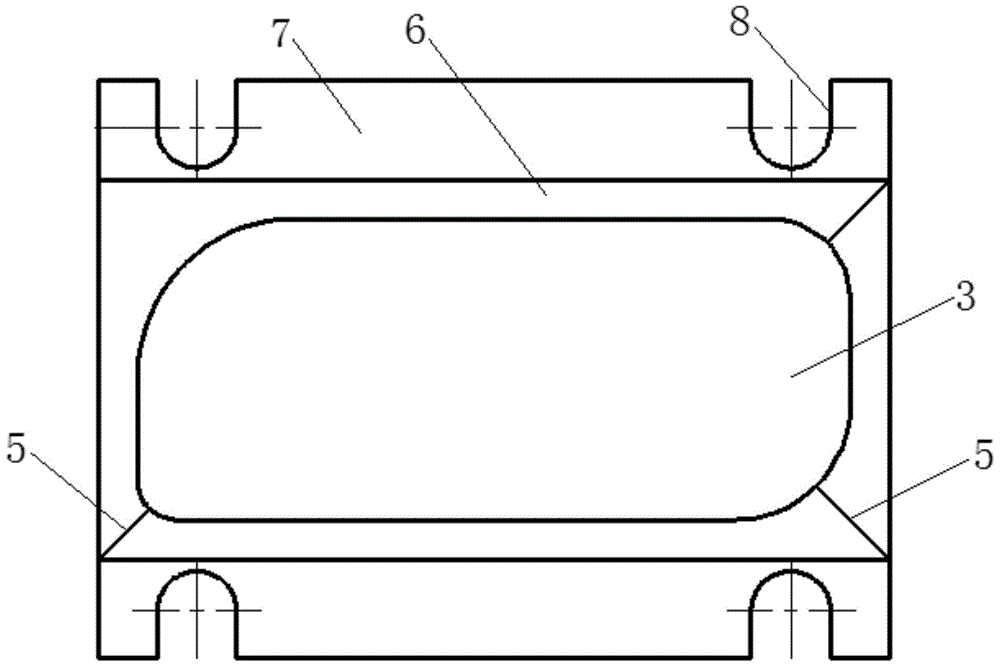

Integral quenched steel corner back gouging test piece and high-speed milling process method thereof

ActiveCN104907616AMeet the needs of efficient processingMeet the needs of processing efficiencyAutomatic control devicesMeasurement/indication equipmentsMechanical engineeringEngineering

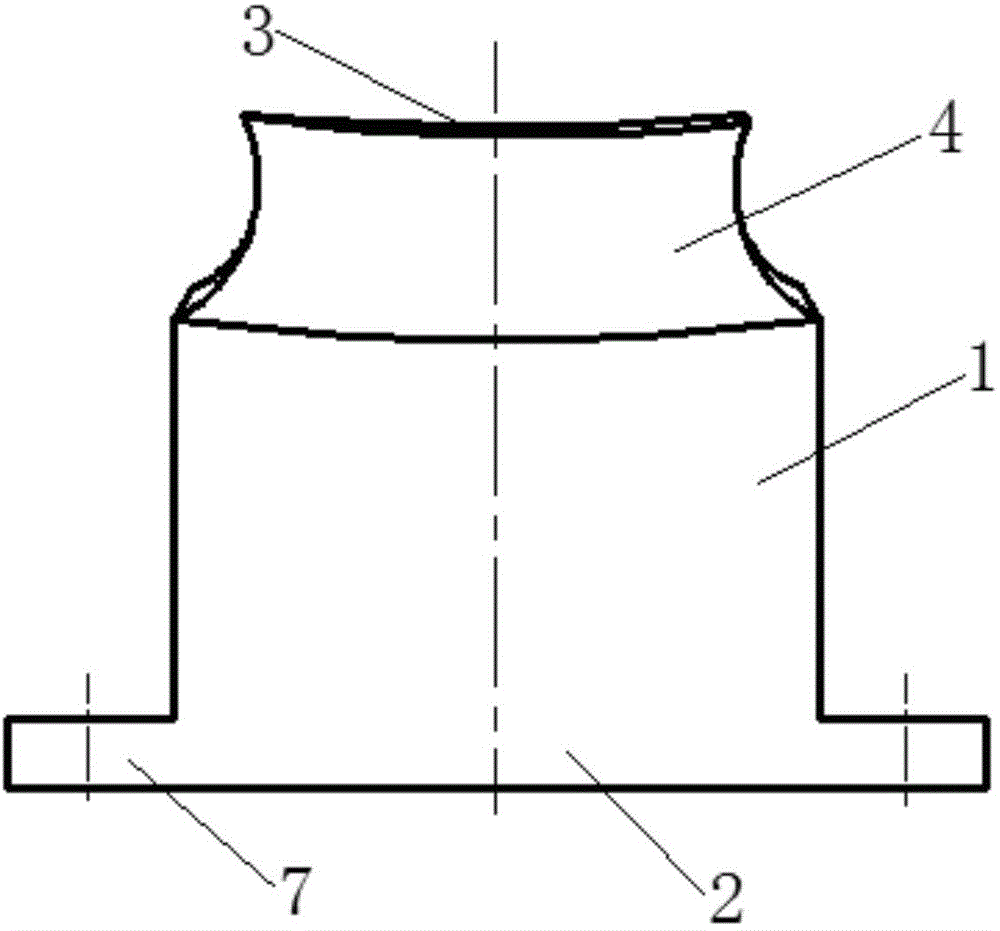

The invention relates to an integral quenched steel back gouging test piece and a high-speed milling process method thereof. The technical key points are as follows: the test piece comprises a milling processing region and a base at the bottom, wherein the top surface of the milling processing region is a top concave curve surface which is bent downwards along the width direction, the top concave curve surface is formed by smooth transition connection of five sections of curve surfaces which are distributed along the length direction and have different curvature radiuses, the four corners of the top concave curve surface are circular arc corners which have different radiuses, the side vertical surface of the milling processing region is provided with one section of side concave curve surface which sinks towards the center, a circumferential lug boss which is positioned below the side concave curve surface is formed on the side vertical surface of the milling processing region, and the surface of the circumferential lug boss is parallel to the top concave curve surface; two sides of the base, in the width direction of the milling processing region, extend outwards to form a lug boss. According to the process scheme, the method comprises the steps of step one, selecting the processing region; step two, designing the cutting path of a cutter; and step three, processing the surface feature when the high-speed quenched steel back gouging is tested.

Owner:HARBIN UNIV OF SCI & TECH

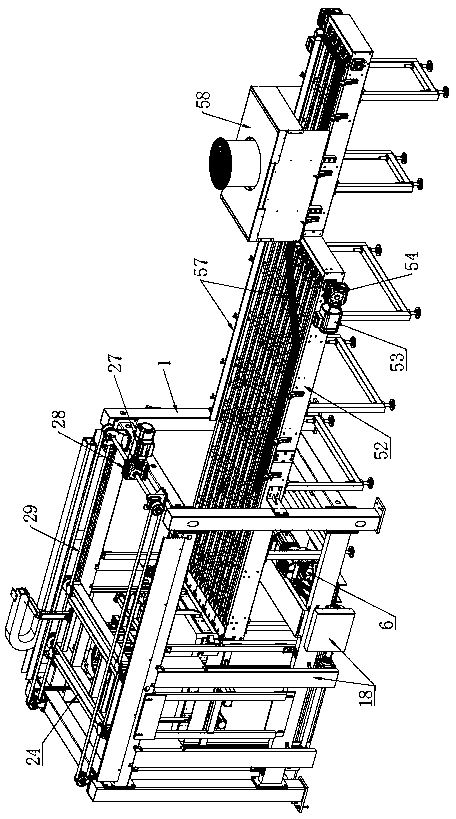

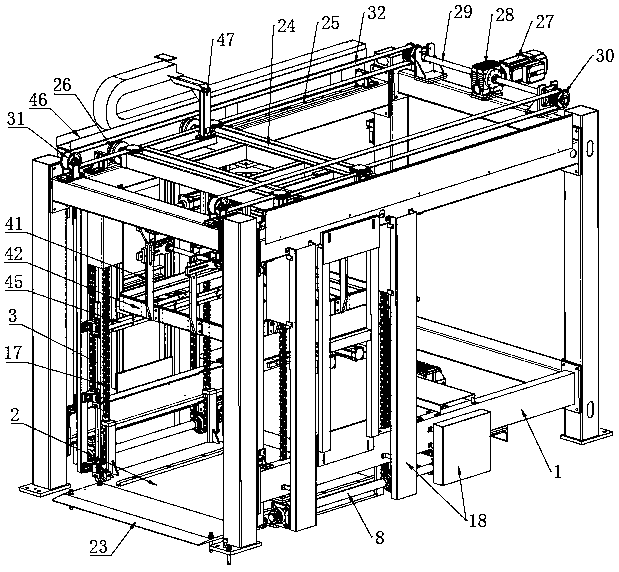

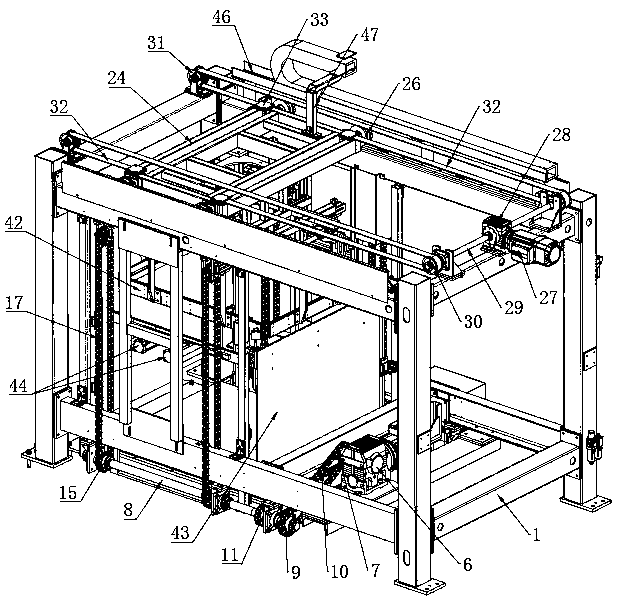

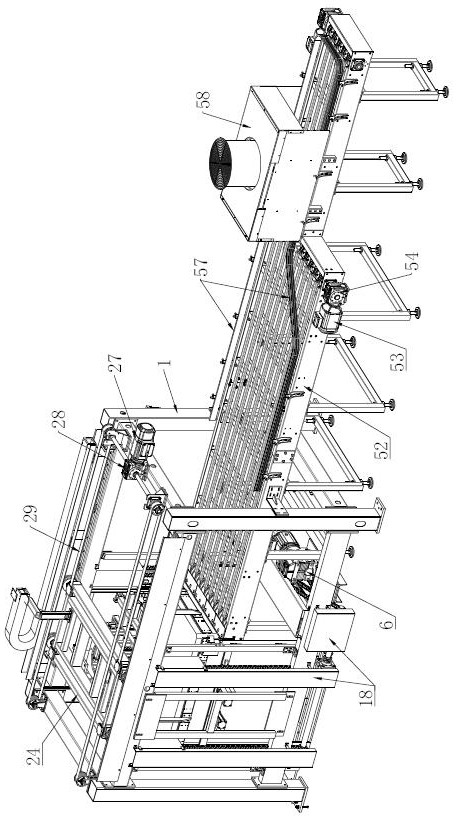

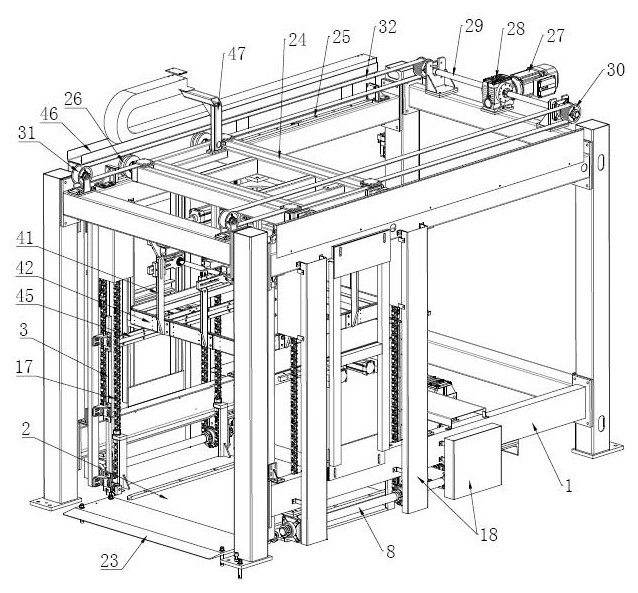

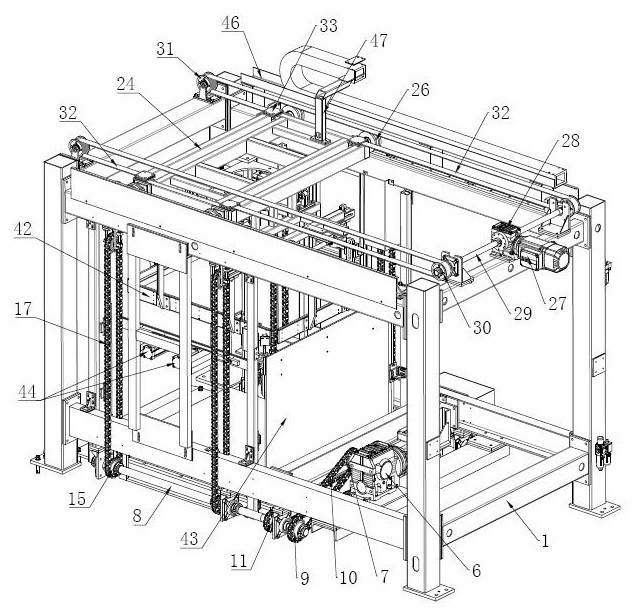

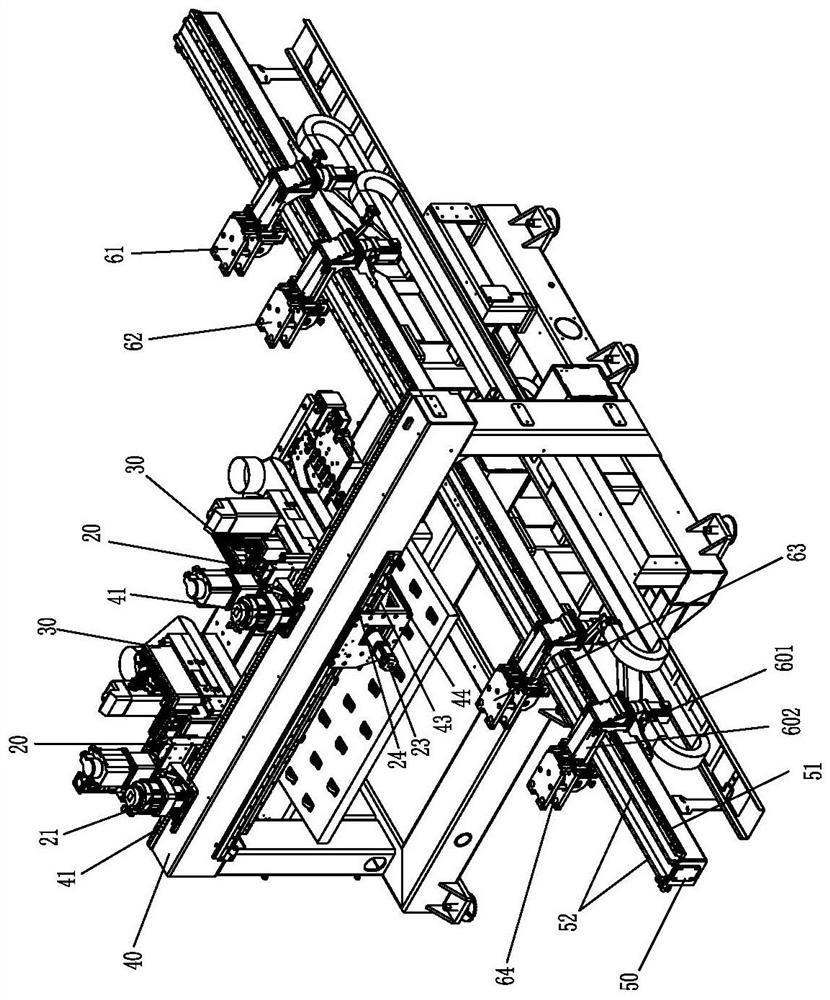

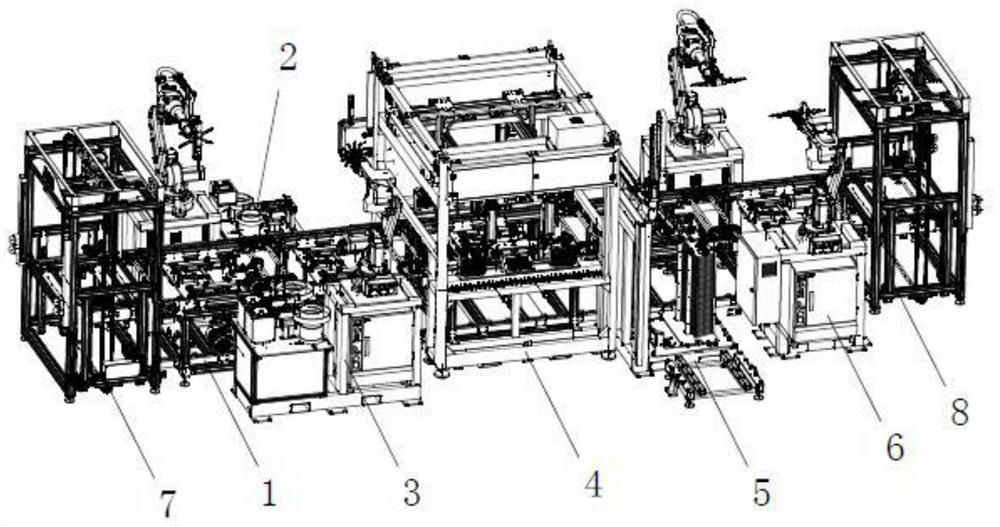

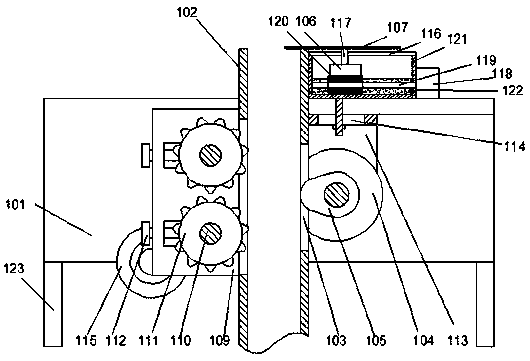

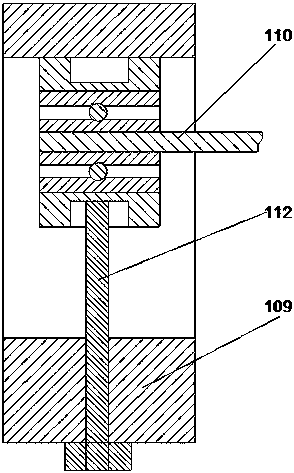

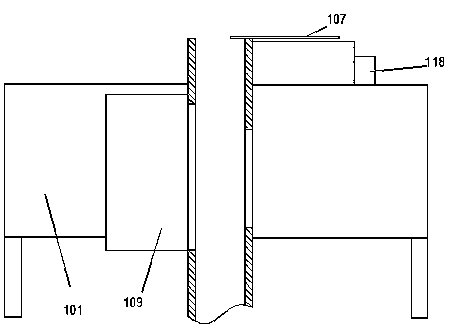

Intelligent assembly line for buckle screws

ActiveCN111037087AMeet the needs of processing efficiencyVersatileNon-electric welding apparatusUltrasonic weldingStructural engineering

