Electrodeposition device

A technology of electrodeposition device and electrodeposition tank, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of uniformity of electrodeposition layer thickness, weak stirring effect, low deposition speed, etc., and achieve high-strength and uniform stirring effect , improved uniformity, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

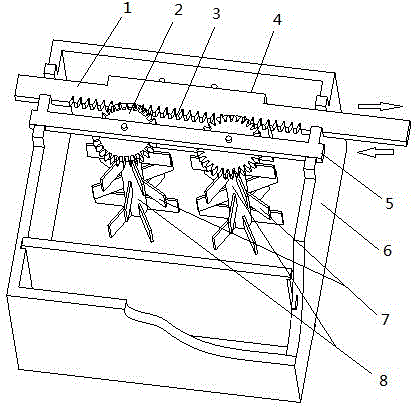

[0016] Combine below figure 1 The implementation of the present invention is described in further detail.

[0017] An electrodeposition device, comprising an electrodeposition tank 6, a cathode moving rod 1, and a cathode 4, is characterized in that: it includes a gear 2, a gear mounting rod 5, and a stirring paddle 7. The cathode 4 is installed on one side of the cathode moving rod 1; the cathode moving rod 1 is provided with a rack 3; the rack 3 is meshed with the gear 2; the gear 2 is rotatably fixed on the gear on the rod 5; the gear installation rod 5 is fixed on the electrodeposition tank 6; the stirring paddle 7 is coaxially installed on the gear shaft 8.

[0018] The cathode moving rod 1 is arranged in parallel on the electrodeposition tank 6 .

[0019] The cathode moving rod 1 can reciprocate under the action of external force.

[0020] The number of the gear shafts 8 can be increased or decreased according to the size and process requirements of the electrodeposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com