High-temperature thermal decomposition incinerator

A high-temperature pyrolysis and equipment technology, applied in lighting and heating equipment, incinerators, combustion types, etc., can solve problems such as incomplete combustion, single-day processing capacity limitation, large amount of exhaust, etc., to minimize heat loss, waste heat Excellent recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

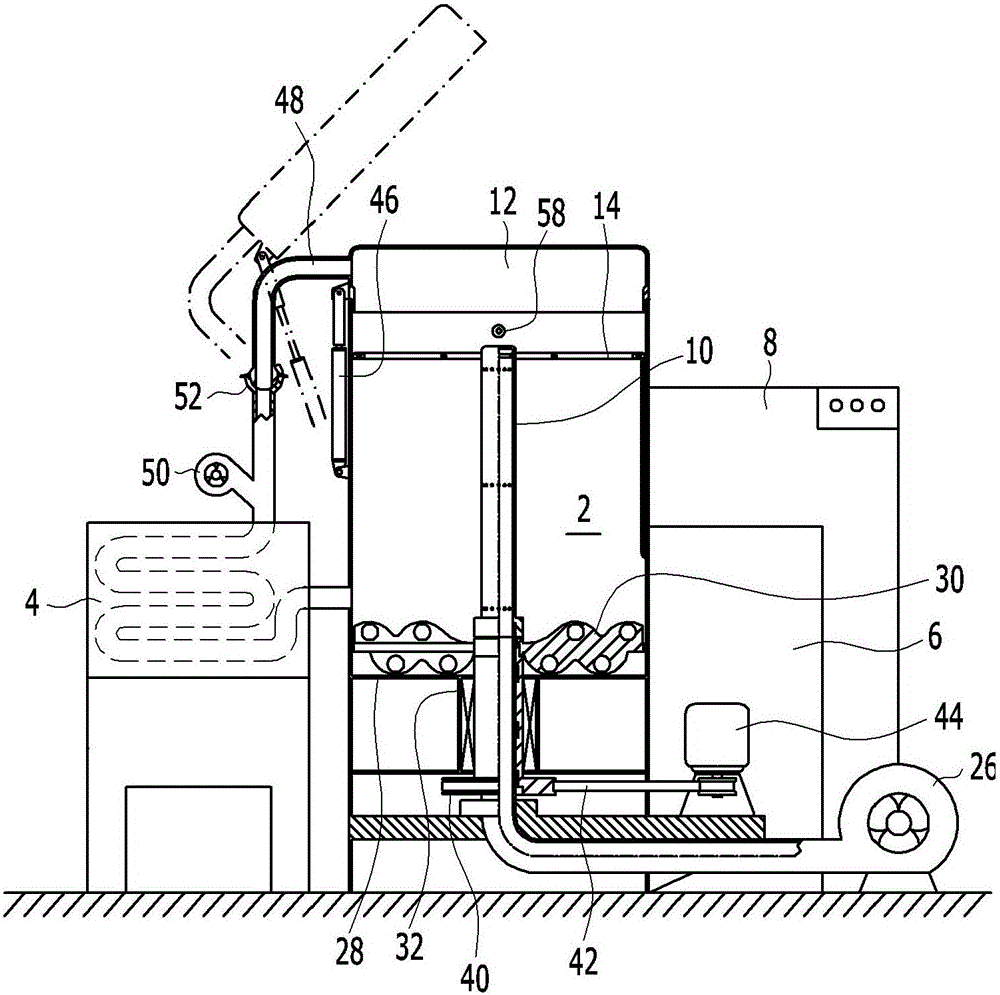

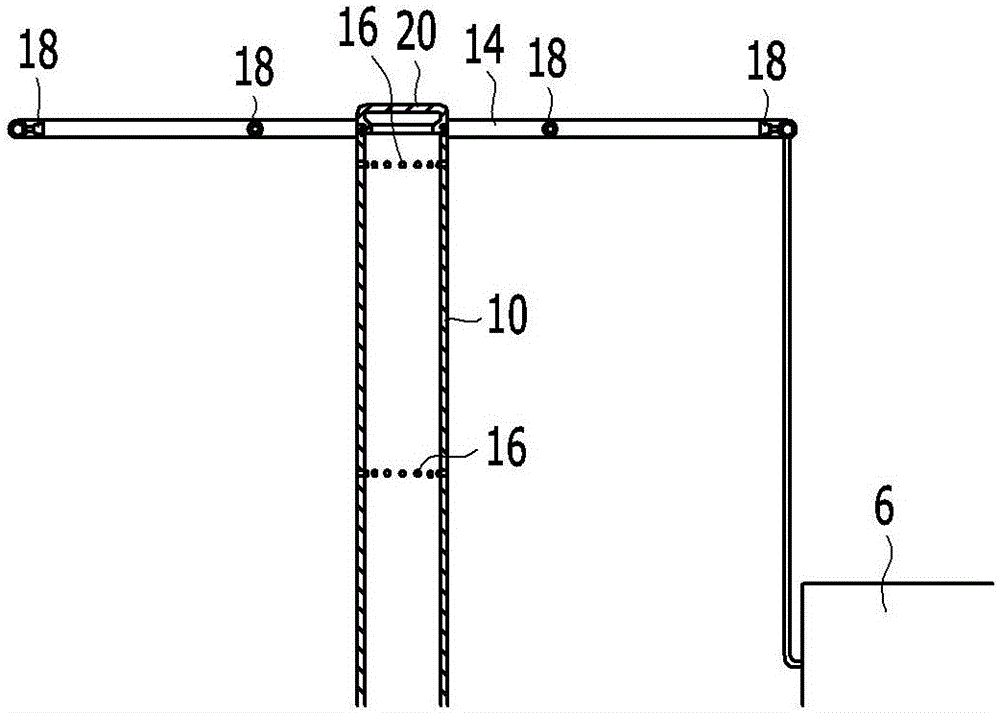

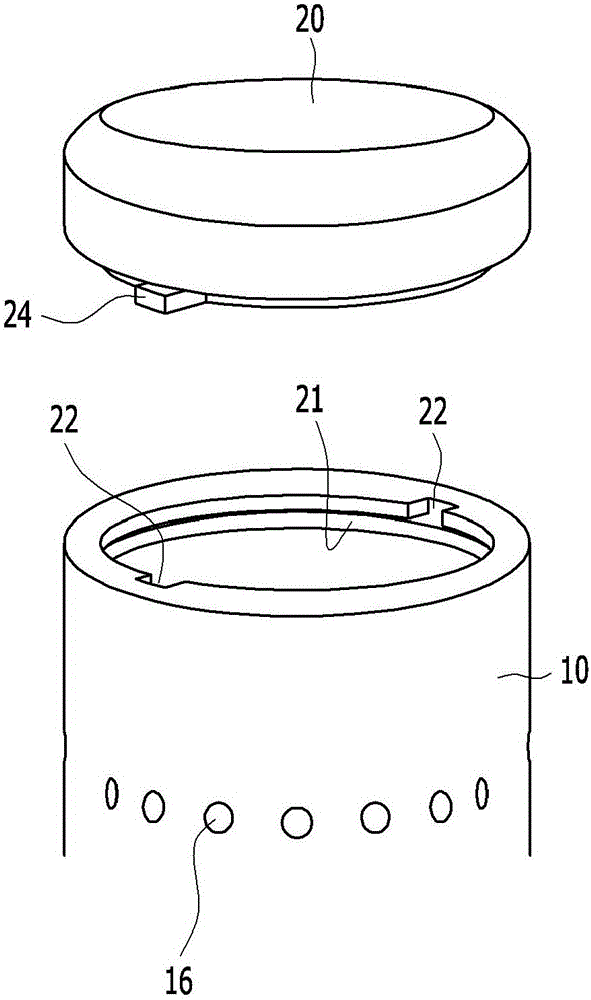

[0039] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0040] However, when describing the exemplary embodiments of the present invention in detail, like reference numerals denote like parts performing similar functions and operations throughout the specification.

[0041] Throughout the specification and the appended claims, when it is described that an element is "connected" to another element, the element may be "directly connected" to the other element or "indirectly connected" to the other element through a third element.

[0042] Additionally, unless expressly stated to the contrary, the word "comprise" and variations thereof will be understood to imply the inclusion of stated elements but not the exclusion of any other elements.

[0043] figure 1 is a side cross-sectional view of a high temperature pyrolysis incineration apparatus according to an exemplary embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com