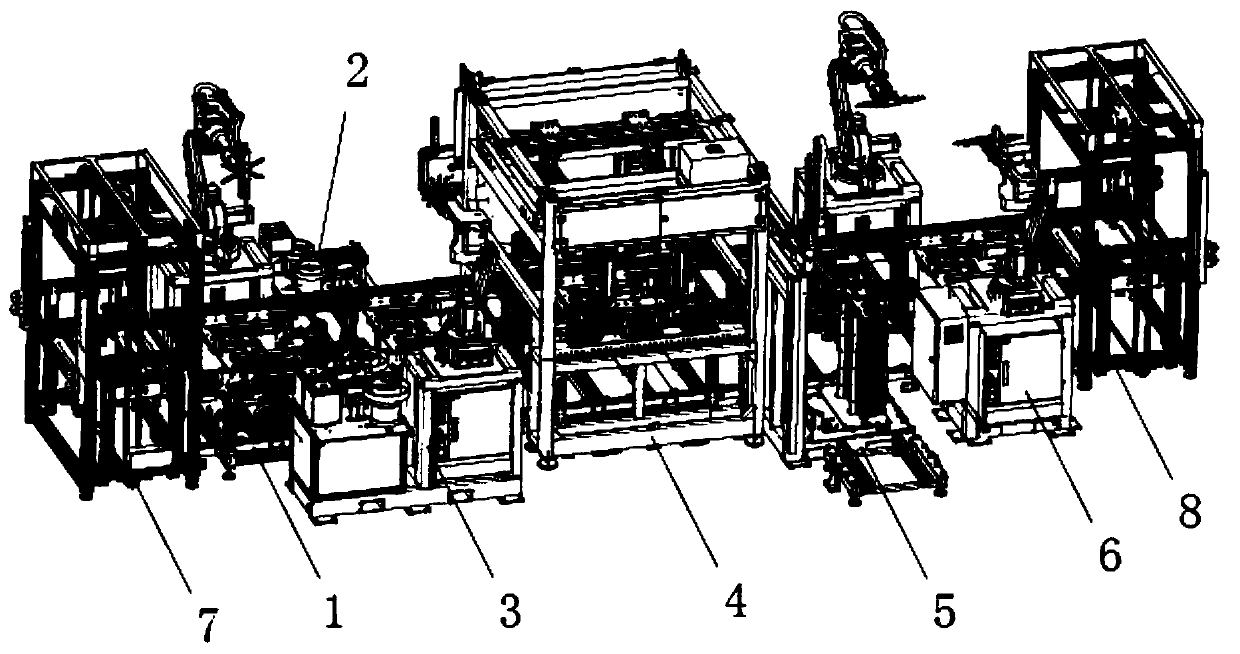

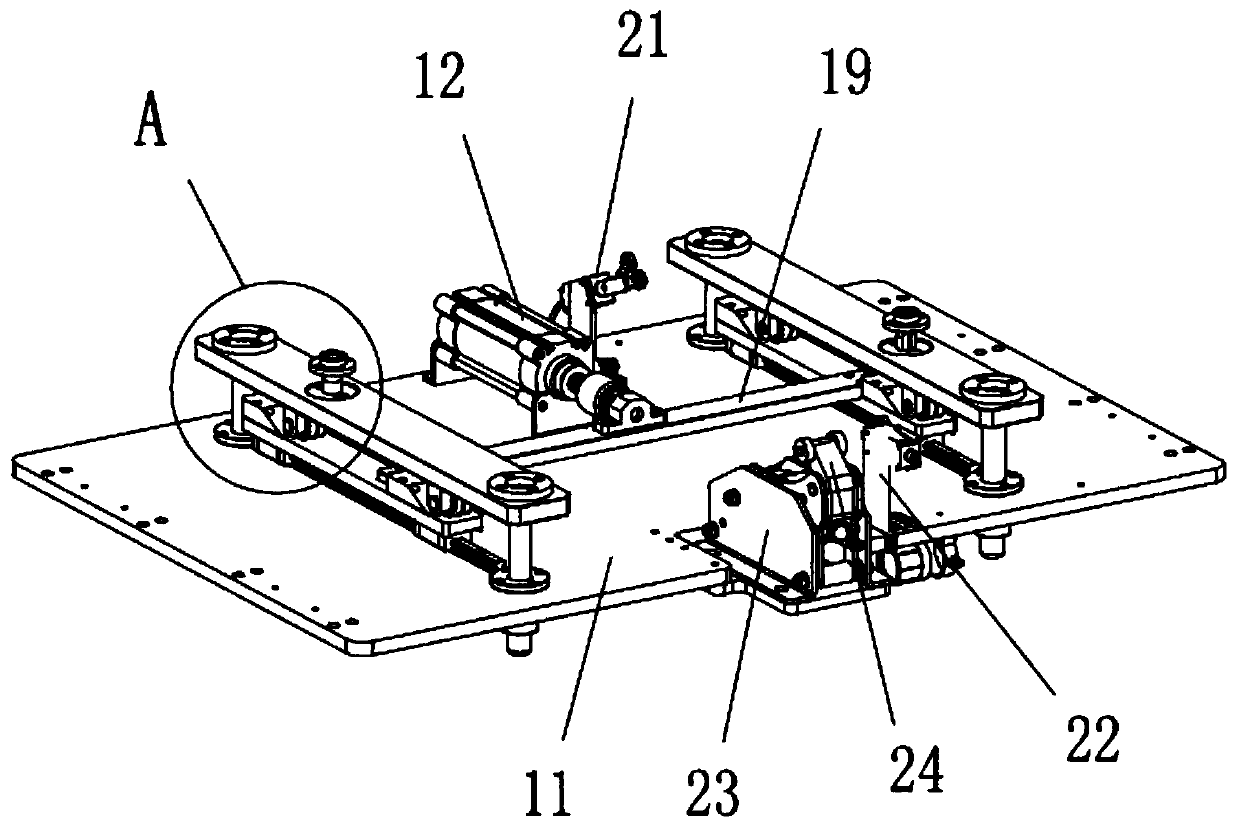

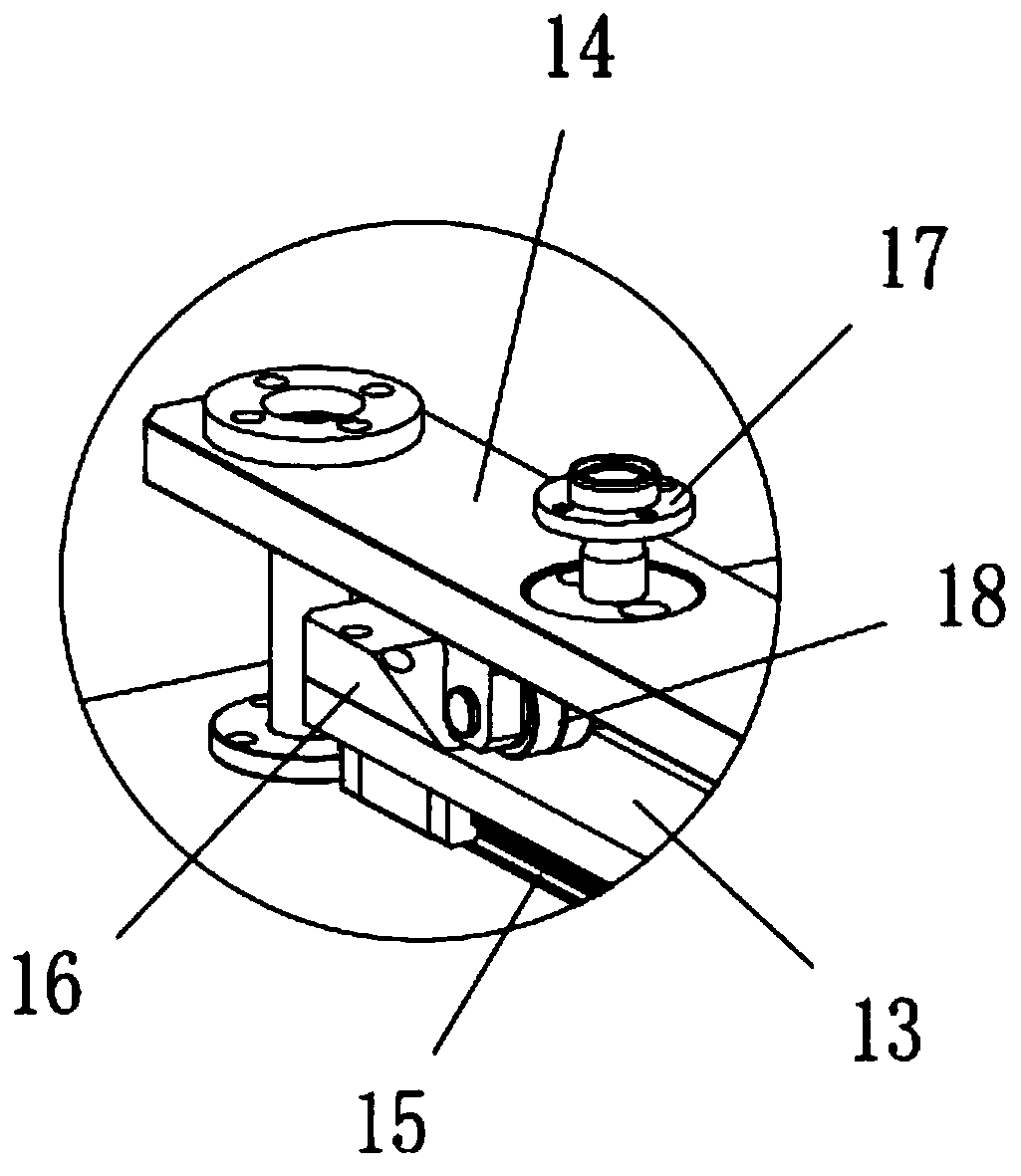

The invention discloses an intelligent assembly line for buckle screws. The intelligent assembly line comprises a conveying line, a buckle screw mounting station, a buckle mounting station, a multi-shaft welding station, a sound absorption cotton feeding station and an ultrasonic welding station. A mold locking mechanism is arranged at a position, corresponding to each station, of the conveying line; a buckle screw mounting mechanism is arranged at the buckle screw mounting station, a buckle mounting mechanism is arranged at the buckle mounting station, a multi-shaft welding machine is arranged at the multi-shaft welding station, a sound absorption cotton feeding mounting mechanism is arranged at the sound absorption cotton feeding station, and an ultrasonic welding mechanism is arranged at the ultrasonic welding station. According to the scheme, the buckle screw mounting station and the sound absorption cotton feeding station are additionally arranged on the basis of an original automobile door panel assembly line, so that the functions of the assembly line are more comprehensive, and the efficient machining requirement of an automobile door panel is met; and the mold locking mechanisms are optimized, so that molds carrying workpieces are positioned more accurately at machining positions, the locking effect is better, and the product quality is improved.

Owner:SUZHOU KEBER PRECISION MACHINERY

Horizontal push type automatic unstacking device

The invention belongs to the technical field of glass bottle production, and provides a horizontal push type automatic unstacking device. The horizontal push type automatic unstacking device comprisesa unstacking machine and a bottle conveying machine; the unstacking machine comprises a unstacking frame with a stack storing opening; a supporting plate driven by a first driving device is slidablyarranged on the unstacking frame along the vertical direction; a bottle pushing frame driven by a second driving device is slidably arranged on the top of the unstacking frame along the horizontal direction; a bottle holding mechanism is arranged at the bottom of the bottle pushing frame; a stack blocking plate is fixedly arranged in the middle of the unstacking frame; clamping mechanisms are correspondingly arranged on the two sides of the unstacking frame respectively; the bottle conveying machine comprises a conveyor frame; a conveying plate chain driven by a third driving device is wound around the conveyor frame; and one end of the conveyor frame is arranged against the stack blocking plate and is flush with the top of the stack blocking plate. According to the horizontal push type automatic unstacking device, a horizontal push type unstacking mode is adopted, and whole layers of glass bottles can be directly pushed onto the bottle conveying machine for conveying; and compared with a traditional manual unstacking mode, labor cost is saved, work intensity is greatly reduced, and working efficiency is greatly improved.

