Circular stirring concrete stirrer

A concrete mixer and circulating mixing technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of inability to mix a large amount of concrete, low discharge efficiency, and insufficiency, and achieve rapid mixing operations. even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

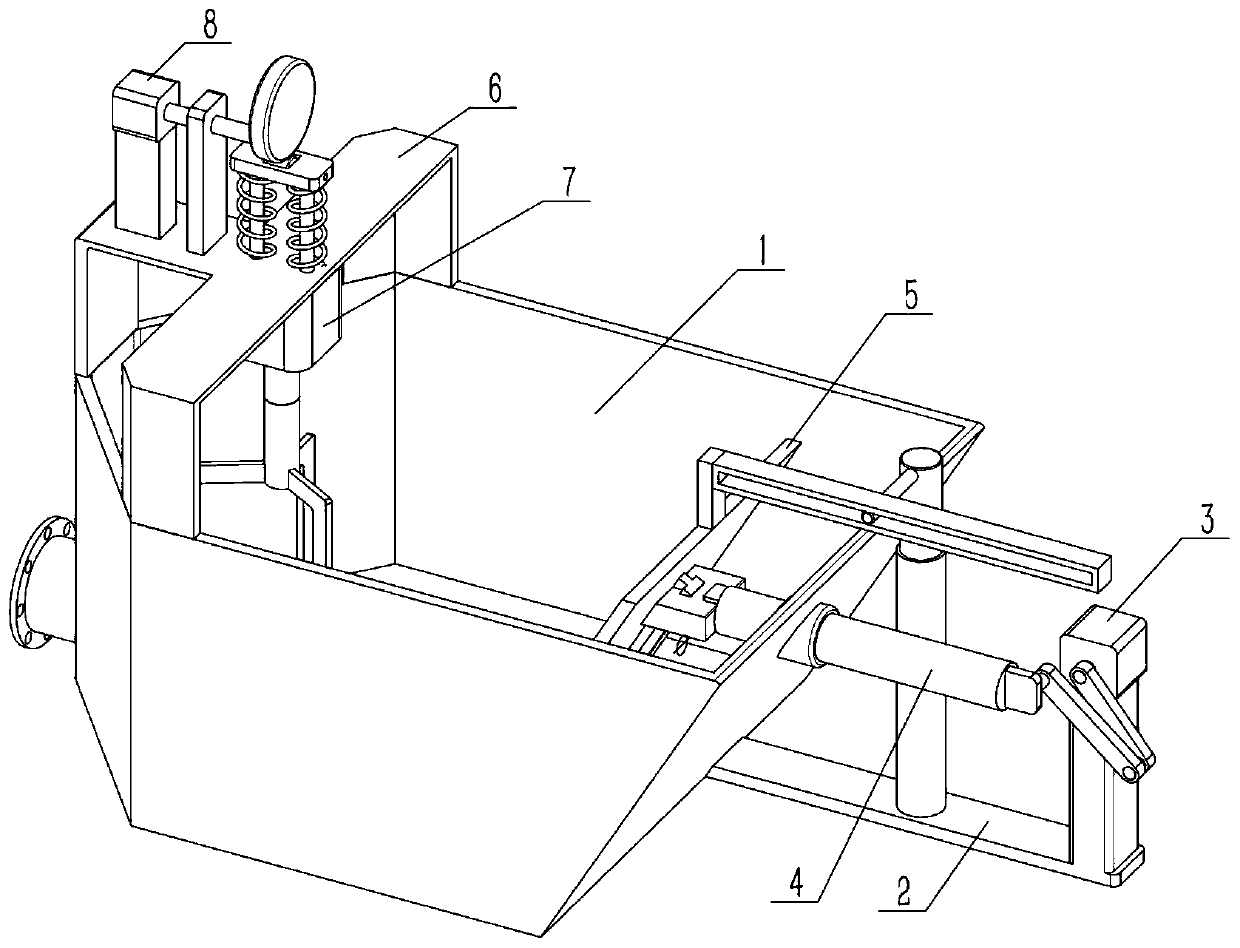

[0030] Such as Figure 1-9 As shown, a circulating mixing concrete mixer includes a motor II7, a main shaft 705, a stirring blade 706 and a pounding blade 707. The output shaft of the motor II7 is fixedly connected to the main shaft 705, and the lower side of the main shaft 705 is provided with a stirring blade 706. The lower end of leaf 706 is fixedly connected with stamping leaf 707, and the cross-sectional area of stamping leaf 707 is greater than the cross-sectional area of the junction of stirring leaf 706 and stamping leaf 707, and stirring leaf 706 can drive stamping leaf 707 to move up and down when stirring and preparing concrete, and stamping leaf The lowest position of the 707 movement reaches the bottom of the prepared concrete. The stirring blade 706 is driven by the motor Ⅱ7 to realize the rotation. During this action, the stirring blade 706 is controlled to move up and down, and then the stirring blade 706 is used to drive the pounding blade 707 to move up a...

