Machining center and machining method for switching clamping feeding and discharging and machining positioning

A processing center and clamp technology, applied in the field of wood processing, can solve problems such as control and guarantee of unfavorable processing accuracy, limitation of the overall efficiency of wood processing centers, and inability to meet high-efficiency processing needs, so as to save waiting time and meet high-efficiency processing. Demand, not easy to shake the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

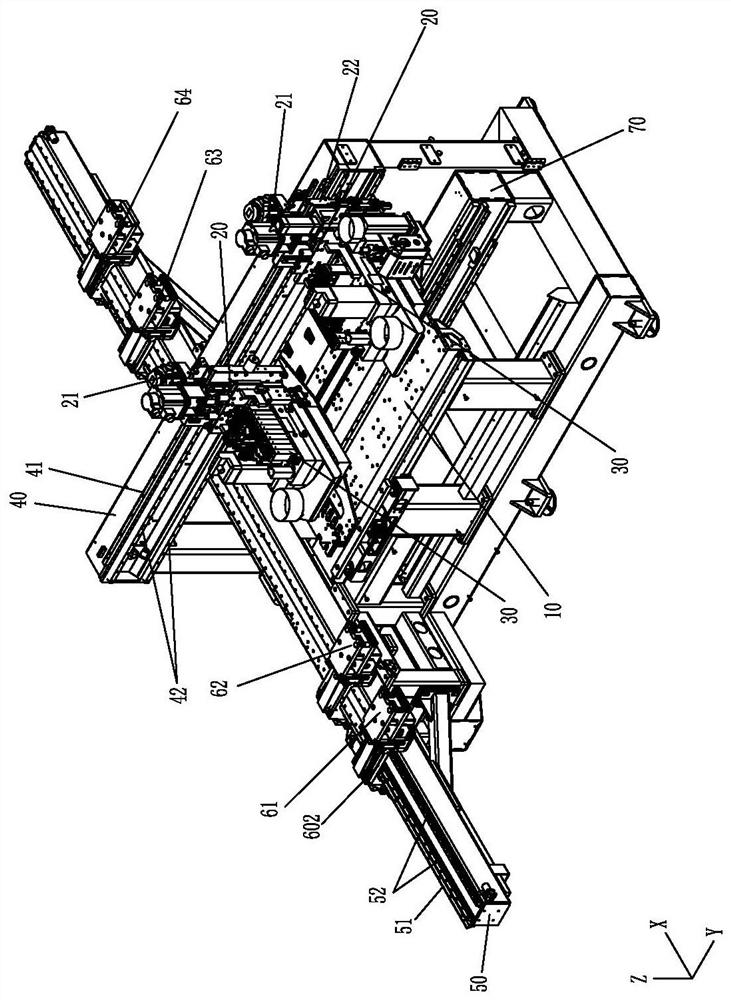

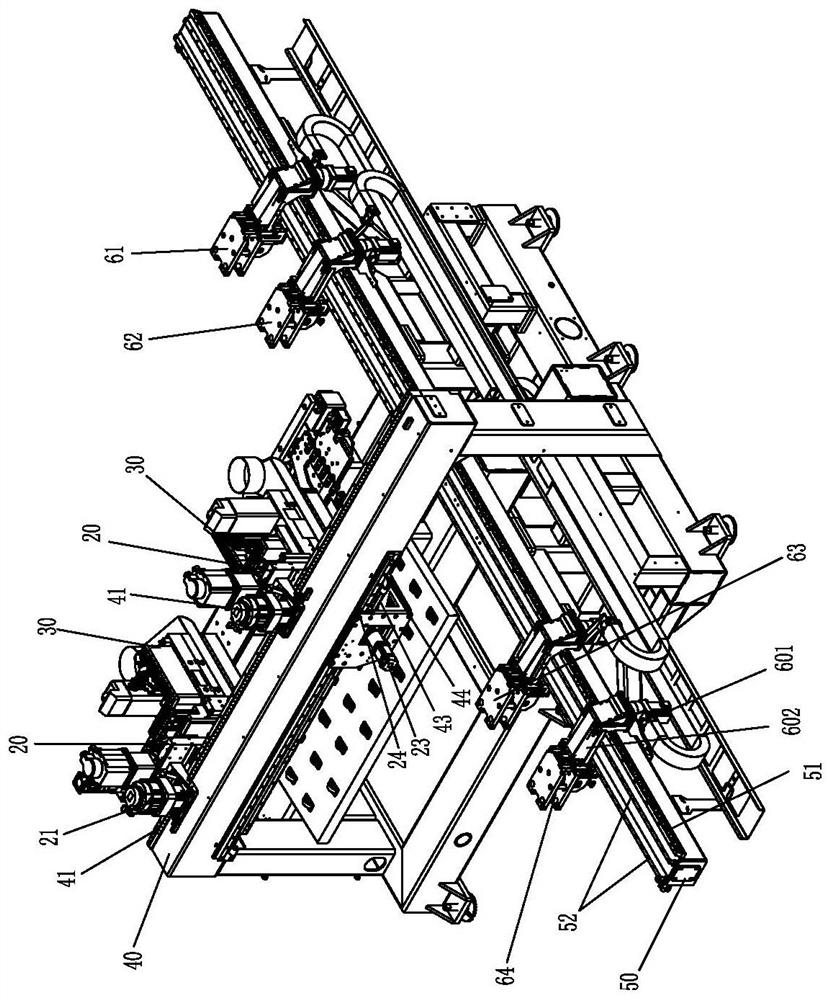

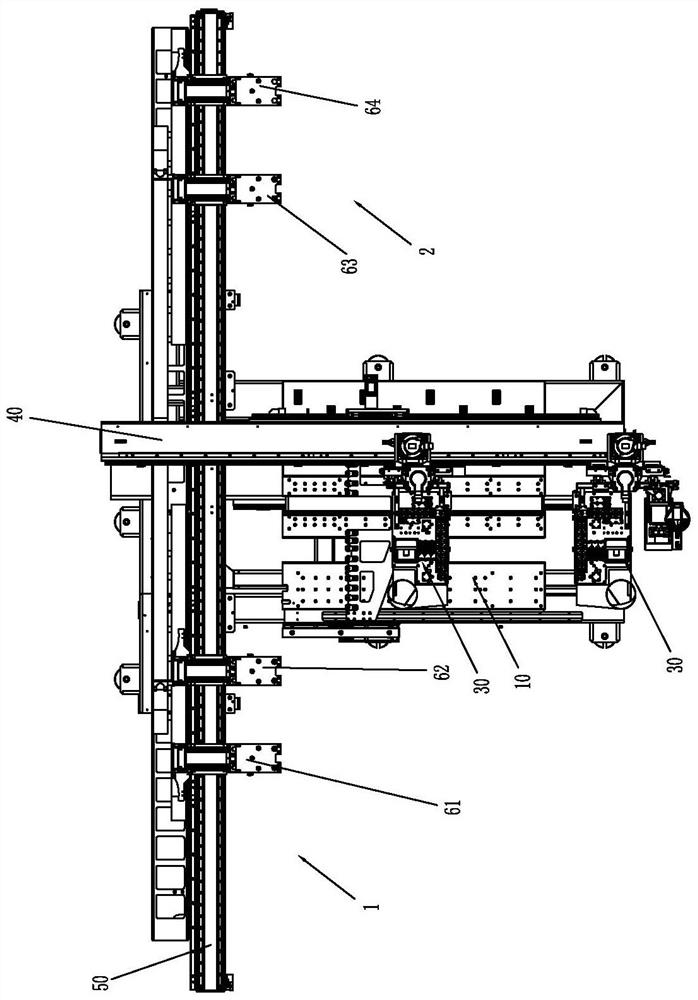

[0056] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the embodiment of the present invention.

[0057] A machining center for switching clamping, loading, unloading, and machining positioning, including a bed, a workbench 10, a beam clamp module, an upper workbench module 20, and an upper machine head 30; wherein:

[0058] The bed includes a Y upward guide rail seat 40, and the Y upward guide rail seat 40 is located above the workbench 10; the upper machine head 30 is installed on the upper workbench module 20, and the Y upward guide rail seat 40 can displacement;

[0059] The beam clamping module includes an X-direction beam 50 and at least four clamping mechanisms that can work independently, which are respectively defined as the first to fourth clamping mechanisms 61, 62, 63, 64 from left to right; The clamp mechanism includes a lower clamp, an upper clamp, and a clamp driving mechanism that controls the opening and closing of the two;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com