Owner:山东三江智能装备有限公司

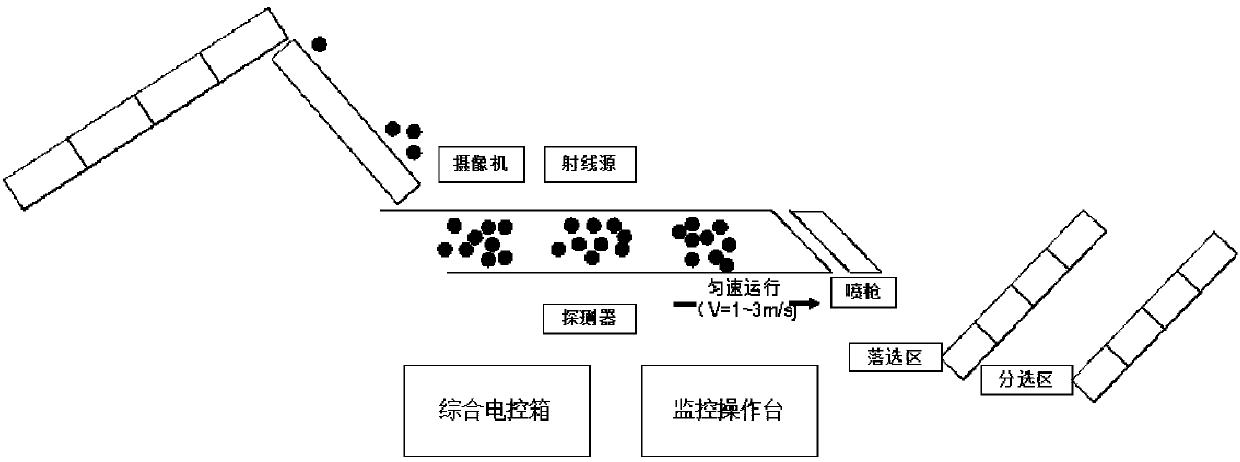

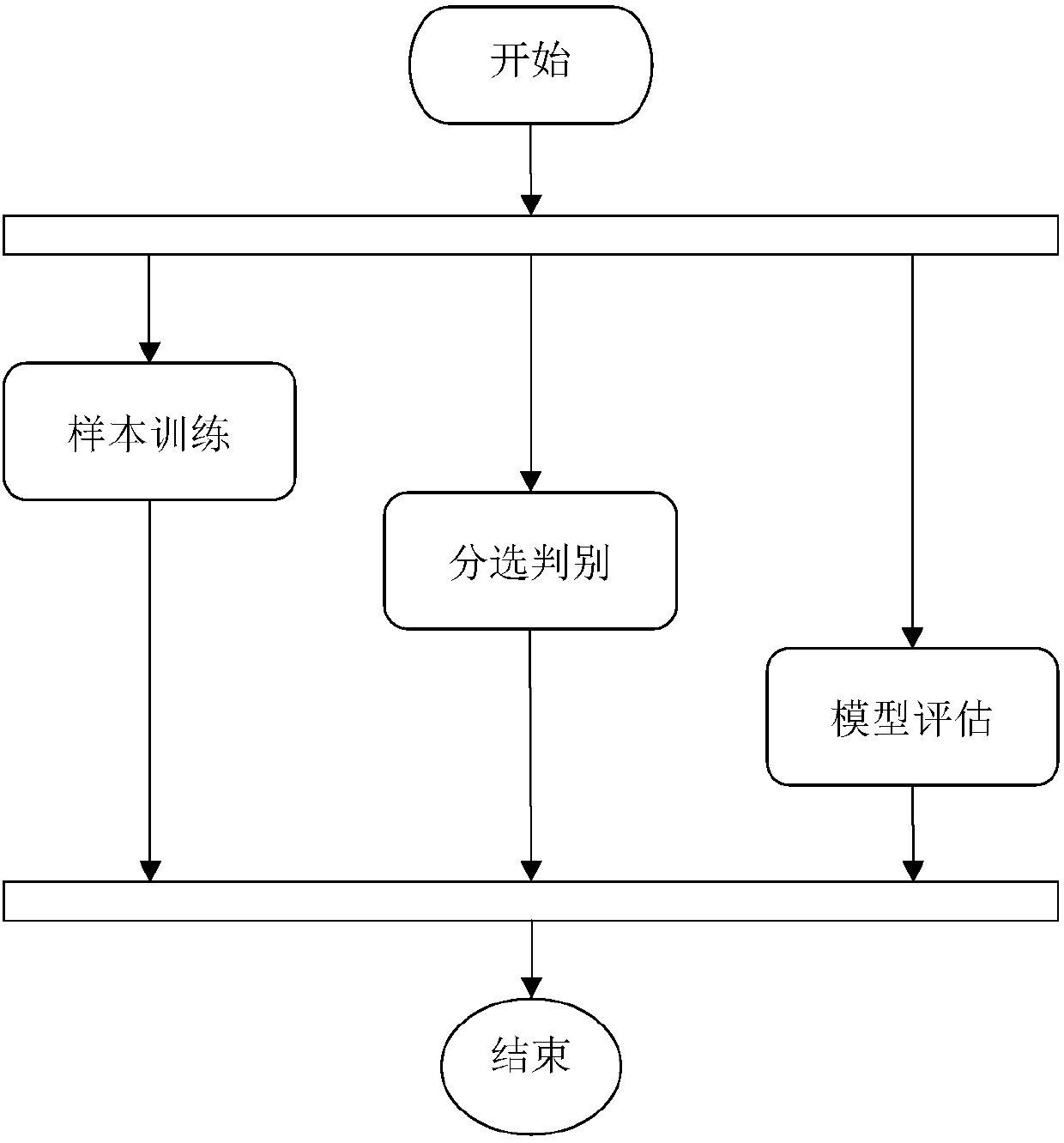

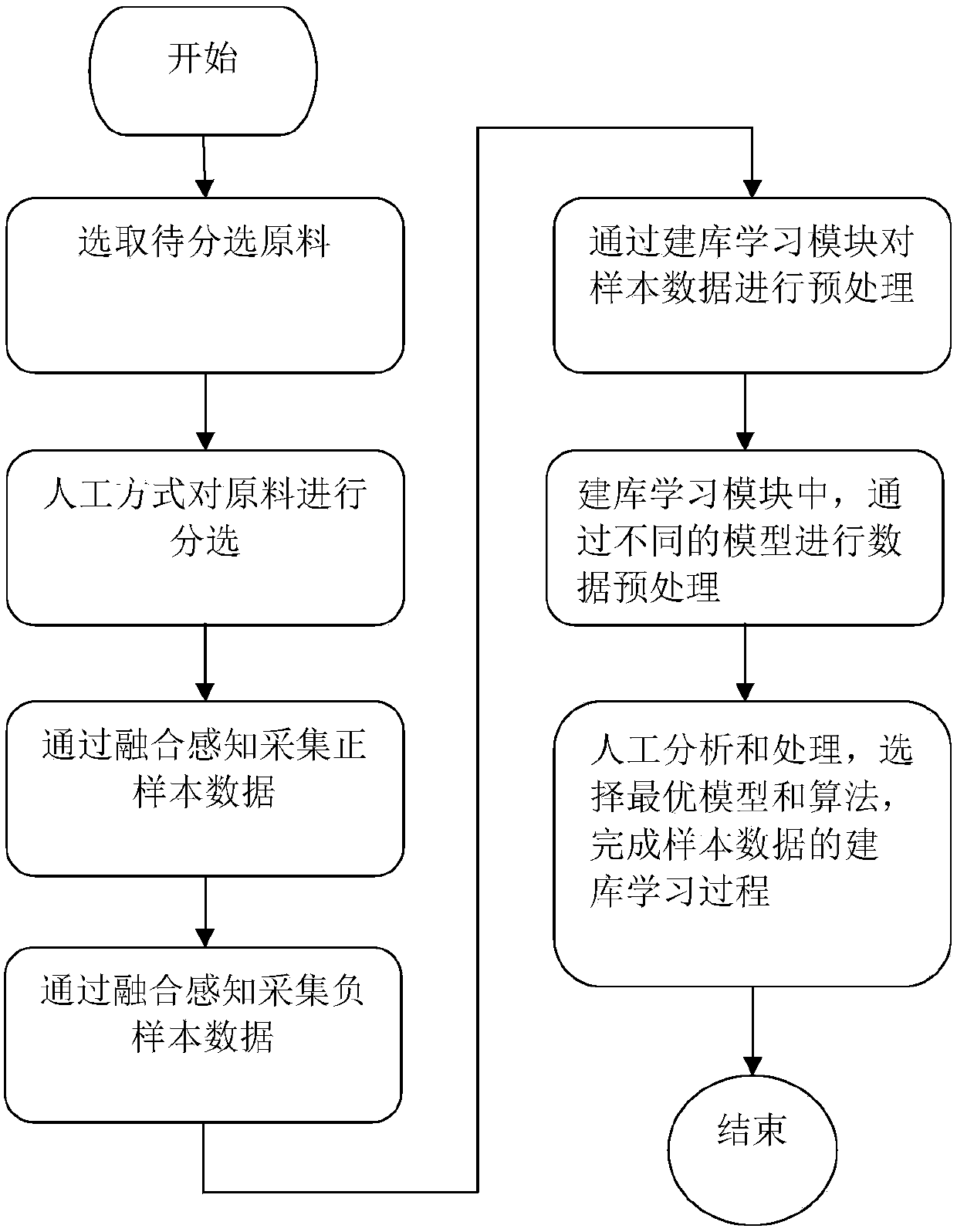

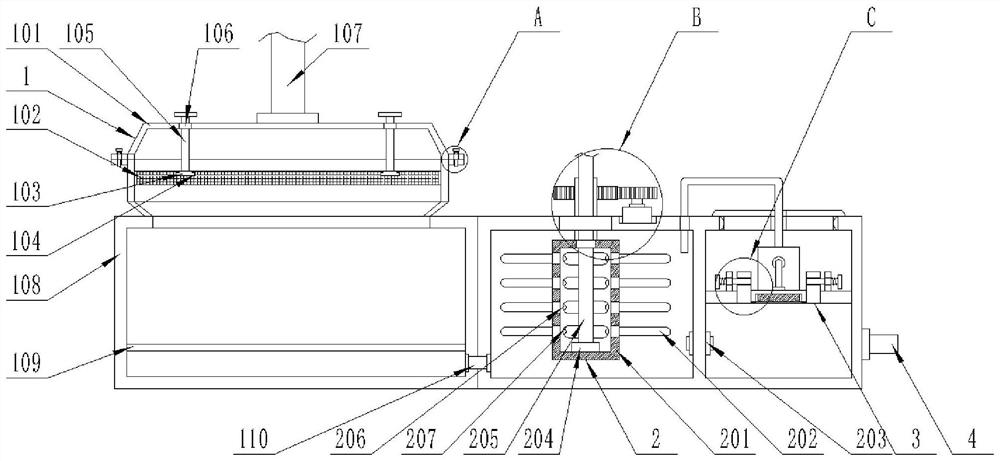

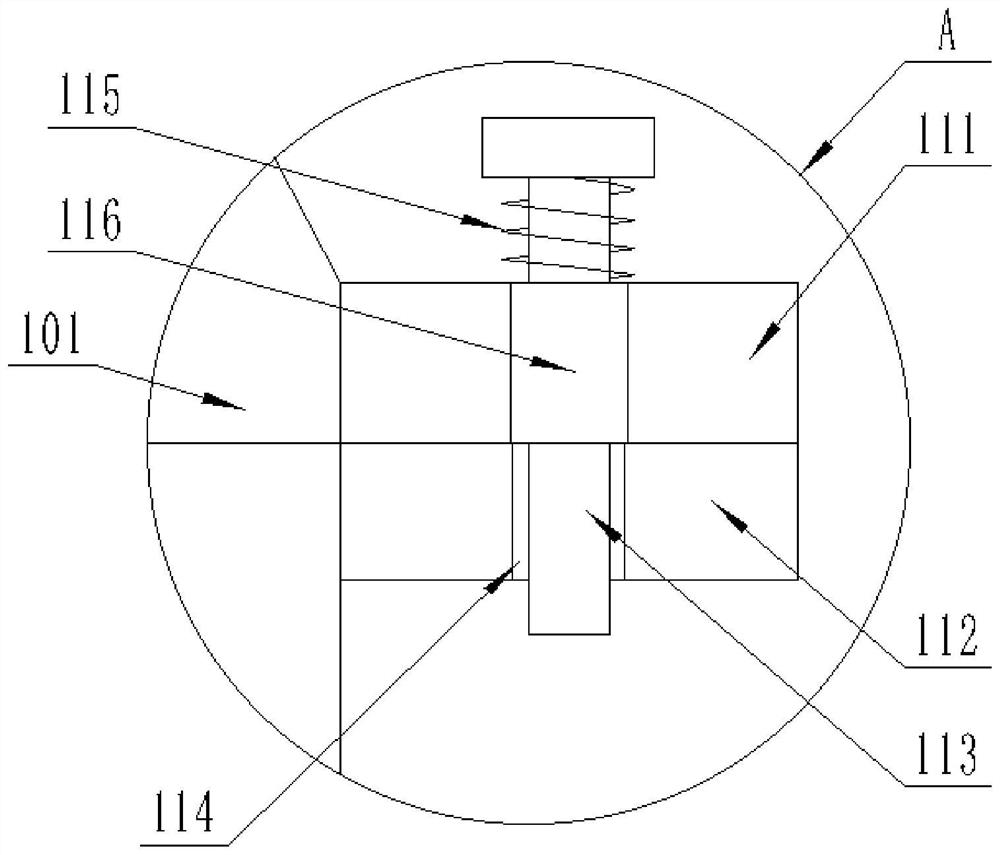

Fusion perception online sorting system and sorting method for metals recycled from scrapped automobiles

InactiveCN107737735AEnsure operation accuracyImprove sorting efficiencyCharacter and pattern recognitionProcess efficiency improvementAlgorithmMetallic materials

The invention relates to a fusion perception online sorting system and sorting method for metals recycled from scrapped automobiles. The fusion perception online sorting system comprises a database-building learning device, a sorting discriminating device and a model evaluation device, wherein the database-building learning device performs pre-processing such as noise reducing on data by acquiringfusion data (containing X-rays and optical data) of material blocks; different characteristic values are obtained by calculating according to different reaction capacities, on fusion perception, of metals such as aluminum and magnesium, and the characteristics values are input into the database-building learning device to complete training learning of the data; an optimized sorting discriminatingmodel is obtained by training learning of the database-building learning device, and sorting of raw materials is completed through the sorting discriminating model in the sorting discriminating device; and the model evaluation device is used for separately evaluating, regulating and optimizing the sorting model according to the sorting results of the sorting discriminating device. The fusion perception online sorting system has a relatively high recognition rate, and can accurately recognize alloys and other metal materials; and when material conveying speed is 3 m / s, an accurate rate of sorting can be 0.25%, and sorting amount reaches 300 t / h.

Owner:江早

Convenient-to-clean pig manure efficient degradation device for pig herd breeding

ActiveCN112125487AImprove mixing efficiencyAdapt to the needs of degradationSpecific water treatment objectivesRotary stirring mixersAnimal scienceElectric machinery

The invention discloses a convenient-to-clean pig manure efficient degradation device for pig herd breeding and belongs to the technical field of pig manure cleaning. The device comprises a precipitation mechanism; one side of the precipitation mechanism is communicated with an anaerobic mechanism; one side of the anaerobic mechanism is provided with a reflux mechanism; one side of the precipitation mechanism is communicated with a liquid discharge pipe; the precipitation mechanism comprises two fixing seats; the fixing seats on the two sides are attached to each other and fixedly connected with an upper fixing block and a lower fixing block correspondingly; a second sliding sleeve is embedded in the top of the upper fixing block. According to the device, a net cage and a dosing pipe are designed; a motor works to drive an output shaft to rotate, the net cage rotates, liquid chemicals are transferred out through centrifugal rotation; the internal water-liquid mixing efficiency is improved through a stirring rod, so that the mixing effect is improved, the requirement for pig manure degradation use can be met; and cleaning water liquid can be pumped in through the dosing pipe for cleaning; the anaerobic treatment efficiency is prevented from being influenced by pig manure adhesion caused by long-time cleaning absence, and use requirements are met.