specific Embodiment approach 2

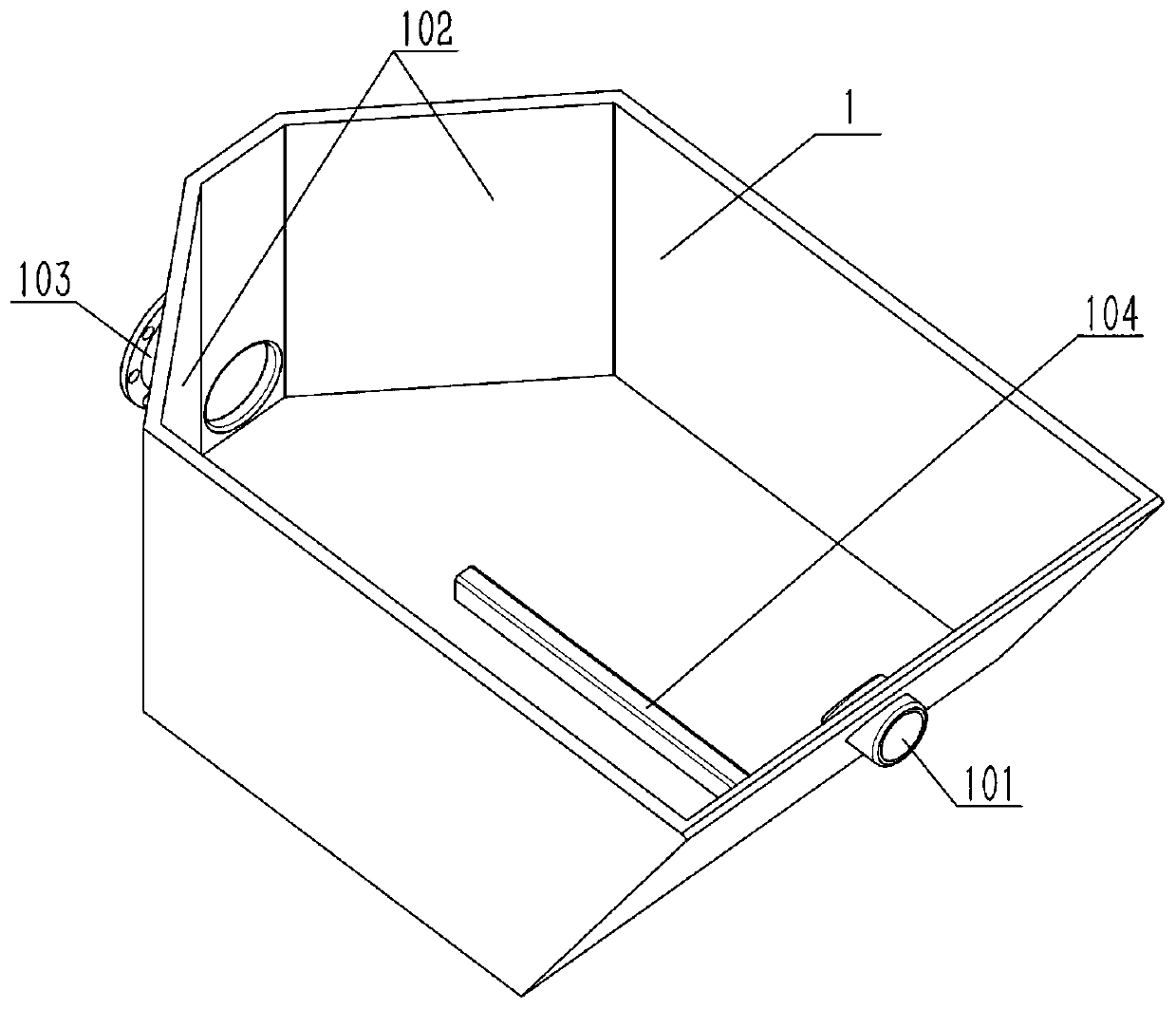

[0032] Such as Figure 1-9 As shown, the circulating mixing concrete mixer also includes a processing box 1, a frame 6, a reset rod 701, a compression spring 702 and a flat plate 703, the upper end of the processing box 1 is fixed to the frame 6, and the upper end of the motor II 7 is fixed to two Reset lever 701, two reset levers 701 are slidably connected on the frame 6, the flat plate 703 is fixedly connected to the upper ends of the two reset levers 701, and the compression spring 702 is located between the flat plate 703 and the frame 6, by controlling the up and down movement of the flat plate 703 Drive the stirring blade 706 to move up and down. The flat plate 703 is convenient to be connected with mechanisms such as electric telescopic rods to realize up and down movement, and is also convenient to realize manual stepping to realize up and down movement. The compression spring 702 can be set by observing the rebound of the flat plate 703. If the rebound is smooth, it m...

