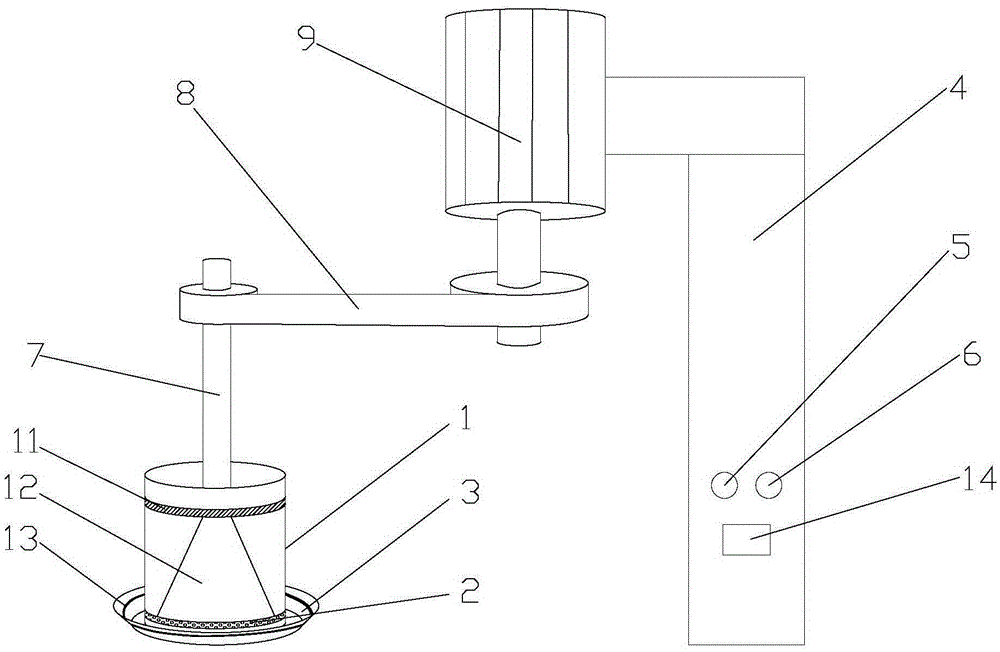

Feeding trough for raising chickens

A feed trough and feed trough technology, applied in the application, poultry industry, animal husbandry, etc., can solve the problems of feed accumulation, single feed trough, staleness, etc., and achieve the effect of uniform stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