Owner:周宁县生隆科技养殖有限公司

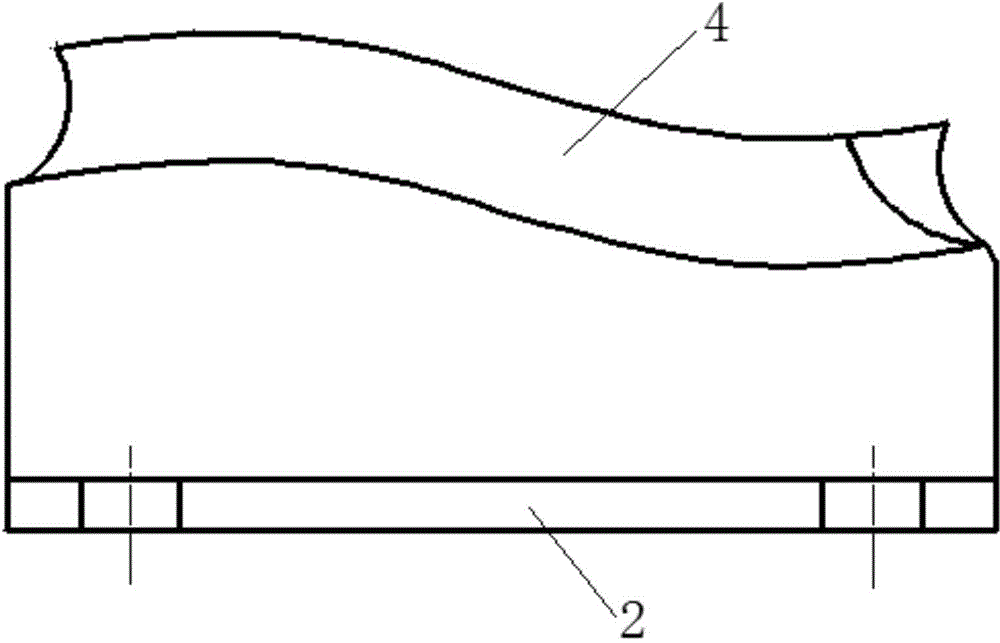

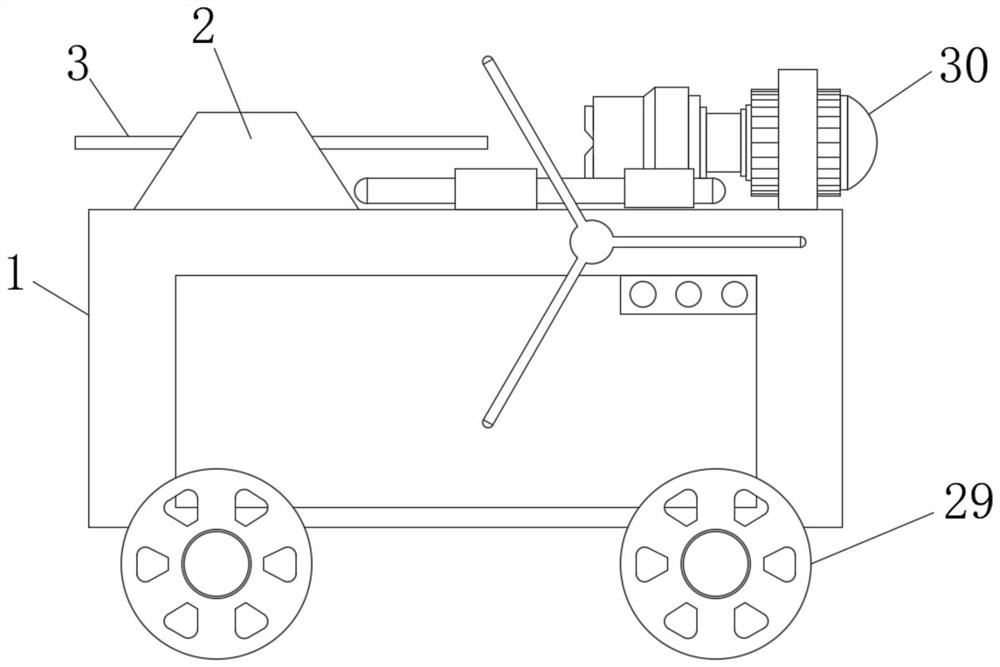

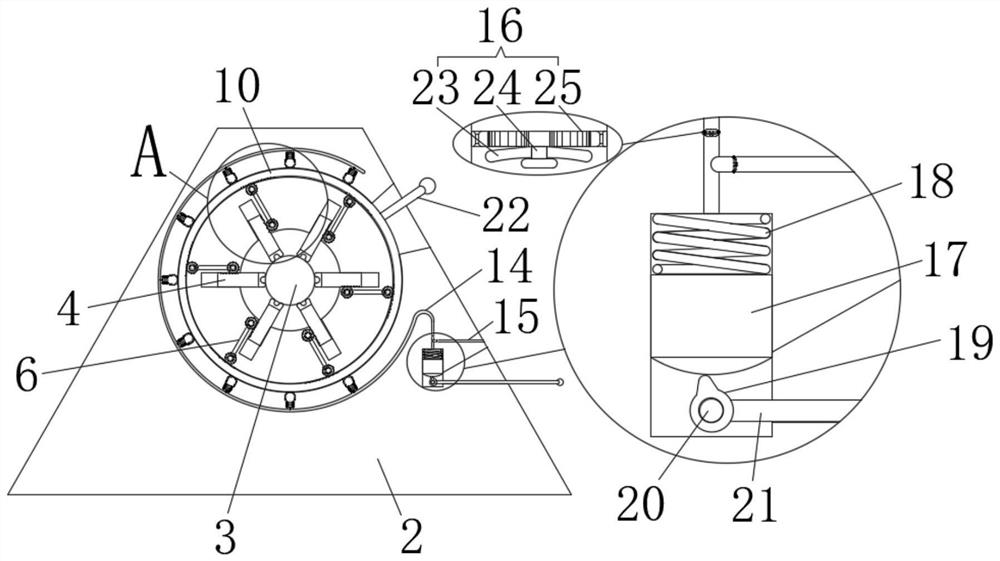

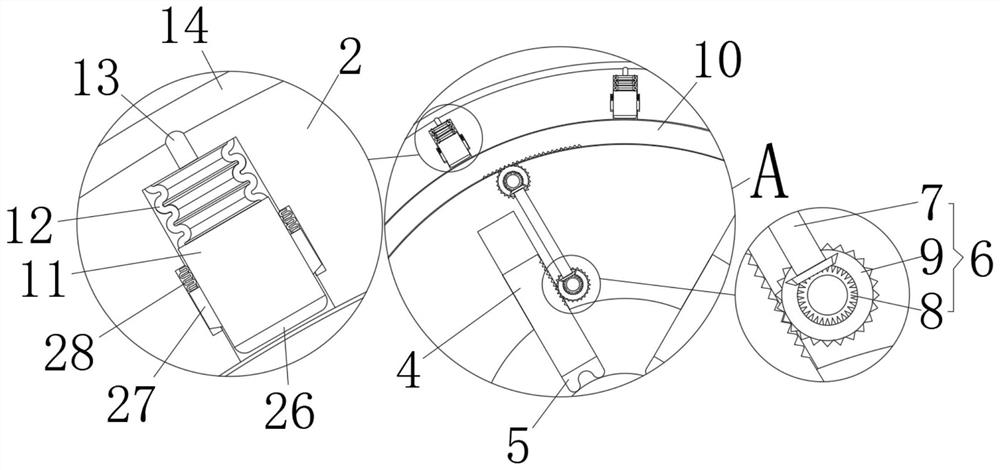

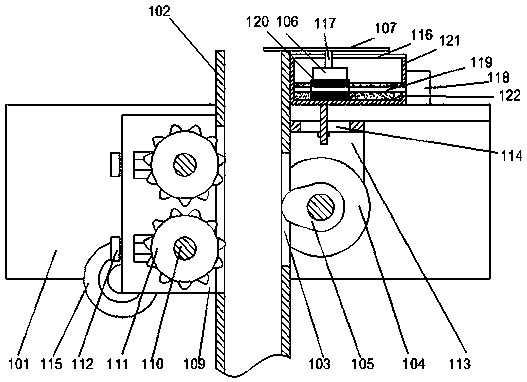

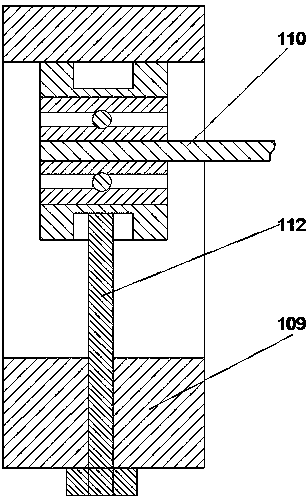

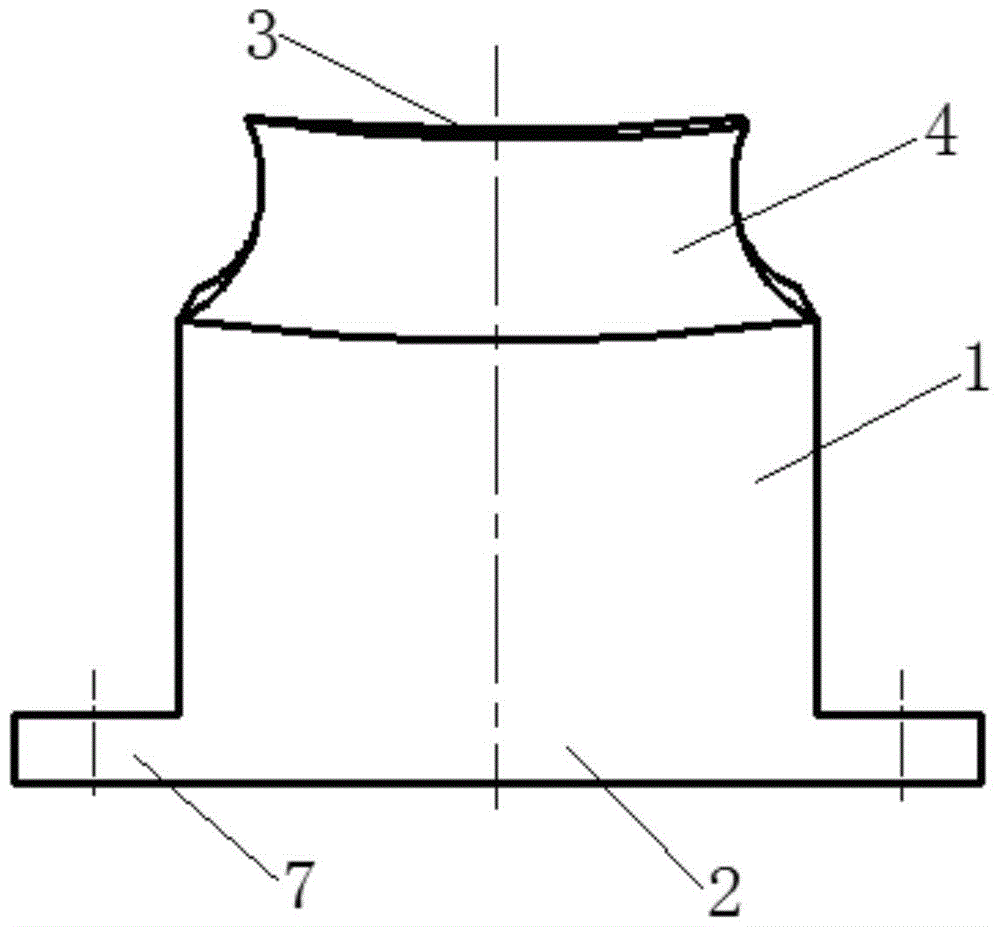

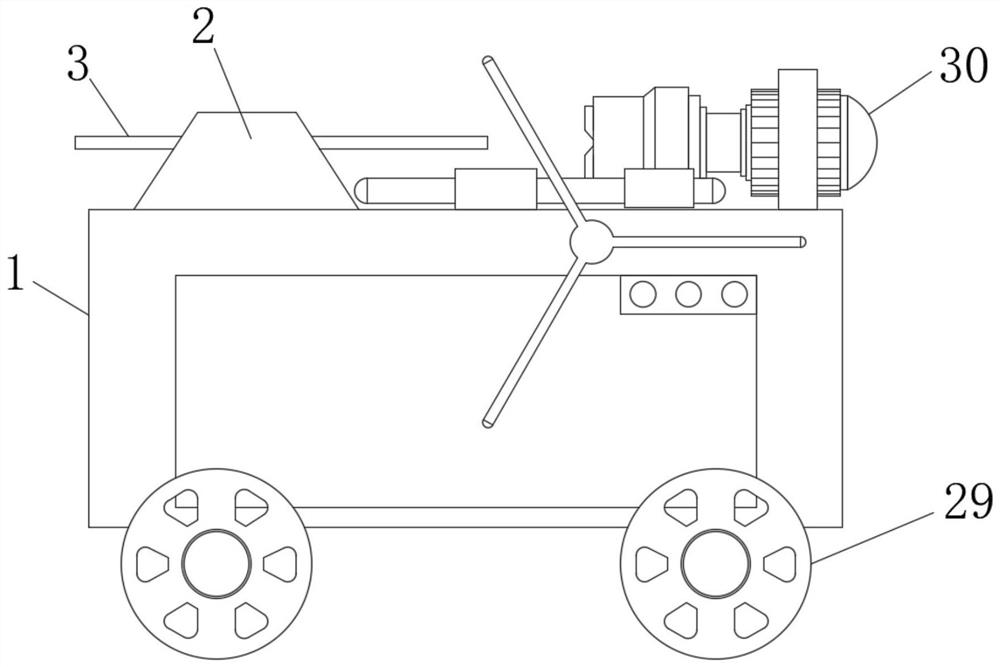

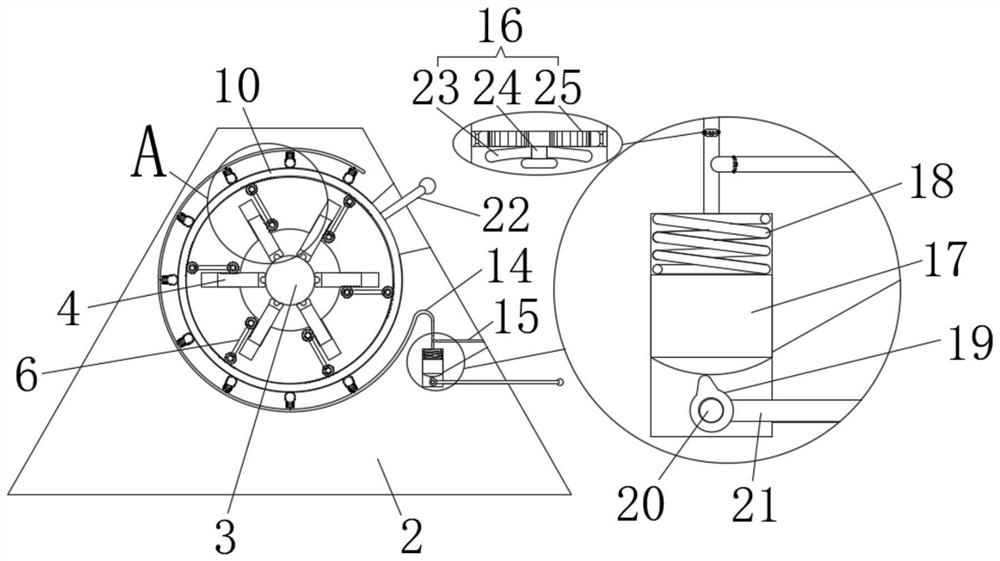

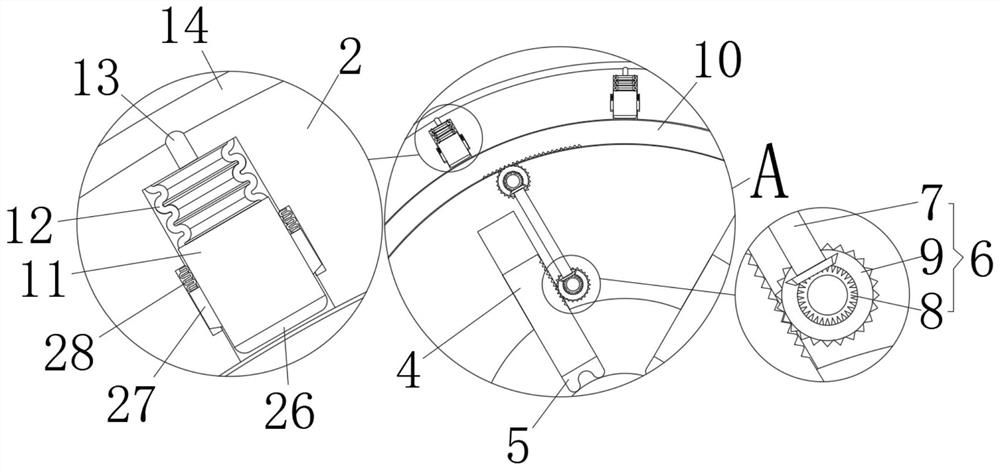

Steel bar thread rolling machine for construction steel bar machining

ActiveCN112045122AMeet the needs of processing efficiencyQuick job locationScrew-threads articlesMachineRebar

The invention relates to the technical field of steel bar thread rolling machines, in particular to a steel bar thread rolling machine for construction steel bar machining. The machine comprises a boxbody 1, a base 2 and a steel bar 3, wherein the base 2 is fixedly connected to the upper end of the box body 1, the steel bar 3 penetrates through the base 2, the base 2 is in a frustum shape and isprovided with a cylindrical hole, the steel bar 3 is arranged in the cylindrical hole of the base 2, a plurality of uniformly-distributed pushing plates 4 are arranged surrounding the steel bar 3, a rubber block 5 is fixedly connected to one end of each pushing plate 4, and the rubber blocks 5 are in contact with the steel bar 3. According to the structural design, the demand for locating steel bars 3 with different outer diameters by the base 2 is met, rapid locating work can be realized just by controlling a first handle 21 and a second handle 22, the efficient machining demand on the wholesteel bar thread rolling machine is met, and functions are stable and powerful.

Owner:广东新拓展建筑工程有限公司

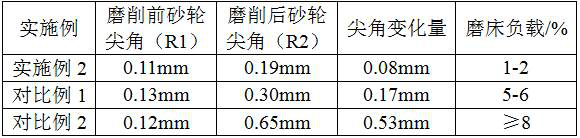

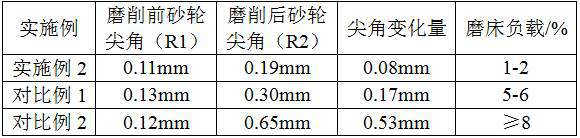

Composite bonded superhard grinding wheel with high shape retention property and preparation method of composite bonded superhard grinding wheel

ActiveCN111922928AImprove liquidityGood formabilityAbrasion apparatusGrinding devicesFiberCarbon fibers

The invention relates to a composite bonded superhard grinding wheel with a high shape retention property. The superhard grinding wheel is prepared from raw materials in percentage by weight as follows: 15%-45% of polyimide resin, 15%-50% of copper powder, 8%-20% of silicon dioxide, 5%-15% of tin powder, 2%-10% of carbon fibers and the balance an abrasive material. The superhard grinding wheel notonly has sharpness of a resin bonded grinding wheel, but also has the shape retention property and heat resistance of a metal grinding wheel, that is, the superhard grinding wheel has better sharpness and sharp corner retention property, the load of a grinding machine is 1%-2%, and the demand of high-efficiency machining of the industry can be met.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

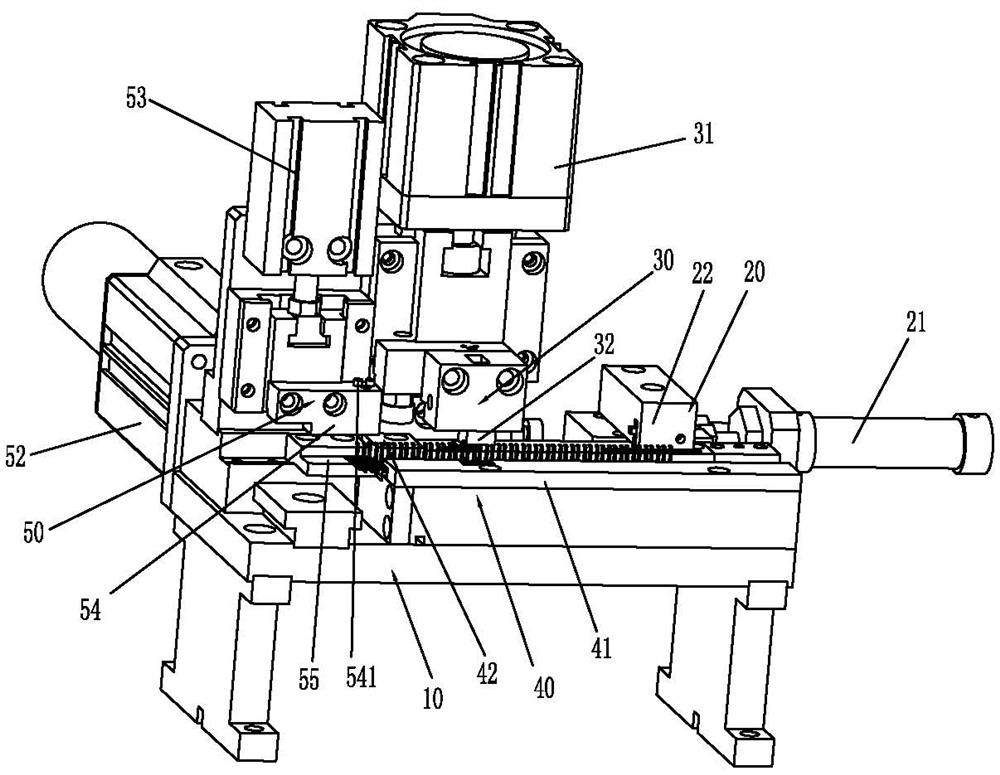

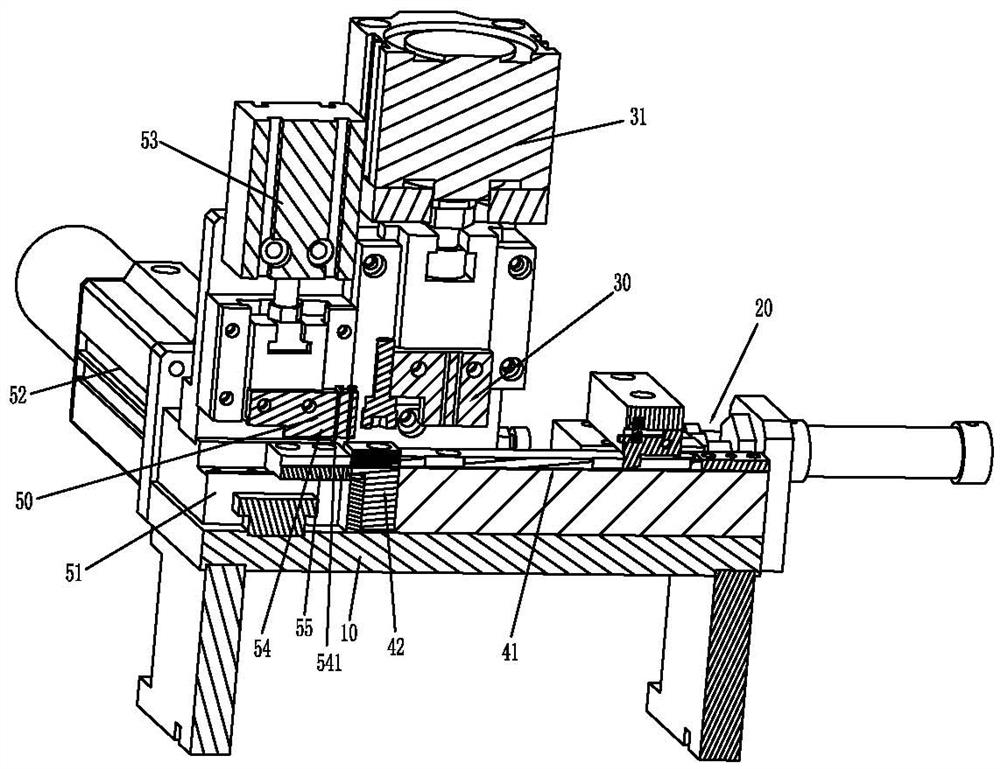

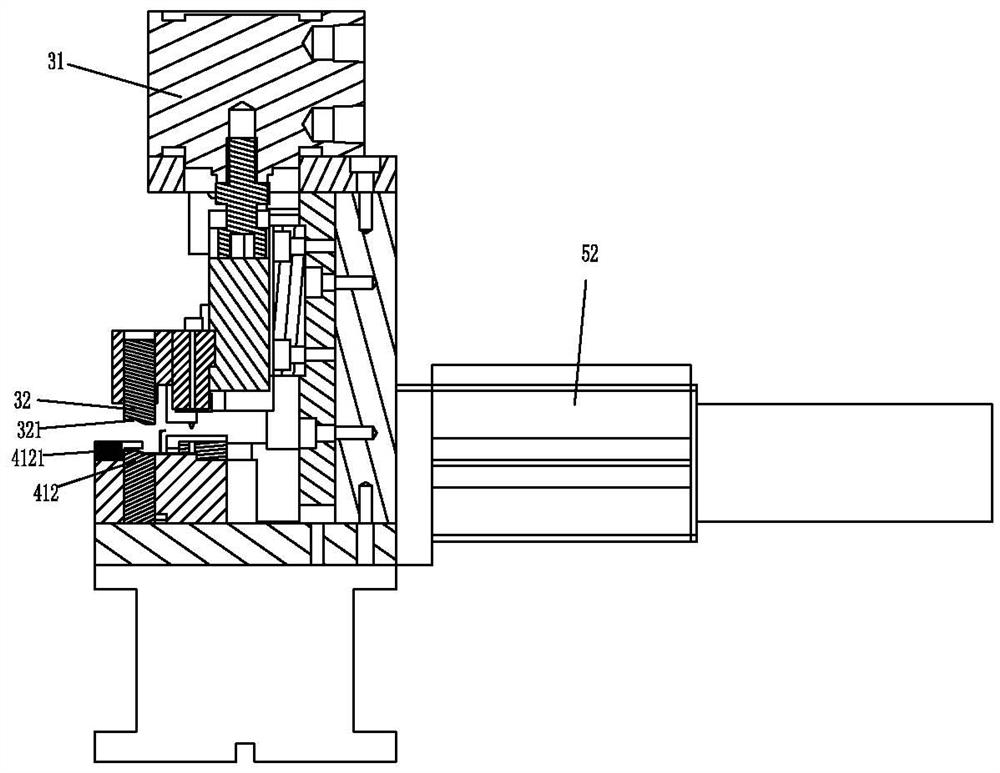

USB terminal cutting device

PendingCN114309234ASimple structureSmall footprintContact member manufacturingContact member assembly/disassemblyStructural engineeringUSB

The invention discloses a USB terminal cutting device which comprises a base, a terminal material belt conveying track, a material belt pushing module and a terminal shaping module. The terminal material belt conveying track comprises a fixed track and a floating track. The inner bottom surface of the second channel of the floating seat is higher than the inner bottom surface of the first channel of the fixed rail; the tail end of the floating track is provided with a terminal cutting and plugging module. The terminal cutting and end inserting module comprises a sliding seat, a first driving unit, a second driving unit, a cutting die and a material receiving plate, the first driving unit can drive the sliding seat to move in the vertical conveying direction, the cutting die is located above the material receiving plate, and the second driving unit can drive the cutting die to move up and down; thus, cutting and terminal insertion are integrated in the same functional module, the device structure is simplified, the occupied space is smaller, clamping and positioning of the terminal group can be completed during cutting, positioning is not needed in the terminal insertion link, terminal insertion accuracy can be ensured, meanwhile, the overall machining and assembling efficiency is effectively improved, and the requirement for higher machining efficiency is better met.

