Mud tank for well drilling

A mud tank and drilling technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., can solve the problems of inability to use automatic welding machines for high-efficiency weld quality, and achieve the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

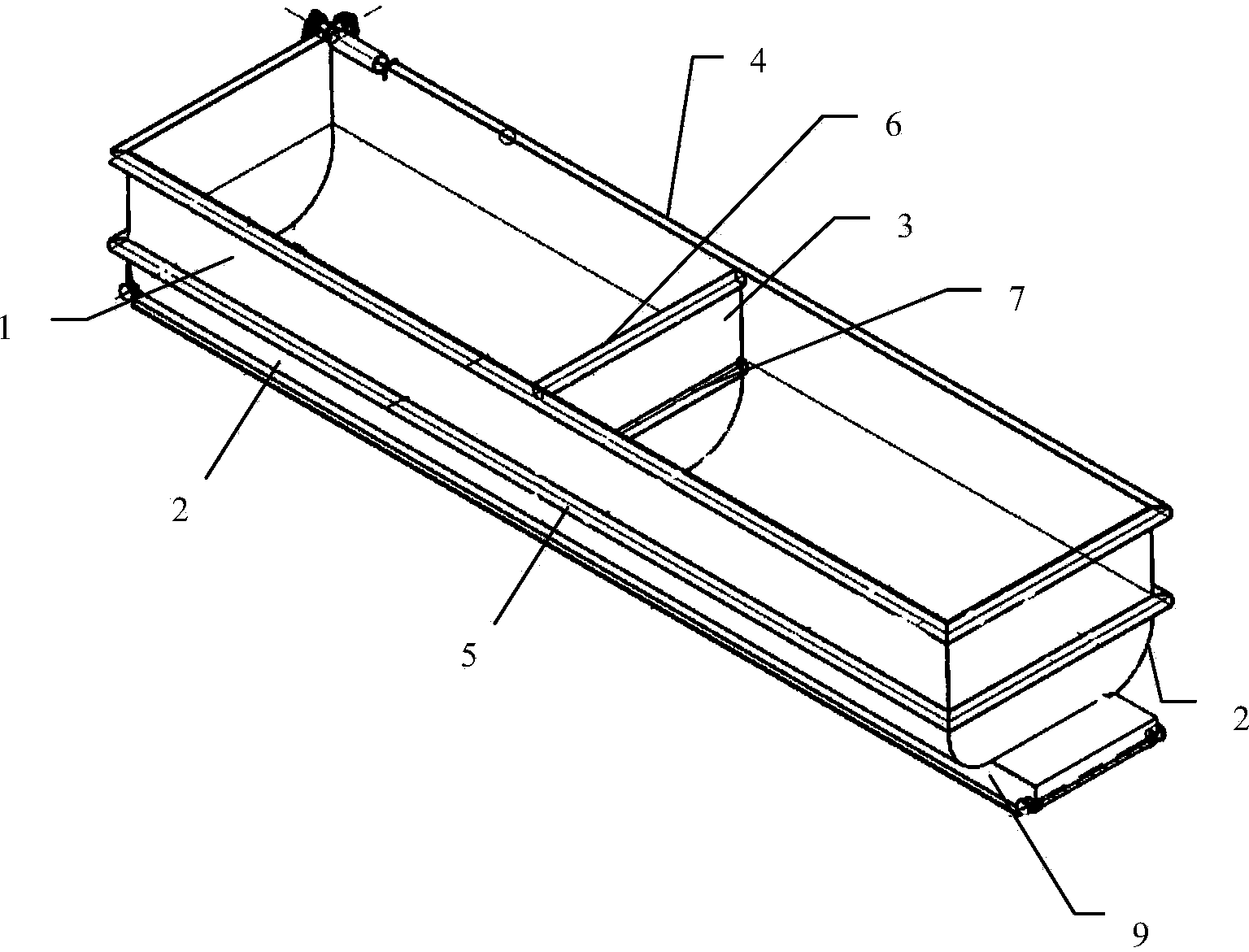

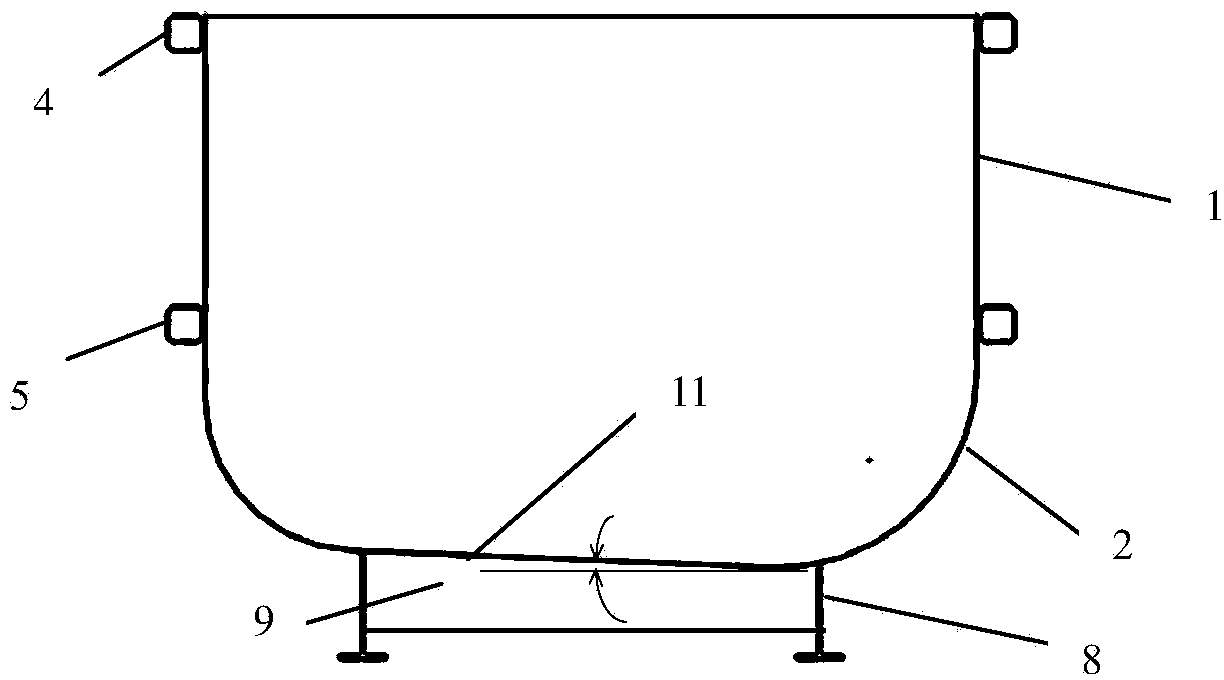

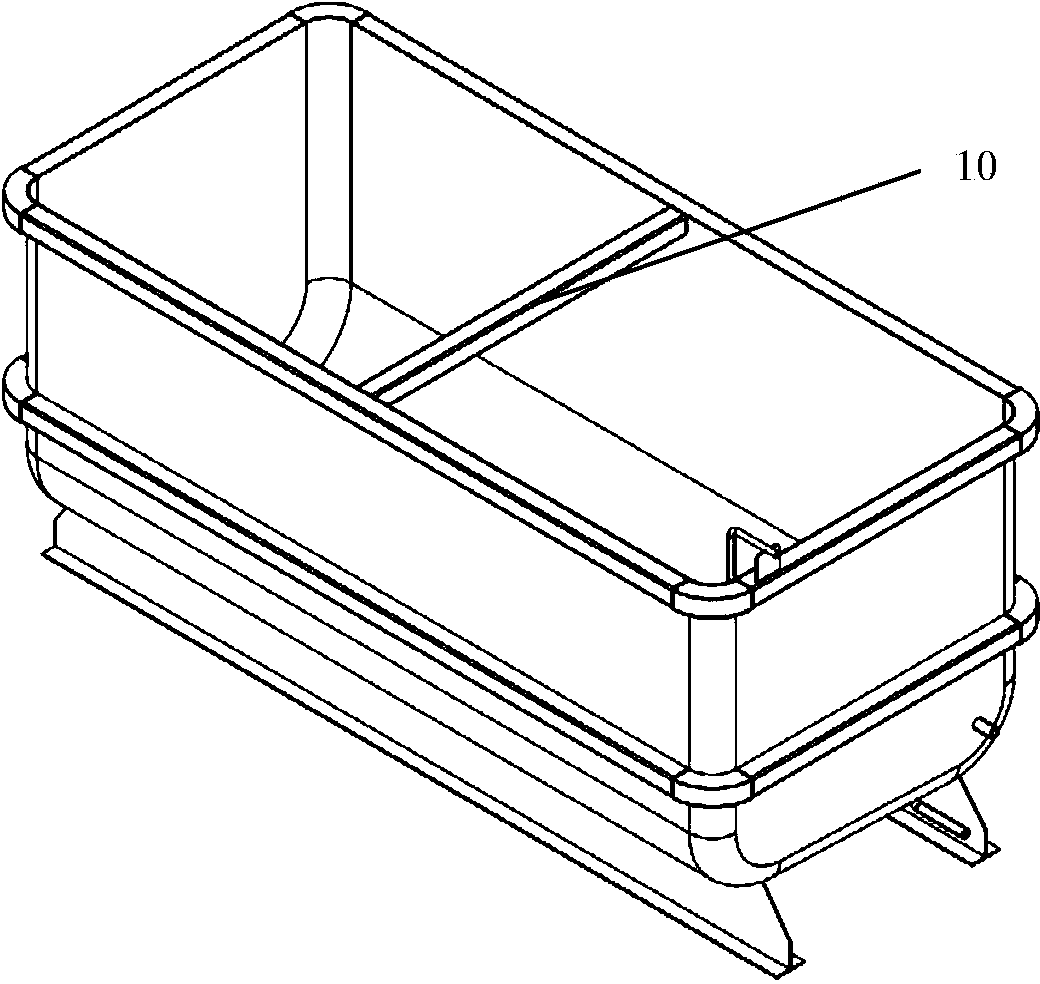

[0027] figure 1 , figure 2 It shows a mud tank for drilling, the main body of the tank body is in the shape of a cuboid tank, including tank side plates and a tank bottom plate 11, a bottom plate support structure is arranged below the tank body bottom plate 11, and the bottom plate support structure It is composed of a bottom transverse rib plate 8 and a bottom longitudinal rib plate 9. The tank side plate is divided into an upper tank side plate 1 and a lower tank side plate 2. The upper tank side plate 1 is vertical Side plate, the short side of the lower tank body side plate 2 is a vertical side plate, and the long side is a quarter arc plate bent inward; the tank at the upper opening of the tank body The outer periphery of the body side plate is fixedly provided with a rib plate 4 on the side plate, and the rib plate 5 in the side plate is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com