Patents

Literature

49results about How to "Achieve reverse rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

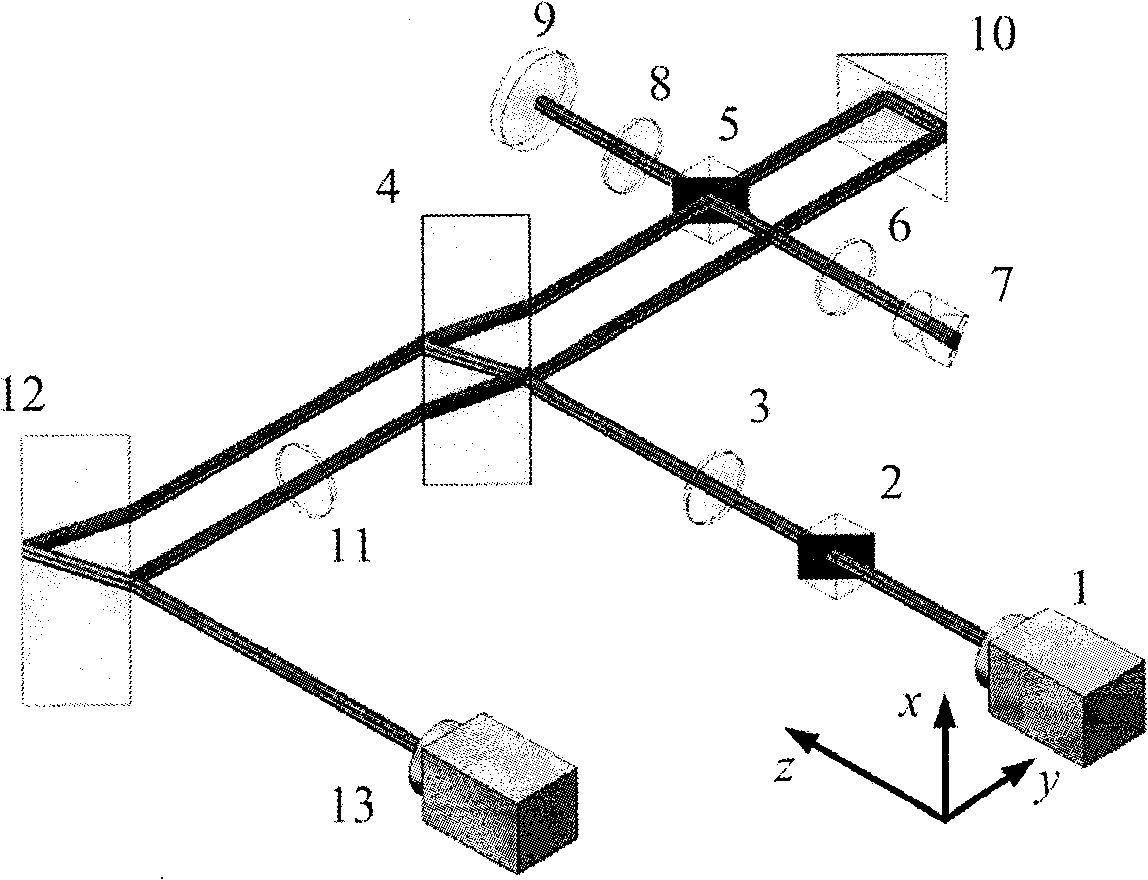

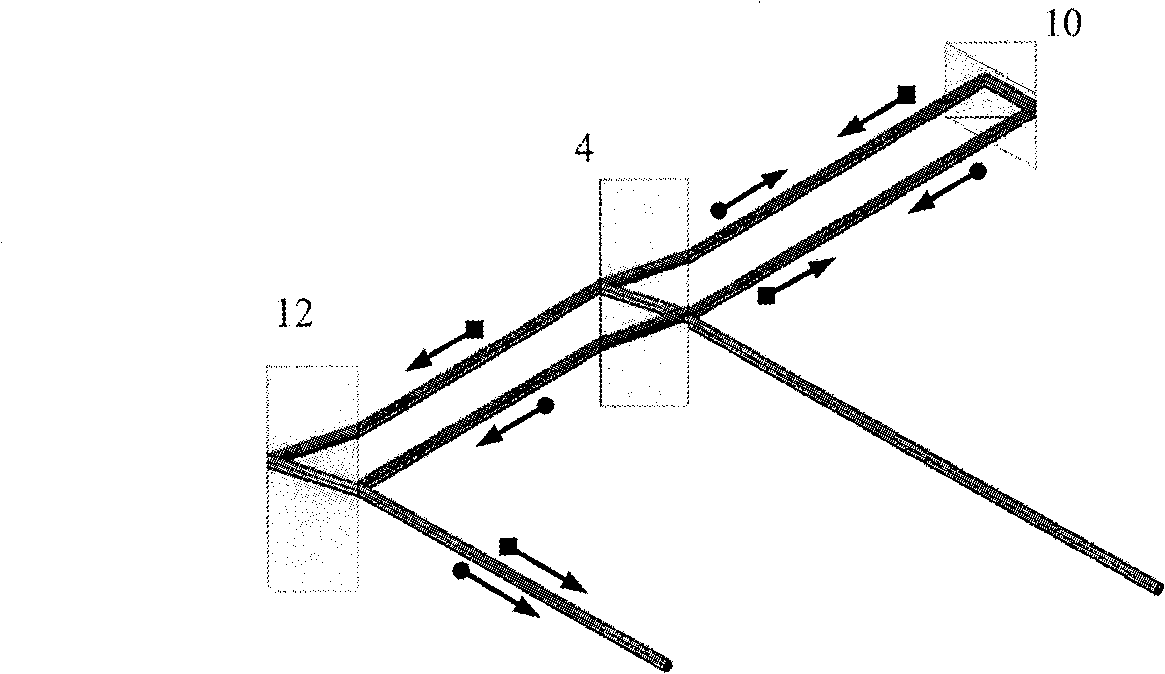

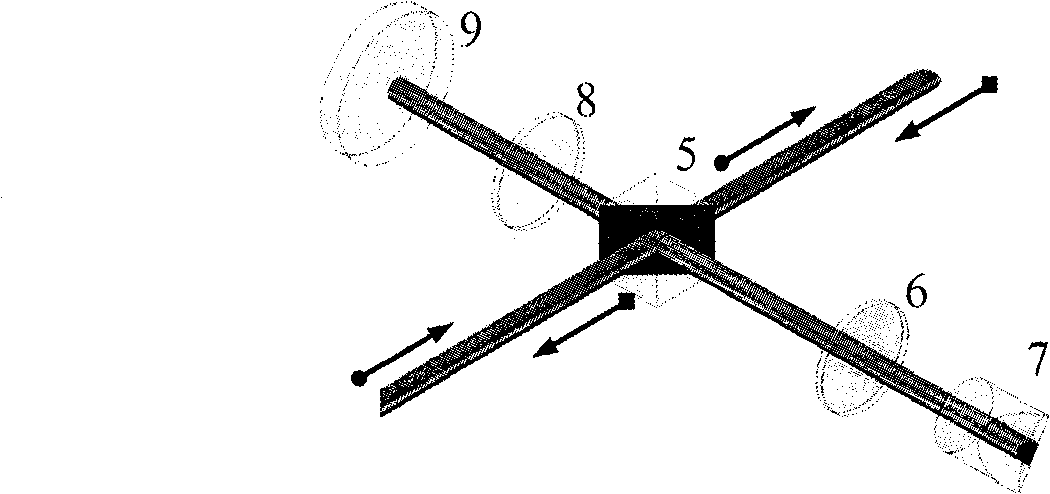

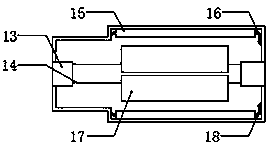

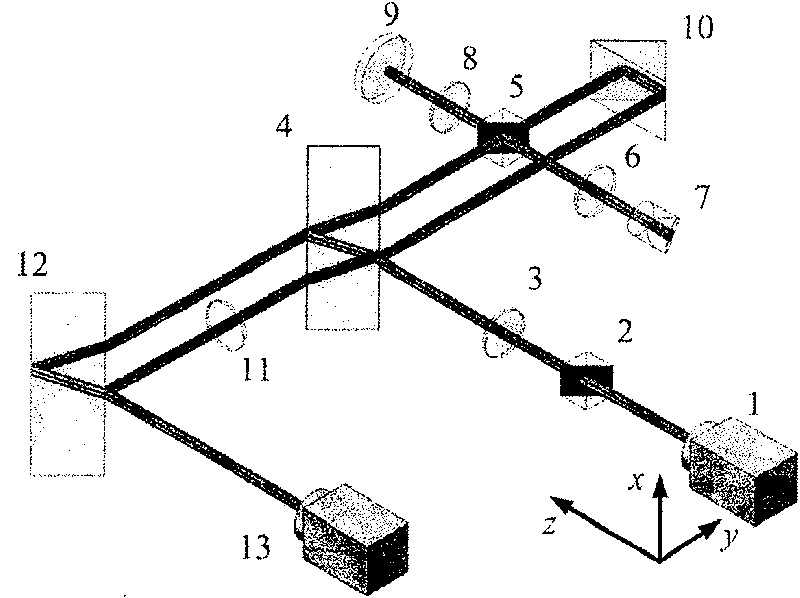

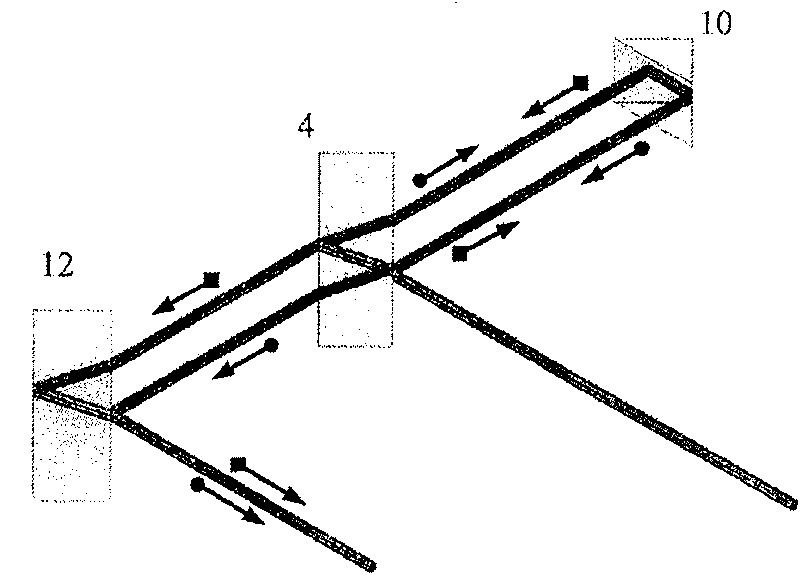

Method and device for measuring light beam orbit angular momentum spectrum

InactiveCN101334315AImprove parallelismImprove coaxialityOptical measurementsPhotometryBeam splittingPower detector

The invention relates to a method for realizing beam orbital angular momentum spectrometry, which belongs to the technical field of laser application. The invention consists of a light source to be tested, two polarization dispersion prisms, 1 / 2 wave plate, two parallel optical flats, two pieces of 1 / 4 wave plates, a total reflector, a rectangular prism, a Porro prism, a Pi / 2 phase delay piece and a power detector. The invention adopts the two parallel optical flats and the rectangular prism to realize the beam splitting and the beam combining of the beams, ensure the good parallelism of beam splitting light and the coaxiality of beam combining light, and realize the complete identical optical paths and attenuation of the two bunches of light. The invention adopts the polarization dispersion prism, the total reflector, the Porro prism and the two 1 / 4 wave plates to realize the beam splitting, and the two bunches of light obtained by the beam splitting rotate coaxially to further realize the coaxial superimposition of the beam and a rotating mirror image thereof. The orbital angular momentum spectrum of an incident beam can be analyzed by measuring the relation between the power of the beam combining light and the rotation of the Porro prism. The method of the invention has application value in the laser intelligence processing field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