Owner:FREEPORT GUANGDONG PRECISION IND CO LTD

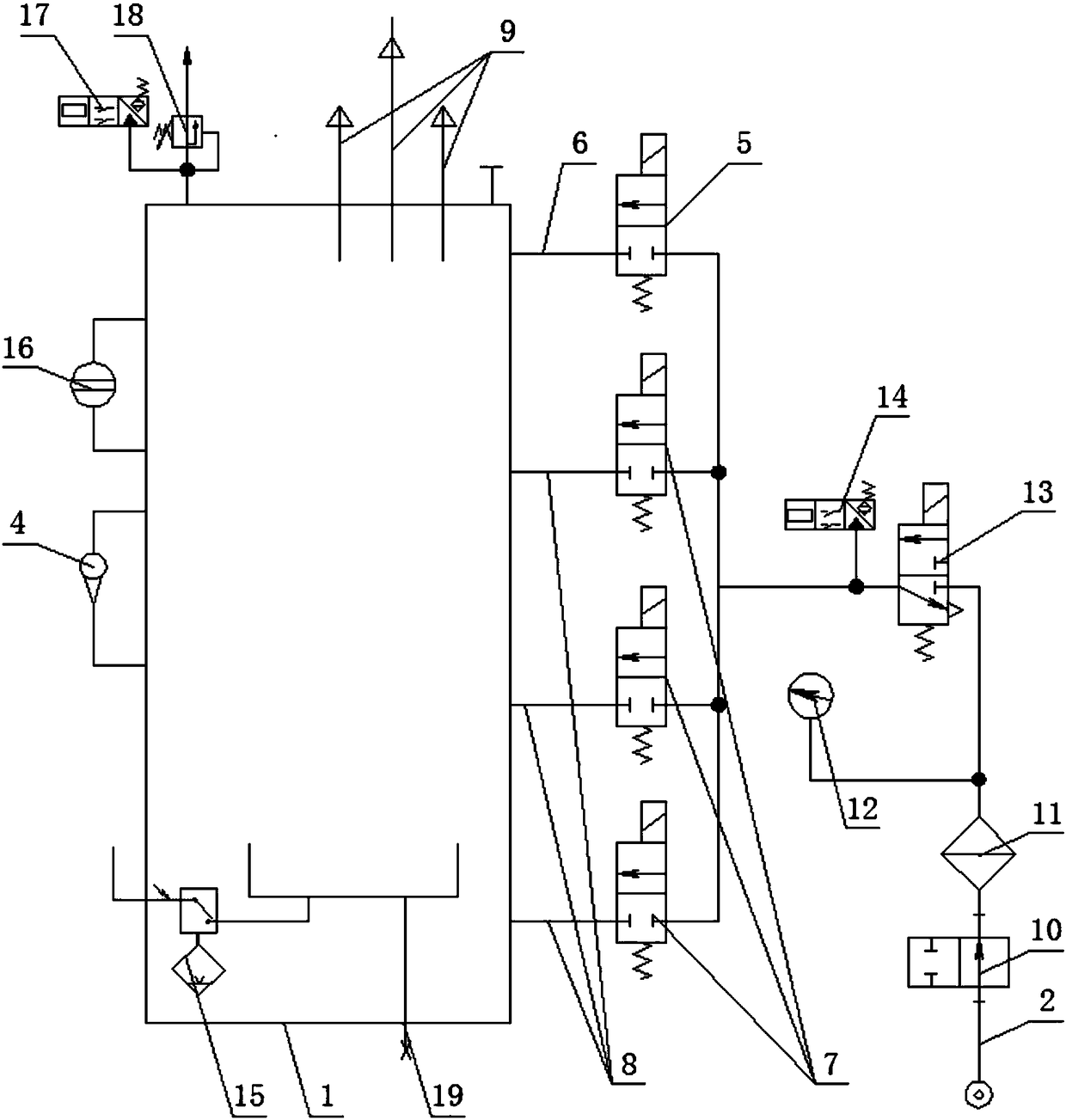

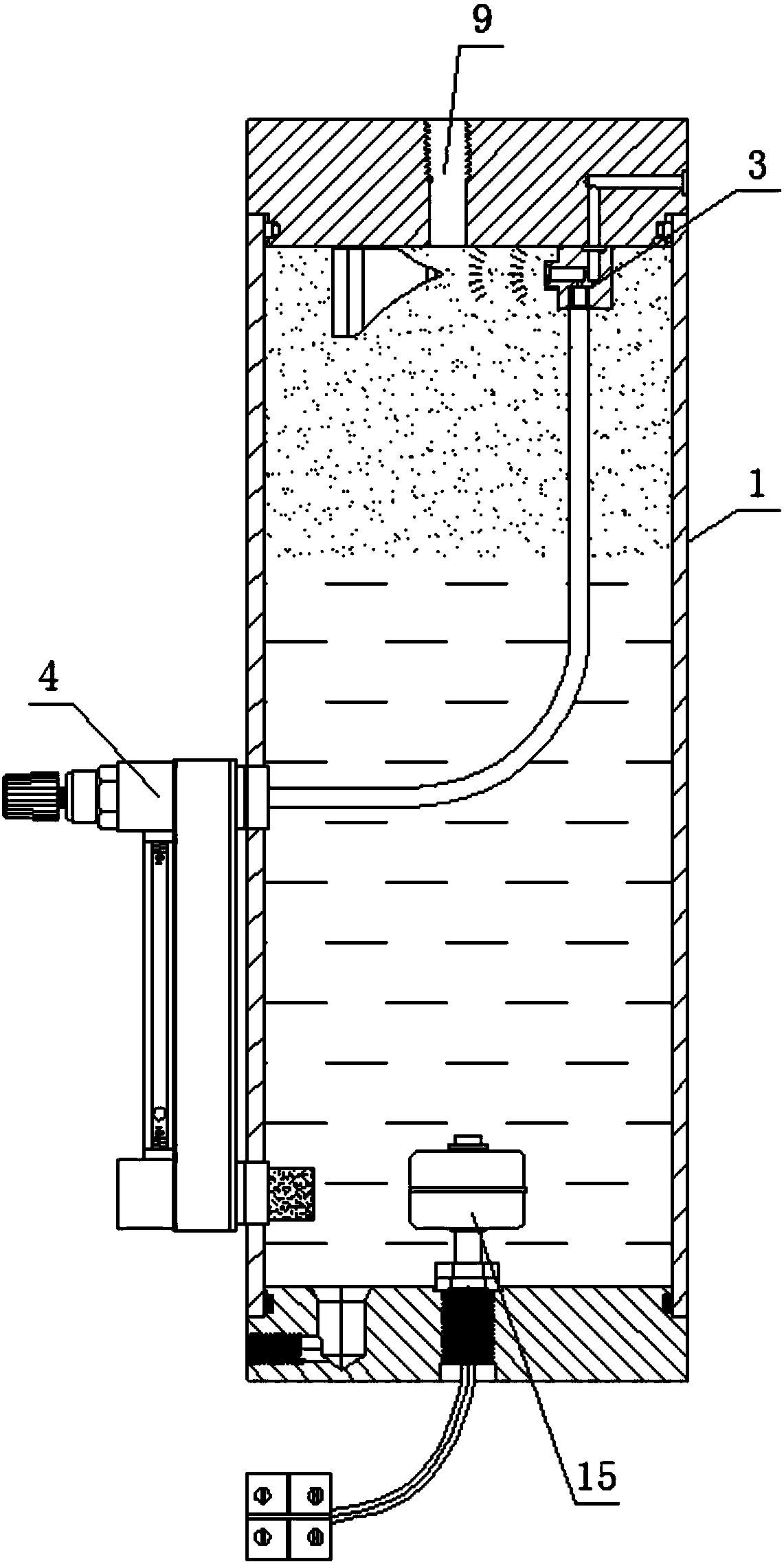

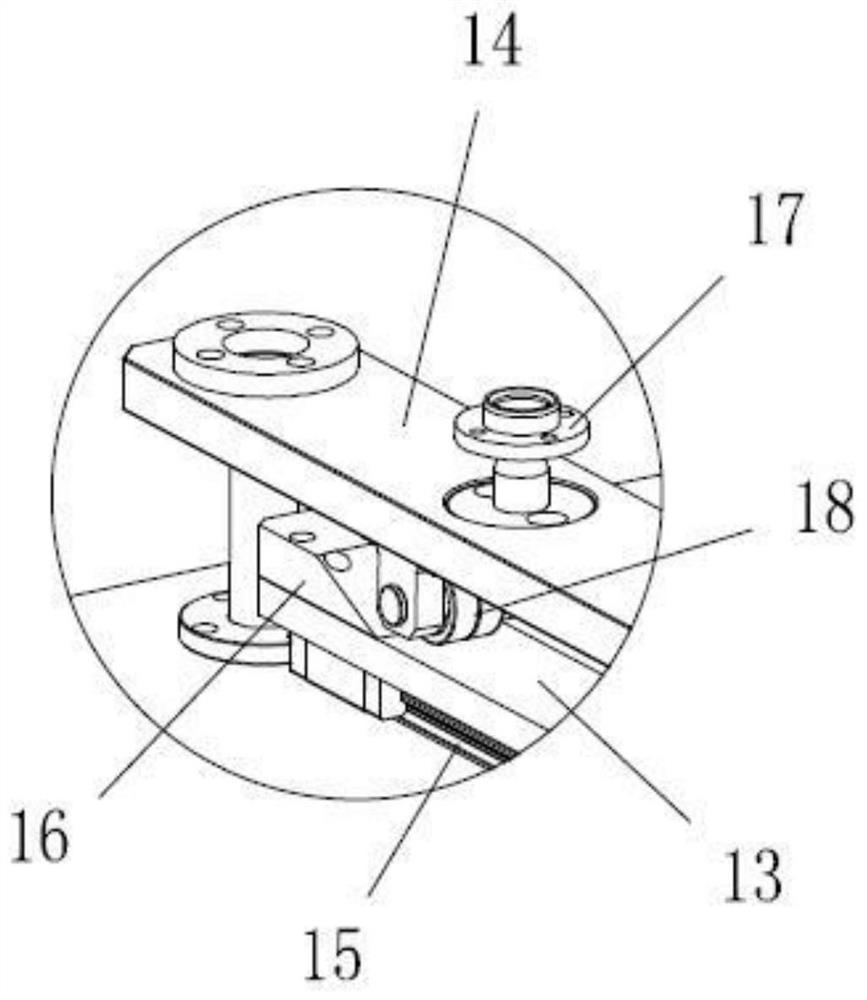

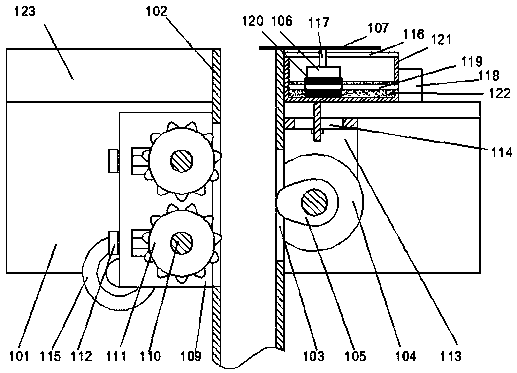

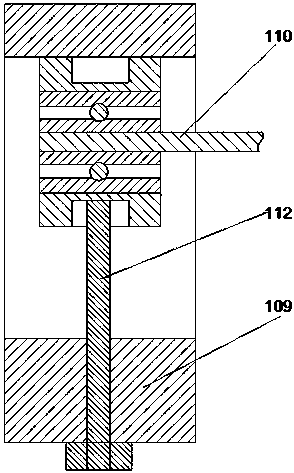

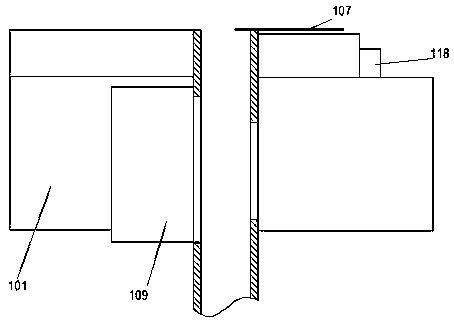

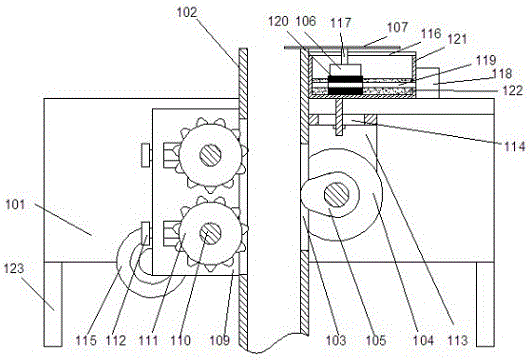

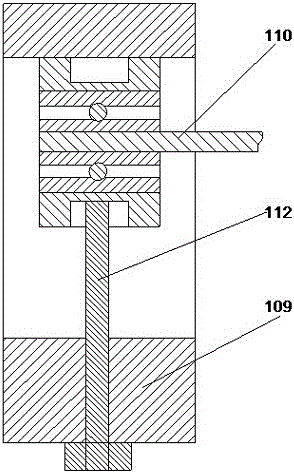

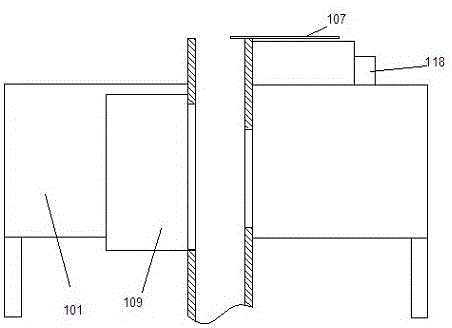

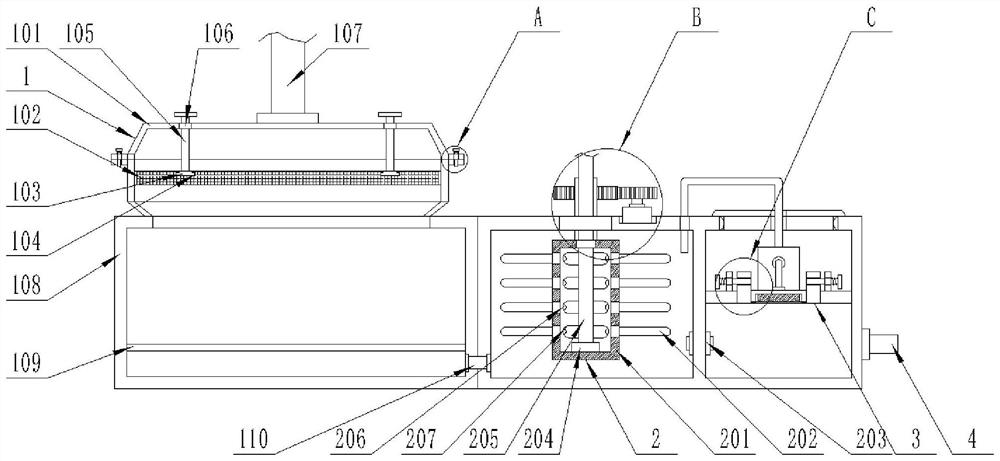

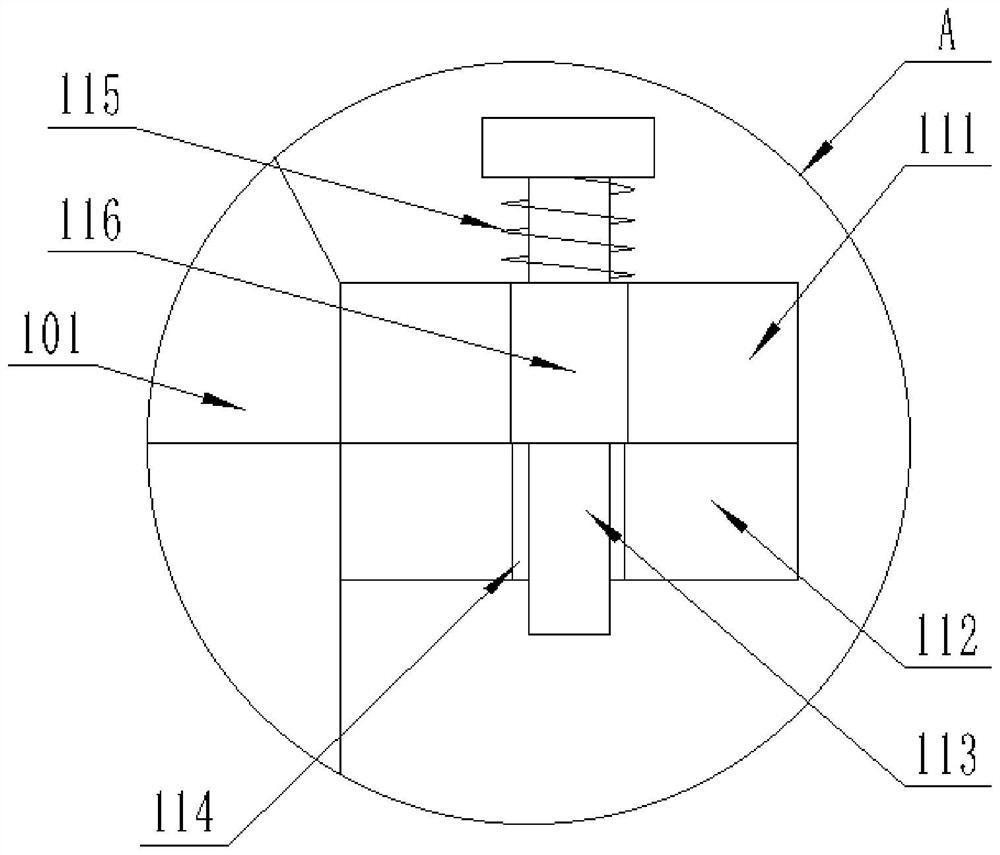

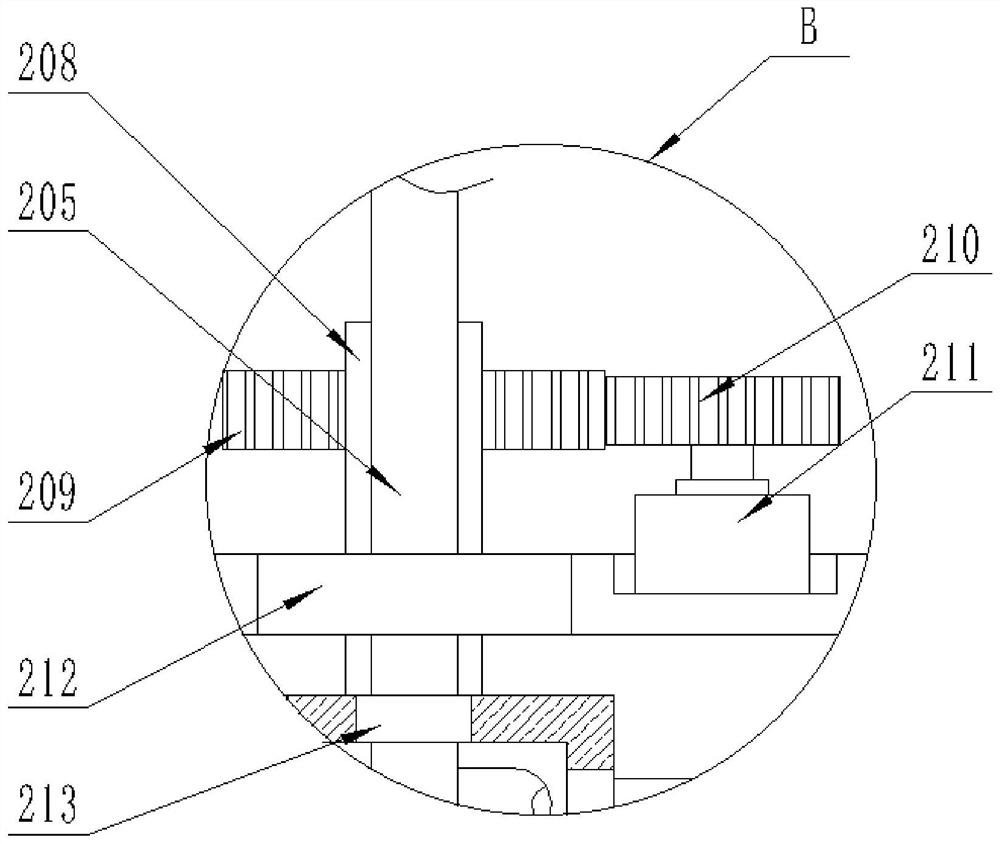

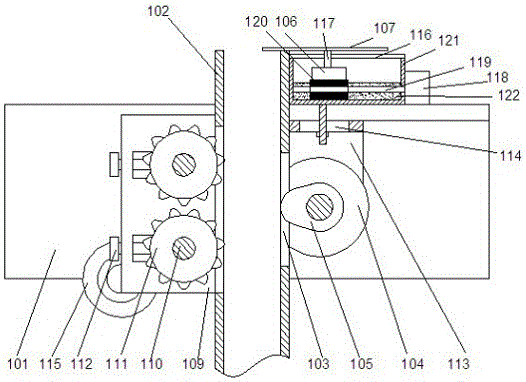

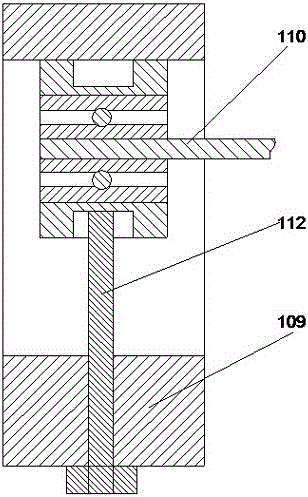

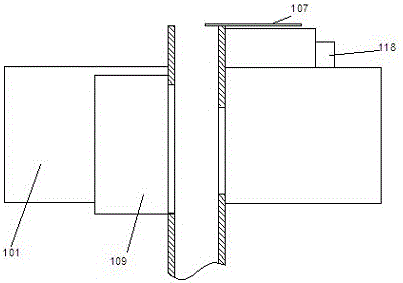

Micro lubrication device

PendingCN108555686ARealize cutting processQuick lubricationMaintainance and safety accessoriesMetalworkingFuel tank

The invention discloses a micro lubrication device. The micro lubrication device comprises an oil storage tank and an air source inlet pipe, wherein the air source inlet pipe is connected with an aerosol generation control valve set; the aerosol generation control valve set is connected with an aerosol generator; a liquid inlet end of the aerosol generator is connected with a flow gauge; the air source inlet pipe is also connected with an aerosol mixing and air replenishing valve; the aerosol mixing and air replenishing valve is connected with an aerosol output pressure air pipe extending to the upper part of the oil storage tank; the top of the oil storage tank is connected with an aerosol outlet set. The micro lubrication device is capable of generating aerosol in a pressure container, outputting and controlling the generation amount of the aerosol; the aerosol is used for replacing the conventional cutting fluid for processing metals, so that the metal cutting positions are efficiently, greenly and environmentally friendly lubricated and cooled; the aerosol is especially applied to places for processing deep holes with length-diameter ratio being greater than 30-70, and cuttingand processing cutters with ultra-small inner holes, cutters with large inner cooling holes and cutters with multiple inner cooling holes; meanwhile, the aerosol can be controlled so as to meet different requirements of cutting and processing of various types of metals on lubrication.

