Long-acting composite type graphite stirring device for aluminum alloy refining and preparation method

A technology of stirring device and aluminum alloy, which is applied to mixers with rotating stirring devices, chemical instruments and methods, mixers, etc., to achieve uniform stirring effect, reliable use, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

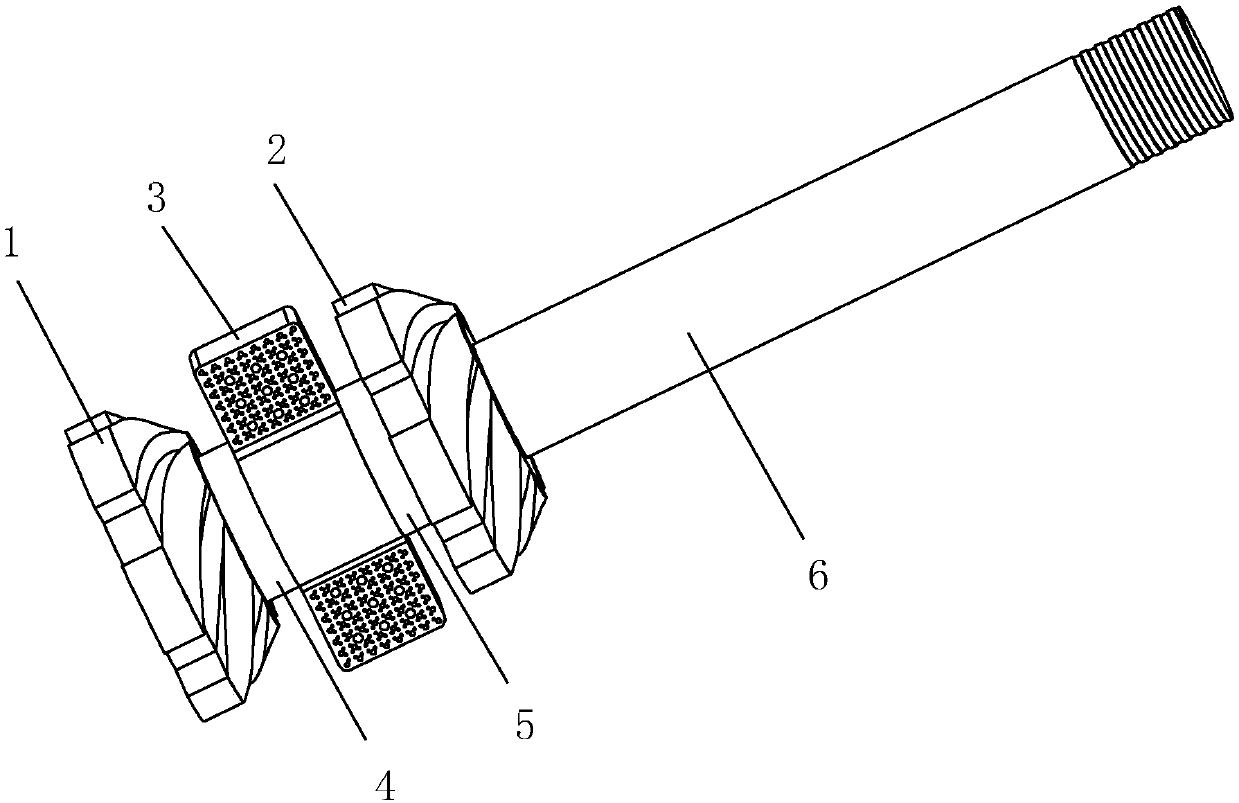

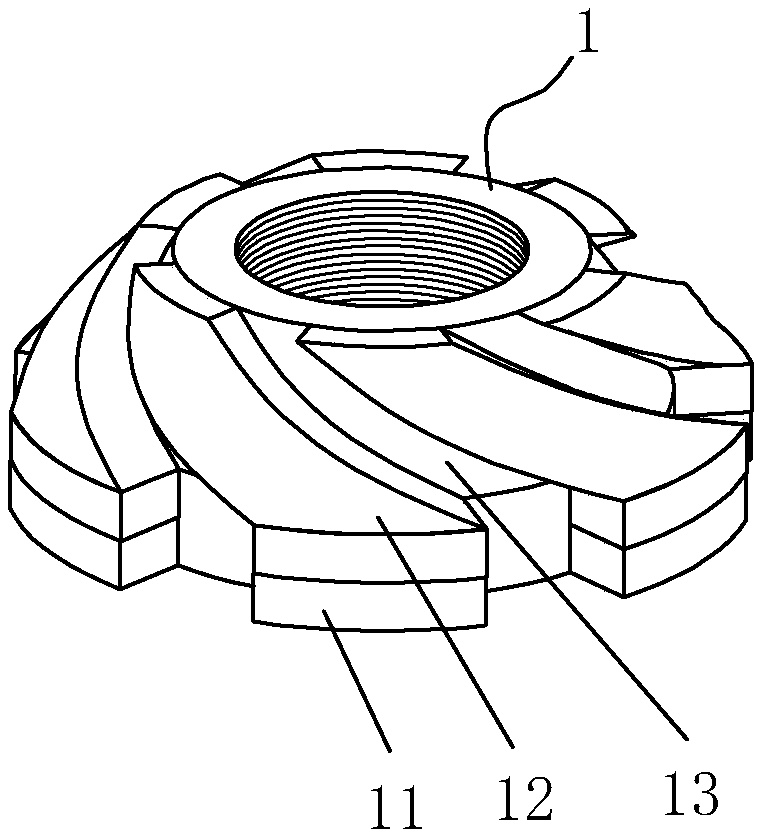

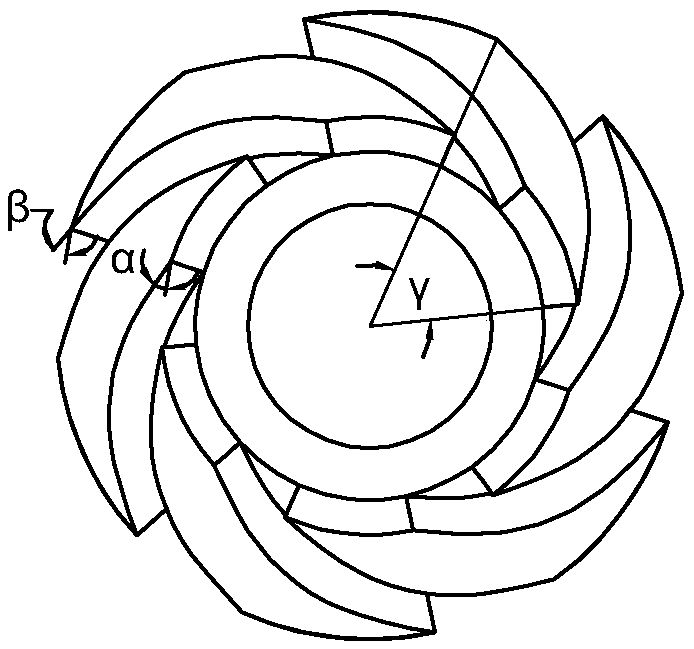

[0037] A long-term composite graphite stirring device for aluminum alloy refining, such as Figure 1-Figure 5 As shown, it includes a hollow shaft 6 with a through hole 61 and a lower straight-leaf spiral mixed-flow impeller 1, a lower sleeve 4, a multi-aperture blade 3, an upper sleeve 5, and an upper layer installed on the hollow shaft in sequence from bottom to top. Straight-leaf spiral mixed-flow impeller 2, the lower straight-leaf spiral mixed-flow impeller, the multi-aperture blade, the upper straight-leaf spiral mixed-flow impeller and the hollow shaft are connected by left-handed threads, the lower sleeve, the upper sleeve and the hollow shaft There is a gap fit between them. The lower straight blade spiral mixed flow impeller and the upper straight blade spiral mixed flow impeller are mainly composed of 5 straight blade radial flow blades 11 arranged at the bottom and 5 helical surface shafts with logarithmic helix as the profile line located above. The water guide b...

Embodiment 2

[0047] A long-term composite graphite stirring device for aluminum alloy refining, such as Figure 1-Figure 5 As shown, it includes a hollow shaft 6 with a through hole 61 and a lower straight-leaf spiral mixed-flow impeller 1, a lower sleeve 4, a multi-aperture blade 3, an