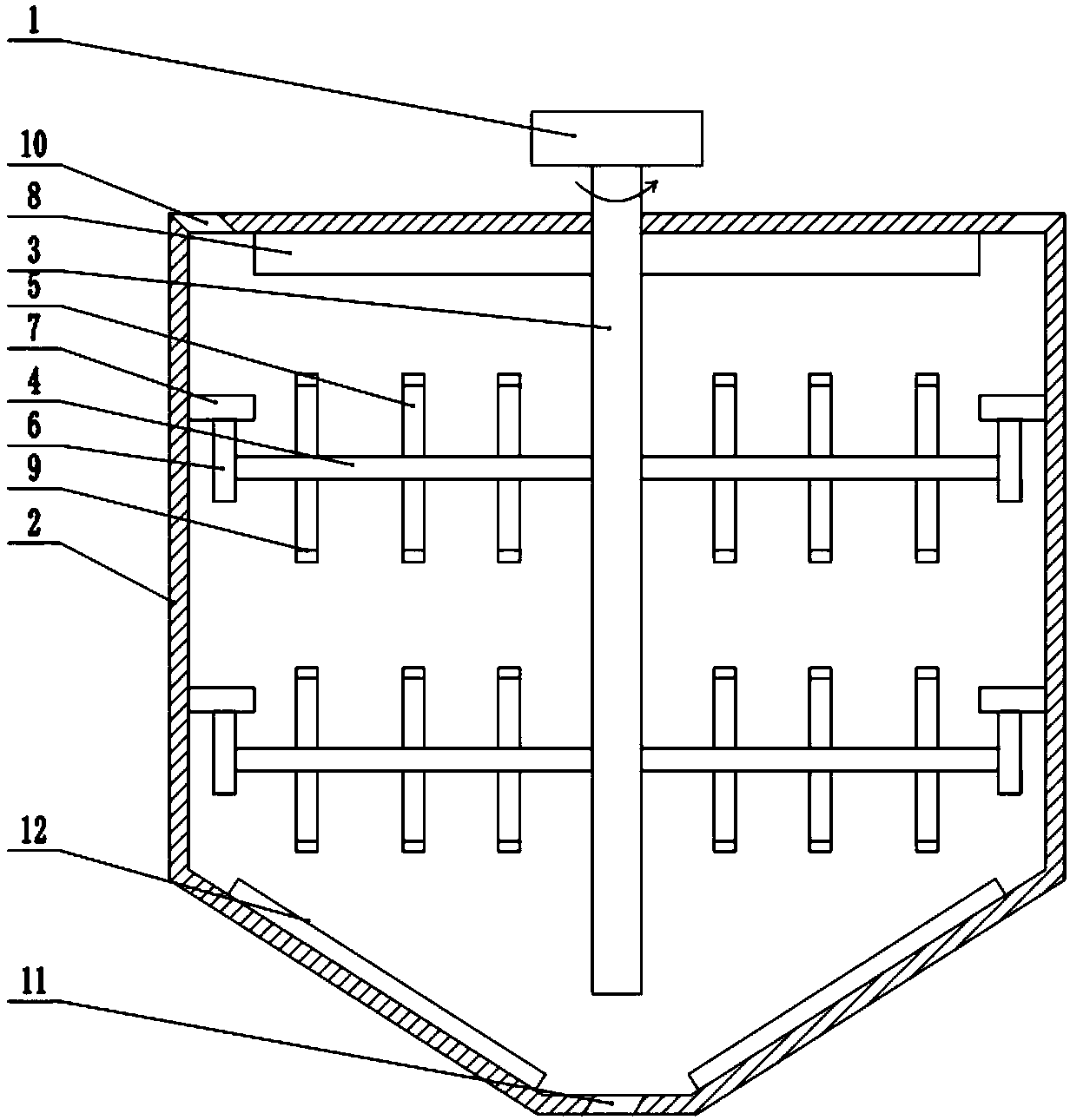

Pet food stirring device

InactiveCN108404760AAchieve circumferential stirringStir wellFeeding-stuffTransportation and packagingEngineeringMagnetic polarity

The invention discloses a pet food stirring device. The pet food stirring device comprises a motor, a housing and a vertical spindle; the top surface of the housing is provided with a feeding port, and the center of the top surface of the housing and the spindle are rotatingly sealed; the spindle is rotatingly matched with a horizontal first stirring rod which is perpendicularly provided with a second stirring rod, and the end portion of the first stirring rod is provided with a disc; the inner wall of the housing is fixedly provided with a ring-shaped baffle, and the circumference of the discabuts against the ring-shaped baffle; the second stirring rod is composed of a shaft rod and stirring blades, and the first stirring rod is provided with a sliding groove inside which the shaft rod can penetrate and slide; both extended ends of the shaft rod are connected with the stirring blades, and the shaft rod between the stirring blades and the first stirring rod is provided with a first spring in a sleeve mode; the inner wall of the top surface of the housing is provided with a first magnet, the stirring blades are provided with a second magnet, the closes ends of the first magnet andthe second magnet are identical in magnetic polarity, the lower portion of the housing is in an inverted cone shape, and the bottom of the housing is provided with a discharging port. The pet food stirring device can uniformly stir pet food.

Owner:CHONGQING SIWEITE PET SUPPLIES CO LTD

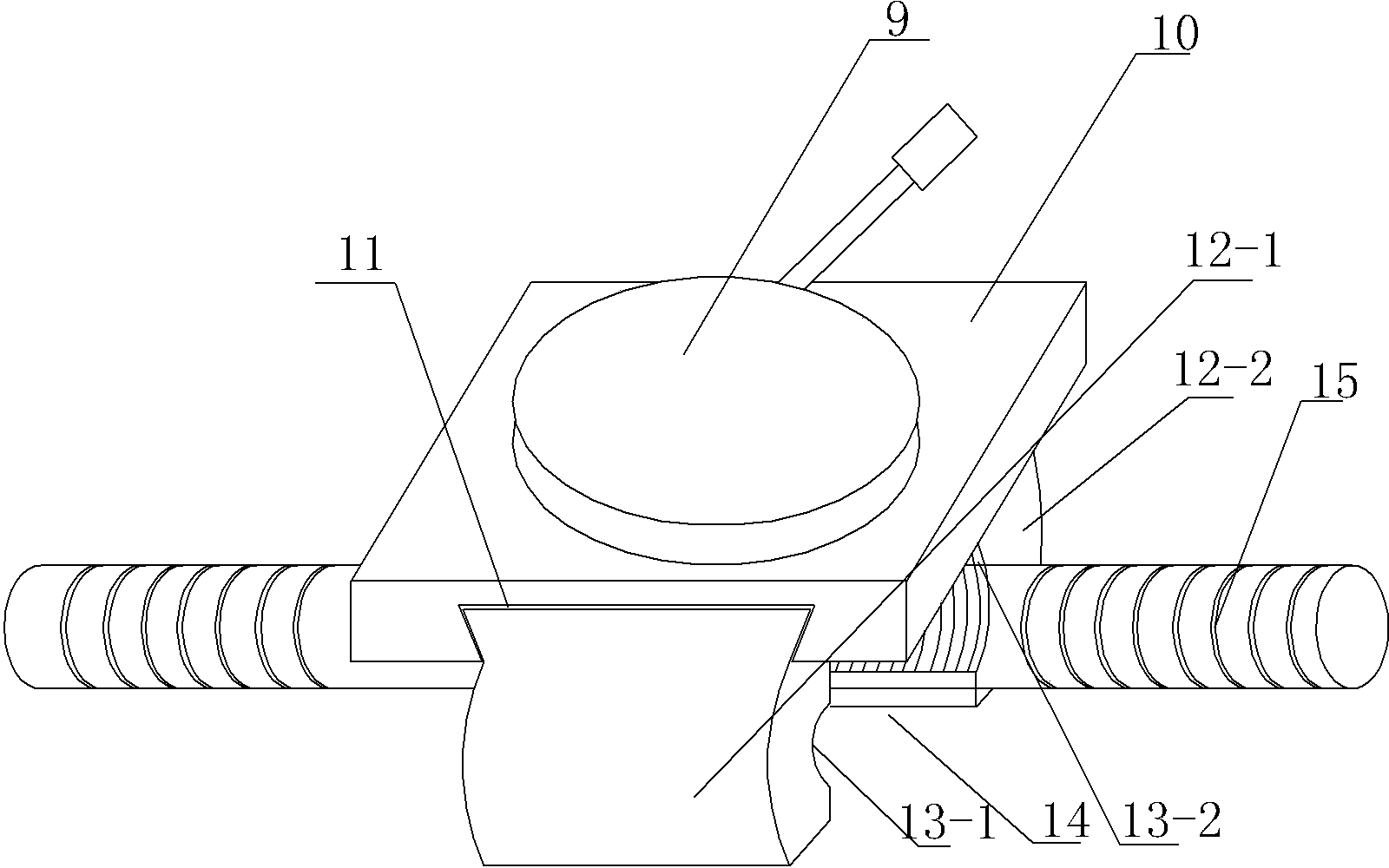

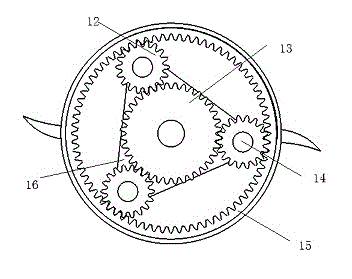

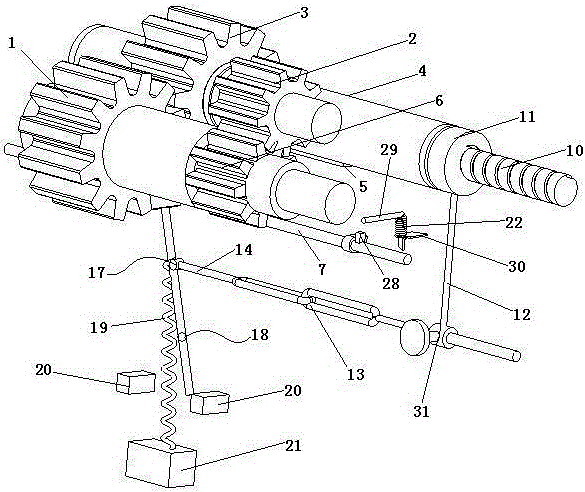

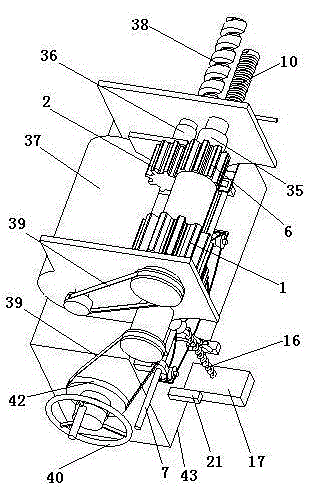

Horizontal type smashing machine

InactiveCN107051676AAchieve reverse rotationHigh shear forceGrain treatmentsEngineeringMechanical engineering

The invention discloses a horizontal pulverizer, which comprises a primary pulverizing barrel; a drum is arranged inside the primary pulverizing bucket, and rotating shafts are arranged at both ends of the drum, and the rotating shaft protrudes from the primary pulverizing bucket; Pulverizing motor; the two rotating shafts are provided with a planetary gear structure. The planetary gear structure includes a sun gear, a planetary gear and a ring gear. The sun gear is fixedly connected to the rotating shaft, and the ring gear is fixedly connected to the primary crushing barrel. A connecting rod is provided between the gears, and a plurality of crushing rods are arranged on the connecting rod; a plurality of cutting blocks are arranged on the inner surface of the housing, and the cutting blocks and the chopping blocks are arranged in dislocation; the upper end of the primary crushing barrel is provided with a feeding Mouth; the casing is provided with a ring gear, and the ring gear is equipped with a gear matched with it, and the gear is provided with a motor to drive it to rotate. The horizontal pulverizer can improve working efficiency.

