A kind of three-group nitride crystal growth device

A nitride crystal and growth device technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of lack of solution stirring and low solubility of reactants, etc., to improve crystal quality, improve raw material utilization, and suppress polycrystalline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

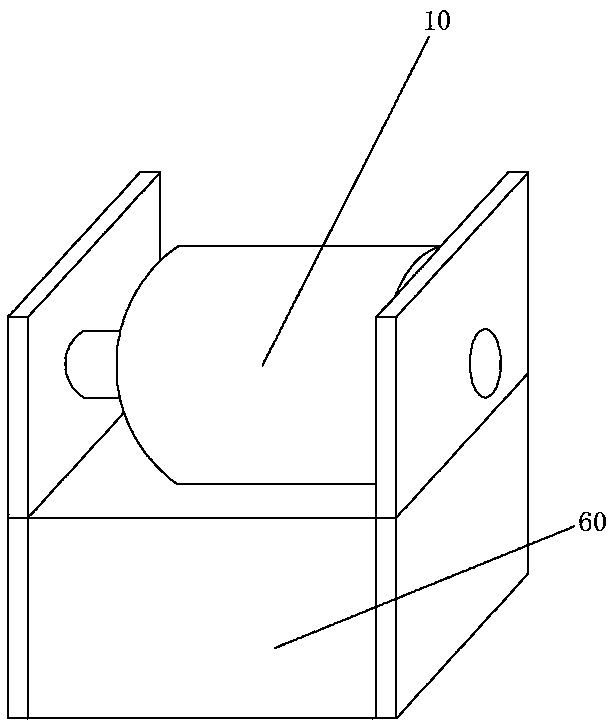

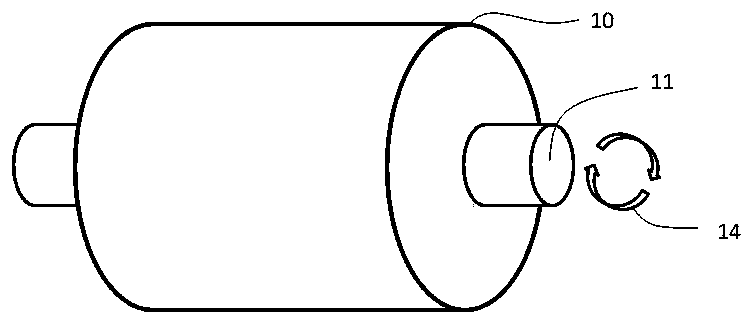

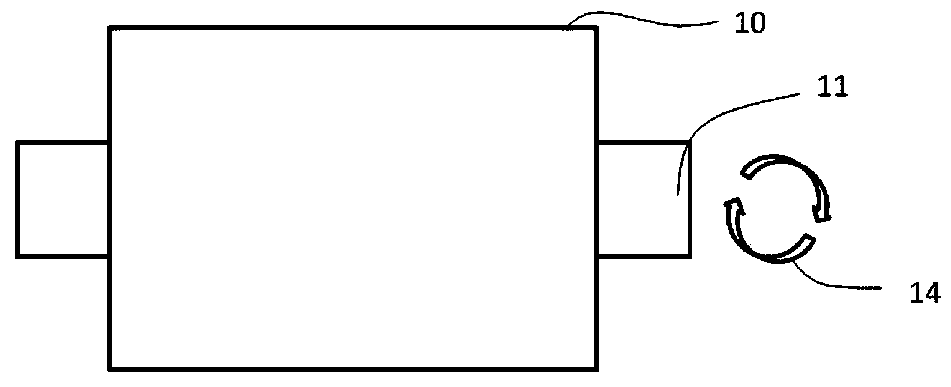

Embodiment 1

[0038] Embodiment one, as attached Figure 2-5 As shown, the reactor 10 is set in a cylindrical shape, and the reactor 10 is placed horizontally, that is, the reactor 10 is placed horizontally based on its central axis. Rolling shafts 11 are arranged on both sides of the reaction kettle 10, and the rolling mode is shaft rolling, and the rolling shafts are connected with a rolling driving device. The number of the seed crystal template 13 is one, and the seed crystal template 13 is fixed on the bottom of the reactor 10, and will not move with the movement of the reactor 10, and the seed crystal template 13 does not move synchronously with the reactor 10. The reaction raw material Ga, Na solution 12 is immersed in the seed crystal template 13, and the filling degree of the growth solution to the inner space of the reactor is 30%. Nitrogen gas 15 is above the reaction raw material solution 12 .

[0039] The reaction kettle 10 is heated and pressurized to the required conditions...

Embodiment 2

[0040] Embodiment two, as attached Figure 6 As shown, the reactor 20 is in the shape of a cylinder, and the reactor 20 is placed horizontally, that is, the reactor 20 is placed horizontally based on its central axis. The rolling mode is transmission belt rolling. The transmission belt 28 is connected to the side of the cylinder, and the transmission belt 28 is connected with the rolling drive device 26. The rolling drive device 26 drives the reactor to roll through the transmission belt 28, and rolls according to the rolling direction 24. The number of the seed crystal template 23 is one, and the seed crystal template 23 is fixed at the bottom of the reactor 20 and does not move with the reactor 20, and the seed crystal template 23 does not move synchronously with the reactor 20. The reaction raw material Ga, Na solution 22 is immersed in the seed crystal template 23, and the filling degree of the growth solution to the internal space of the reactor is 30%. Nitrogen gas 25 i...

Embodiment 3

[0042] Embodiment three, as attached Figure 7As shown, the reactor 30 is cylindrical, and the reactor 30 is placed horizontally, that is, the reactor 30 is placed horizontally based on its central axis. The rolling mode is guide wheel rolling. A guide wheel 36 is installed on the side of the cylinder. The guide wheel 36 is connected with the rolling drive device. The number of seed crystal template 33 is one, and the seed crystal template 33 is fixed on the bottom of the reactor 30 and does not move with the reactor 30, that is, the seed crystal template does not move synchronously with the reactor during the rolling process of the reactor 30. The reaction raw material Ga, Na solution 32 is immersed in the seed crystal template 33, and the filling degree of the growth solution to the internal space of the reactor is 30%. Nitrogen gas 35 is above the reaction raw material solution 32 .

[0043] The reaction kettle 30 is heated and pressurized to the required conditions for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com