upper sleeve 5, and an upper layer installed on the hollow shaft in sequence from bottom to top. Straight-leaf spiral mixed-flow impeller 2, the lower straight-leaf spiral mixed-flow impeller, the multi-aperture blade, the upper straight-leaf spiral mixed-flow impeller and the hollow shaft are connected by left-handed threads, the lower sleeve, the upper sleeve and the hollow shaft There is a gap fit between them. The lower straight blade spiral mixed flow impeller and the upper straight blade spiral mixed flow impeller are mainly composed of 6 straight blade radial flow blades 11 arranged at the bottom and 6 helicoid shafts with logarithmic helix as the profile line located above. The water guide blade 12...

Embodiment 3

[0050] A long-term composite graphite stirring device for aluminum alloy refining, such as Figure 1-Figure 5 As shown, it includes a hollow shaft 6 with a through hole 61 and a lower straight-leaf spiral mixed-flow impeller 1, a lower sleeve 4, a multi-aperture blade 3, an upper sleeve 5, and an upper layer installed on the hollow shaft in sequence from bottom to top. Straight-leaf spiral mixed-flow impeller 2, the lower straight-leaf spiral mixed-flow impeller, the multi-aperture blade, the upper straight-leaf spiral mixed-flow impeller and the hollow shaft are connected by left-handed threads, the lower sleeve, the upper sleeve and the hollow shaft There is a gap fit between them. The lower straight blade spiral mixed flow impeller and the upper straight blade spiral mixed flow impeller are mainly composed of 8 straight blade radial flow blades 11 arranged at the bottom and 8 helicoid shafts with logarithmic helix as the profile line located above. The water guide blade 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com