Owner:四川东工电机有限公司

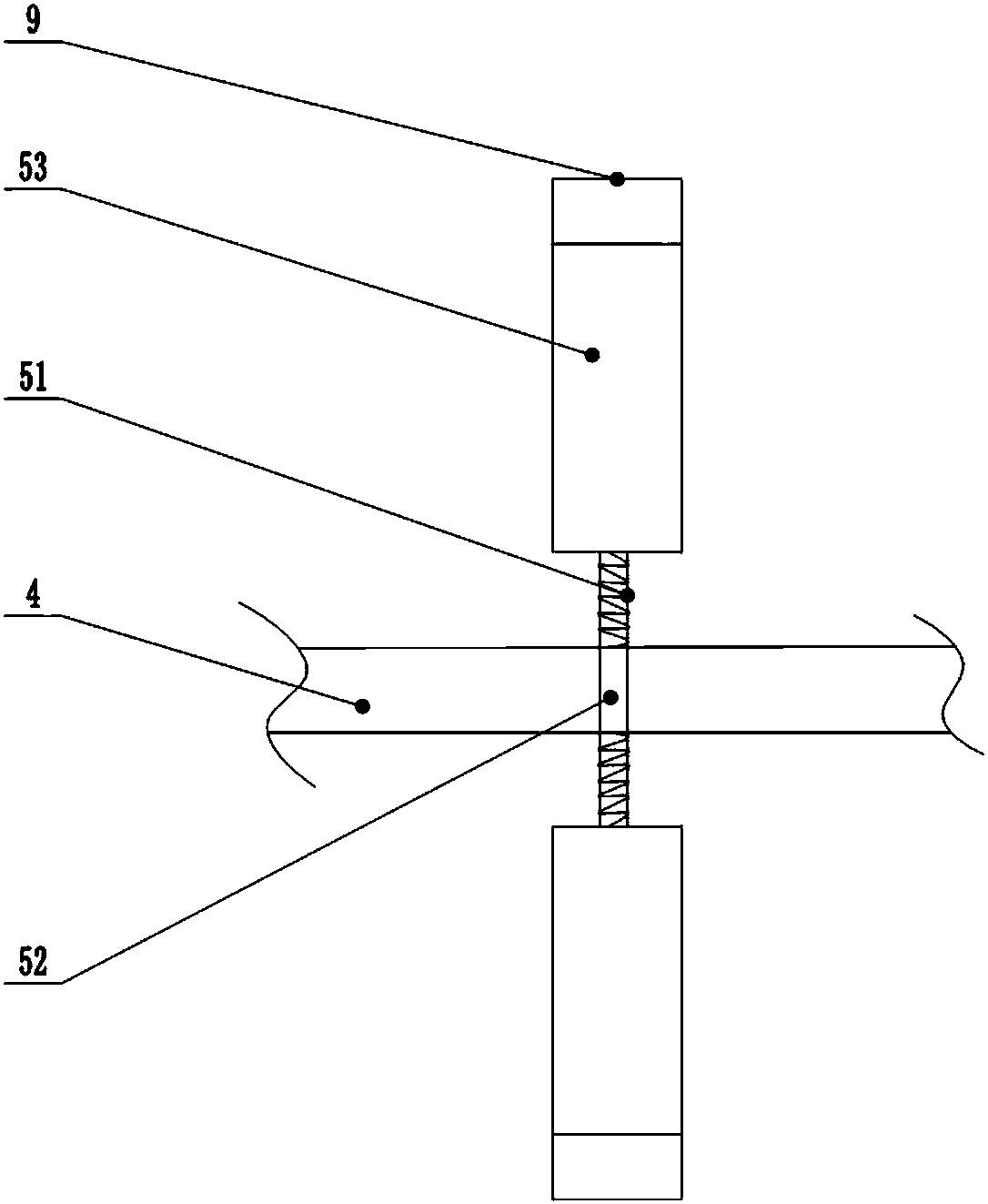

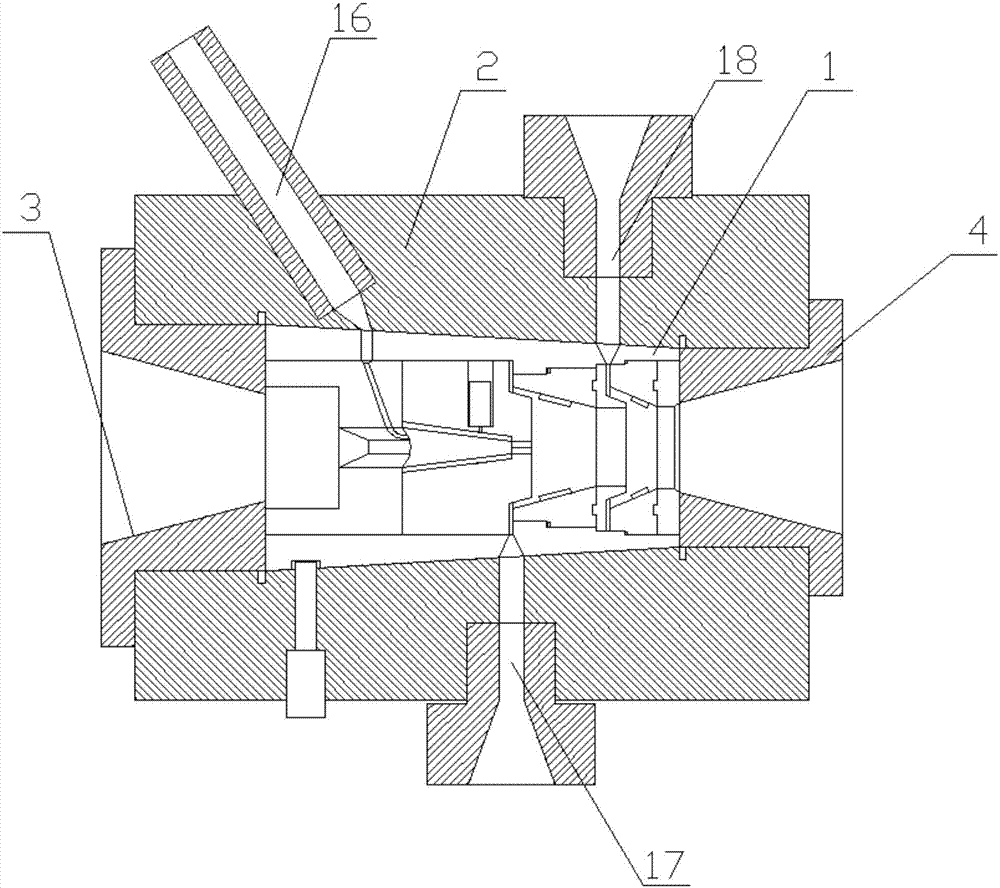

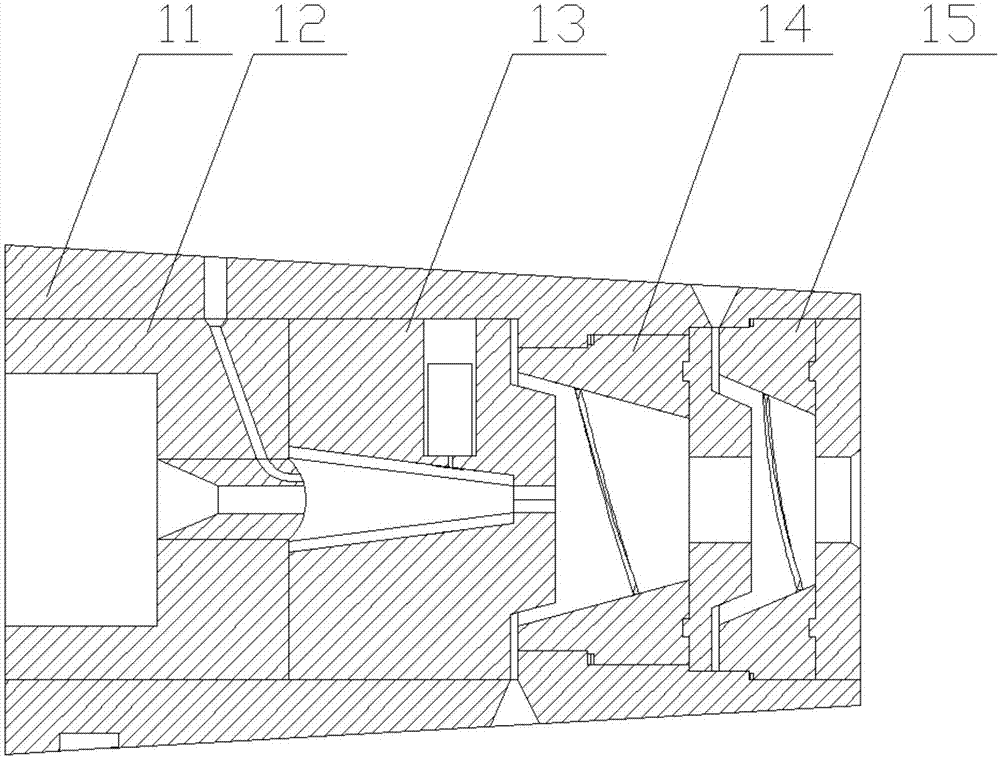

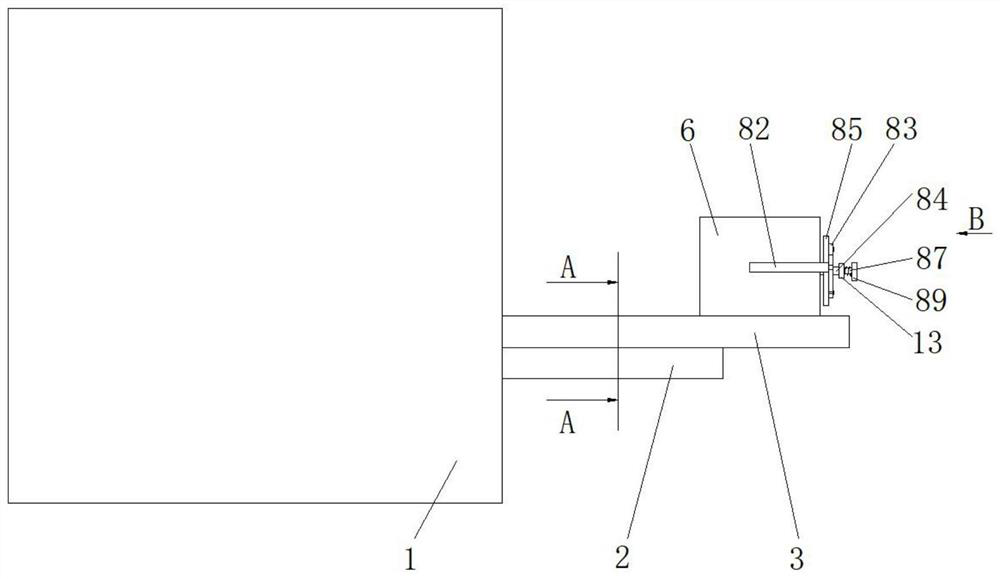

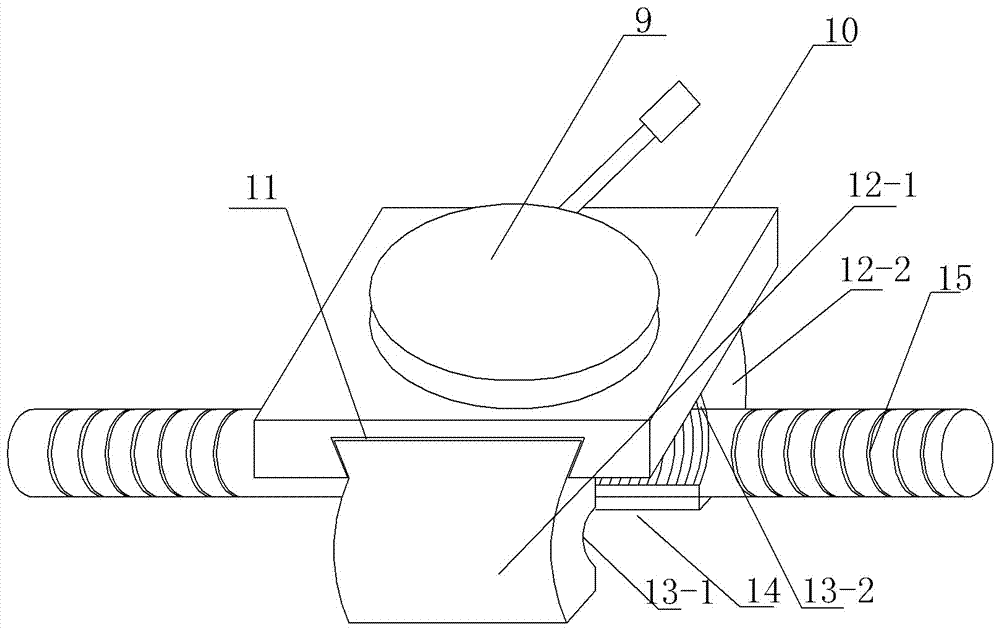

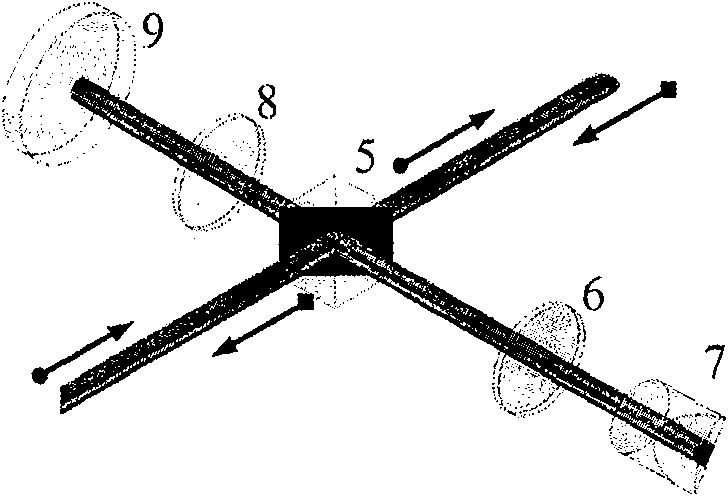

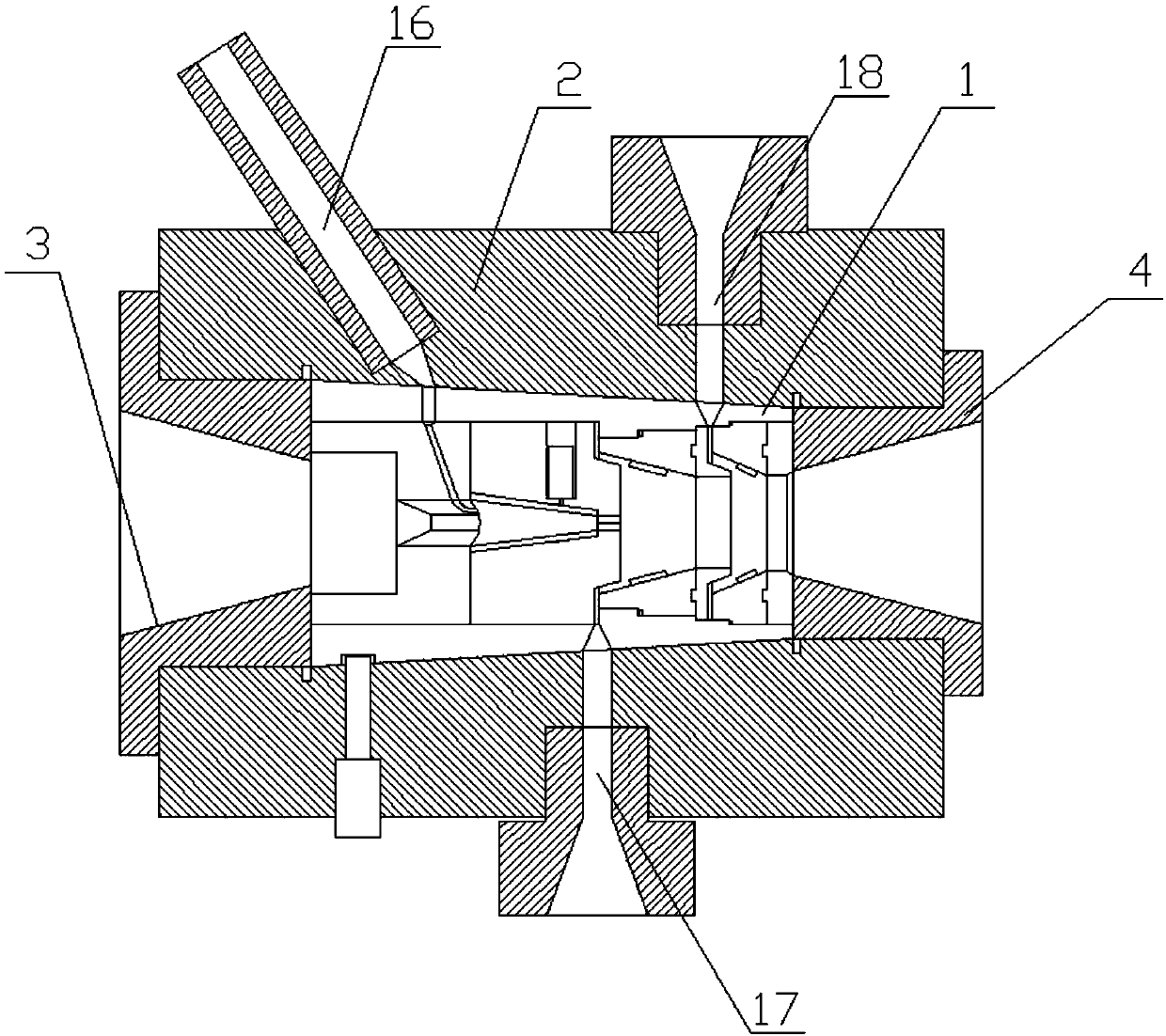

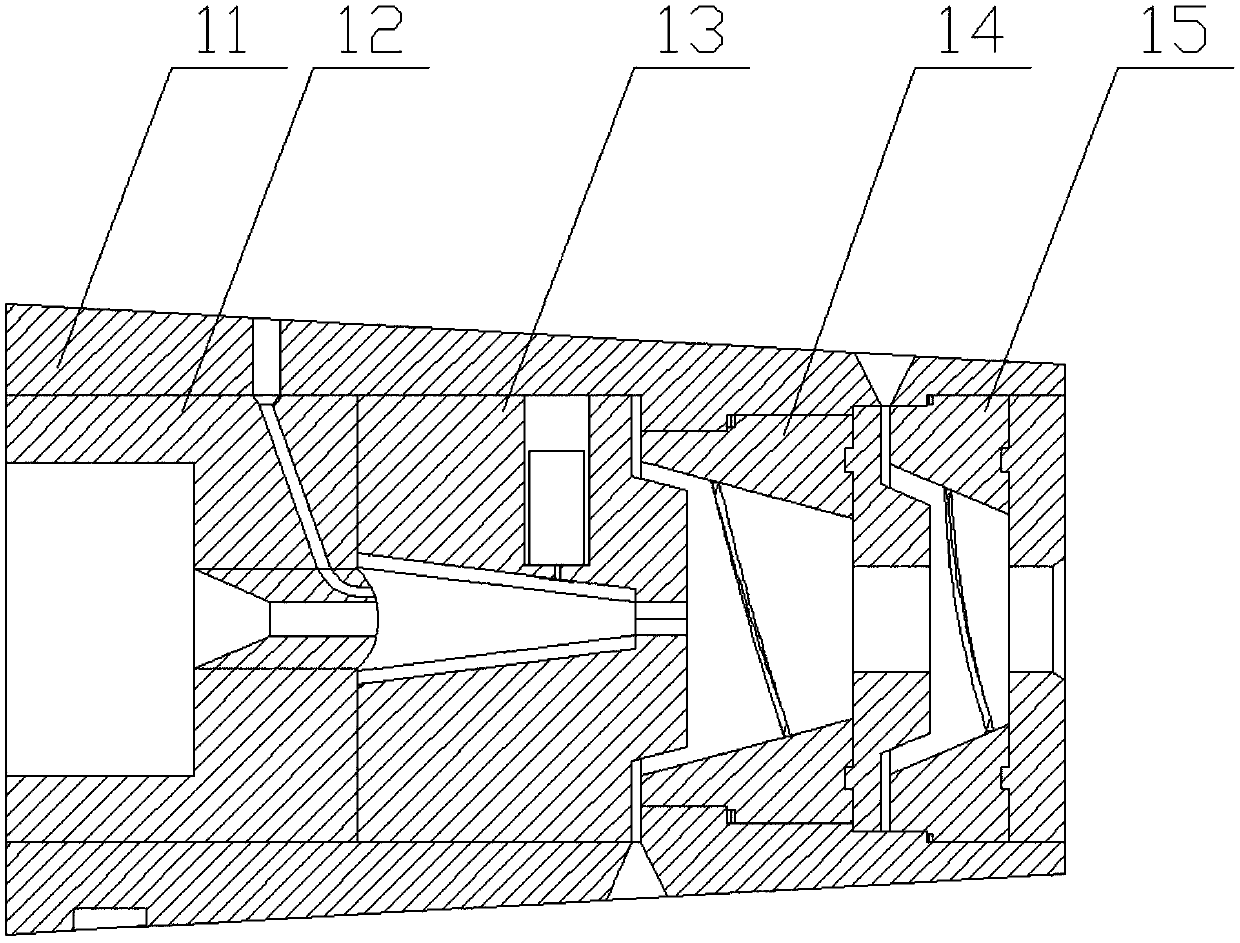

Fluid atomizing nozzle, density measuring device with nozzle and drying device with nozzle

InactiveCN105750111AAchieve reverse rotationAchieve hybridMachine part testingLiquid spraying apparatusUltra high speedAtomizer nozzle

The invention provides a fluid atomizing nozzle, a density measuring device with the nozzle and a drying device with the nozzle. According to the fluid atomizing nozzle, fluid enters the atomizing nozzle in the tangential direction of the side wall of the atomizing nozzle, the ratio of the upper diameter to the lower diameter of an inner cavity of the nozzle is increased, the methods that the rotating direction of the fluid is controlled, and the outlet diameters and number of single-hole sprayers on different atomizing nozzles, fluid pressure, measurement and the like are adjusted are adopted, and rotation of the fluid is improved. When angular momentums of multiple kinds of fluid are the same in size and opposite in direction, mixing among the fluid can be enhanced, the side effect that single fluid enters the inner cavity of the nozzle in the tangential direction can be avoided, and positive effects are generated for improving fuel combustion performance and driving force of rockets and jet aircrafts and on other occasions needing uniform atomizing density; when umbrella-shaped fog columns are needed, rotation of the multiple kinds of fluid can be controlled to be identical to achieve the effect of increasing the diameter of large particles. The effects that the needed minimum pressure is small and the fluid rotates at an ultra-high speed can be achieved without adding a rotating part.