Owner:北京培峰技术有限责任公司

A pipe cutting device

ActiveCN106334829BCut evenlyImprove continuityTube shearing machinesShearing machine accessoriesIndustrial engineeringBase station

The invention discloses a pipe cutting device which comprises a base station and a pipe lifting device arranged on one side of the base station. A cutting device is arranged above the base station; the pipe lifting device comprises a pipe lifting cavity arranged on one side of the base station and used for lifting a pipe, a concave hole is formed in the right end of the pipe lifting cavity, and the length direction of the concave hole is parallel to the length direction of the pipe lifting cavity; and a first driving motor is arranged on the base station, an incline wheel corresponding to the concave hole in position is arranged on the first driving motor, teeth are arranged on the incline wheel, and the teeth on the incline wheel can abut against the pipe when the incline wheel rotates.

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

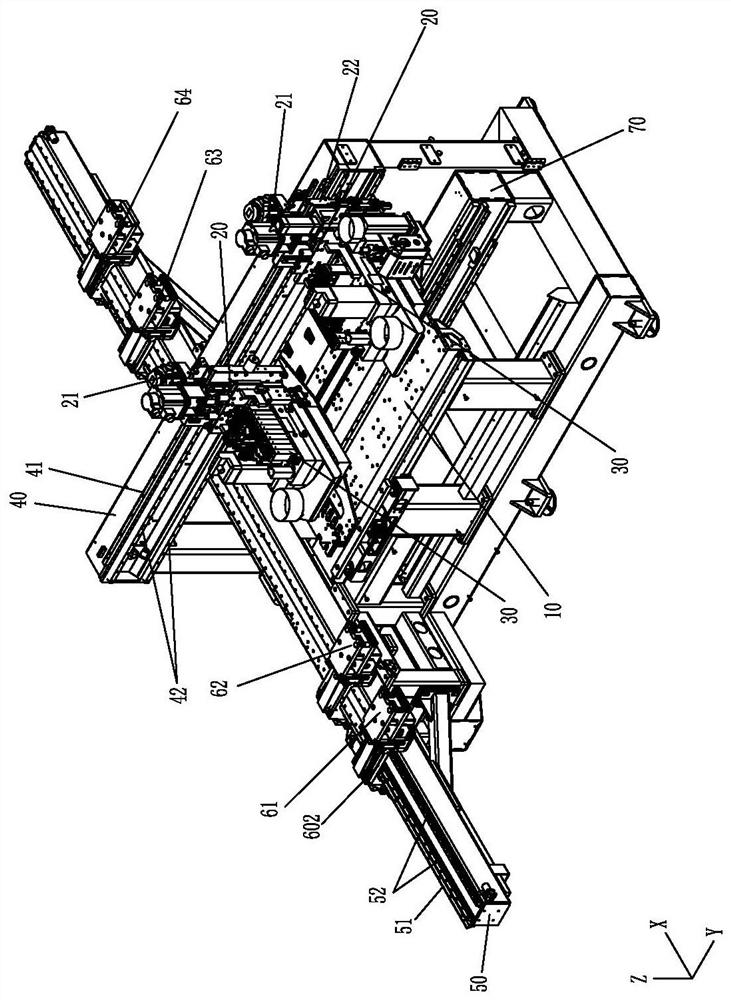

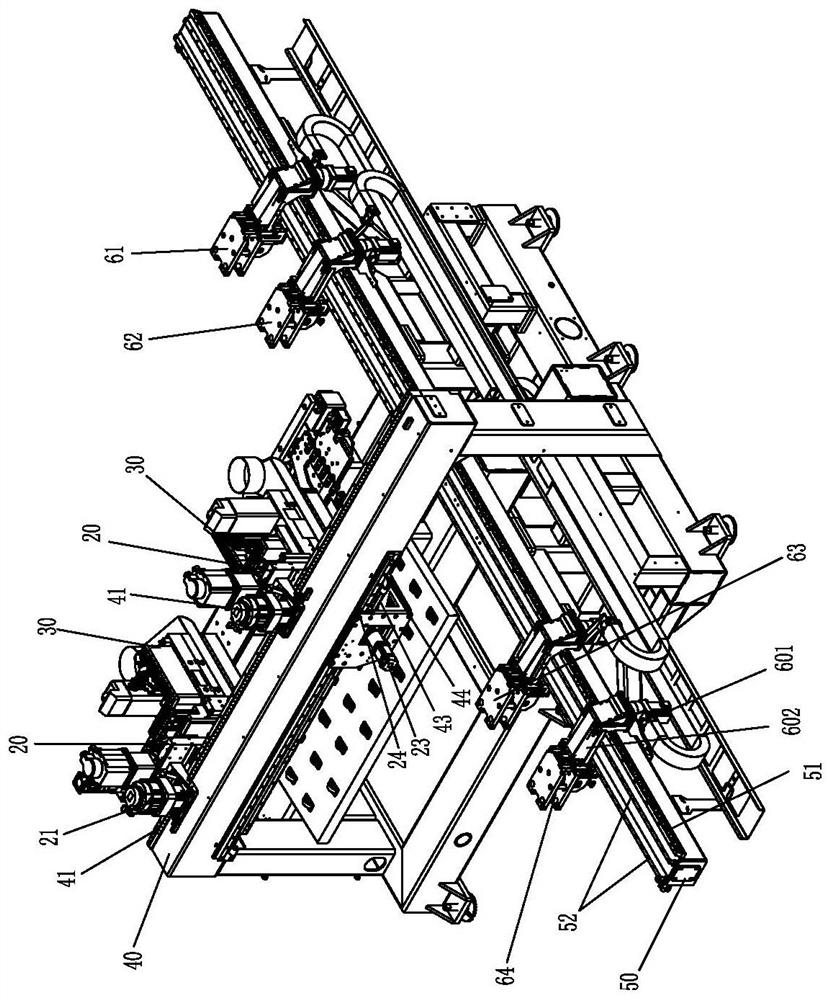

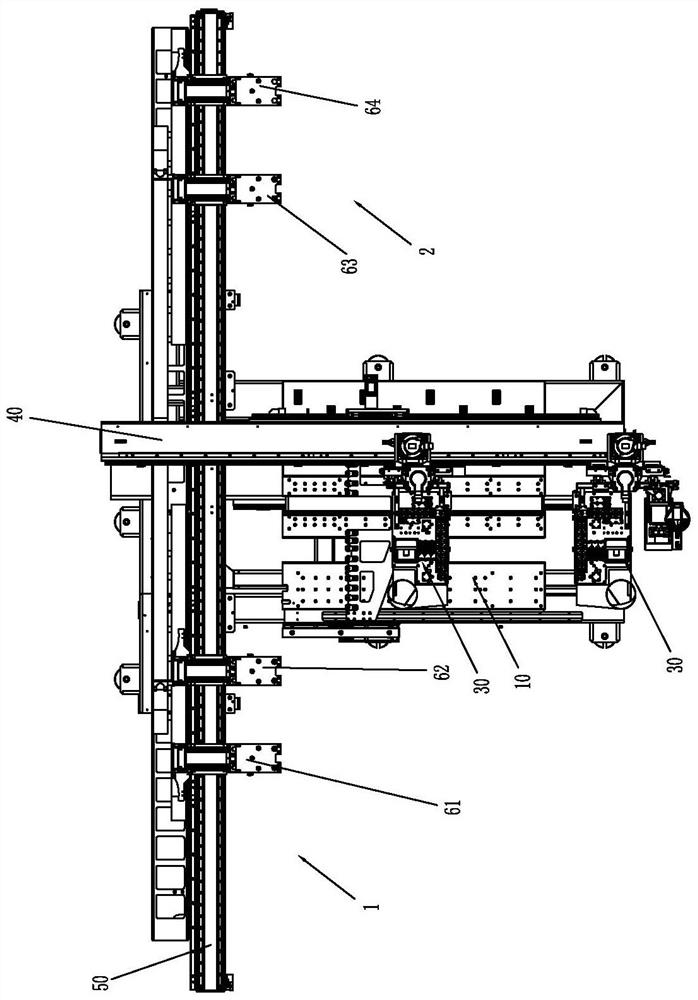

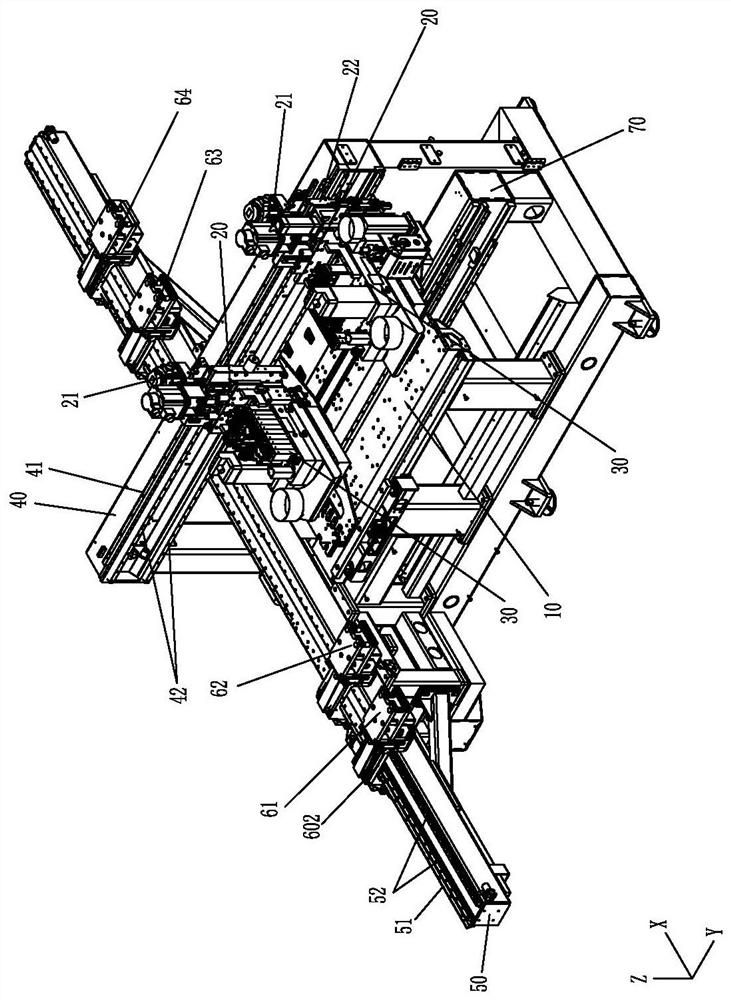

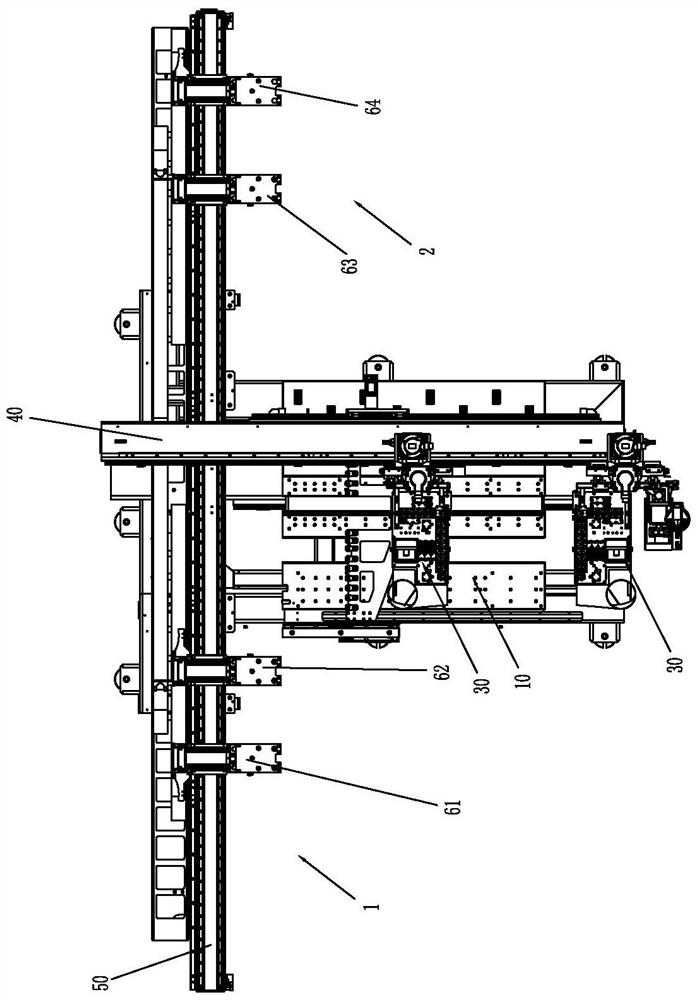

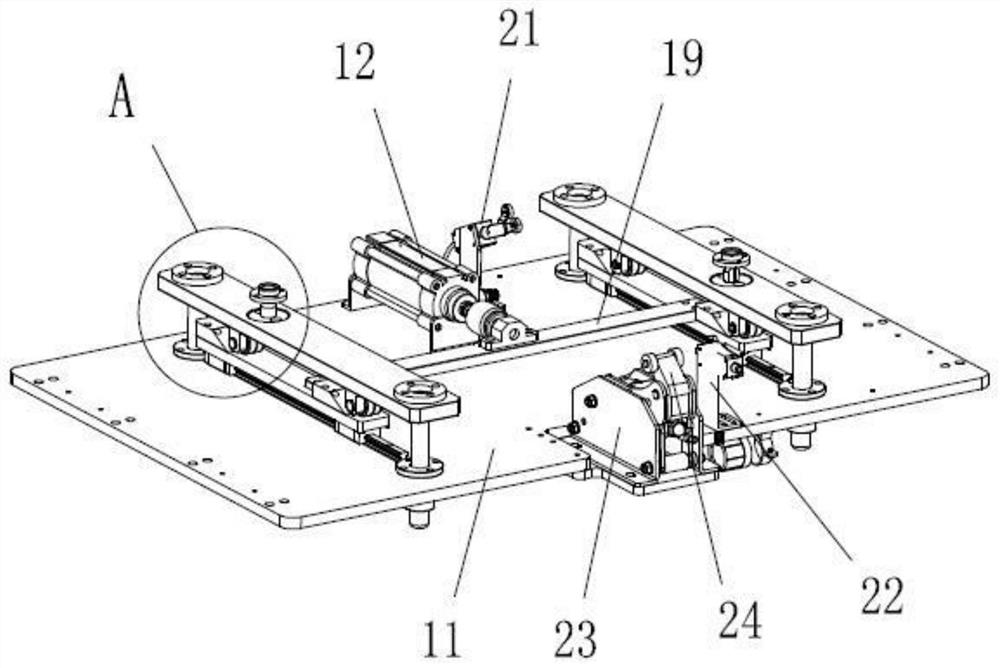

Machining center and machining method for switching clamping feeding and discharging and machining positioning

ActiveCN113001687AImprove precise clamping and positioningImprove efficiencyStationary drilling machinesMulti-purpose machinesWood machiningMachine

The invention discloses a machining center and machining method for switching clamping feeding and discharging and machining positioning. The machining center comprises a lathe bed, a workbench, a cross beam clamp module, an upper workbench module, and an upper machine head; the upper machine head is a drilling machine head; the lathe bed comprises a Y-direction upper guide rail base which is located above the workbench; the upper machine head is arranged on the upper workbench module and can move along the Y-direction upper guide rail base; the cross beam clamp module comprises an X-direction cross beam and at least four clamp mechanisms capable of working independently, and the clamp mechanisms are defined as a first clamp mechanism, a second clamp mechanism, a third clamp mechanism and a fourth clamp mechanism from left to right; the X-direction cross beam, the X-direction rack and the X-direction guide rail extend out of the left and right sides of the workbench; the left and right sides of the workbench are a feeding area and a discharging area, respectively; the first clamp mechanism corresponds to the feeding area; the second and third clamp mechanisms both can move back and forth to correspond to the feeding area and the workbench; and the fourth clamp mechanism can move back and forth to correspond to the workbench and the discharging area. The overall efficiency of a wood processing center is effectively improved.

Owner:NANXING MACHINERY CO LTD

A horizontal push type automatic unstacking device

ActiveCN111559649BReduce labor costsReduce labor intensityConveyorsDe-stacking articlesBottleChain drive

The invention belongs to the technical field of glass bottle production, and provides a flat-push automatic depalletizing device, which includes a depalletizing machine and a bottle conveying machine; The supporting plate driven by the first driving device is slid and installed in the vertical direction, and the bottle pushing rack driven by the second driving device is slid and installed on the top of the unstacking frame along the horizontal direction. The position is fixed and the baffle plate is installed, and the two sides of the unstacking frame are respectively equipped with clamping mechanisms; the bottle conveyor includes a conveyor frame, and the conveyor frame is wound with a conveyor plate chain driven by a third drive device. One end of the rack is positioned against the baffle, flush with the top of the baffle. The horizontal pushing depalletizing method adopted by the present invention can directly push the entire layer of glass bottles to the bottle conveying machine for transportation. Compared with the traditional manual depalletizing method, it not only saves labor costs, but also greatly reduces labor intensity, and the work Efficiency is greatly improved.

Owner:山东三江智能装备有限公司

Machining center and processing method for switching clamping, loading and unloading and processing positioning

ActiveCN113001687BImprove precise clamping and positioningImprove efficiencyStationary drilling machinesMulti-purpose machinesWood machiningEngineering

The invention discloses a machining center and a machining method for switching, clamping, loading, unloading, and machining positioning, including a bed, a workbench, a beam clamp module, an upper workbench module, and an upper machine head; the upper machine head is a drilling machine head; the bed includes a Y upward guide rail seat, and the Y upward guide rail seat is located above the workbench; the upper machine head is installed on the upper workbench module, and can be displaced along the Y upward guide rail seat; the beam clamp module includes a X The X-direction beam and at least four clamping mechanisms that can work independently are respectively defined as the first to fourth clamping mechanisms from left to right; the X-direction beam, the X-direction rack, and the X-direction rail all extend beyond the left and right sides of the workbench. The left and right sides of the worktable are respectively the loading area and the unloading area. The first clamping mechanism is set corresponding to the loading area, and the second and third clamping mechanisms can be moved back and forth corresponding to the loading area and the working table. The four-clamp mechanism can move back and forth corresponding to the workbench and the blanking area; effectively improving the overall efficiency of the wood processing center.

