Stirring device for yoghurt production

A stirring device and yogurt technology, which is applied in applications, milk preparations, dairy products, etc., can solve problems such as temperature drop and yogurt activity impact, and achieve the effect of ensuring stirring effect, product quality, and avoiding excessive temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

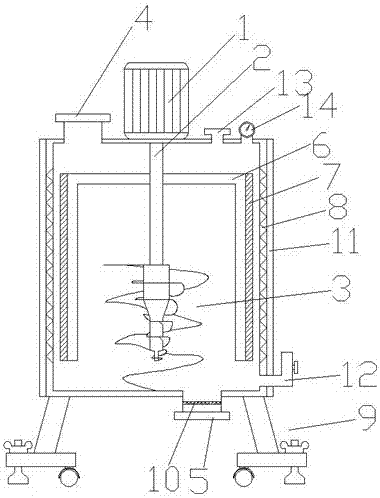

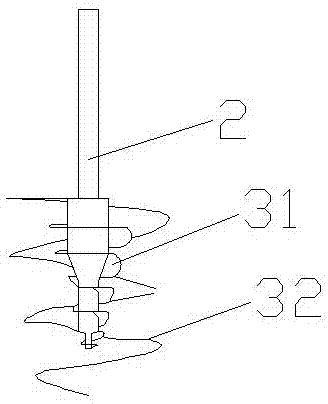

[0027] refer to Figure 1-2 , a stirring device for yogurt production, comprising a stirring barrel, a stirring device 3 located inside the stirring barrel and a mobile device 9 located at the bottom of the stirring barrel, the stirring device 3 comprising a stirring shaft 2 vertically arranged inside the stirring barrel and a stirring paddle arranged on the stirring shaft 2; a motor 1 is arranged on the top of the stirring barrel, and the stirring shaft 2 passes upward through the stirring barrel and is connected with the motor 1 through transmission. The top of the mixing tank is provided with a feed port 4, and the bottom of the mixing tank is provided with a discharge port 5. The raw materials for making yogurt are put into the mixing tank through the feeding port 4, and the motor 1 drives the stirring shaft 2 to rotate, and then drives the stirring paddle to rotate, to stir the raw materials to make them fully mixed, and finally the completely mixed yogurt raw materials a...

Embodiment 2

[0036] The inner wall of the mixing tank is provided with a heating wire 8, which is connected to a power supply. At the beginning of stirring, the yogurt raw material in the mixing tank can be heated rapidly through the heating wire 8, so that the yogurt raw material reaches a suitable temperature as soon as possible to ensure stirring. Effect.

[0037] The outer wall of the mixing tank is covered with an insulating layer 11, which can prevent the temperature in the mixing tank from dropping too quickly and ensure product quality.

Embodiment 3

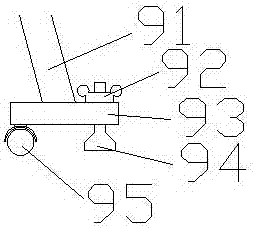

[0039] refer to image 3 , the bottom of the mixing bucket is evenly provided with some moving devices 9, the moving device 9 includes supporting legs 91, cross bar 93, universal wheels 95 and fixed feet 94, the upper end of the supporting legs 91 is connected to the bottom of the mixing bucket connection, the lower end of the supporting leg 91 is connected with a crossbar part 93, and the two sides of the bottom of the crossbar part 93 are respectively provided with universal wheels 95 and fixed feet 94, and the fixed feet 94 and the crossbar part 93 are threaded and threaded. Through the crossbar part 93, the part of the fixed foot 94 located above the crossbar part 93 is screwed with an adjustment wheel 92, and the length of the fixed foot 94 can be adjusted by rotating the adjustment wheel 92. Under normal conditions, the fixed foot 94 is on the ground, and the universal wheel 95 is suspended in the air to realize the fixing of the device; move the unit around.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com