High-performance electric injection molding device

An injection molding system and injection molding machine technology, applied in the field of plastics, can solve the problems of reduced injection response speed, fast contact surface wear, and great influence of working conditions, so as to reduce the total mass, improve the effect speed and injection precision, and improve The effect of injection acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

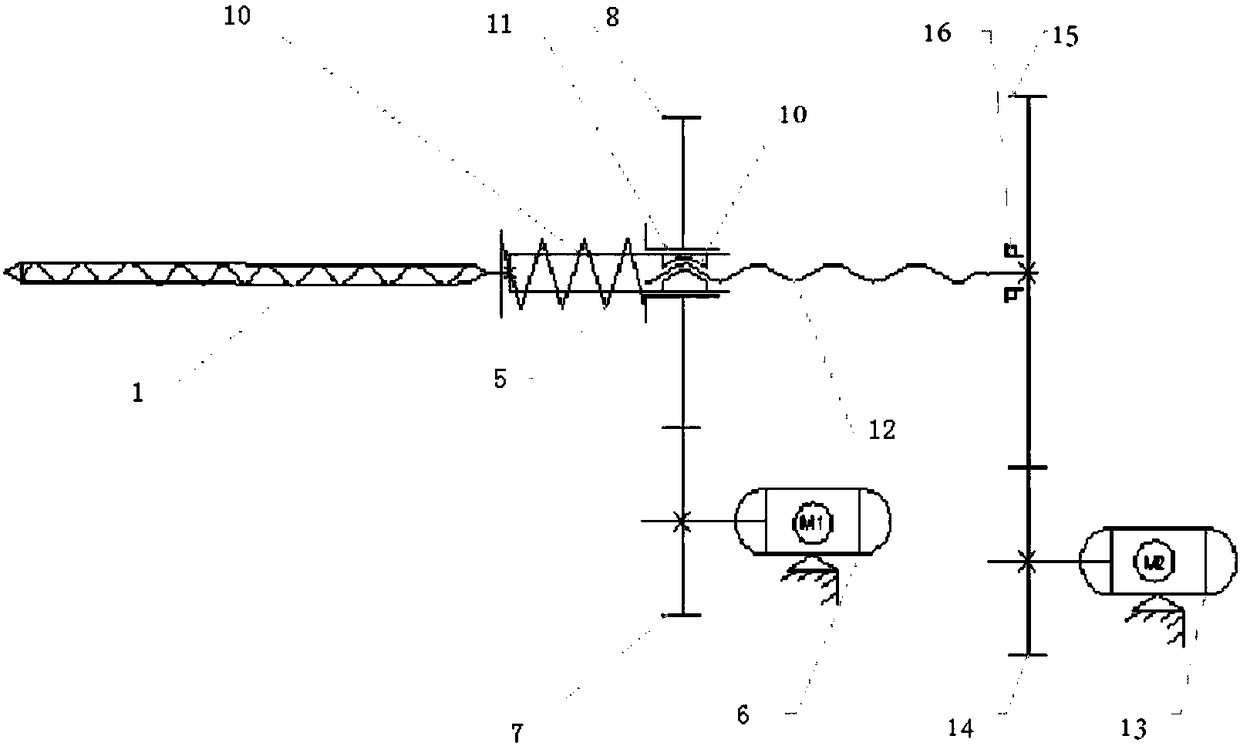

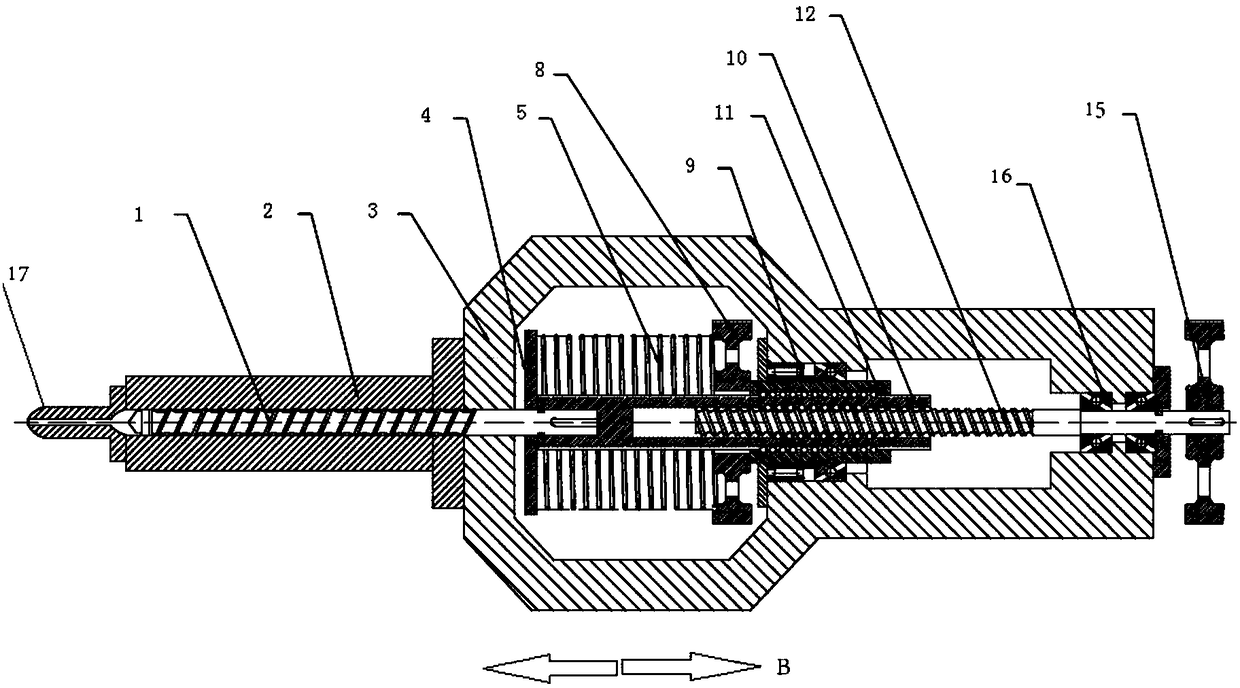

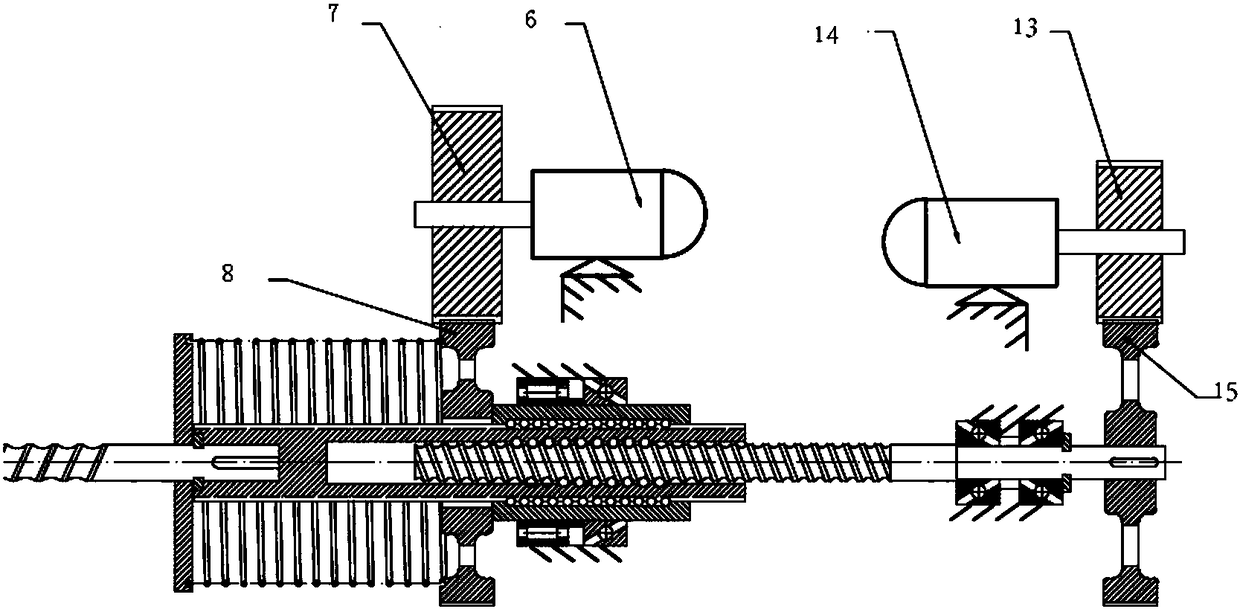

[0044] Below, refer to Figure 1-3 The structure of the injection molding system according to the first embodiment of the present invention will be described.

[0045] figure 1 A schematic diagram of the principle of the injection molding system according to the first embodiment of the present invention is shown.

[0046] figure 2 It is a plan view showing the injection molding system of the first embodiment in section.

[0047] The barrel is 2, the fixed frame is 3, and the fixed frame 3 is used to support the injection molding system. The barrel 2 is fixedly connected to the front end of the fixed frame 3 by bolts, the front end of the barrel 2 is provided with a nozzle 17, and a mold clamping system (not shown in the figure) can be configured in front of the nozzle 17.

[0048] The screw rod 1 that plays the role of pushing out the member, the main body of the screw rod 1 is installed in cooperation with the inner chamber of the barrel 2, and the screw rod 1 can move bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com