Owner:李依真

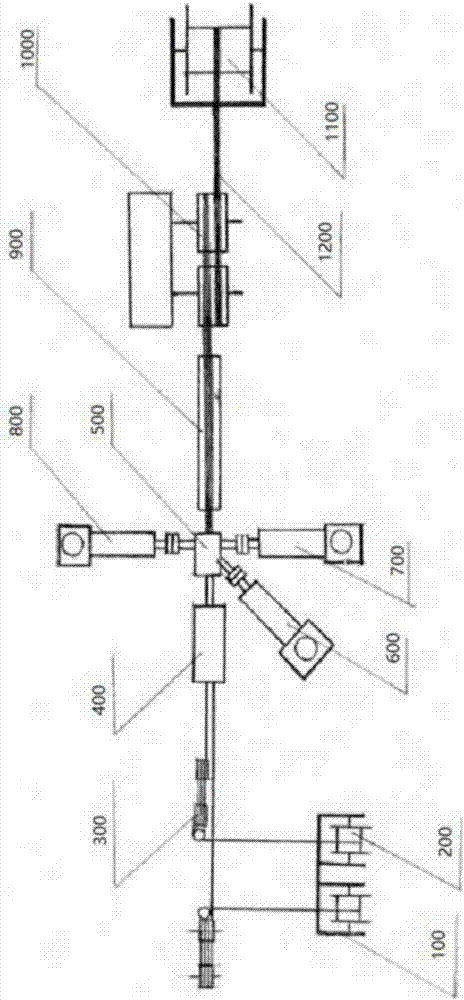

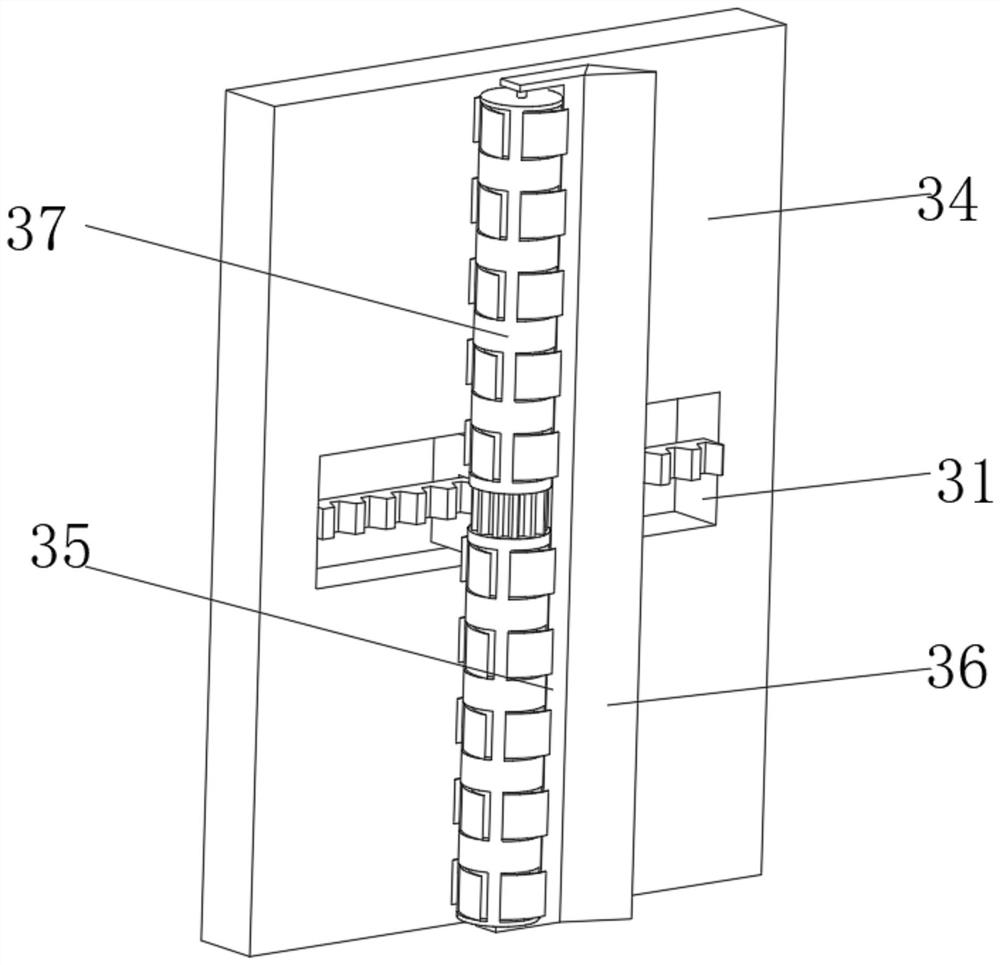

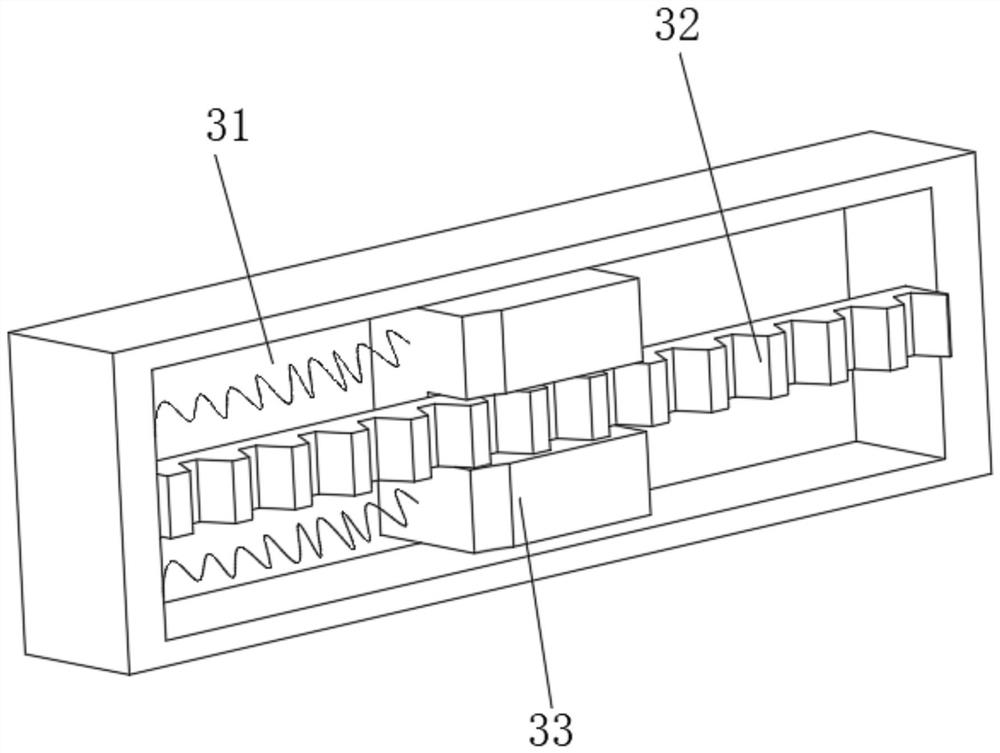

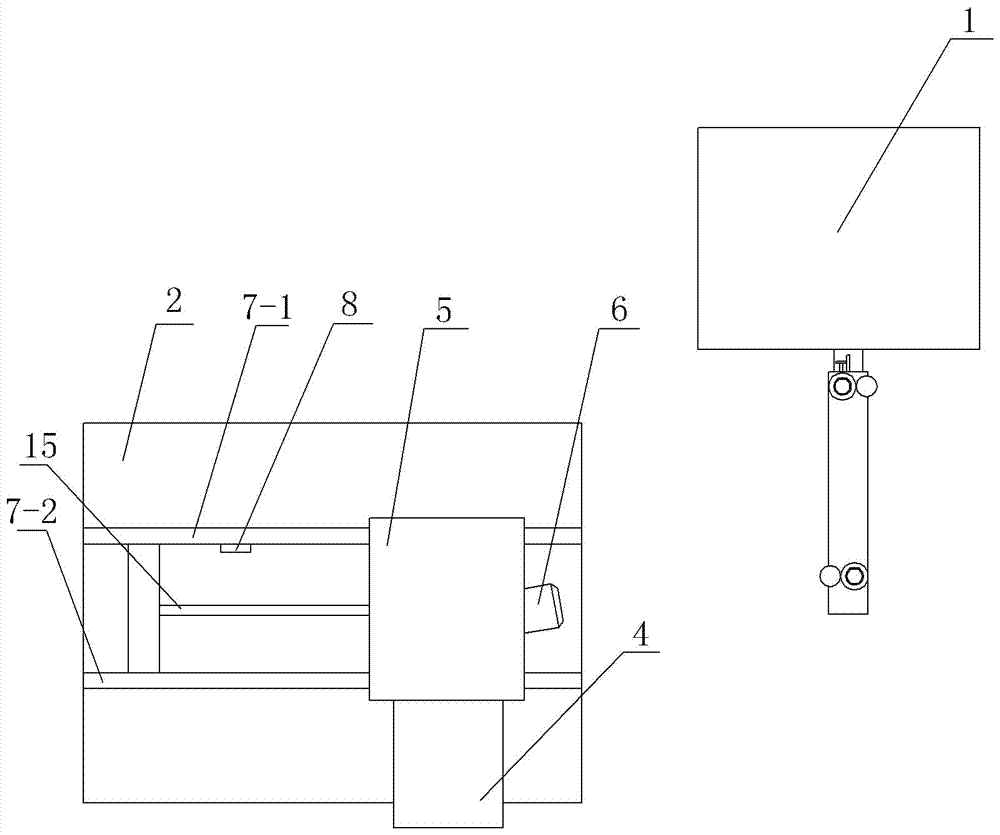

Multi-layer coextrusion device and application method thereof

ActiveCN108000835AAchieve reverse rotationFixed tightlyDomestic articlesCoatingsElectrical conductorInsulation layer

The invention discloses a multi-layer coextrusion device and an application method thereof. The multi-layer coextrusion device comprises a machine head, an active paying-off machine, a conductor paying-off disc, a dance wheel, a heater, a coextrusion machine head, a constant-temperature water tank, a traction device and a winding disc. The coextrusion machine head comprises a composite module, a shell, a front gland and a rear gland. The composite module comprises a die core supporting sleeve, a wire inlet positioning module, an inner conductor layer module, a PTC layer module and an insulation layer module. The PTC layer module comprises a PCT wrapping die and a sizing die. The position, at the PTC layer module, of the die core supporting sleeve is provided with a first annular boss. ThePCT wrapping die is provided with a first linkage part to be matched with the first annular boss, and the PCT wrapping die is in sliding connection with the sizing die. According to the multi-layer coextrusion device and the application method thereof, through the arrangement of a first gear set and a second gear set, reverse rotation of the PTC layer module and the insulation layer module is achieved, and fixation between a PTC heating body layer and a composite insulation layer is tighter.

Owner:ANHUI HUANRUI ELECTROTHERMAL EQUIP

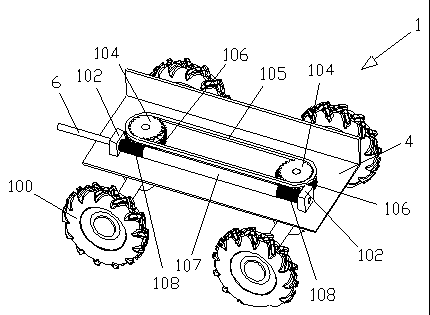

Four-wheel reclamation machine

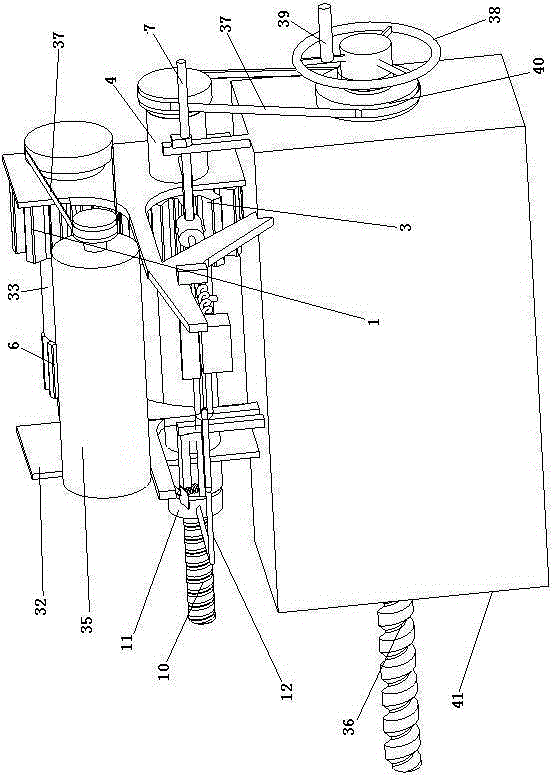

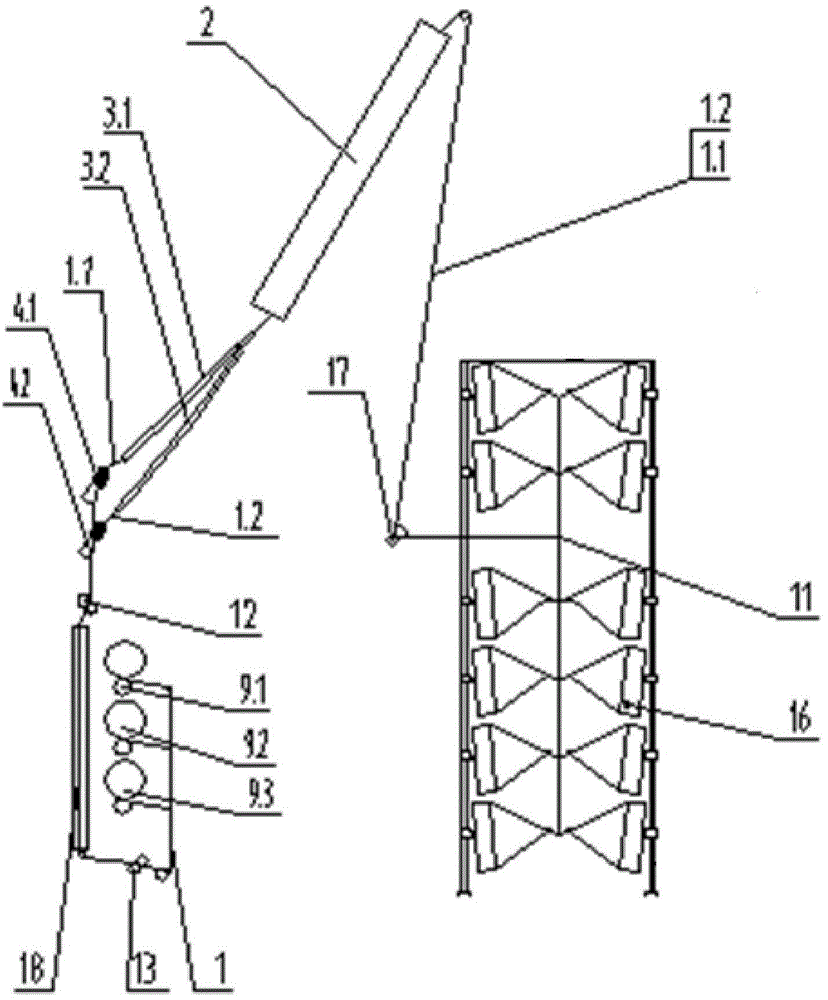

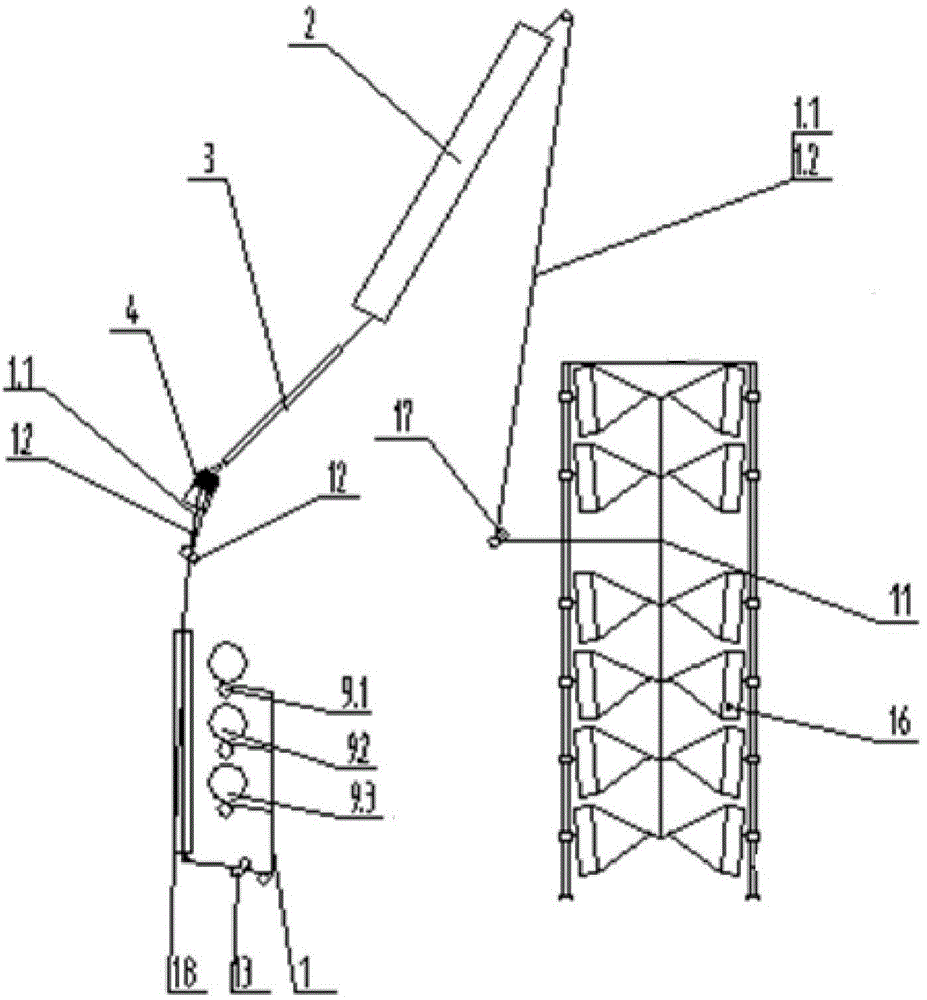

ActiveCN104303644AAchieve reverse rotationThe angle does not changePlantingMechanical steering gearsEngineeringMechanical engineering

The invention discloses a four-wheel reclamation machine, belonging to the field of machines. The four-wheel reclamation machine comprise a traveling mechanism and a power mechanism as well as a reclamation mechanism for reclamation, wherein the traveling mechanism is arranged below a base, a bottom plate is arranged above the base, the power mechanism is arranged on the base plate, and the reclamation mechanism is fixed above one side of the bottom plate. The reclamation machine can be used to dig a trench, drill a ground hole, move a tree and transplant a seedling.

