Self-cleaning type agitating vessel

A mixing tank and self-cleaning technology, which is applied to mixer accessories, mixers with rotating stirring devices, dissolution, etc., can solve problems such as large centrifugal force at the end, affecting the mixing effect, and deposition on the inner wall of the bucket, so as to achieve enhanced stability, Prevent the barrel wall deposition, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

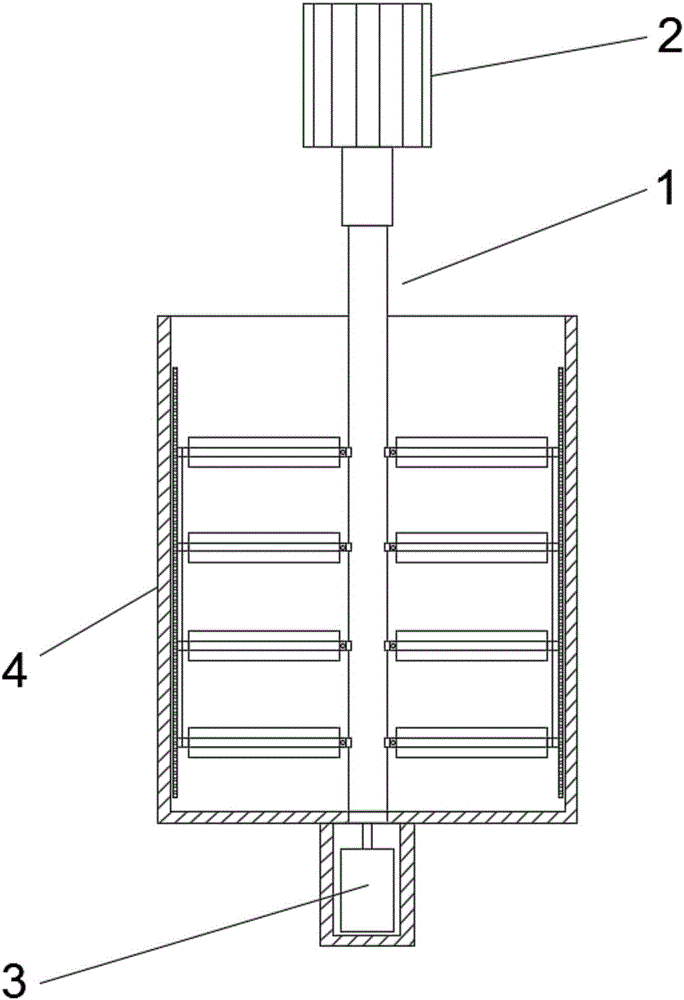

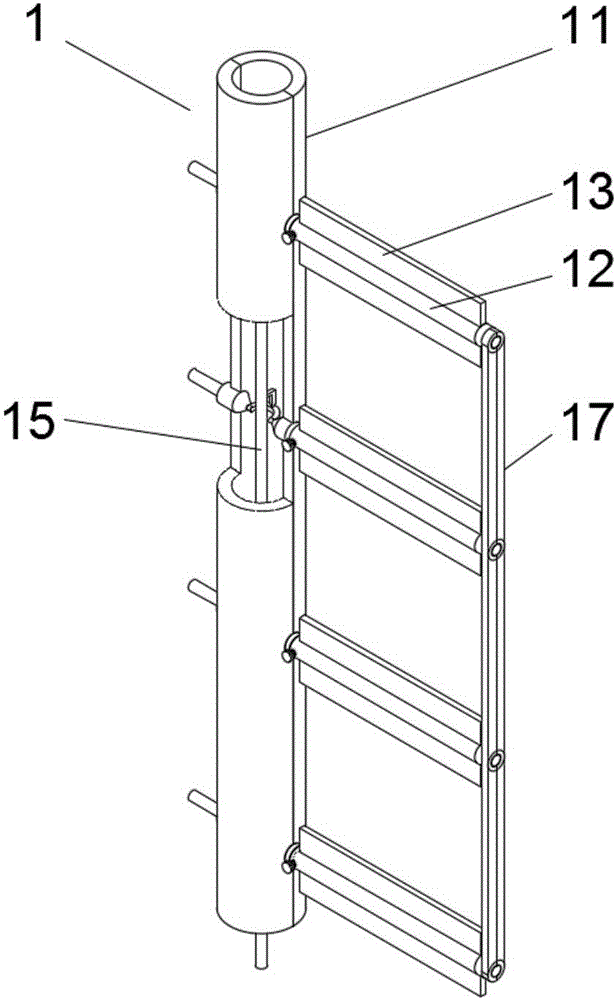

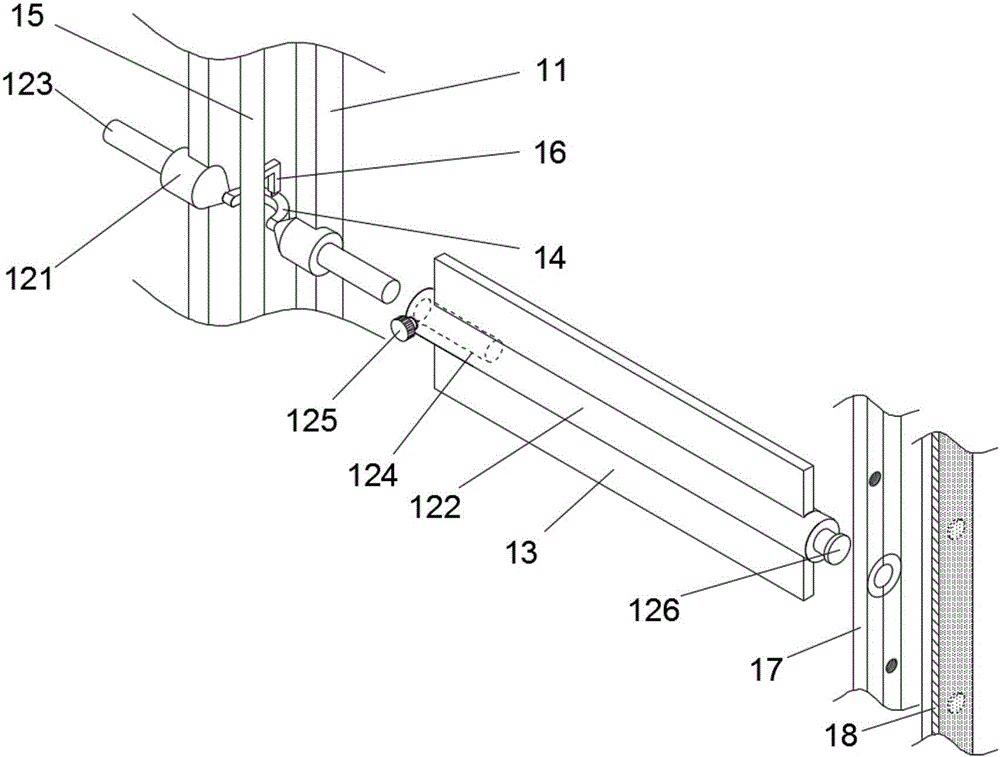

[0015] Such as Figure 1 to Figure 3 As shown, this embodiment provides a self-cleaning mixing tank, which includes a tank body 4; a stirring paddle 1 is arranged inside the tank body 4; a stirring motor 2 is connected to the top of the stirring paddle 1, and a cylinder 3 is connected to the bottom ; The stirring paddle 1 includes a hollow stirring shaft 11 composed of two semicircles; a plurality of stirring rods 12 are evenly distributed in symmetrical pairs on the stirring shaft 11; the stirring rod 12 includes a fixed part 121 and an insertion part 122; the fixed part 121 is provided with a boss 123; the insertion part 122 is provided with a hollow groove 124 used in conjunction with the boss 123; the upper and lower sides of the insertion part 122 of the stirring rod 12 are respectively provided with Stirring blades 13; the inner axis position of the stirring shaft 11 is also provided with an adjustment connecting rod 15; the inside of the stirring shaft 11 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com