Owner:NANXING MACHINERY CO LTD

An intelligent assembly line for buckle screws

ActiveCN111037087BMeet the needs of processing efficiencyVersatileNon-electric welding apparatusUltrasonic weldingStructural engineering

The invention discloses an intelligent assembly line for buckle screws. The intelligent assembly line comprises a conveying line, a buckle screw mounting station, a buckle mounting station, a multi-shaft welding station, a sound absorption cotton feeding station and an ultrasonic welding station. A mold locking mechanism is arranged at a position, corresponding to each station, of the conveying line; a buckle screw mounting mechanism is arranged at the buckle screw mounting station, a buckle mounting mechanism is arranged at the buckle mounting station, a multi-shaft welding machine is arranged at the multi-shaft welding station, a sound absorption cotton feeding mounting mechanism is arranged at the sound absorption cotton feeding station, and an ultrasonic welding mechanism is arranged at the ultrasonic welding station. According to the scheme, the buckle screw mounting station and the sound absorption cotton feeding station are additionally arranged on the basis of an original automobile door panel assembly line, so that the functions of the assembly line are more comprehensive, and the efficient machining requirement of an automobile door panel is met; and the mold locking mechanisms are optimized, so that molds carrying workpieces are positioned more accurately at machining positions, the locking effect is better, and the product quality is improved.

Owner:SUZHOU KEBER PRECISION MACHINERY

An integral hardened steel corner rooting test piece and its high-speed milling process method

ActiveCN104907616BMeet the needs of processing efficiencyAutomatic control devicesMeasurement/indication equipmentsEngineeringMechanical engineering

The invention relates to an integral quenched steel back gouging test piece and a high-speed milling process method thereof. The technical key points are as follows: the test piece comprises a milling processing region and a base at the bottom, wherein the top surface of the milling processing region is a top concave curve surface which is bent downwards along the width direction, the top concave curve surface is formed by smooth transition connection of five sections of curve surfaces which are distributed along the length direction and have different curvature radiuses, the four corners of the top concave curve surface are circular arc corners which have different radiuses, the side vertical surface of the milling processing region is provided with one section of side concave curve surface which sinks towards the center, a circumferential lug boss which is positioned below the side concave curve surface is formed on the side vertical surface of the milling processing region, and the surface of the circumferential lug boss is parallel to the top concave curve surface; two sides of the base, in the width direction of the milling processing region, extend outwards to form a lug boss. According to the process scheme, the method comprises the steps of step one, selecting the processing region; step two, designing the cutting path of a cutter; and step three, processing the surface feature when the high-speed quenched steel back gouging is tested.

Owner:HARBIN UNIV OF SCI & TECH

A high-shape-retaining composite bond superhard grinding wheel and its preparation method

ActiveCN111922928BImprove liquidityGood formabilityAbrasion apparatusGrinding devicesFiberCarbon fibers

The invention relates to a composite bond superhard grinding wheel with high shape retention properties. The superhard grinding wheel is made of the following raw materials in weight percentages: polyimide resin 15-45%, copper powder 15-50%, silica 8 -20%, tin powder 5-15%, carbon fiber 2-10%, the balance is abrasive. The superhard grinding wheel of the present invention not only has the sharpness of a resin bond grinding wheel, but also has the shape retention and heat resistance of a metal grinding wheel, that is, it has better sharpness and sharp corner retention. The grinder load is 1-2%. It can meet the needs of efficient processing in the industry.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

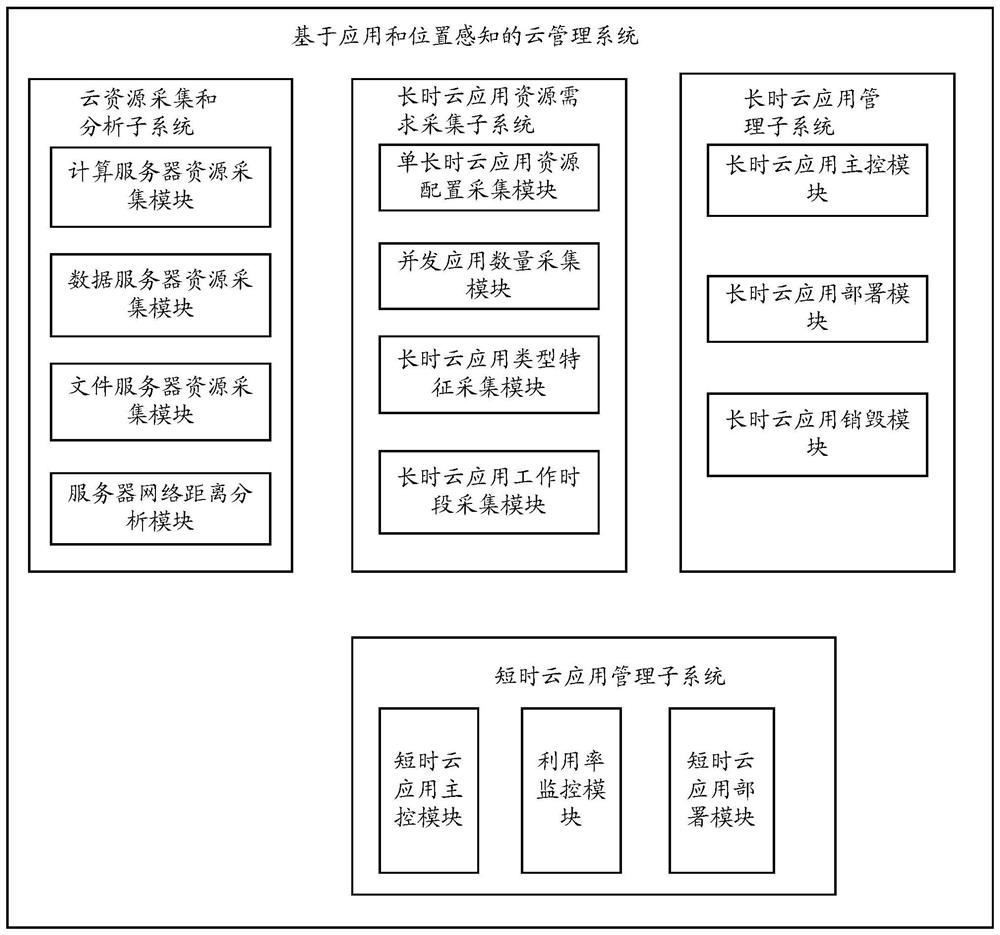

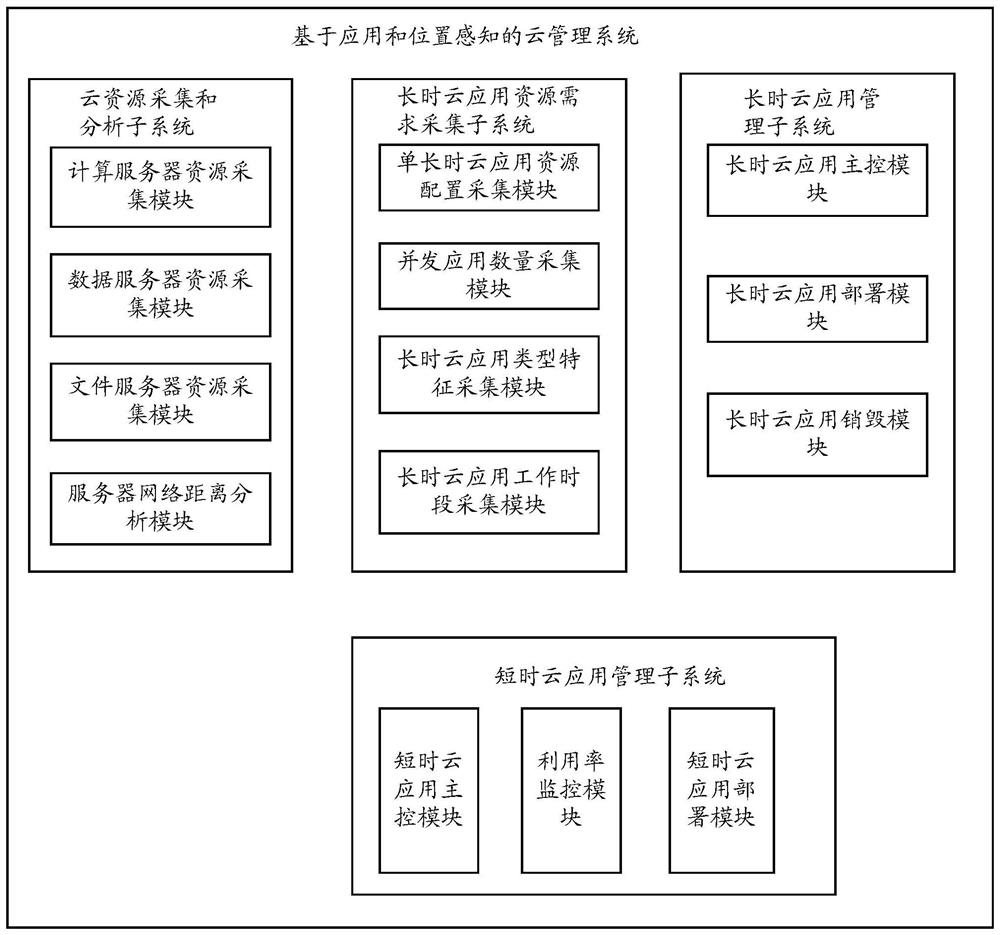

A cloud management system based on application and location awareness

ActiveCN111800514BImprove service qualityIncrease profitDigital data information retrievalResource allocationQuality of serviceHigh availability

The present invention provides a cloud management system based on application and location awareness, including: cloud resource collection and analysis subsystem, long-term cloud application resource demand collection subsystem, long-term cloud application management subsystem and short-term cloud application management subsystem ; Among them, the cloud resource pool is composed of server clusters, including computing servers, data servers and file servers; cloud applications include long-term cloud applications and short-term cloud applications; the long-term cloud applications have high requirements on the immediate availability of computing resources, and require A fixed computing resource is maintained; the short-term cloud application refers to an application whose user interaction is short and fast, and allows interruption of switching and failure to re-operate. The advantages are: a cloud management system based on application and location awareness provided by the present invention realizes the high efficiency of cloud applications, high utilization rate of cloud resources, and improves the service quality of cloud applications, thereby satisfying people's increasing data requests efficiently. processing needs.

Owner:HUAQIAO UNIVERSITY

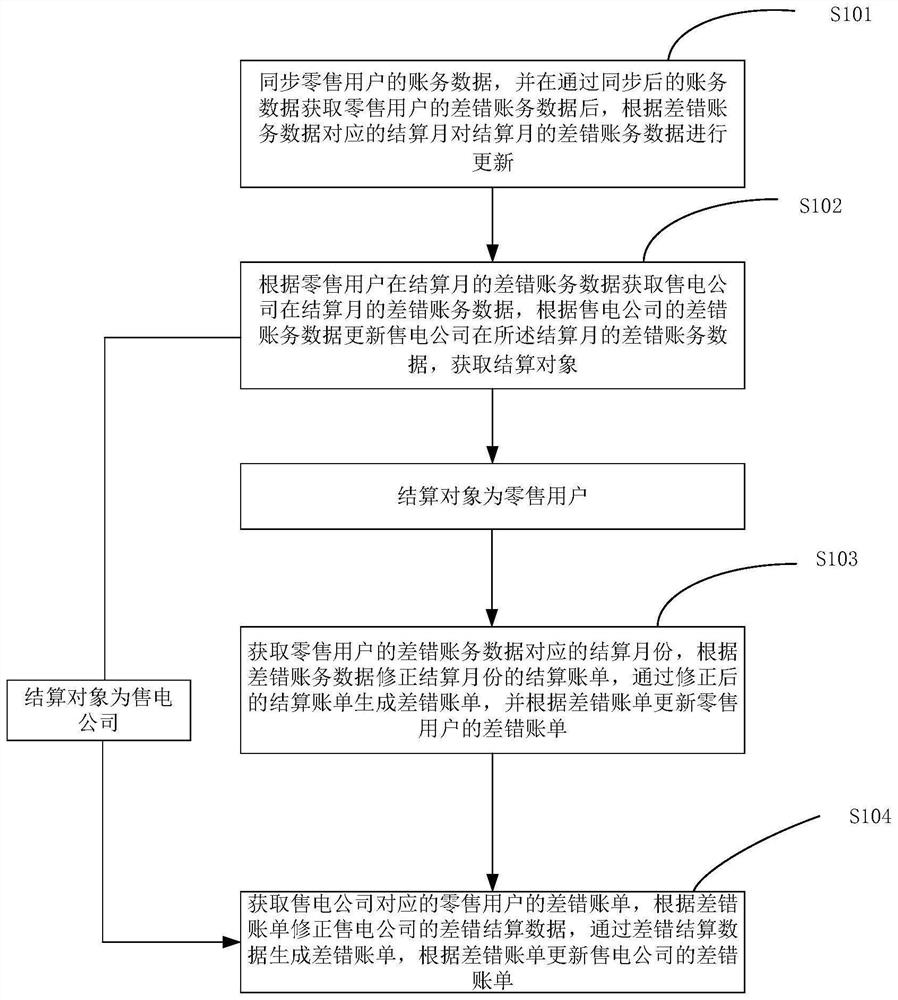

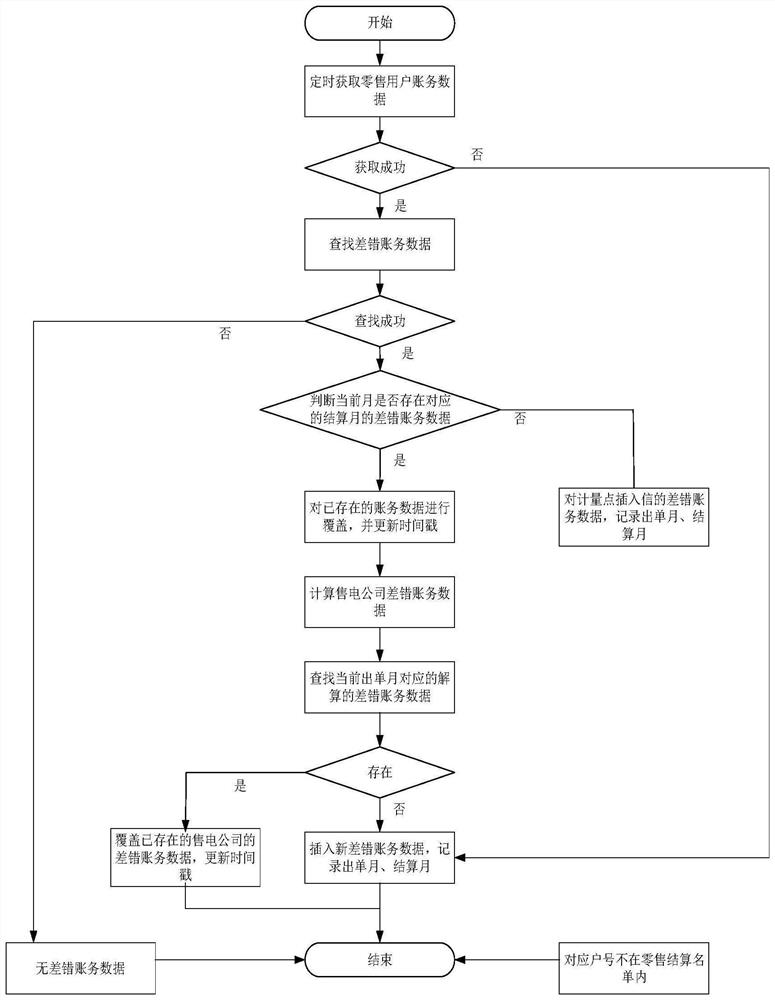

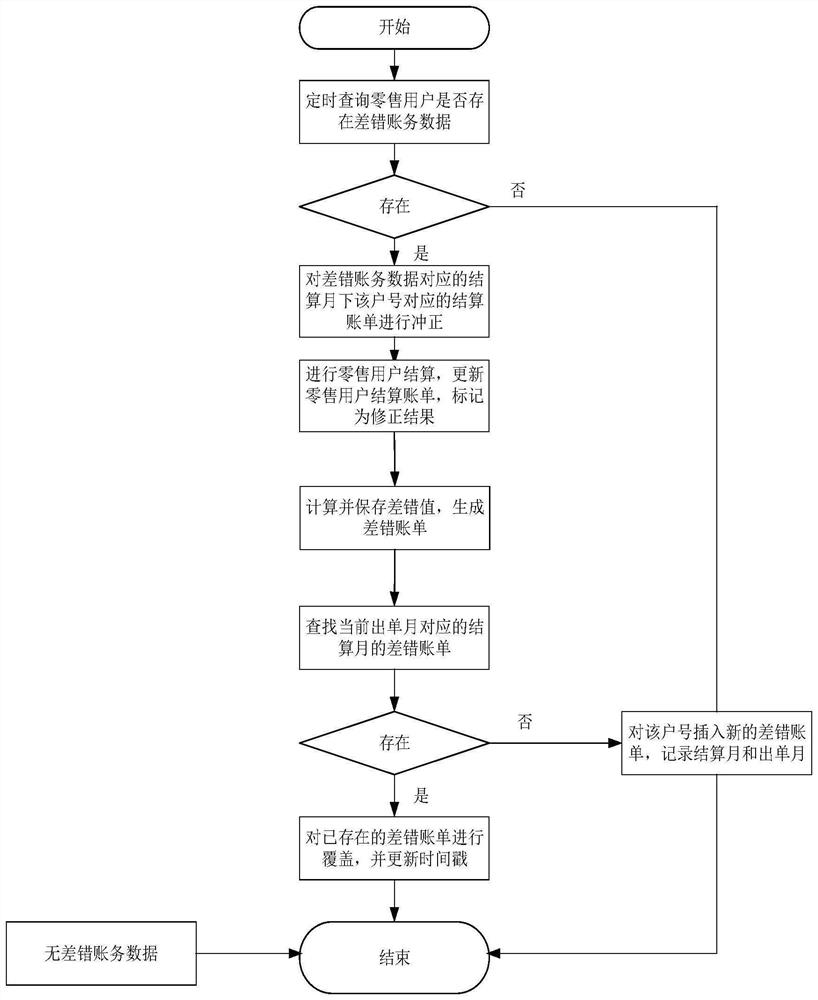

Power retail transaction settlement method, terminal and storage medium

PendingCN114066640ARealize automatic acquisitionComputationally efficientDatabase updatingFinanceFinancial transactionElectricity retailing

The invention relates to a power retail transaction settlement method, a terminal and a storage medium. The method comprises the following steps: S101, updating error accounting data of a settlement month according to error accounting data of a retail user; S102, updating error accounting data of the electricity selling company in the settlement month, obtaining a settlement object, if the settlement object is a retail user, executing S103, and if the settlement object is the electricity selling company, executing S104; S103, correcting the settlement bill of the settlement month according to the error accounting data of the retail user, and updating the error bill of the retail user through the corrected settlement bill; and S104, correcting the error settlement data of the electricity selling company according to the error bill of the electricity selling company, and updating the error bill of the electricity selling company according to the generated error bill. The settlement bill can be efficiently corrected, the efficiency is high, the consumed time is short, the labor cost is reduced, the settlement risk is reduced, and the efficient processing requirement of the power retail transaction is met.

