A high-shape-retaining composite bond superhard grinding wheel and its preparation method

A compound binder and high shape retention technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor self-sharpening of grinding wheels, poor sharp corner retention, frequent dressing, etc., to reduce agglomeration, Effects of improving impact strength and abrasion resistance, improving fluidity and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A superhard grinding wheel with high shape retention compound binder, which is made of the following raw materials in weight percentage: polyimide resin 23%, copper powder (particle size 10μm) 31%, silicon dioxide (particle size W28) 15%, tin powder (particle size 10μm) 8%, carbon fiber 3% with an aspect ratio of 15:1, abrasive diamond 20% (particle size D64); among them, polyimide resin and carbon fiber were pre-treated as follows: In the formula, pour polyimide resin and carbon fiber with an aspect ratio of 15:1 into the steel mixing tank, add cemented carbide balls (ball diameter 5mm) twice the volume of raw material powder at a volume ratio of 1:2, and put Put the mixing tank into the planetary mixer and mix for 6 hours; put the evenly mixed material resin and carbon fiber into the abrasive tool, and press it into a cylindrical material with a diameter of 100mm and a height of 50mm on a hot press at 150°C, and then put the cylindrical material The material is turned...

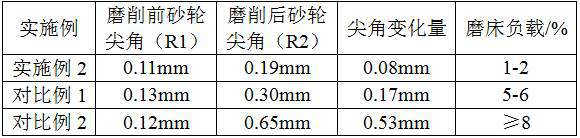

Embodiment 2

[0035] A superhard grinding wheel with high shape retention composite bond, which is made of the following raw materials in weight percentage: 30% polyimide resin, 23% copper-tin pre-alloyed powder (wherein the mass ratio of copper to tin is 2:1 , particle size 15μm), silicon dioxide (particle size W28) 15%, carbon fiber with aspect ratio 15:1 7%, abrasive diamond 25% (particle size D64); among them, polyimide resin and carbon fiber are pretreated as follows Obtain: Pour polyimide resin and carbon fiber with aspect ratio 15:1 into the steel mixing tank according to the proportion in the formula, and add cemented carbide balls (ball diameter 5mm ), put the mixing tank into the planetary mixer and mix for 6 hours; put the evenly mixed material resin and carbon fiber into the abrasive tool, and press it into a cylindrical material with a diameter of 100mm and a height of 50mm on a hot press at 150°C. Then the cylindrical material is turned into powder on a common car with a singl...

Embodiment 3

[0043]A superhard grinding wheel with high shape retention composite bond, the superhard grinding wheel is made of the following raw materials in weight percentage: polyimide resin 28%, copper-tin pre-alloyed powder 20% (wherein the mass ratio of copper to tin is 4:1 , particle size 8μm), silica (particle size W28) 20%, carbon fiber 5% with an aspect ratio of 15:1, abrasive CBN 27% (particle size D64); among them, polyimide resin and carbon fiber are pre-treated as follows Obtain: Pour polyimide resin and carbon fiber with aspect ratio 15:1 into the steel mixing tank according to the proportion in the formula, and add cemented carbide balls (ball diameter 5mm ), put the mixing tank into the planetary mixer and mix for 6 hours; put the evenly mixed material resin and carbon fiber into the abrasive tool, and press it into a cylindrical material with a diameter of 100mm and a height of 50mm on a hot press at 150°C. Then the cylindrical material is turned into powder on a common c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com