Owner:安徽铸星机械制造有限公司

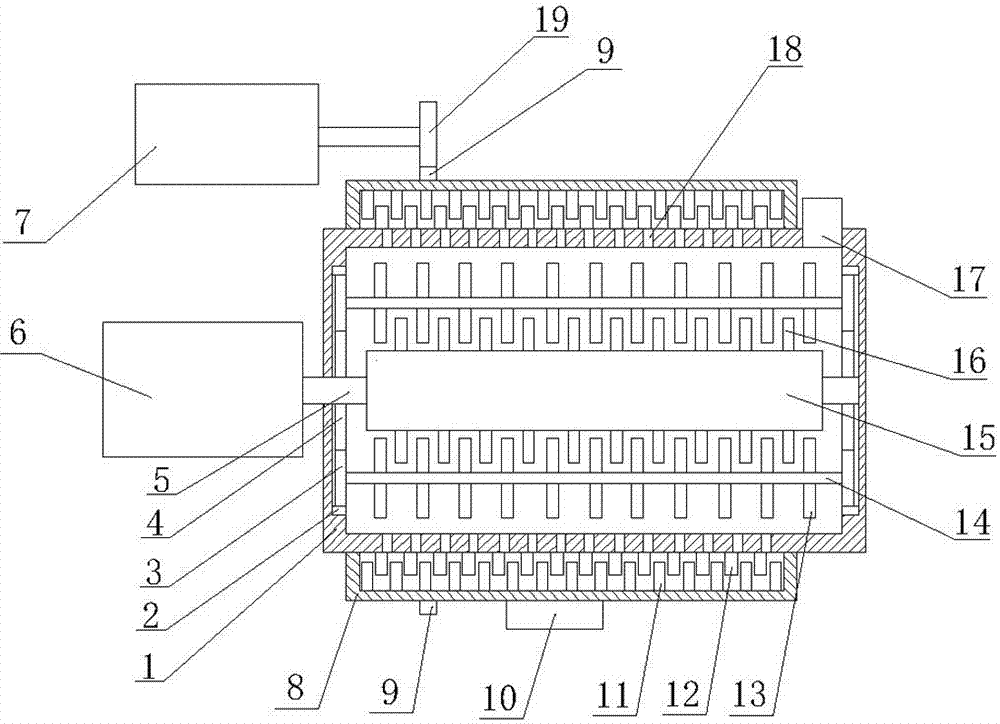

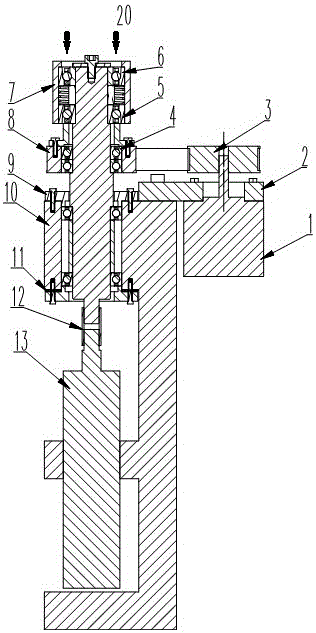

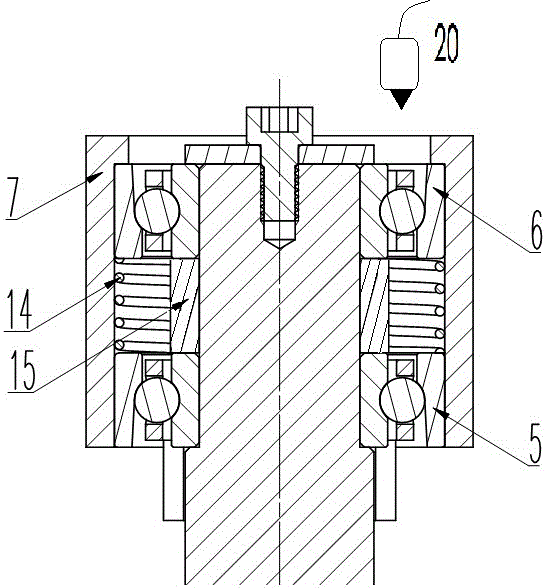

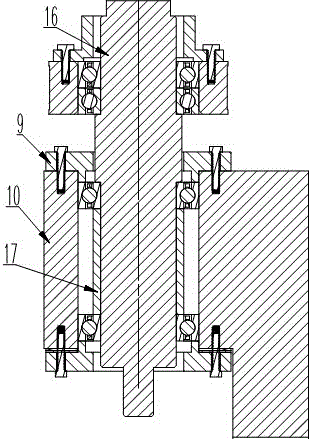

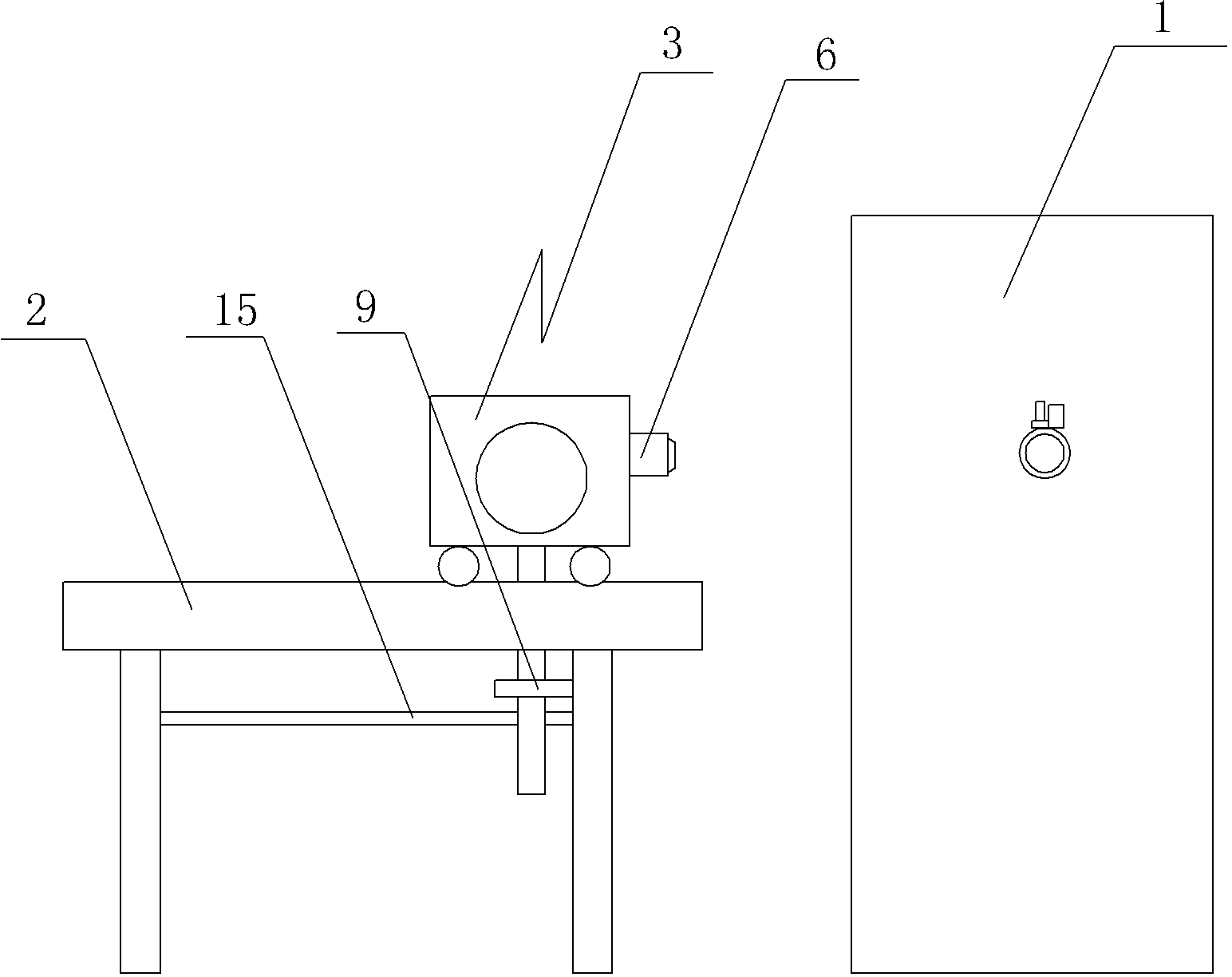

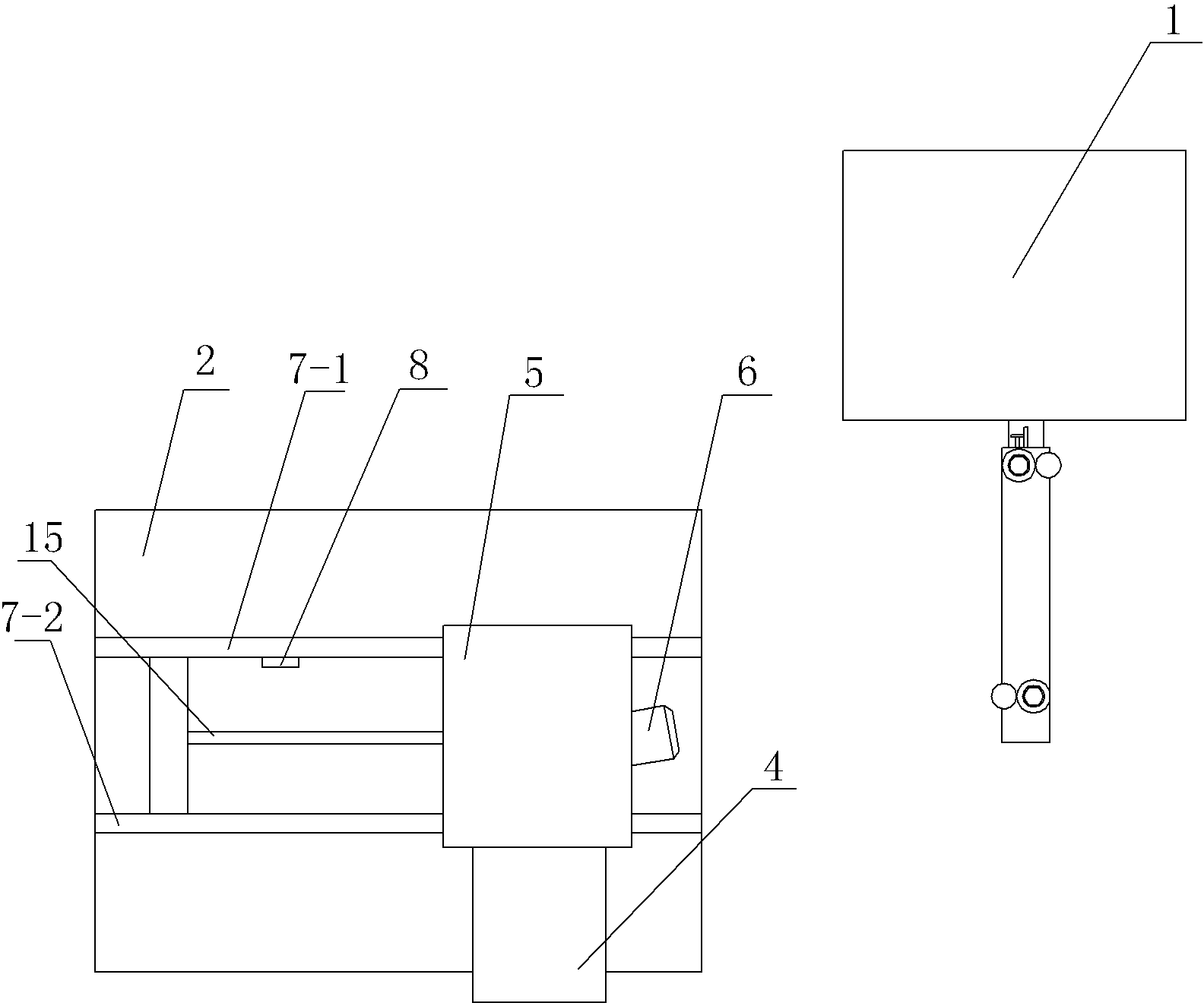