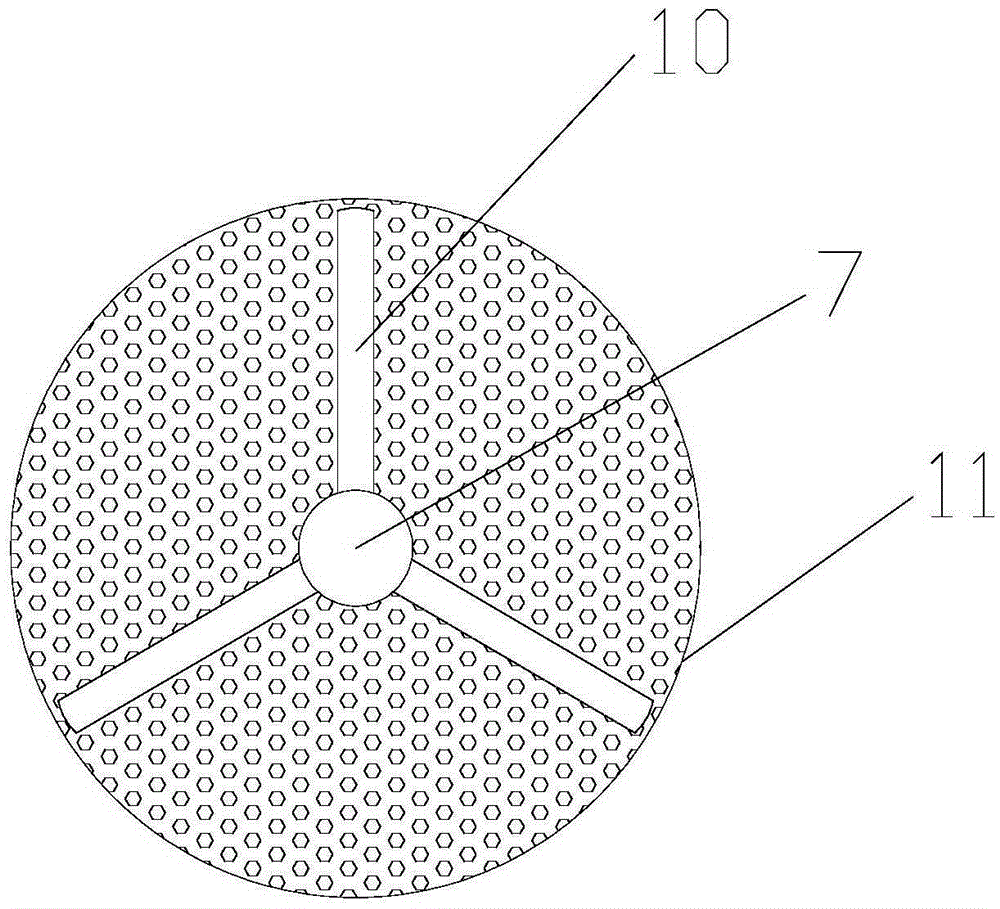

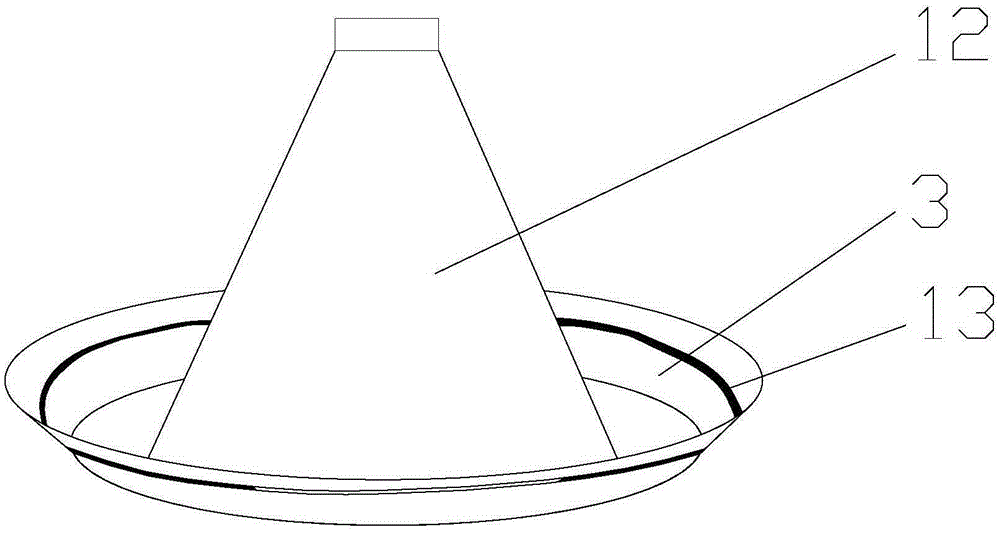

[0020] Pour the stirred feed into the sieve 11, press the start button 5, the drive motor 5 drives the main shaft 7 to rotate, the scraper 10 on the main shaft 7 will rotate along the main shaft, and the material is stirred twice while rotating, and the Part of the feed in the screen 11 is scraped through the screen 11, and the material on the screen 11 will continue to fall when it is continuously rotating. Between the flow column 12 and the material barrel 1, when the falling material exceeds the material level line 13 of the material barrel 1, it will be automatically discharged. When the feed exceeds the material level line 13, the closing button 6 can be started to stop feeding.

Embodiment 2

[0022] Pour the stirred feed into the screen 11, press the start button 5 and the induction switch 14, the drive motor 5 drives the main shaft 7 to rotate, and the scraper 10 on the main shaft 7 will rotate along the main shaft, and the material will be processed twice while rotating. Stir once, scrape a part of the feed in the screen 11 through the screen 11, when it rotates continuously, the material on the screen 11 will continue to fall, and under the influence of the conical diversion column 12, the material will gather Between the conical guide column 12 and the barrel 1, when the dropped material exceeds the upper material level line 13 of the barrel 1, it will be automatically discharged. When the feed exceeds the material level line 13, the start switch 5 will pop up automatically to close the feeding mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com