End surface bulge type wing-less stirring disc and wing-less stirring device

A stirring plate and end face technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of overload, increase the resistance of stirring, and increase the current value, and reduce the stirring radius. Easy to overload, good to supplement the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

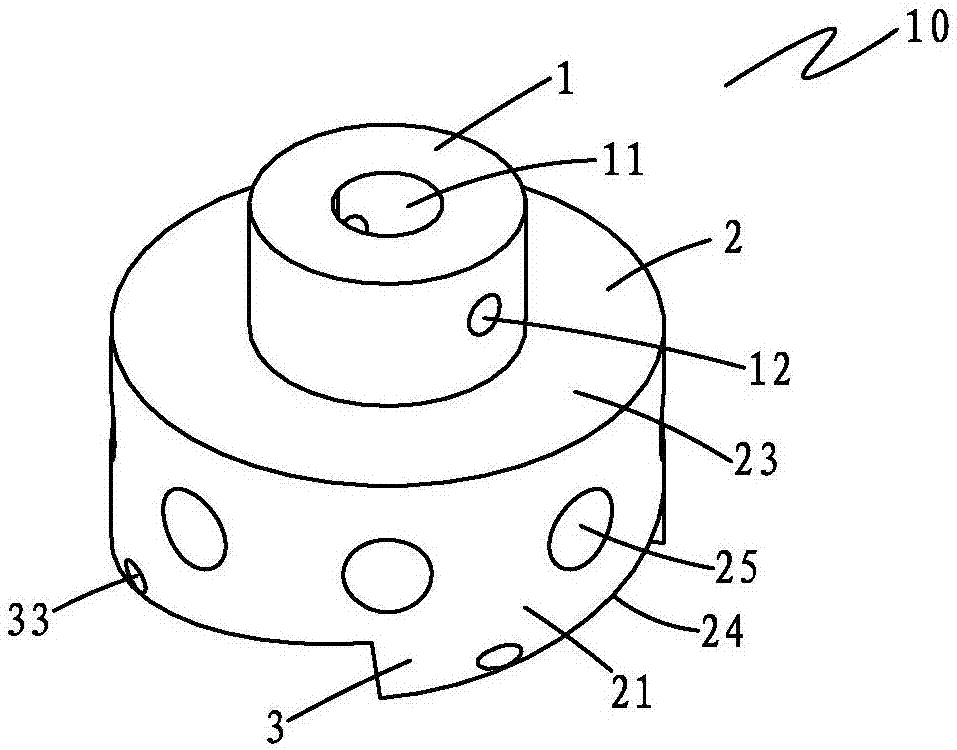

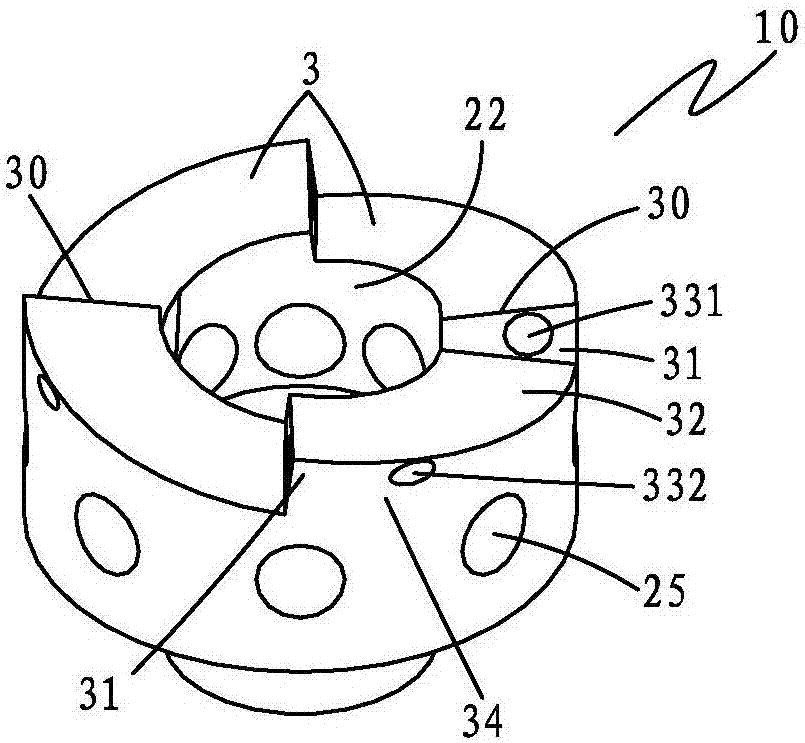

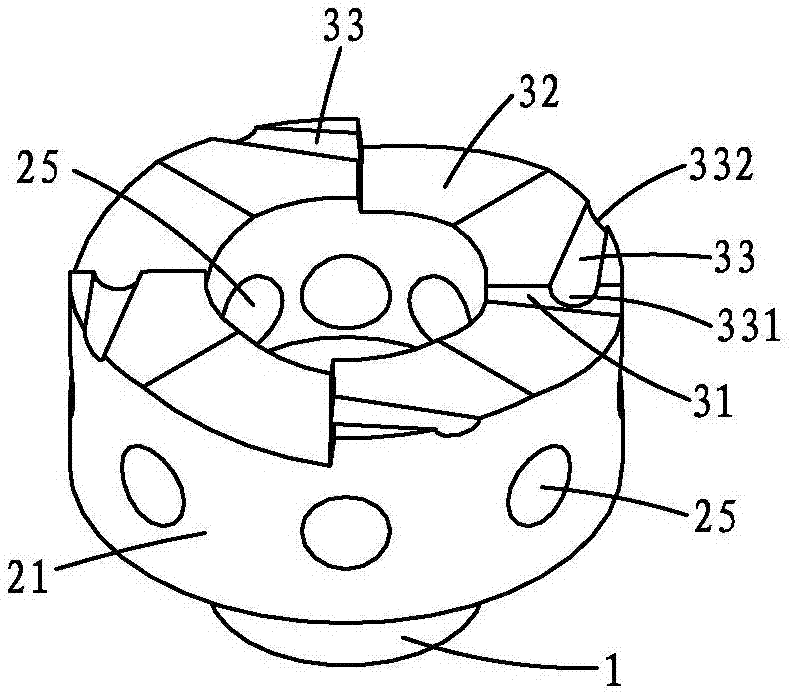

[0020] see Figure 1 to Figure 6 As shown, the end surface raised type wingless stirring disc 10 of the present invention can be used on the stirring device, and the described wingless stirring disc 10 includes a shaft sleeve 1 and a disc body 2, and the upper end of the disc body 2 passes through the The bushing 1 is connected to the stirring shaft, the outer surface 21 of the disc body 2 is a cylindrical surface, and no stirring blade is provided, and at least one of the upper end surface 23 and the lower end surface 24 of the disc body 2 is provided with a stirring protrusion 3.

[0021] As a preferred embodiment of the present invention, the stirring protrusions 3 on the upper end surface 23 or the lower end face 24 of the disc body 2 have a plurality of evenly arranged, and each stirring protrusion 3 is in the shape of a ridge, and the ridge line is in the shape of a diameter. The front and rear sides of each ridge line 30 are respectively a front slope 31 and a rear slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com