Automatic control method for ladle bottom argon blowing of converter

A bottom-blowing argon and ladle technology, which is applied in the manufacture of converters, etc., can solve the problems of argon blowing pressure and flow setting errors, affecting the stirring effect of molten steel, and difficulty in standardizing argon blowing operations, etc., to achieve strong versatility, guaranteed effect, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments of the present invention.

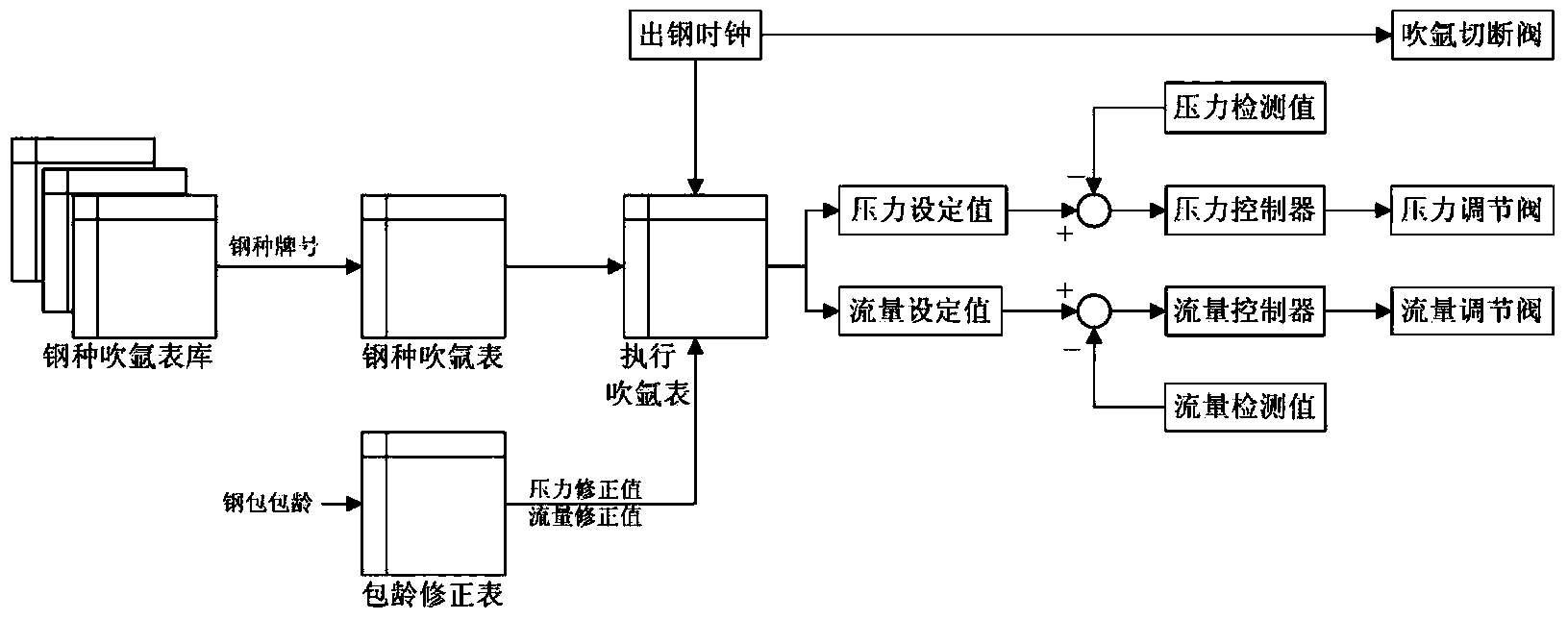

[0035] figure 1 It is the control flowchart of a kind of converter ladle bottom blowing argon automatic control method of the present invention, as figure 1 As shown, the method mainly includes:

[0036] Step 1: Establish the steel type argon blowing table library and the package age correction table;

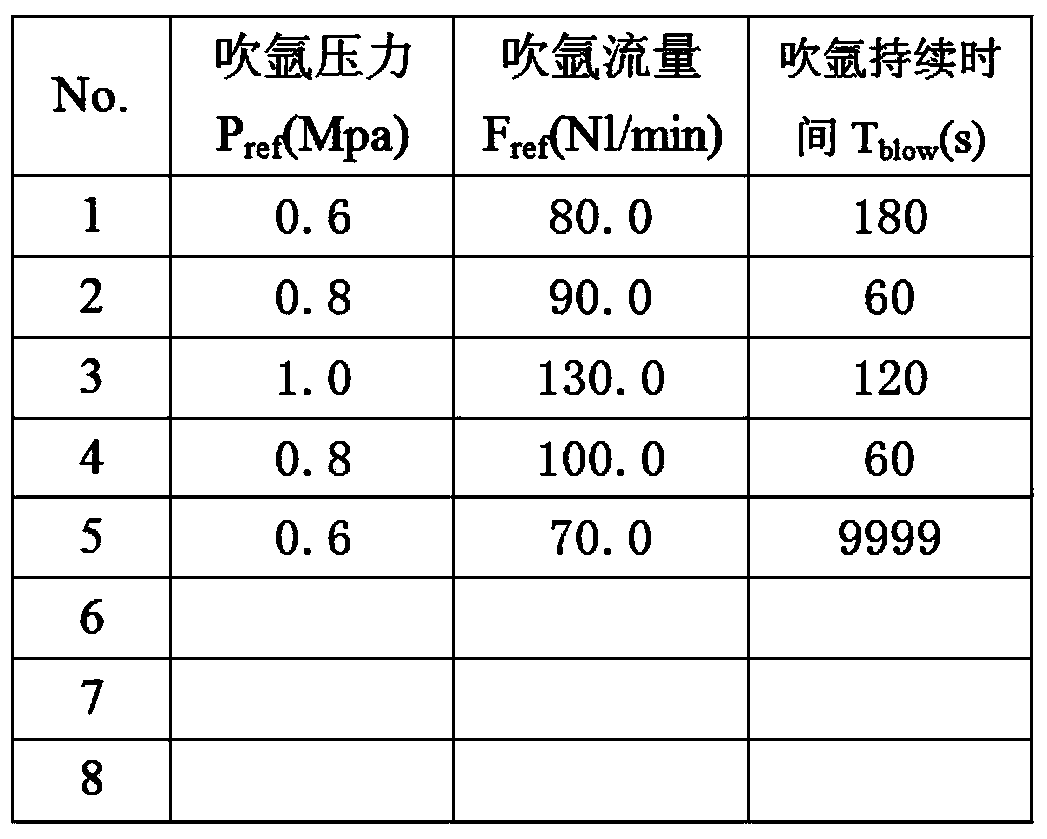

[0037] Step 2: Select a specific steel type argon blowing table according to the grade of smelted steel, obtain the pressure correction value and flow correction value from the ladle age correction table according to the actual ladle age, and automatically generate and execute the argon blowing pressure and argon blowing table in the argon blowing table Argon blowing flow rate, switching timing and other information;

[0038] Step 3: According to the argon blowing pressure, argon blowing flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com