Owner:昆明电力交易中心有限责任公司

A Workflow Task Scheduling Method in Distributed Environment

ActiveCN106155791BReduce the number of tasksImprove scheduling abilityProgram initiation/switchingDistributed Computing EnvironmentScheduling (computing)

The invention discloses a workflow task scheduling method in a distributed computing environment, which uses a directed acyclic graph to describe workflow tasks and resources, and calculates the average task execution time and average task according to node weight information and edge weight information Transfer time, so as to judge the workflow task type and perform classification model processing, and divide the tasks with data dependencies into several independent task sets, each task set contains one or several tasks, and each task set Multiple tasks of have data dependencies, thus turning workflow tasks into "independent tasks". The task set gathers tasks with a relatively large amount of computing data or data transmission together, and at the same time reduces the number of tasks that need to be allocated independently, and improves the performance of later task scheduling as a whole. In addition, when the number of workflow tasks increases, it is only necessary to strengthen the gathering operation of the tasks, and there is no need to process all the tasks, which has better scalability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A pipe cutting device

The invention discloses a pipeline cutting machining device. The pipeline cutting machining device comprises a base platform and a pipeline lifting device arranged on one side of the base platform. A cutting device is arranged above the base platform. The pipeline lifting device comprises a pipeline lifting chamber arranged on one side of the base platform and used for lifting a pipeline. A concave hole is formed in the right side of the pipeline lifting chamber, a pipeline storage frame is arranged at the left end of the pipeline lifting chamber, the right end of the pipeline storage frame is detachably connected with the pipeline lifting chamber, and therefore the pipeline which is machined can be conveyed conveniently. The length direction of the concave hole is parallel to the length direction of the pipeline lifting chamber. A first drive motor is arranged on the base platform. An oblique wheel corresponding to the concave hole in position is arranged on the first drive motor, teeth are arranged on the oblique wheel, and when the oblique wheel rotates, the teeth on the oblique wheel can abut against the pipeline.

Owner:安徽沃尔顶密封工业股份有限公司

Cutting equipment capable of moving pipeline intermittently

ActiveCN106363226ACut evenlyImprove continuityTube shearing machinesShearing machine accessoriesEngineeringDrive motor

The invention discloses cutting equipment capable of moving a pipeline intermittently. The cutting equipment comprises a base platform and a pipeline elevating device arranged on one side of the base platform. A cutting device is arranged above the base platform. Stand columns are fixedly connected to the lower portion of the base platform and located at the left end and the right end of the base platform separately, and the stand columns are used for supporting the base platform. The pipeline elevating device comprises a pipeline elevating chamber which is arranged on one side of the base platform and used for elevating the pipeline. A concave hole is formed in the right end of the pipeline elevating chamber, and the length direction of the concave hole is parallel to the length direction of the pipeline elevating chamber. A first drive motor is arranged on the base platform. The first drive motor is provided with a bevel wheel corresponding to the concave hole in position, the bevel wheel is provided with teeth, and the teeth on the bevel wheel can abut against the pipeline while the bevel wheel rotates.

Owner:江苏汉徐机械设备有限公司

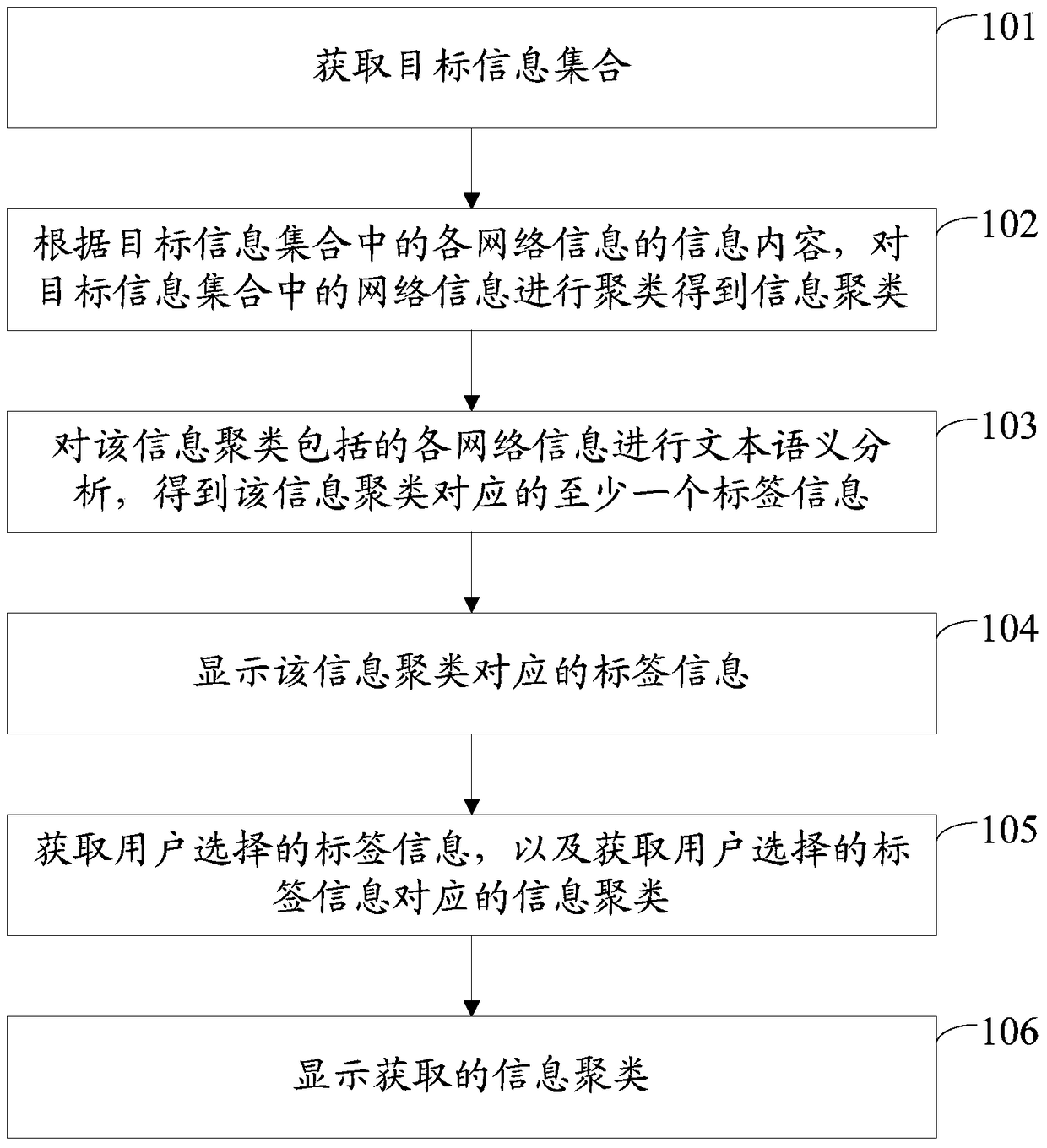

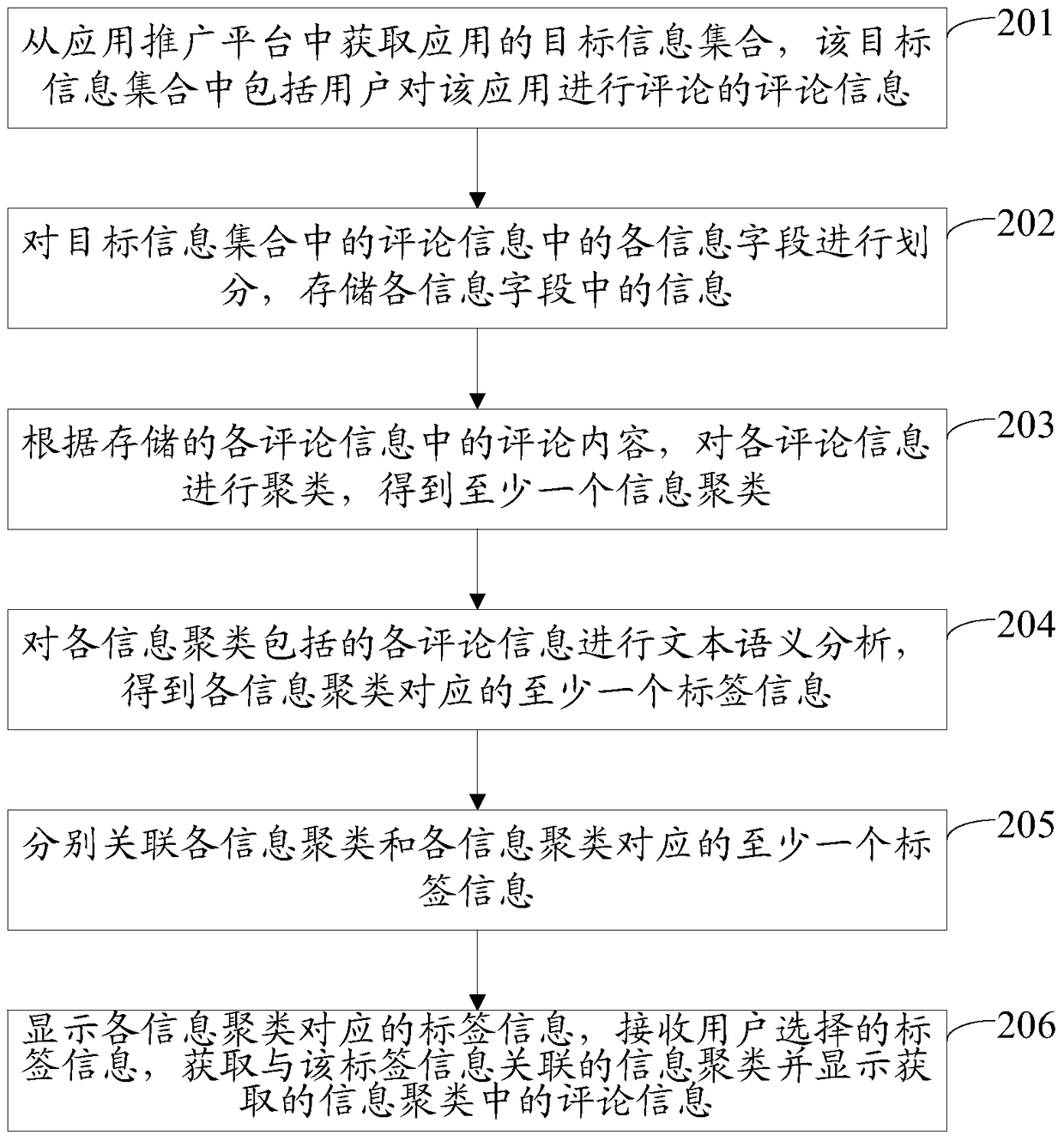

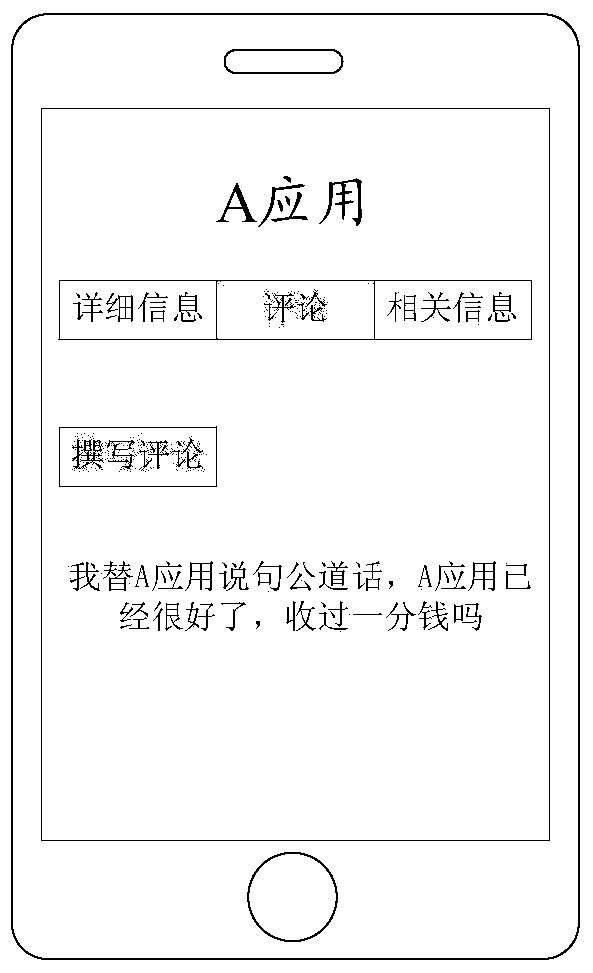

A method and device for processing information

ActiveCN104951432BImprove processing efficiencyMeet the needs of processing efficiencySpecial data processing applicationsInternet communicationInformation processing

The invention discloses an information processing method and device, and belongs to the field of internet communication. The method includes the steps that a target information set is acquired; network information in the target information set is clustered according to information content of the network information in the target information set, and information clusters are acquired, wherein the information clusters comprise the network information with the information content meeting the preset similarity condition; text semantic analysis is conducted on the network information included in the information clusters, and at least one piece of label information corresponding to the information clusters is acquired and used for describing semantics expressed by the network information in the information clusters; the label information corresponding to the information clusters is displayed; the label information selected by a user is acquired, and the information clusters corresponding to the label information selected by the user are acquired; the acquired information clusters are displayed. The information processing efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

A kind of indirect mobile pipe cutting equipment

ActiveCN106363226BCut evenlyImprove continuityTube shearing machinesShearing machine accessoriesElectric machineEngineering

The invention discloses cutting equipment capable of moving a pipeline intermittently. The cutting equipment comprises a base platform and a pipeline elevating device arranged on one side of the base platform. A cutting device is arranged above the base platform. Stand columns are fixedly connected to the lower portion of the base platform and located at the left end and the right end of the base platform separately, and the stand columns are used for supporting the base platform. The pipeline elevating device comprises a pipeline elevating chamber which is arranged on one side of the base platform and used for elevating the pipeline. A concave hole is formed in the right end of the pipeline elevating chamber, and the length direction of the concave hole is parallel to the length direction of the pipeline elevating chamber. A first drive motor is arranged on the base platform. The first drive motor is provided with a bevel wheel corresponding to the concave hole in position, the bevel wheel is provided with teeth, and the teeth on the bevel wheel can abut against the pipeline while the bevel wheel rotates.

Owner:江苏汉徐机械设备有限公司

Cloud management system based on application and location awareness

ActiveCN111800514AImprove service qualityIncrease profitDigital data information retrievalResource allocationQuality of serviceCloud resources

The invention provides a cloud management system based on application and location awareness. The cloud management system comprises a cloud resource acquisition and analysis subsystem, a long-time cloud application resource demand acquisition subsystem, a long-time cloud application management subsystem and a short-time cloud application management subsystem, wherein the cloud resource pool is composed of a server cluster and comprises a computing server, a data server and a file server; wherein the cloud application comprises a long-time cloud application and a short-time cloud application; wherein the long-time cloud application has high requirements on instant availability of computing resources, and needs to keep fixed computing resources; the short-time cloud application refers to anapplication which is short and rapid in user interaction and allows interruption switching and failure reoperation. The cloud management system based on application and location awareness provided bythe invention has the advantages that the high efficiency of the cloud application and the high utilization rate of cloud resources are realized, and the service quality of the cloud application is improved, so that the increasing demand of people for efficient processing of data requests is met.

Owner:HUAQIAO UNIVERSITY

A high-efficiency pig manure degradation device for pig farming that is easy to clean

ActiveCN112125487BImprove mixing efficiencyAdapt to the needs of degradationRotary stirring mixersSpecific water treatment objectivesAnimal scienceElectric machinery

Owner:宁德生隆农业科技有限公司

Pipe cutting device

ActiveCN106334829ACut evenlyImprove continuityTube shearing machinesShearing machine accessoriesIndustrial engineeringBase station

The invention discloses a pipe cutting device which comprises a base station and a pipe lifting device arranged on one side of the base station. A cutting device is arranged above the base station; the pipe lifting device comprises a pipe lifting cavity arranged on one side of the base station and used for lifting a pipe, a concave hole is formed in the right end of the pipe lifting cavity, and the length direction of the concave hole is parallel to the length direction of the pipe lifting cavity; and a first driving motor is arranged on the base station, an incline wheel corresponding to the concave hole in position is arranged on the first driving motor, teeth are arranged on the incline wheel, and the teeth on the incline wheel can abut against the pipe when the incline wheel rotates.

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

A high-performance computing method based on cpu-gpu cooperative parallel text topic model lda

ActiveCN110413776BEnable high-performance modelingQuick discoveryProgram initiation/switchingResource allocationComputational scienceConcurrent computation

Owner:WUHAN UNIV

A steel bar thread rolling machine for building steel bar processing

ActiveCN112045122BMeet the needs of processing efficiencyQuick job locationScrew-threads articlesClassical mechanicsMachine

The present invention relates to the technical field of steel bar rolling machine, in particular to a steel bar thread rolling machine for building steel bar processing, comprising a box body 1, a base 2 and a steel bar 3, the upper end of the box body 1 is fixedly connected with a base 2, on the base 2 The steel bar 3 runs through, the base 2 is prism-shaped and a cylindrical hole is opened on the base 2, the steel bar 3 is arranged in the cylindrical hole of the base 2, and a number of uniformly distributed pusher plates 4 are arranged around the steel bar 3, and the pusher plate 4 One end is fixedly connected with a rubber block 5, and the rubber block 5 is in contact with the steel bar 3. The structural design of the present invention realizes the requirement for the base 2 to locate the steel bar 3 with different outer diameter sizes, and by controlling the handle one 21 and the handle two 22, quick positioning can be realized Work, to meet the high-efficiency processing requirements of the entire steel bar rolling machine, with stable and powerful functions.

Owner:广东新拓展建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

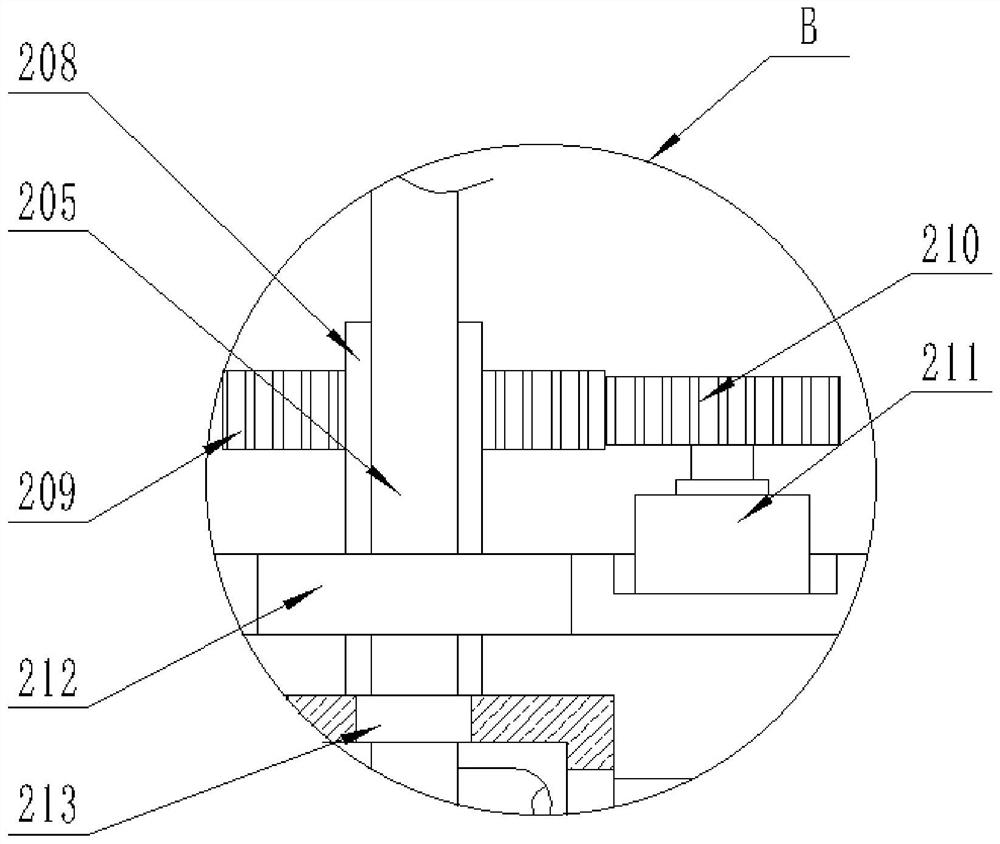

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com