Thermal decomposition tube with fluid stirring element

A stirring element and thermal decomposition technology, applied in tubular elements, heat exchange equipment, non-catalytic thermal cracking, etc., can solve problems such as heating and boundary film formation, and achieve the goals of suppressing gap filling, increasing yield, and improving heat transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment >

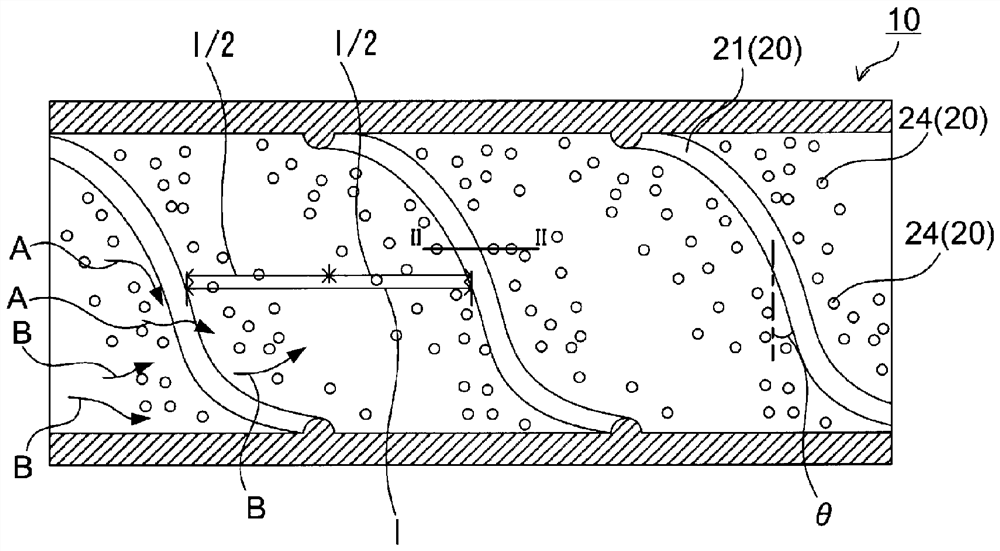

[0048] like Figure 4 As shown in the figure, a run-up section 31 having a 1.6 m upstream side and a downstream side of figure 1 The thermal decomposition tube 10 of the illustrated example of the invention having a length of 0.6 m, or Figure 5 The test thermal decomposition tube 30 to which the thermal decomposition tube 40 of the comparative example having a length of 0.6 m shown was connected, was compared by measuring the outlet temperature (° C.) and the heat exchange amount (kW) by circulating a fluid. The inner diameter of the thermal decomposition tubes 10 and 40 was 40 mm.

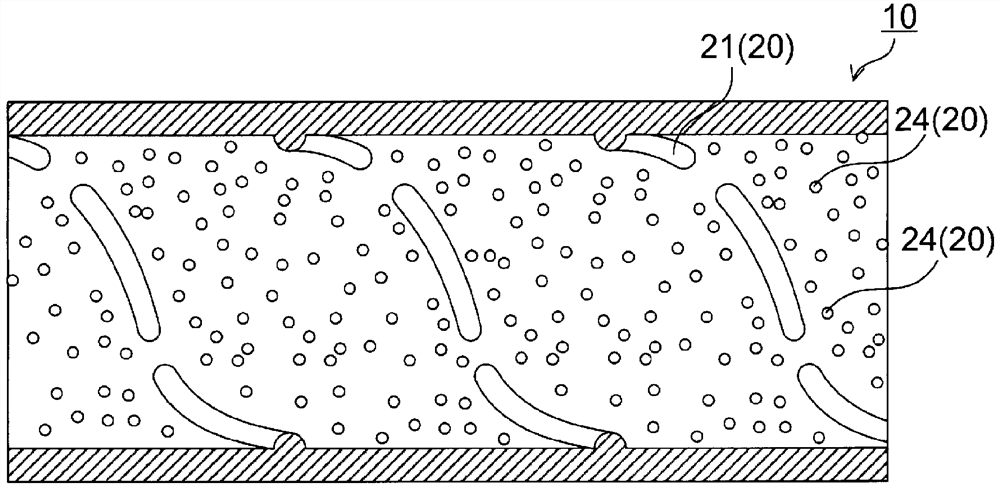

[0049] The thermal decomposition tube 10 of the invention example is as figure 1 As shown, a continuous one spiral ridge 21 is formed as a stirring element inside, and a plurality of protrusions 24 are formed on the peripheral portion thereof. In addition, the thermal decomposition tube 40 of the comparative example is as Figure 5 As shown, only one continuous spiral ridge 21 is formed insid...

no. 2 Embodiment >

[0056] The inner surface of a thermal decomposition tube with an inner diameter of 40 mm and a length of 0.6 mm is fabricated as follows Image 6 As shown in (a) to (f), the invention examples 1 to 6 in which the protrusions 21 and the protrusions 24 are formed are as follows: Image 6 In Comparative Examples 1 and 2 in which only the protrusions 21 are formed as shown in (g), the outlet temperature (° C.), pressure loss (Pa) and heat transfer coefficient (W / m) of the fluid were measured by circulating air inside. 2 K).

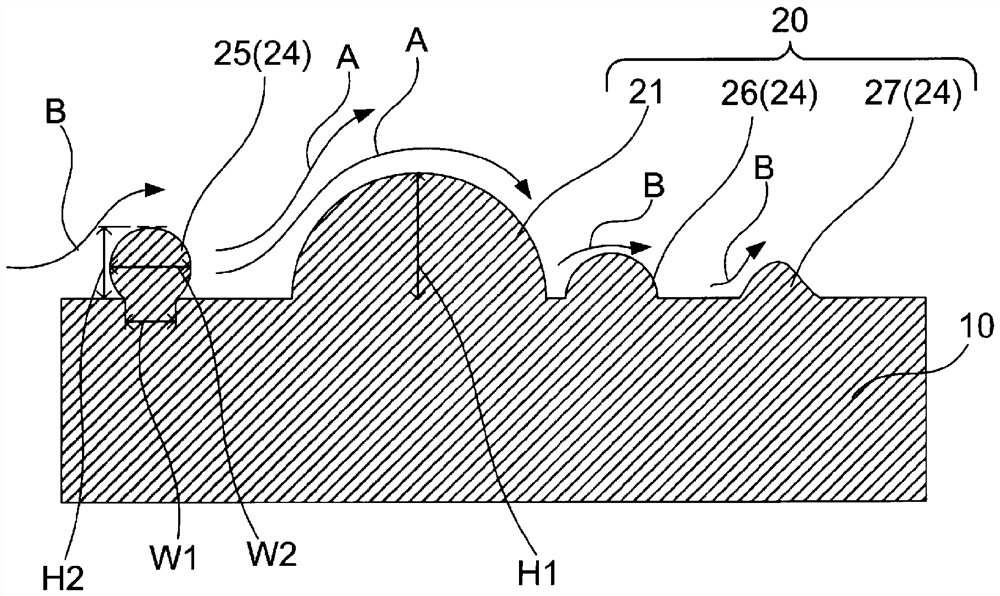

[0057] In each of the invention examples and the comparative examples, the spiral protrusions 21 having an inclination angle θ of 30° and a width of 7.0 mm were formed. The heights of the protrusions 21 of Invention Examples 1 to 6 and Comparative Example 1 were 2.1 mm, and the height of the protrusions 21 of Comparative Example 2 was 1.5 mm.

[0058] In the invention example, the hemispherical protrusions 24 having a diameter of 2.0 mm and a height of 1.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com