Dense-phase semi-dry flue gas desulfurization device and method thereof

A desulfurization device and semi-dry technology, applied in the field of flue gas desulfurization, can solve the problems of insufficient residence time of desulfurizer, easy to cause wet wall phenomenon, and low utilization rate of desulfurizer, so as to reduce wet wall phenomenon and process loss , The effect of saving filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

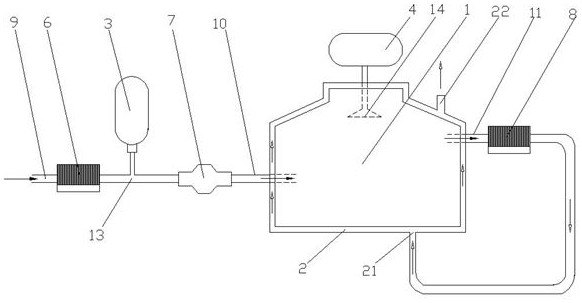

[0037] like figure 1 As shown, this embodiment provides a dense-phase semi-dry flue gas desulfurization device, including a desulfurization tower 1, a first dust collector 6, a second dust collector 8, a flue gas pipeline 9, a desulfurizing agent raw material tank 3, a water tank 4. The two sides of the desulfurization tower 1 are respectively connected with an air inlet pipe 10 and an air outlet pipe 11. The flue gas pipe 9 is connected to the first dust collector 6, and the first dust collector 6 is connected to the air inlet pipe 10 of the desulfurization tower 1. They are connected through the horizontal two ports of the tee pipe 13, and the other port of the tee pipe 13 is connected to the desulfurizer raw material tank 3, and a preheater is provided between the inlet pipe 10 and the tee pipe 13 of the desulfurization tower 1 7. The inner top of the desulfurization tower 1 is provided with a nozzle 14 , the nozzle 14 is connected to the water tank 4 outside the desulfuriz...

Embodiment 2

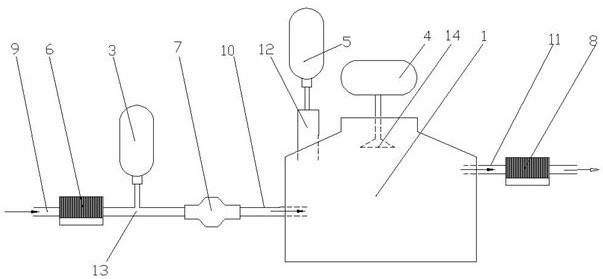

[0040] like figure 2As shown, this embodiment provides a dense-phase semi-dry flue gas desulfurization device, including a desulfurization tower 1, a first dust collector 6, a second dust collector 8, a flue gas pipeline 9, a desulfurizer raw material tank 3, and a water tank 4. Both sides of the desulfurization tower 1 are respectively connected with an inlet pipe 10 and an outlet pipe 11, the flue gas pipe 9 is connected to the first dust remover 6, and the connection between the first dust remover 6 and the inlet pipe 10 of the desulfurization tower 1 The horizontal two ports of the three-way pipe 13 are connected between them, the other port of the three-way pipe 13 is connected to the desulfurizer raw material tank 3, and a preheater is arranged between the inlet pipe 10 and the three-way pipe 13 of the desulfurization tower 1 7. The inner top of the desulfurization tower 1 is provided with a nozzle 14, the nozzle 14 is connected to the water tank 4 outside the desulfuri...

Embodiment 3

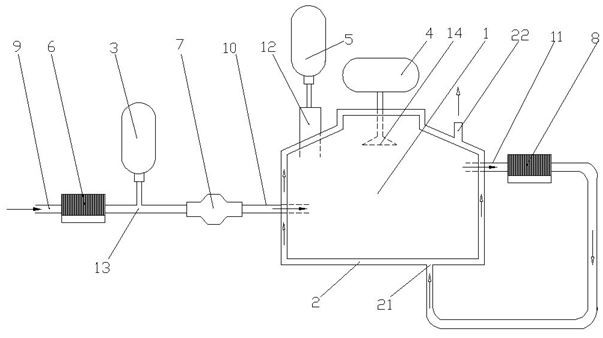

[0043] like image 3 As shown, this embodiment provides a dense-phase semi-dry flue gas desulfurization device, including a desulfurization tower 1, a first dust collector 6, a second dust collector 8, a flue gas pipeline 9, a desulfurizer raw material tank 3, and a water tank 4. Both sides of the desulfurization tower 1 are respectively connected with an inlet pipe 10 and an outlet pipe 11, the flue gas pipe 9 is connected to the first dust remover 6, and the connection between the first dust remover 6 and the inlet pipe 10 of the desulfurization tower 1 The horizontal two ports of the three-way pipe 13 are connected between them, the other port of the three-way pipe 13 is connected to the desulfurizer raw material tank 3, and a preheater is arranged between the inlet pipe 10 and the three-way pipe 13 of the desulfurization tower 1 7. The inner top of the desulfurization tower 1 is provided with a nozzle 14, the nozzle 14 is connected to the water tank 4 outside the desulfuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com