Powder coating extruder

A powder coating and extruder technology, which is used in mixers, mixer accessories, and methods of granulating raw materials, etc., can solve the problems of different densities, poor mixing effect, and difficult mixing of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

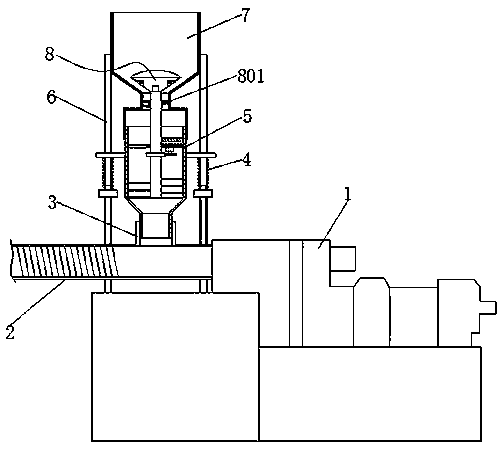

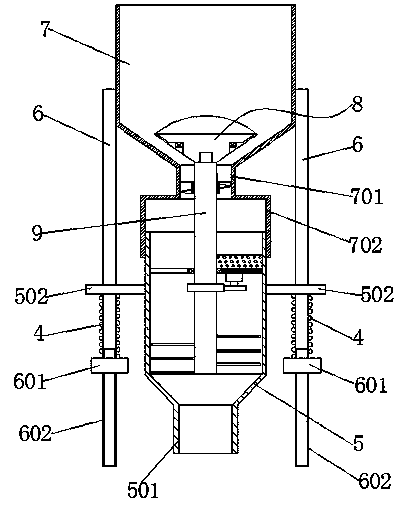

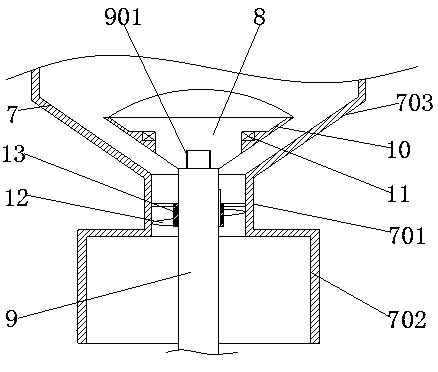

[0032] Such as Figures 1 to 6As shown, a powder coating extruder according to the present invention includes an extruder body 1 and a barrel 2 fixed on the extruder body 1; a storage material is arranged directly above the barrel 2 cylinder 7; several support rods 6 are fixed on the outer wall of the storage cylinder 7; the bottom end of the support rod 6 is fixed on the extruder body 1; between the barrel 2 and the storage cylinder 7 A premixing cylinder 5 is provided; the storage cylinder 7 is provided with a funnel nozzle 703; the end of the funnel nozzle 703 is provided with a storage and discharge pipe 701; The barrel feed pipe 3; the bottom end of the premix cylinder 5 is provided with a premix feed pipe 501; the tube body of the premix feed pipe 501 matches the barrel feed pipe 3; The mixing feeding pipe 501 is inserted into the inner cavity of the barrel fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com