Double-shaft horizontal type mixer for mixing concrete

A double-shaft horizontal mixer technology, which is applied to cement mixing devices, clay preparation devices, liquid ingredient supply devices, etc., to achieve good mixing effects, improve reliability, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

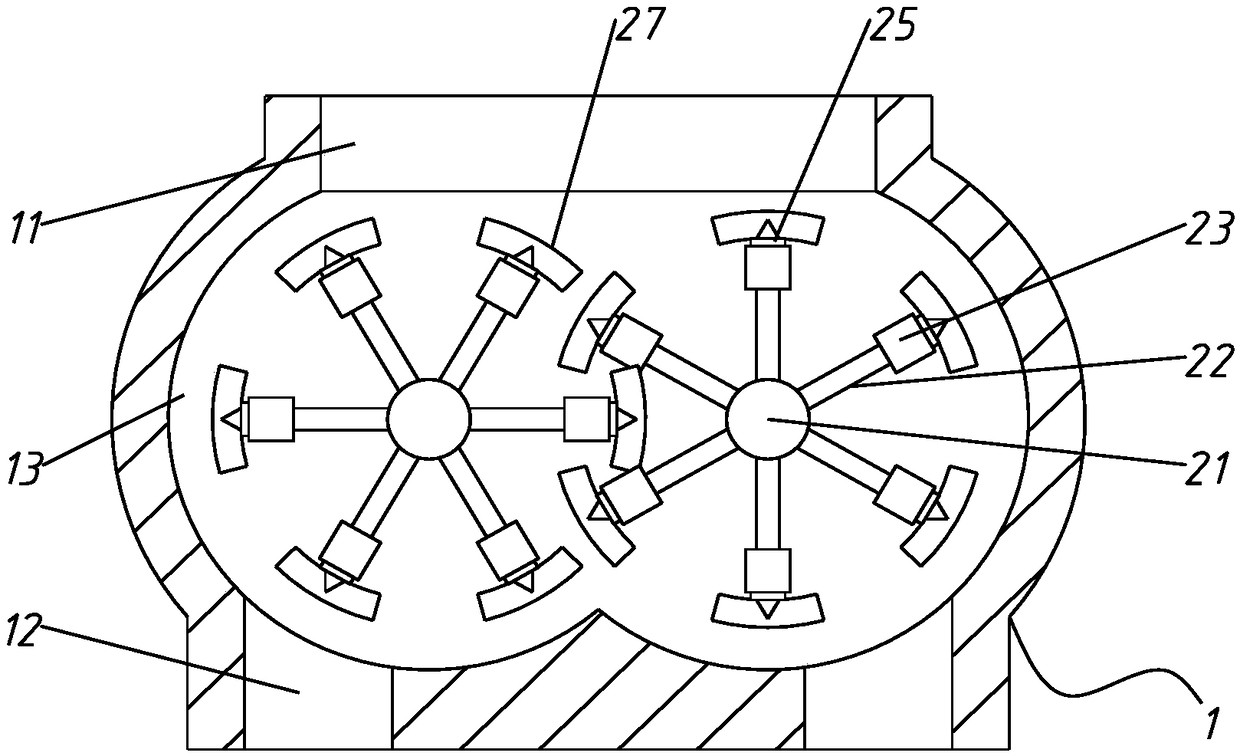

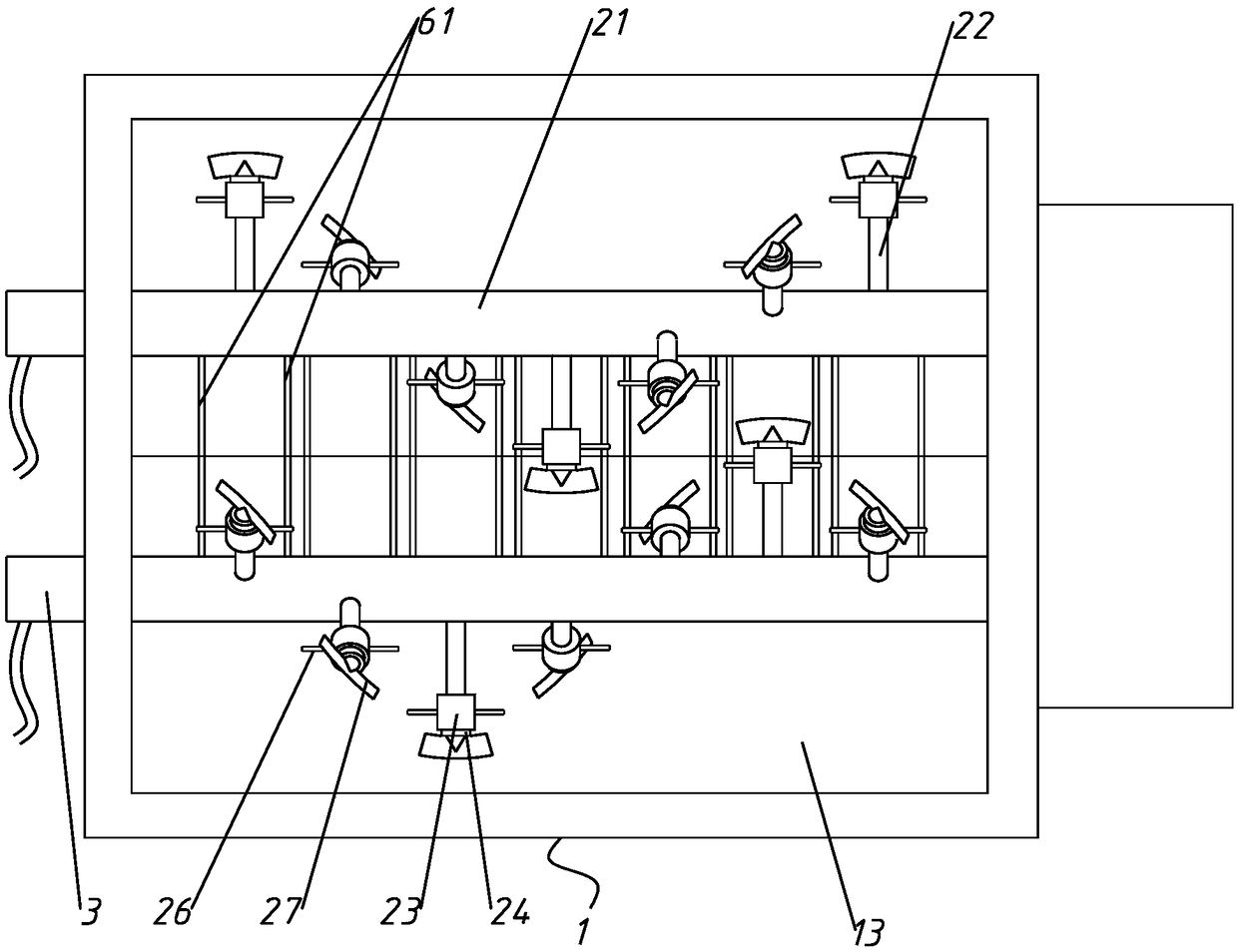

[0055] Such as Figure 1 ~ Figure 2 As shown, a double-shaft horizontal mixer for mixing concrete includes a casing 1, a silo 13 is arranged inside the casing 1, a material inlet 11 is arranged above the casing 1, and a discharge port is arranged below the casing 1 12. Both the material inlet 11 and the material outlet 12 are connected to the silo 13, and the inside of the hopper 13 is provided with a stirring spindle 21, and a number of stirring rods 22 are arranged on the stirring spindle 21 along its radial direction, and the stirring spindle 21 is a hollow structure Cavity 1 is formed inside, and one end of cavity 1 is sealed and the other end is connected to the liquid supply pump through rotary joint 3. The stirring rod 22 is a hollow structure and cavity 2 is formed inside, and cavity 2 communicates with cavity 1.

[0056] The stirring rod 22 is provided with a plurality of through holes 1 221, the through holes 1 221 are connected to the cavity 2, and the stirring rod ...

