USB terminal cutting device

A terminal and cutting technology, which is applied in the field of USB terminal cutting devices, can solve the problems of not being able to meet the processing efficiency requirements, occupy a large space, and complicate the structure of the device, so as to improve the overall processing and assembly efficiency, meet the requirements of high processing efficiency, and simplify the device structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

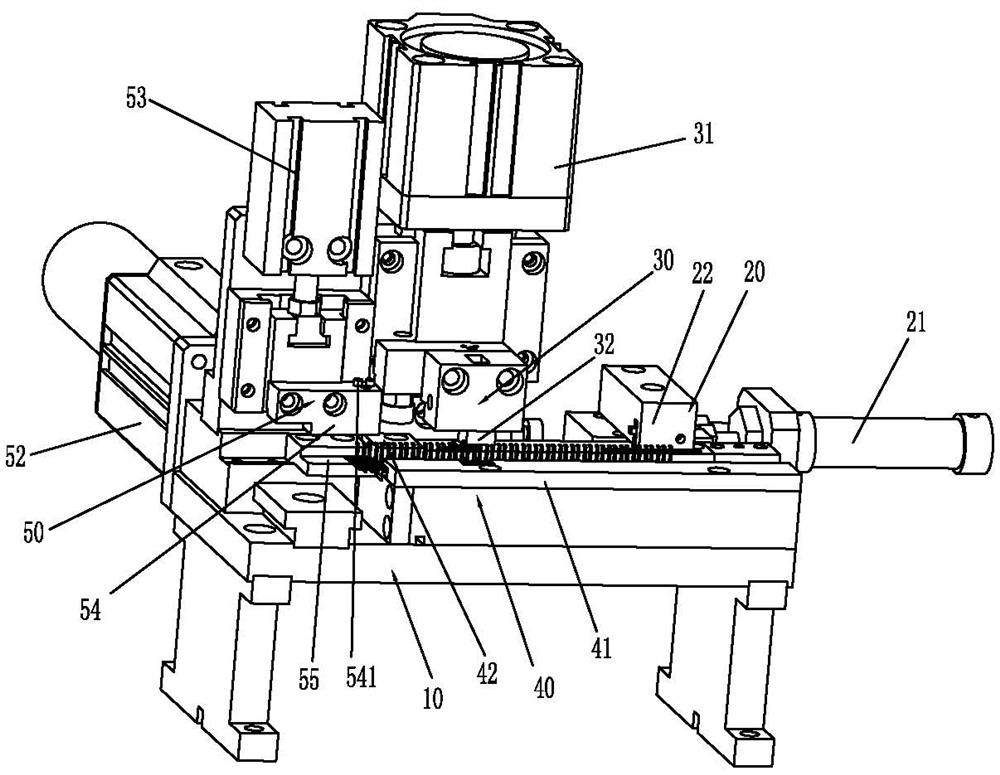

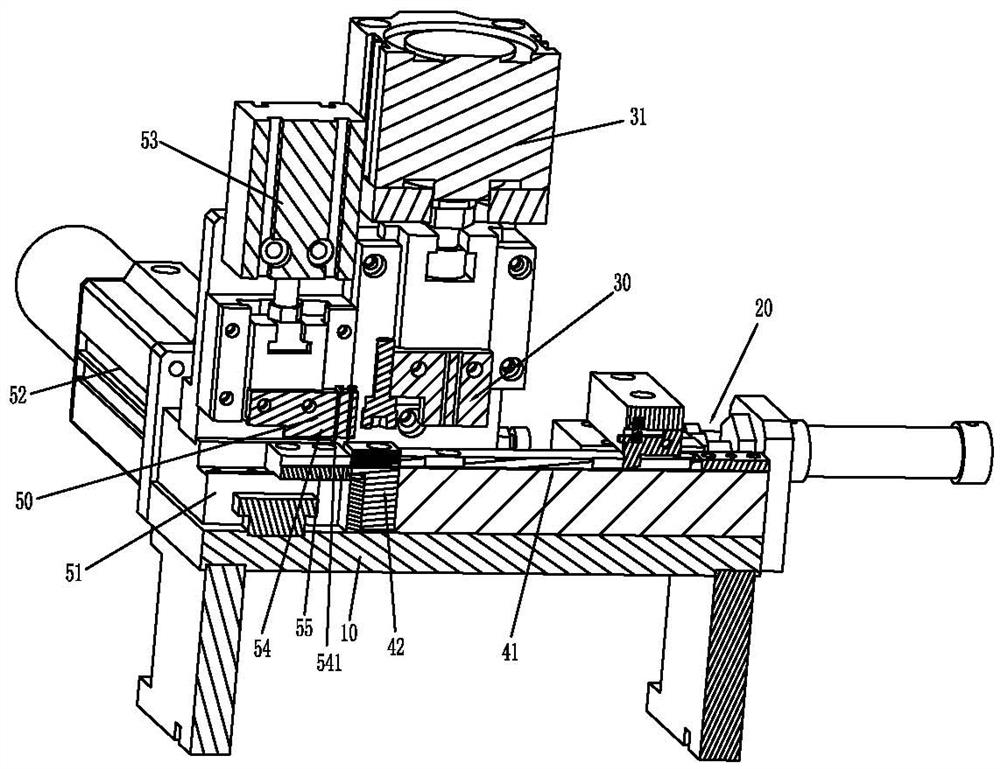

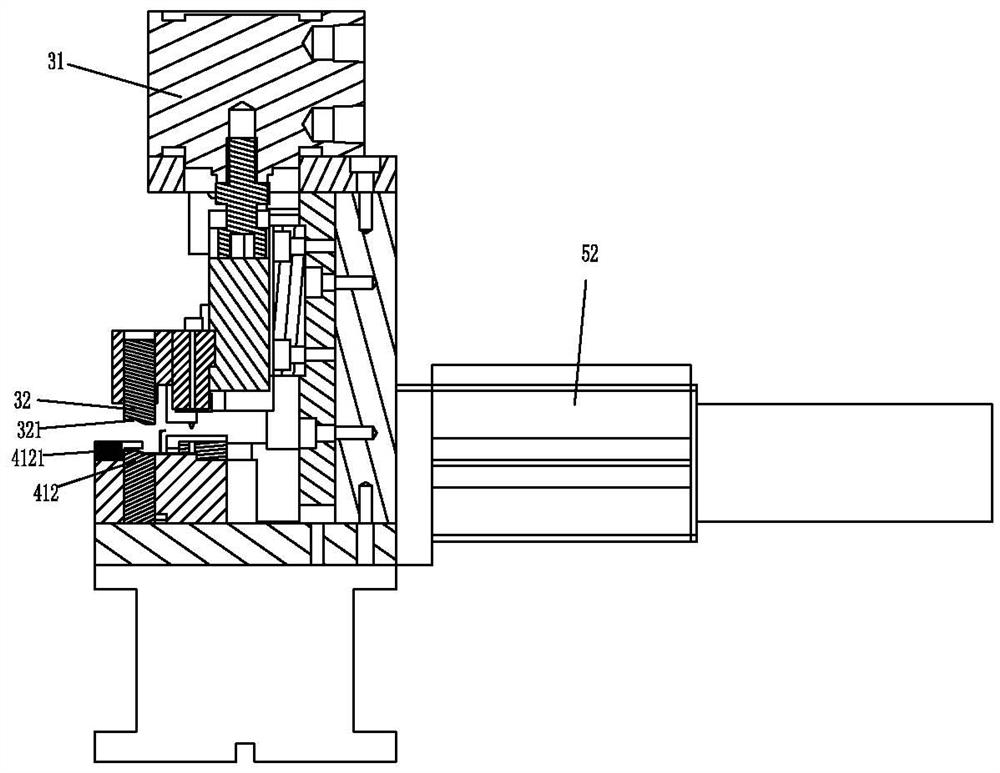

[0062] Please refer to Figure 1 to Figure 15 As shown, it shows the specific structure of the embodiment of the present invention and a terminal strip structure used for cutting.

[0063] Such as figure 1 and figure 2 As shown, a USB terminal cutting device includes a base 10, on which a terminal strip conveying track 40 is arranged; along the conveying direction of the terminal strip conveying track 40, a strip pushing module 20 is sequentially arranged. , Terminal shaping module 30.

[0064] The terminal strip delivery track 40 includes a fixed track 41 and a floating track 42 connected to the delivery end of the fixed track 41; Channel 411; the floating track 42 includes a floating seat 421, and a second channel 422 passing through the floating seat 421 along the conveying direction of the terminal strip conveying track 40, the second channel 422 is connected to the first channel 411, and the The inner bottom surface of the second channel 422 is higher than the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com