High-speed and high-efficiency blender with mighty rotating flow

A kind of mixer, high-efficiency technology, applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of large mixing noise, difficult adjustment of angle, uneven mixing, etc., achieve high automation, high production efficiency, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

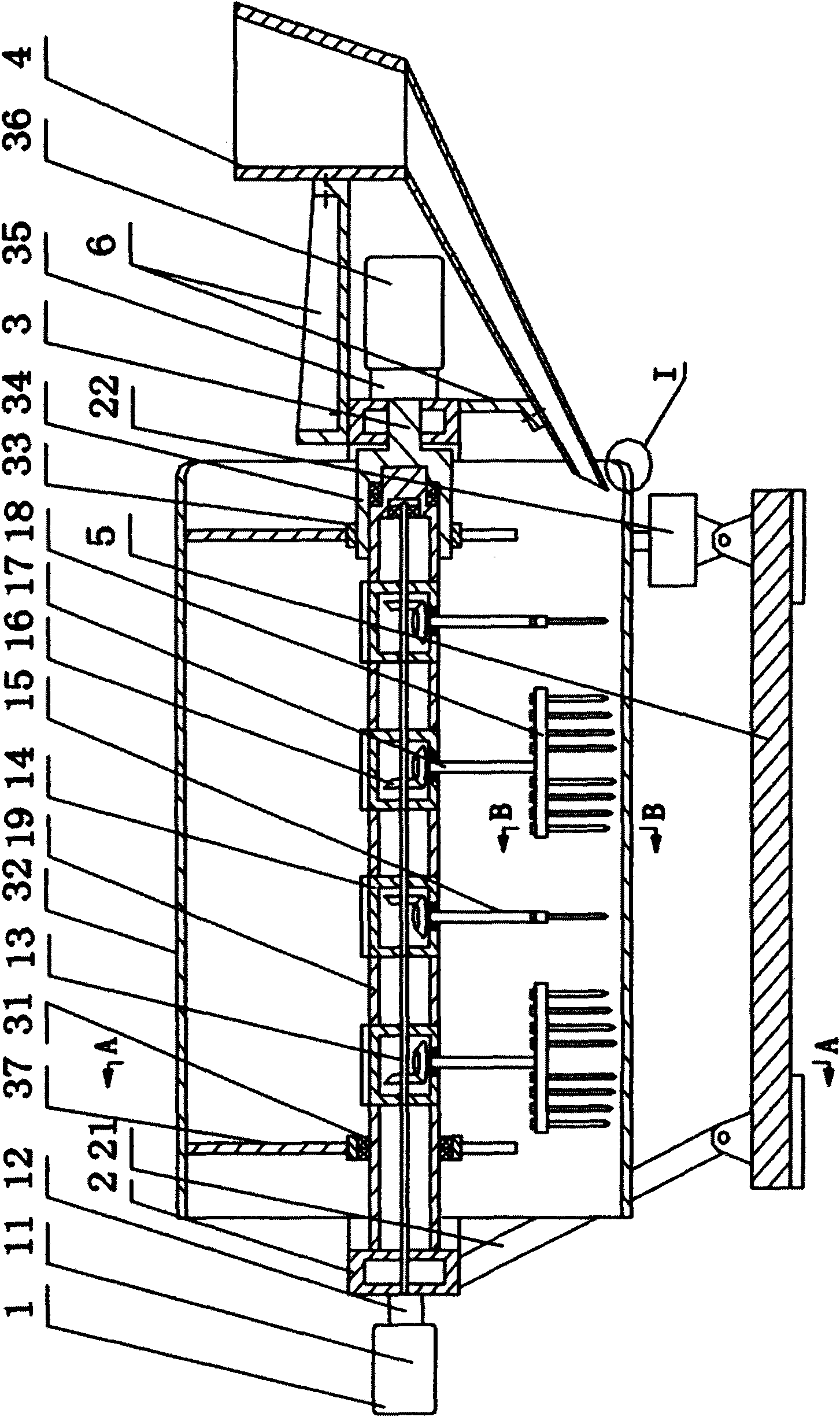

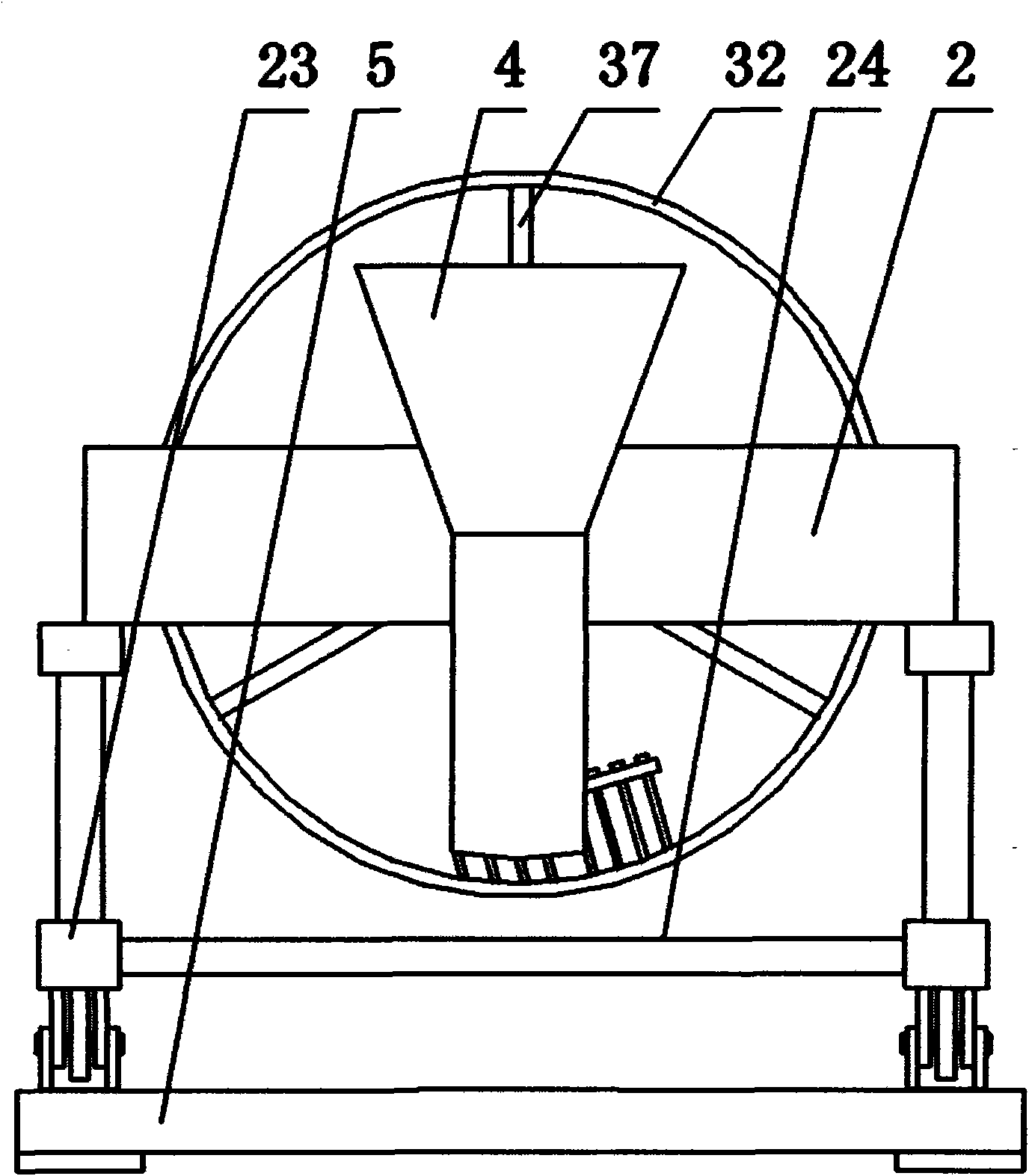

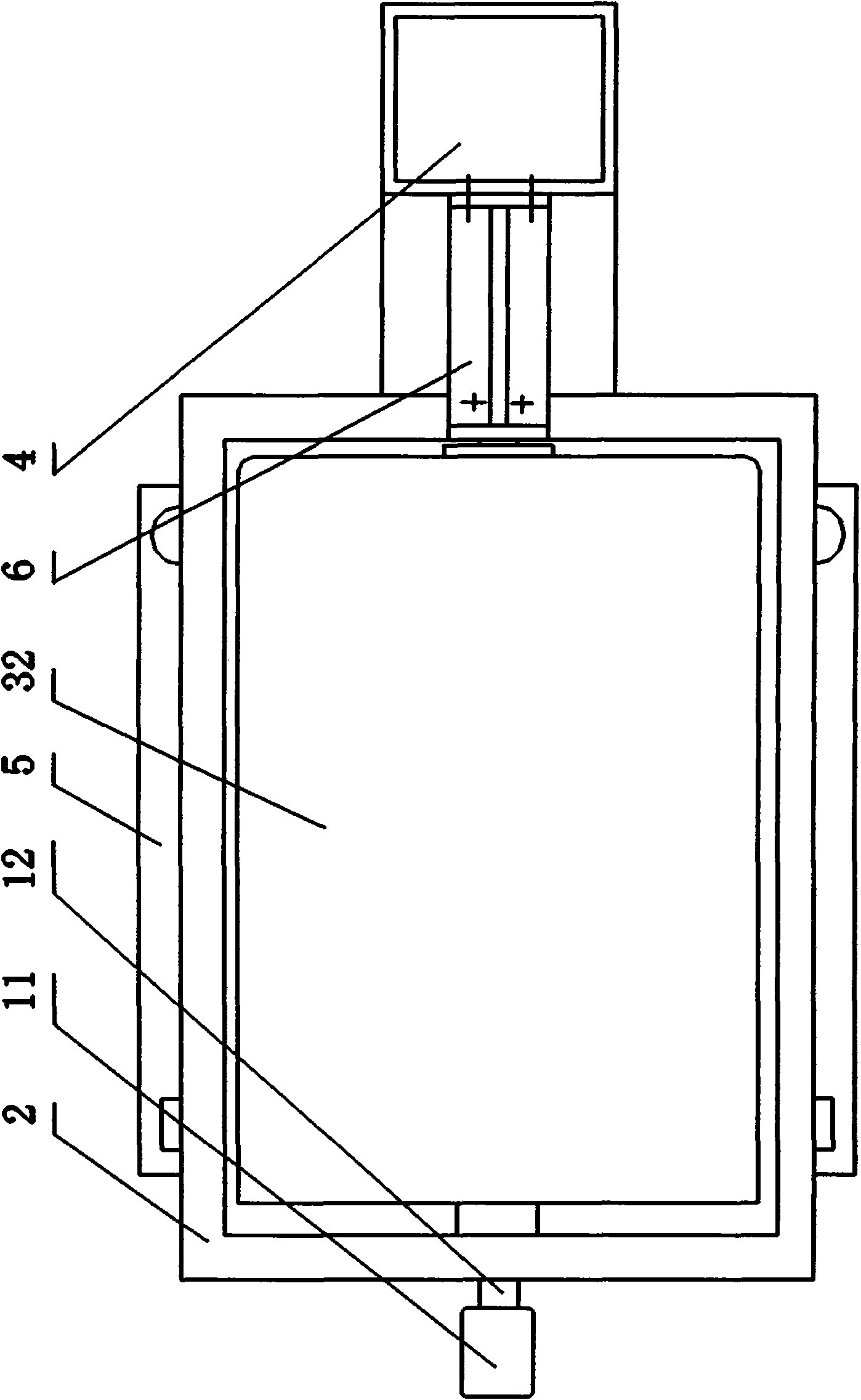

[0015] The present invention includes a machine base 5, a frame 2, a drum 32 arranged on the frame 2 and a feed hopper 4, and a stirring mechanism 17 is arranged in the drum 32; a drum driving device 3 and a stirring driving device 1 are respectively arranged on both sides of the frame 2, Frame supporting mechanism 22 is arranged on machine base 5, and stirring mechanism 17 comprises fixed axle sleeve 19, main shaft 13, stirring shaft 15 and the stirring fin 18 that is arranged on the lower end of stirring shaft 15, and fixed axle sleeve 19 and main shaft 13 are along cylinder 32 axial direction. One end of the fixed shaft sleeve 19 is fixedly connected with the frame 2, and the other end is rotationally connected with the drum driving device 3; no less than two gear boxes 14 are arranged on the fixed shaft sleeve 19, and each gear box 14 is respectively provided with a group of transmission Gear 16; one end of the main shaft 13 is connected with the stirring drive device 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com