specific Embodiment approach 3

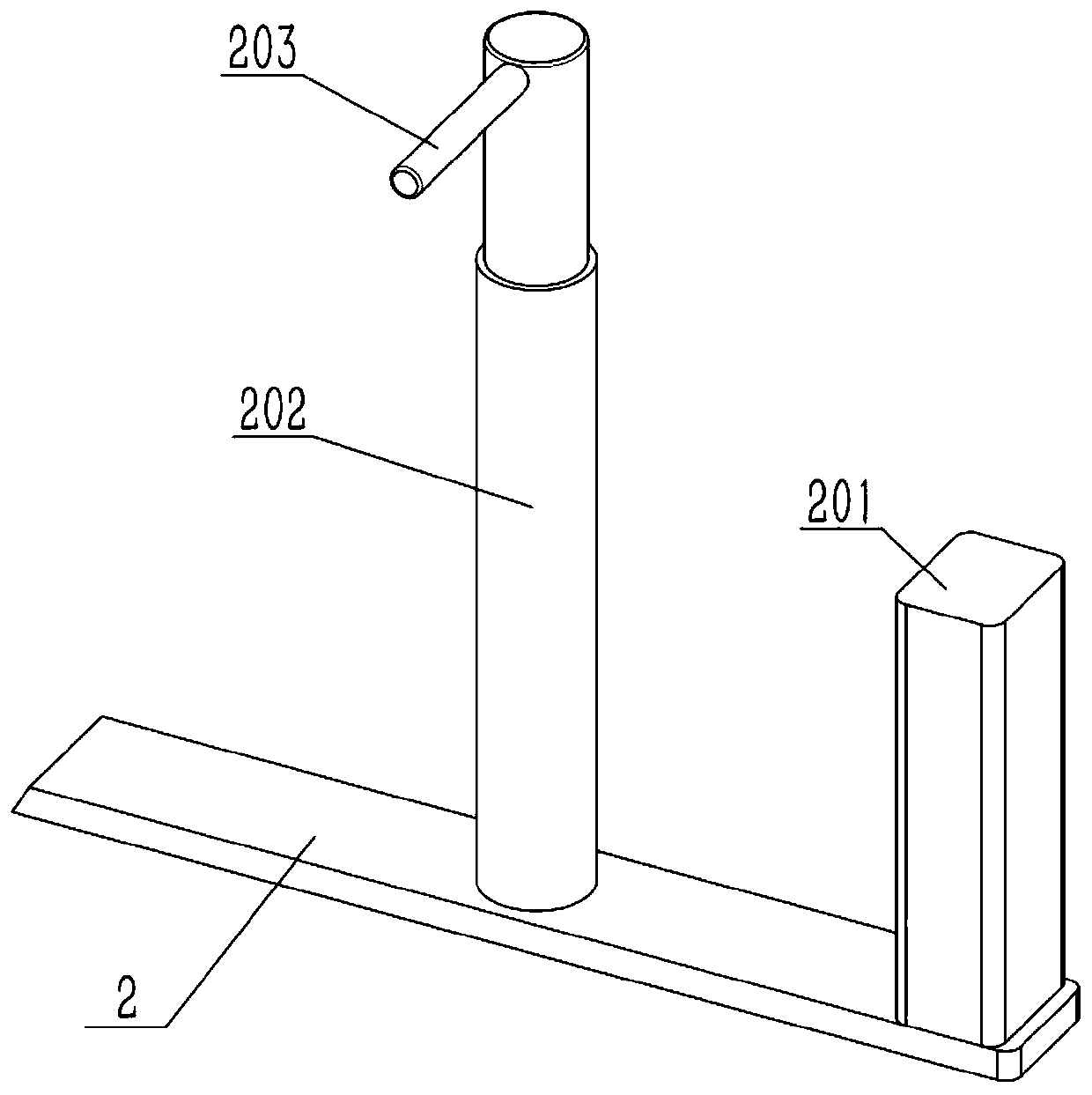

[0034] Such as Figure 1-9 As shown, the circulating mixing concrete mixer also includes a base II601, a bearing with seat 602, a wheel 704, a motor III8 and an eccentric wheel 801, the base II601 is fixed on the frame 6, and the motor III8 is fixed on the base II601 Above, the output shaft of the motor III8 is rotatably connected to the bearing 602 with seat, the eccentric position of the eccentric wheel 801 is fixedly connected to the output shaft of the motor III8, the eccentric wheel 801 is in contact with the wheel 704, and the wheel 704 is rotatably connected to the flat plate 703. The rotation of the eccentric wheel 801 drives the wheel 704 to move up and down to realize the up and down movement of the flat plate 703 . Start the motor Ⅲ8, the output shaft of the motor Ⅲ8 drives the eccentric wheel 801 to rotate, and the eccentric wheel 801 can press the wheel 704 to move downward once every time the eccentric wheel 801 rotates, so that the up and down reciprocating moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com