Embodiment 2

[0060] Such as Figure 1 to Figure 5 As shown, the stirring rod 22 is provided with several switch rods 41 along the longitudinal section, and the middle of the switch rod 41 is hinged with the stirring rod 22,

[0061] The gap between the stirring block 23 and the stirring rod 22 is less than the length of the stirring rod 22 when the switch rod 41 is perpendicular to the outer wall of the stirring rod 22,

[0062] Stirrer rod 22 interior sliding is provided with some switch sleeves 42, is provided with some through holes 43 on the switch sleeve 42,

[0063] The stirring rod 22 is also provided with a self-righting device 5,

[0064] When the stirring block 23 does not slide to the switch rod 41, the automatic righting device 5 keeps the direction of the switch rod 41 consistent with the radial direction of the stirring rod 22, and the second through hole 43 is not connected to the first through hole 221.

[0065] When the stirring block 23 slides to the switch lever 41 , p...

Embodiment 3

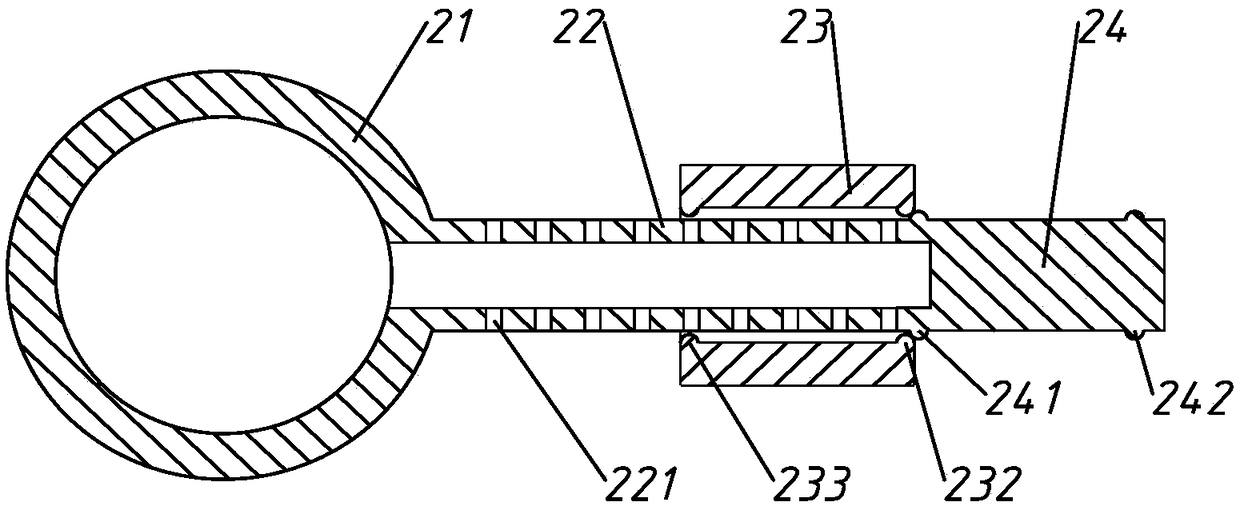

[0076] Such as Figure 1 ~ Figure 3 As shown, the far end of the stirring rod 22 from the stirring main shaft 21 is connected to one end of the connecting rod 24, the outer diameter of the stirring rod 22 is consistent with the outer diameter of the connecting rod 24, and the other end of the connecting rod 24 is provided with a limiting block 25, and the outer diameter of the limiting block 25 is greater than the inner diameter of the stirring block 23, the stirring rod 22, the connecting rod 24 and the limit block 25 are collinearly arranged,

[0077] The connecting rod 24 is circumferentially provided with a protruding edge 241 on the outer side near the limit block 25; Both the second convex edge 232 are made of elastic material, and the inner diameter of the second convex edge 232 is larger than the outer diameter of the connecting rod 24 and smaller than the outer diameter of the first convex edge 241 .

[0078] In this embodiment, when working, when the stirring liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com