Gas burner with reinforced smoke internal circulation

A gas burner and internal circulation technology, applied in gas fuel burners, flue gas combustion, burners, etc., can solve the problems of NOx effect not as good as external circulation of flue gas, limited flue gas volume, and inability of flue gas to enter the interior of the flame. , to achieve the effect of reducing the concentration, reducing the combustion temperature, and reducing the oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

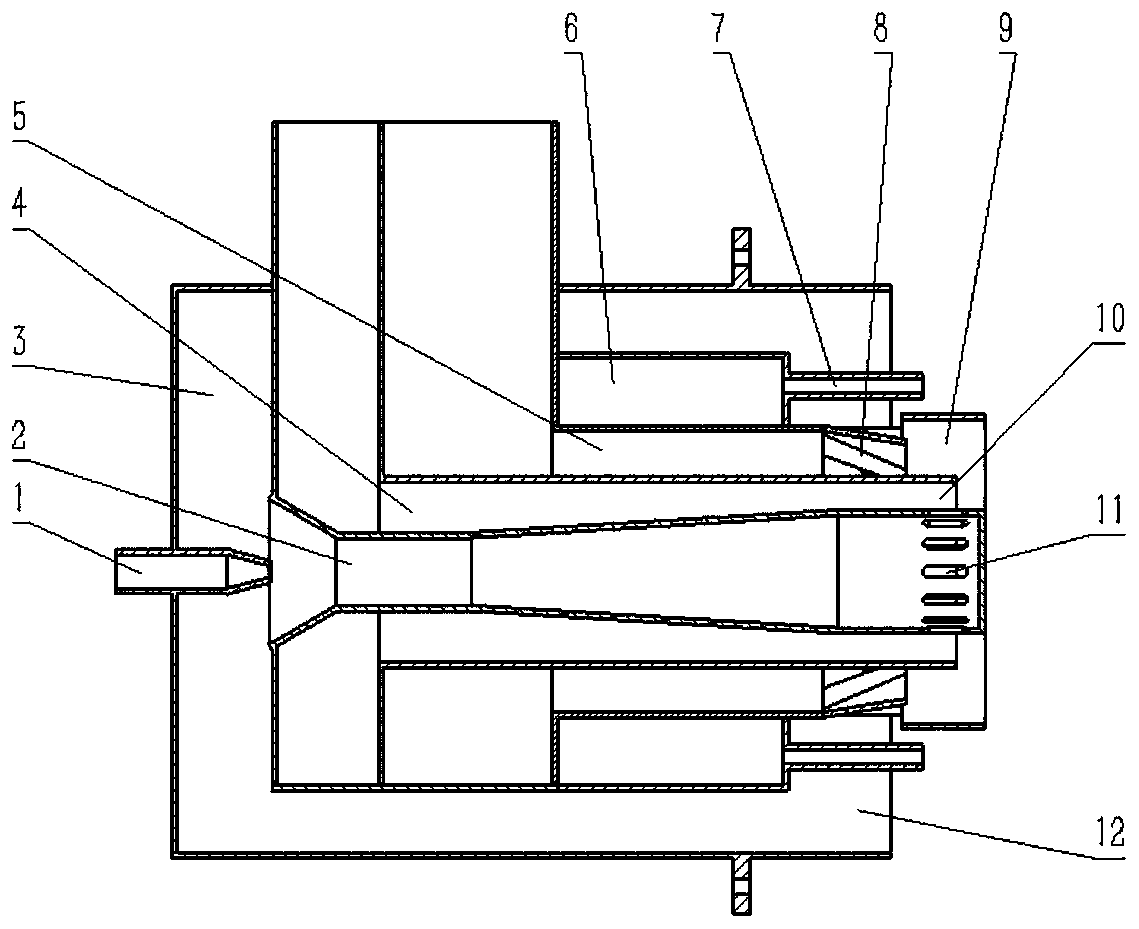

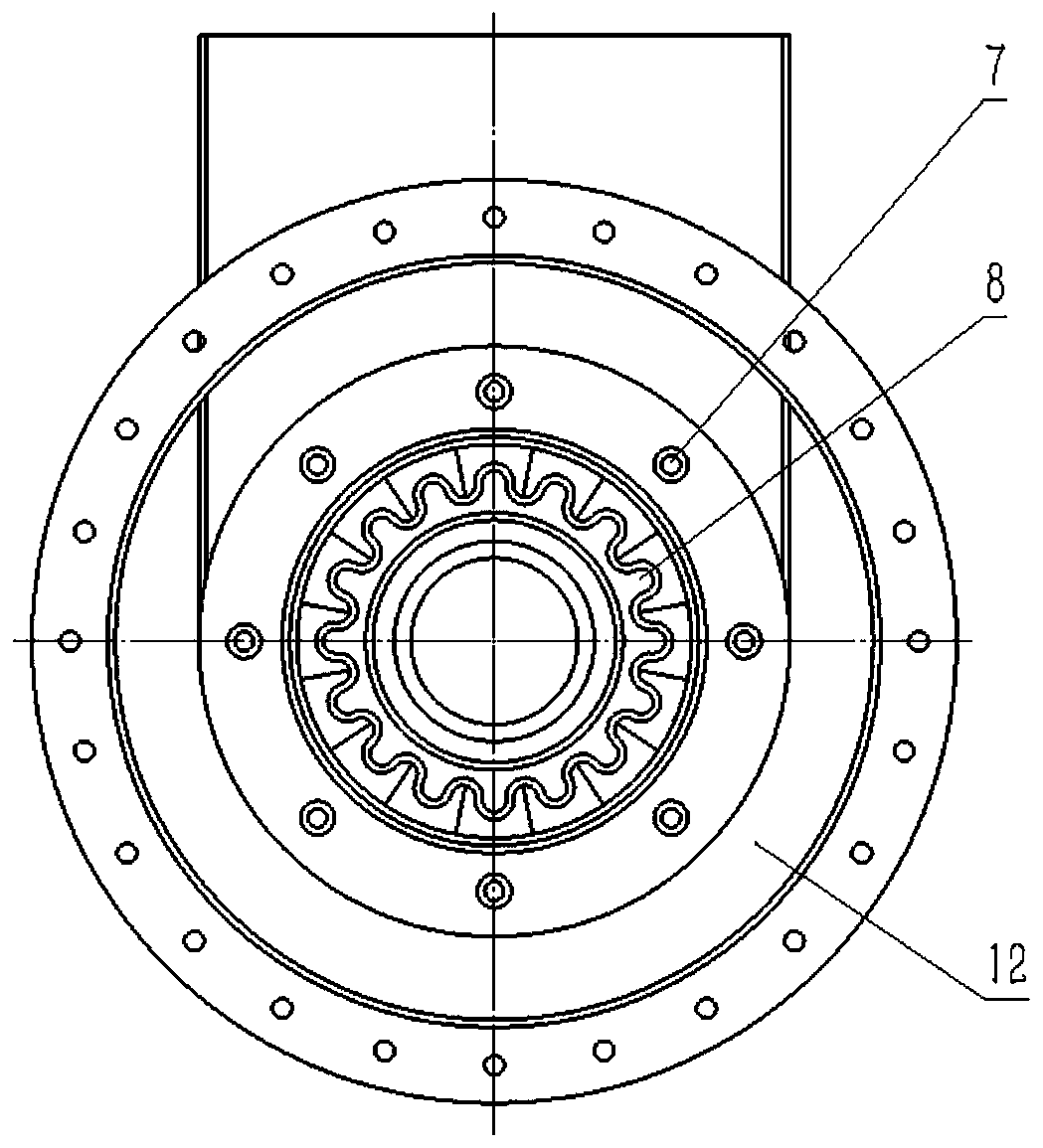

[0019] The enhanced flue gas internal circulation gas burner of the present invention mainly includes: a primary fuel nozzle 1 located on the central axis of the burner, a primary fuel conditioning processor 2 behind the primary fuel nozzle 1, and a primary fuel conditioning processor 2 The inner circulation smoke chamber 3 at the entrance, the primary air passage 4 on the periphery of the primary fuel conditioning processor 2, the secondary air passage 5 on the periphery of the primary air passage 4, and the secondary fuel gas chamber 6 on the periphery of the secondary air passage 5 And the secondary air spout 8 at the outlet of the secondary fuel nozzle 7, the secondary air passage 5, the secondary air spout 9 at the rear of the secondary air spout 8, the primary air spout 10 at the exit of the primary air passage 4, The primary fuel conditioning nozzle 11 at the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com