Combined feeler gauge tool capable of realizing step boring and depth control

A technology of drilling depth and feeler gauge, applied in the direction of mechanical depth measurement, etc., can solve problems such as inability to easily control the step hole depth, deviation of measurement results, etc., to achieve the effect of easy replacement, assembly, portability, and prevention of deformation under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the present invention will be described in further detail below in conjunction with the drawings.

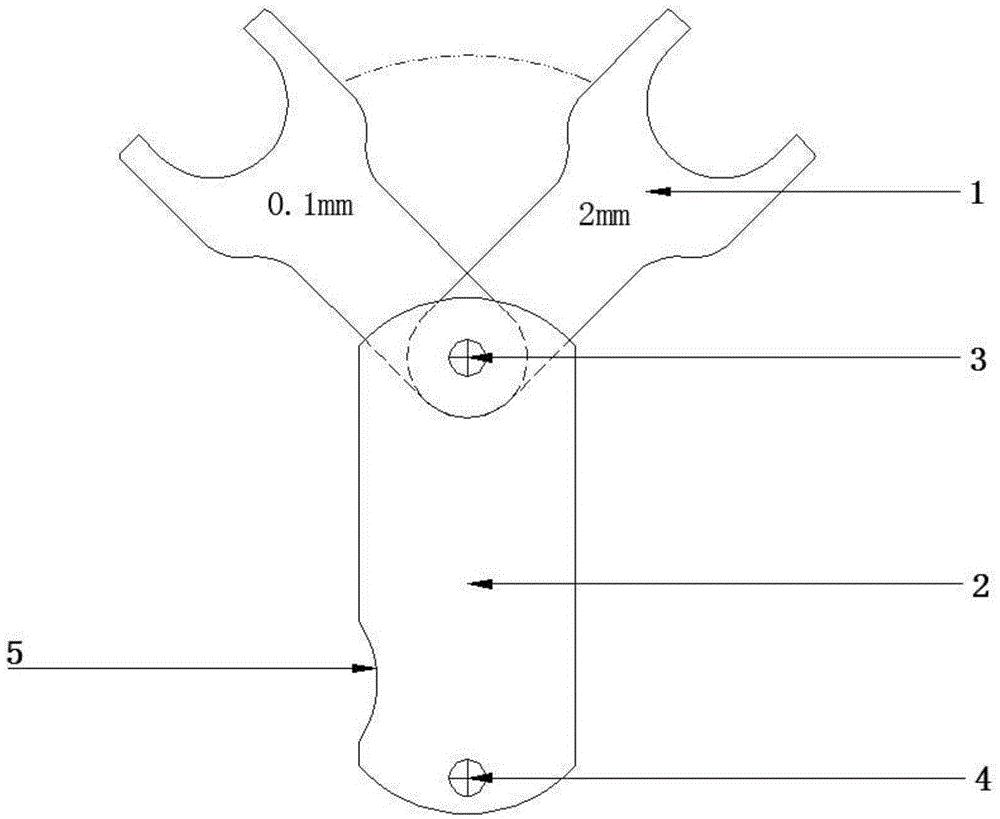

[0019] figure 1 Through the overall assembly diagram, the assembly diagram of each component is given.

[0020] by Figure 1-2 It can be seen that the combined feeler gauge tool that can realize the stepwise drilling depth control of the present invention includes a total of twenty pieces of feeler gauges (1) with a specified thickness including laminated settings, the thickness of the feeler gauge ranges from 0.1mm-2mm, and the adjacent plugs The distance between the rulers is 0.1mm; the feeler gauge is fixed in the metal shell (2) by anchor bolts (3) and (4), and each feeler gauge can be screwed into or out of the metal shell around the anchor bolt. The metal shell (2) is provided with a notch (5) which is convenient for the operator to rotate the feeler gauge outward with his fingers.

[0021] According to different use occasions, the number of feeler gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com