Fungus material stirring machine

A technology of mixer and fungus material, applied in the directions of mixer, dissolving, gardening, etc., can solve the problems of restricting the development of edible fungus planting industry, unsatisfactory effect of mixing materials, restricting labor force utilization, etc. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

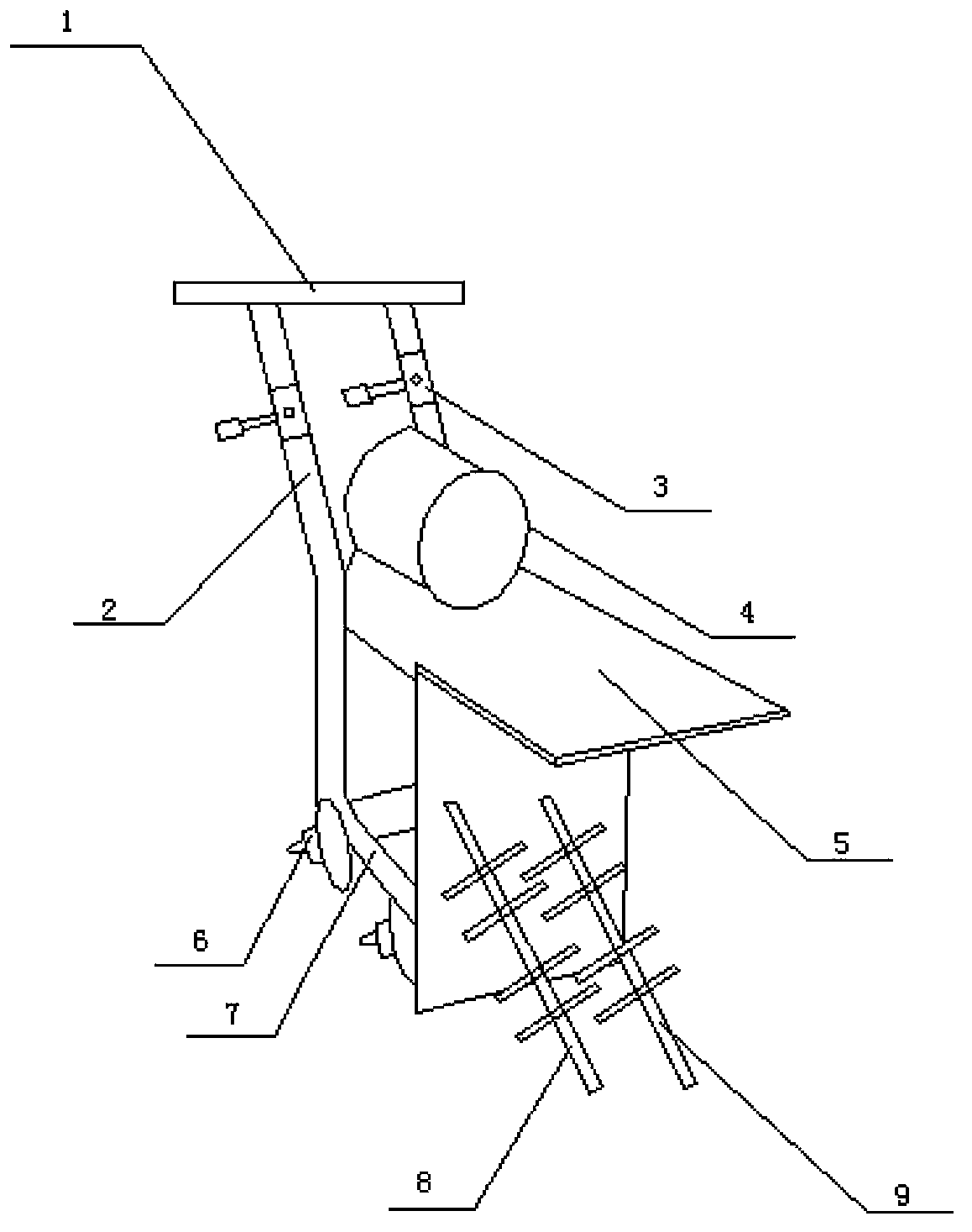

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it includes a push rod 1, a connecting rod 2, a height adjustment device 3, a motor 4, a baffle plate 5, a roller 6, a base 7, a first stirring rod 8 and a second stirring rod 9 , a hand push rod 1 is set above the connecting rod 2, a height adjustment device 3 is connected to the connecting rod 2, a base 7 is set under the connecting rod 2, a roller 6 is set under the base 7, and a roller 6 is set between the two connecting rods 2 There is a motor 4, and the motor 4 is installed above the baffle plate 5, and the front end of the base 7 is connected with a first stirring rod 8 and a second stirring rod 9.

[0009] The first stirring rod 8 and the second stirring rod 9 are provided with several horizontal stirring rods, and the horizontal stirring rods are welded on the first stirring rod 8 and the second stirring rod 9 .

[0010] This specific embodiment has the following beneficial e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com