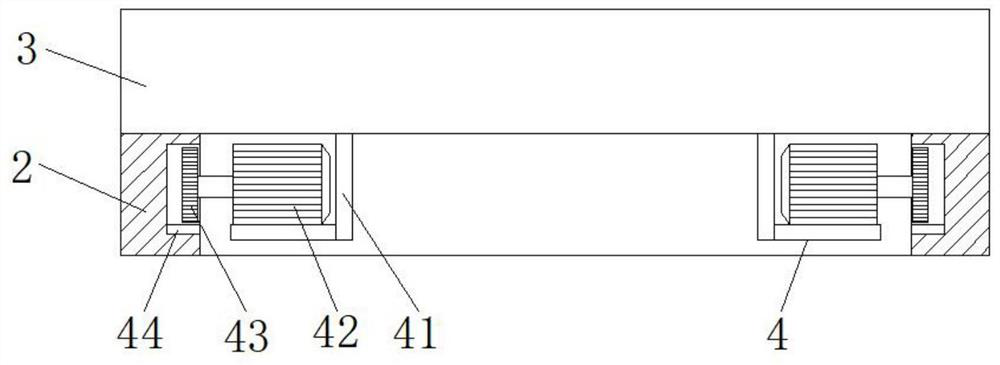

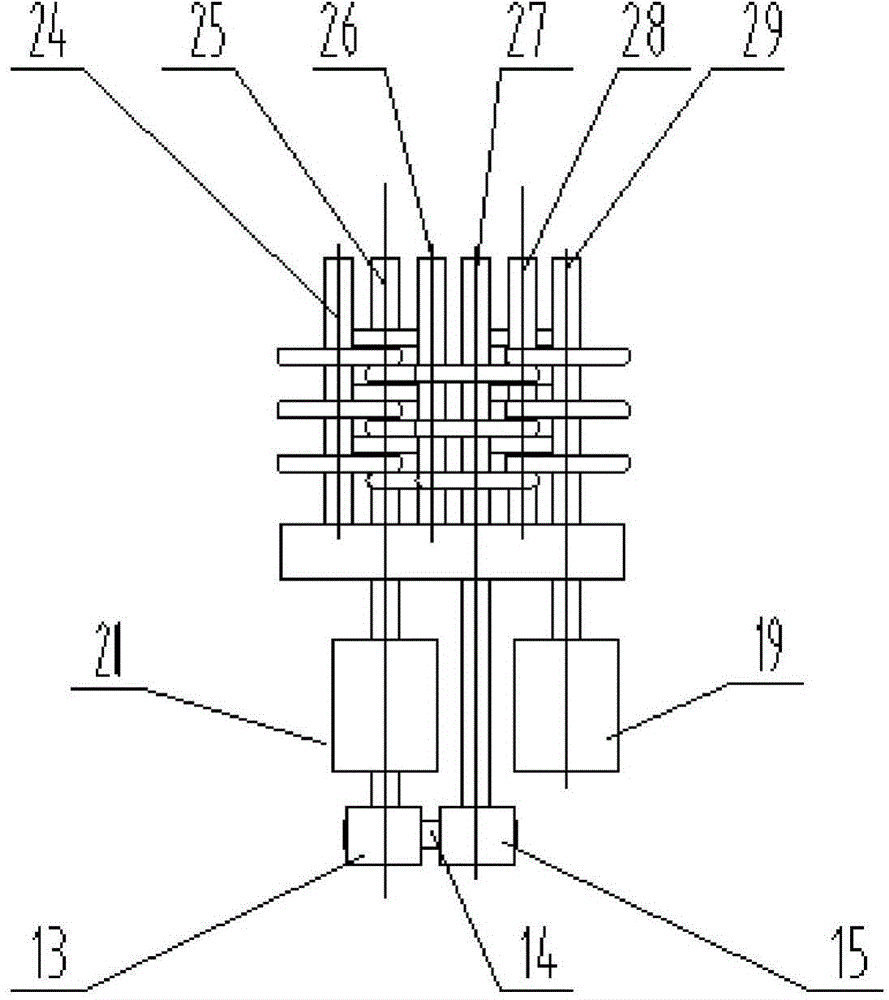

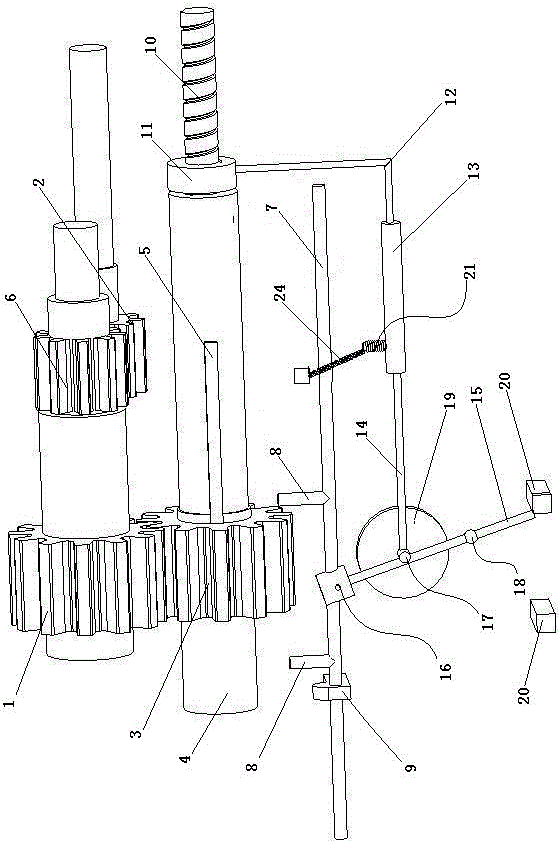

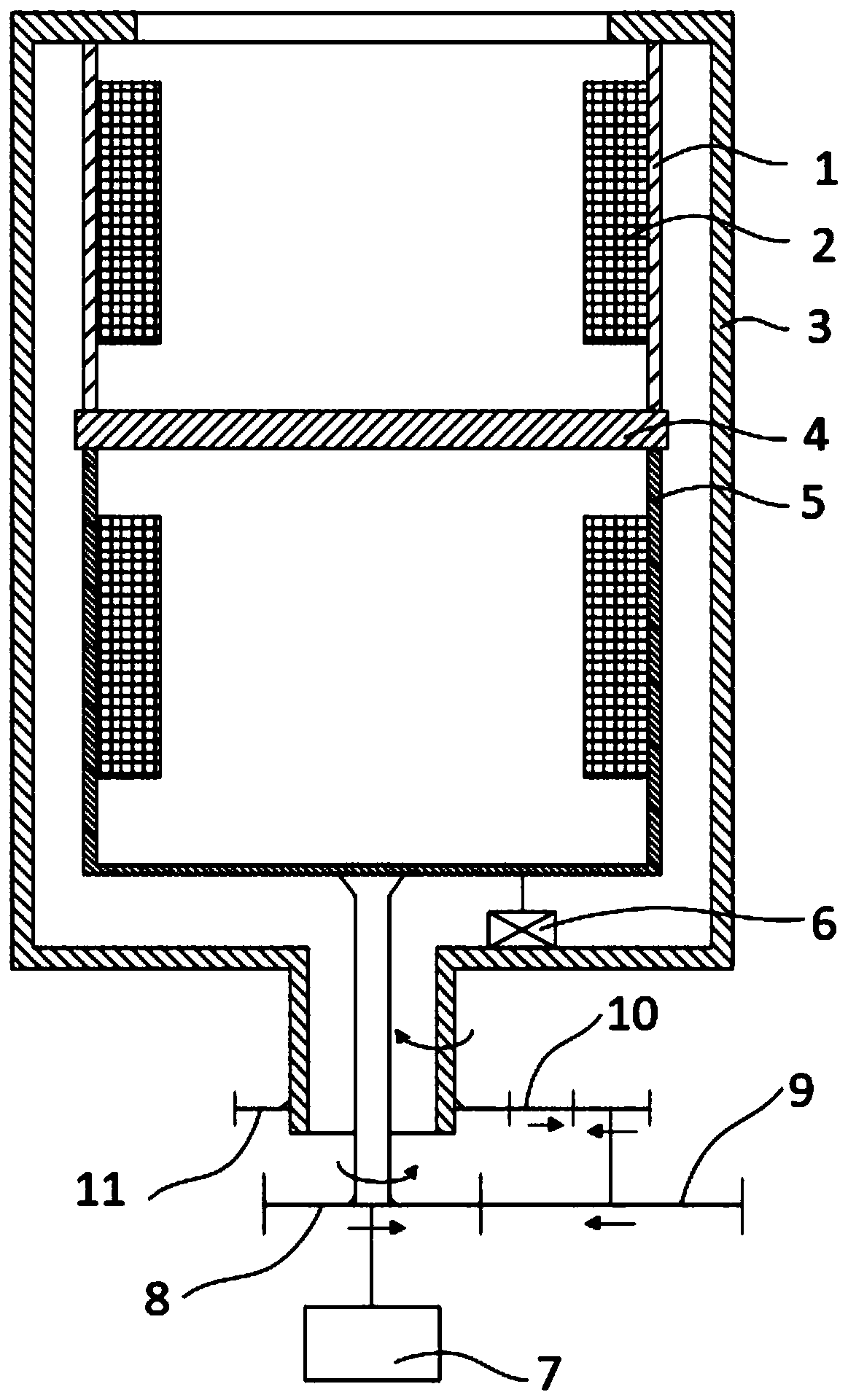

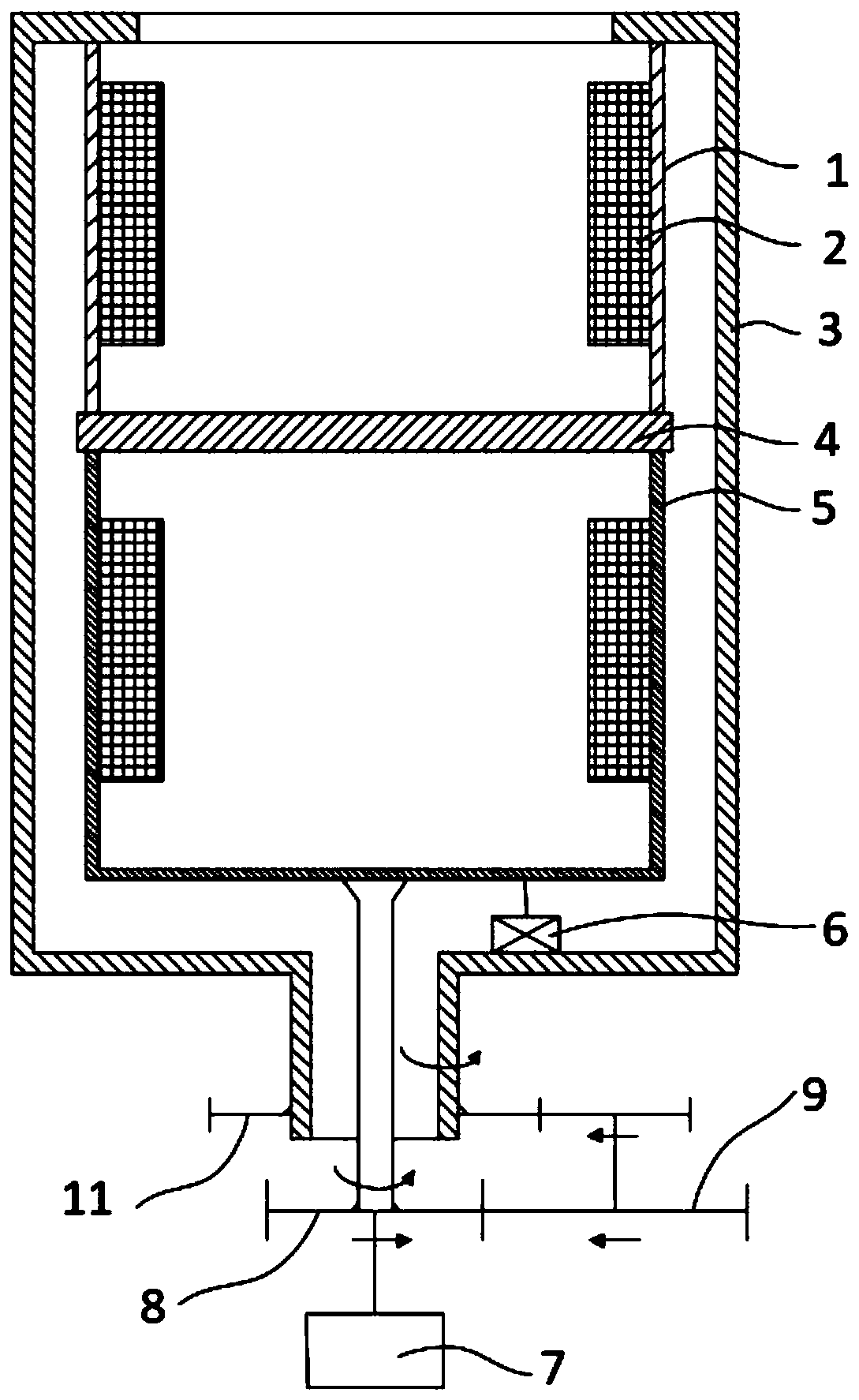

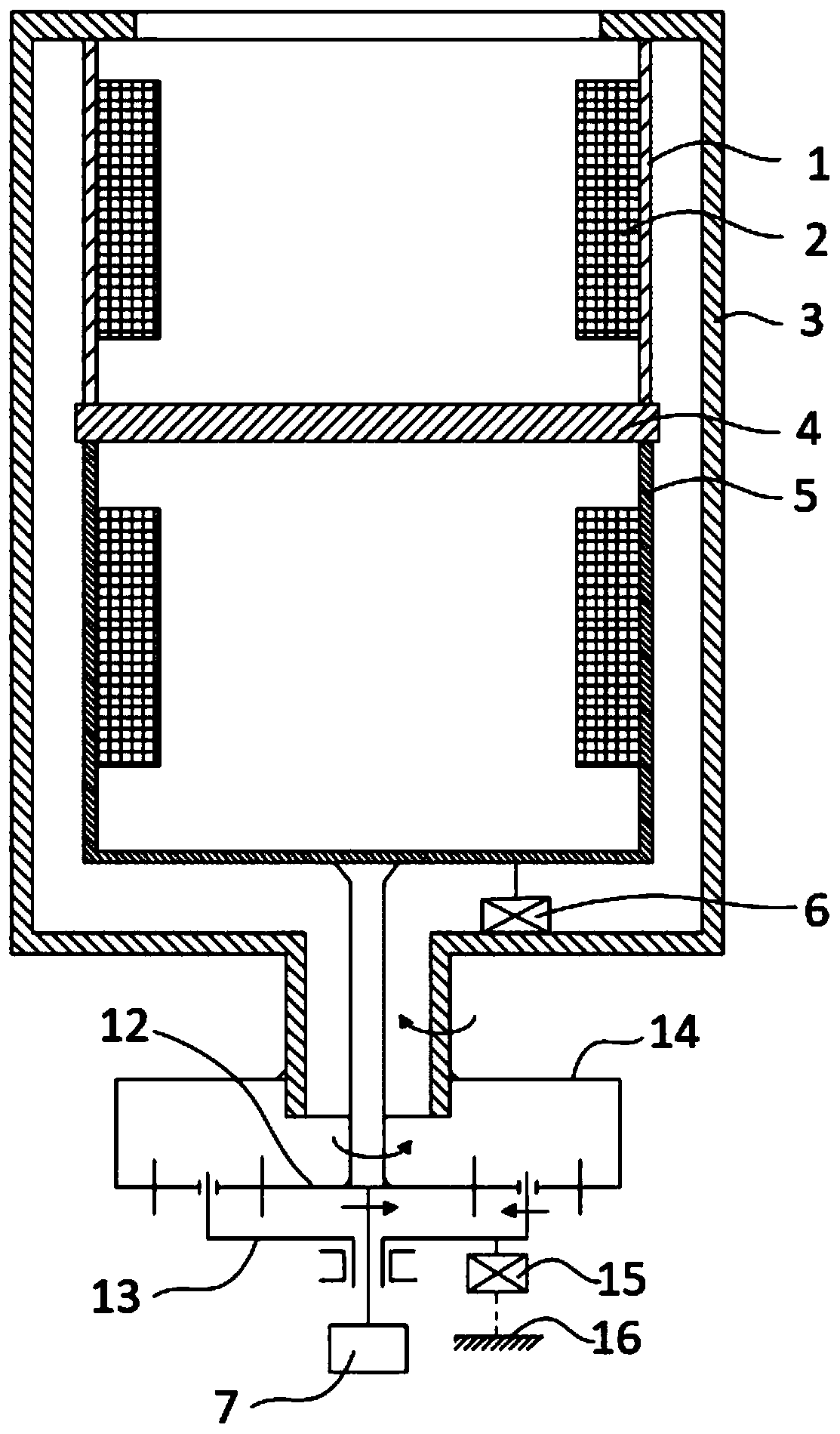

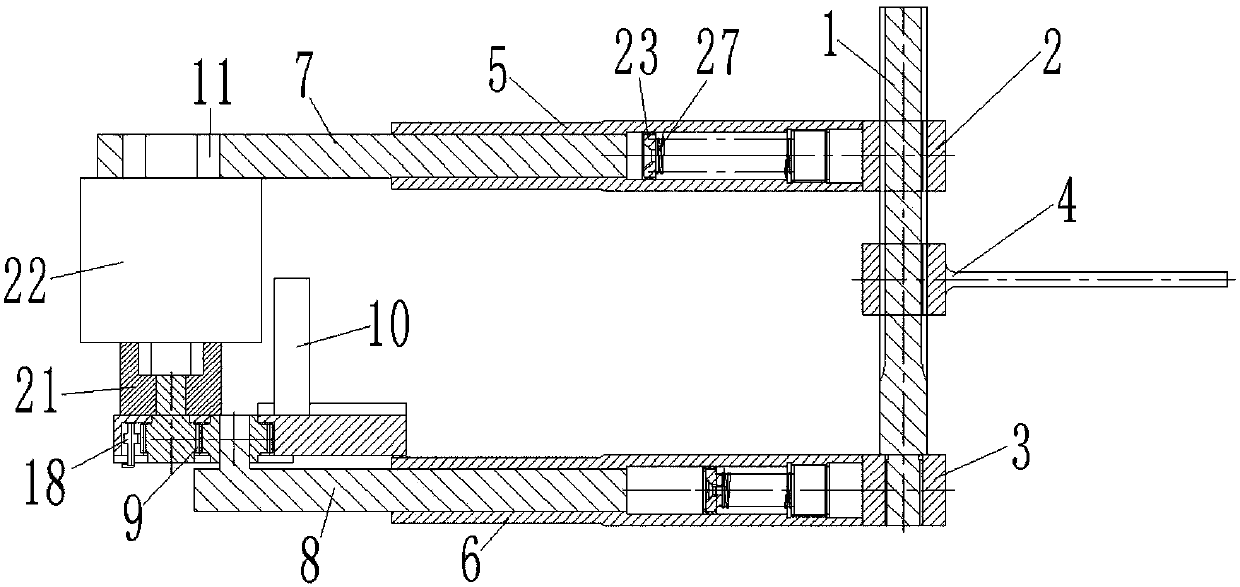

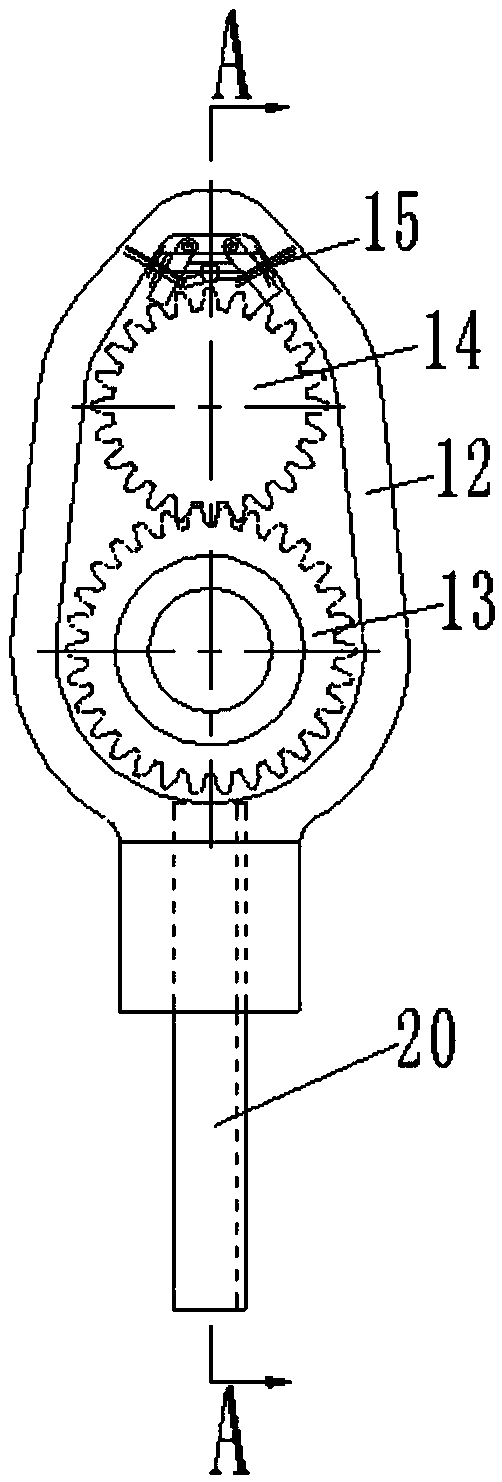

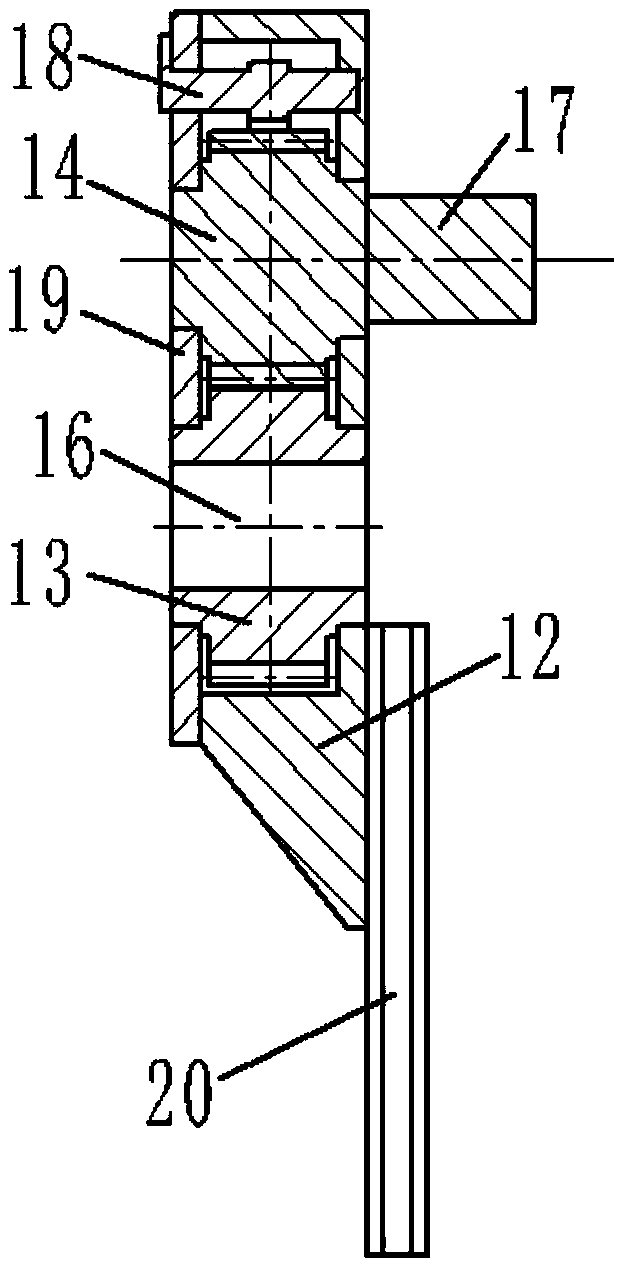

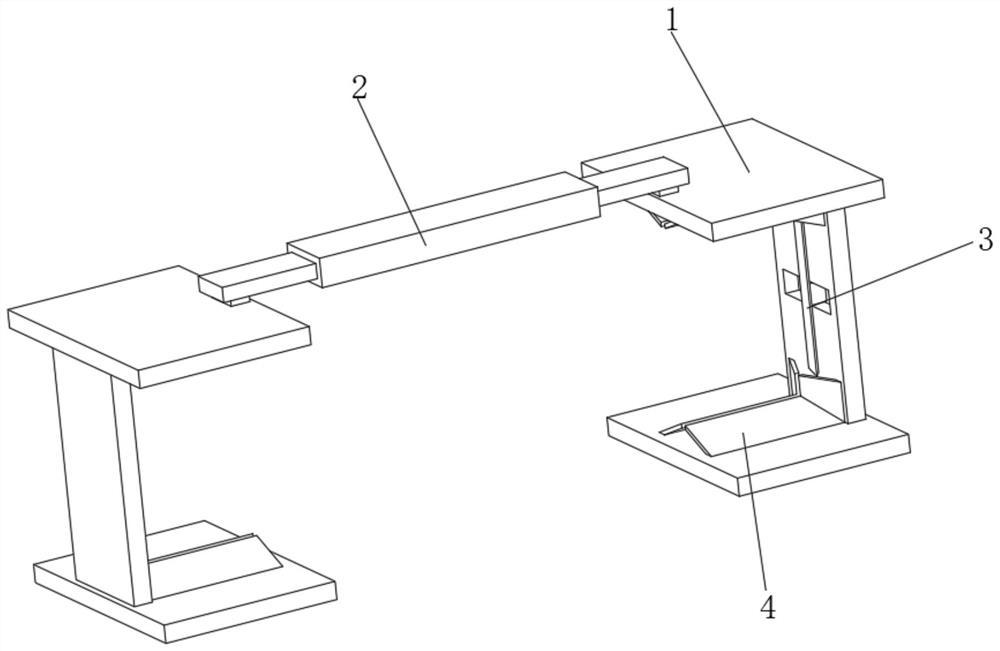

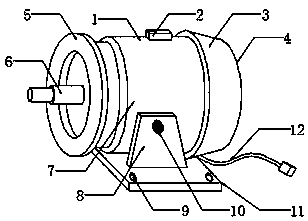

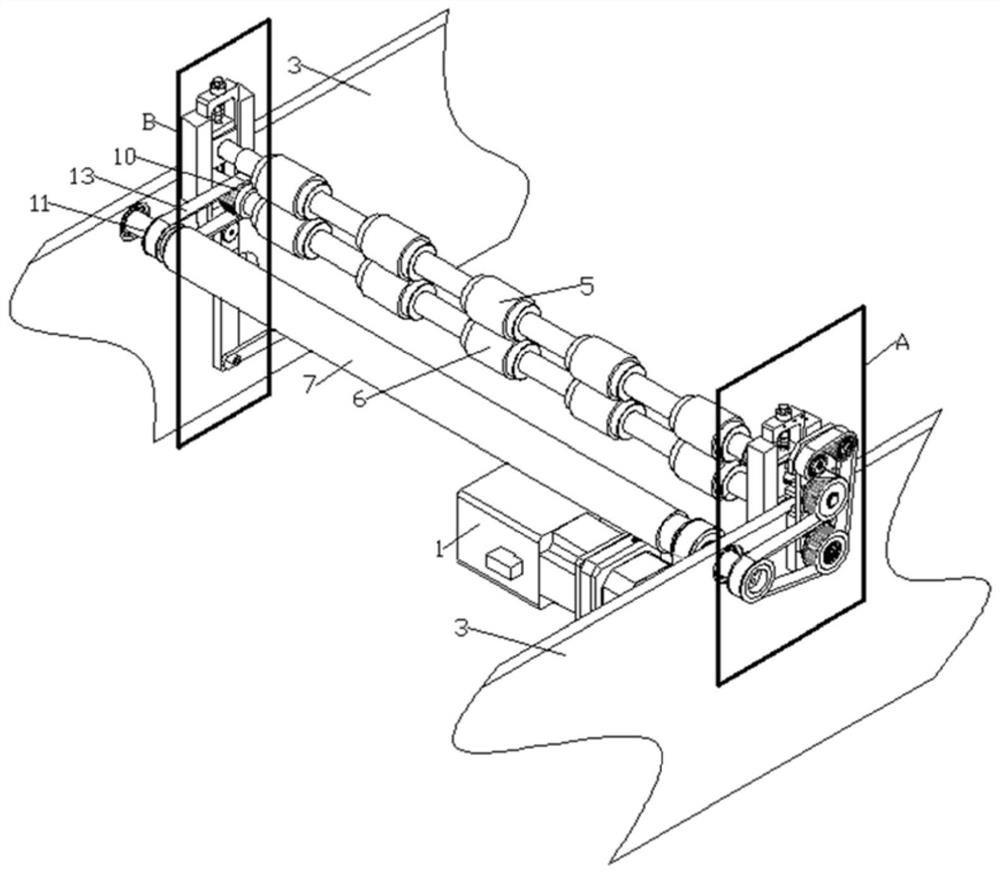

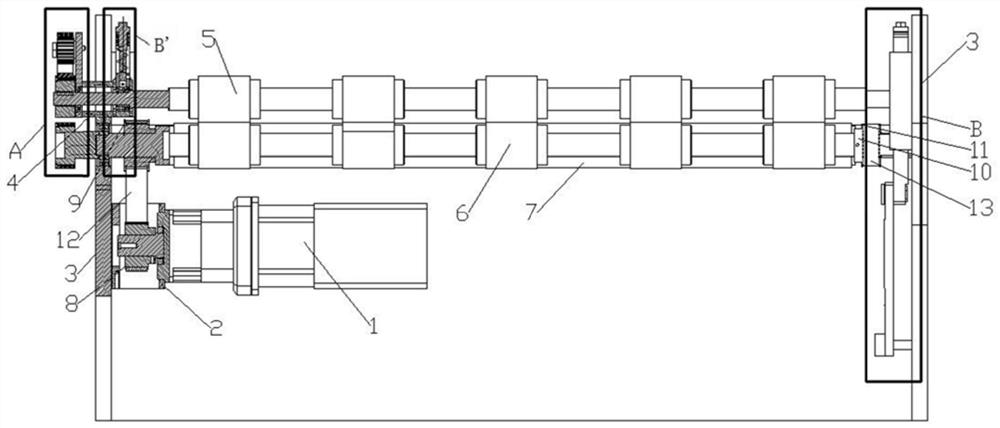

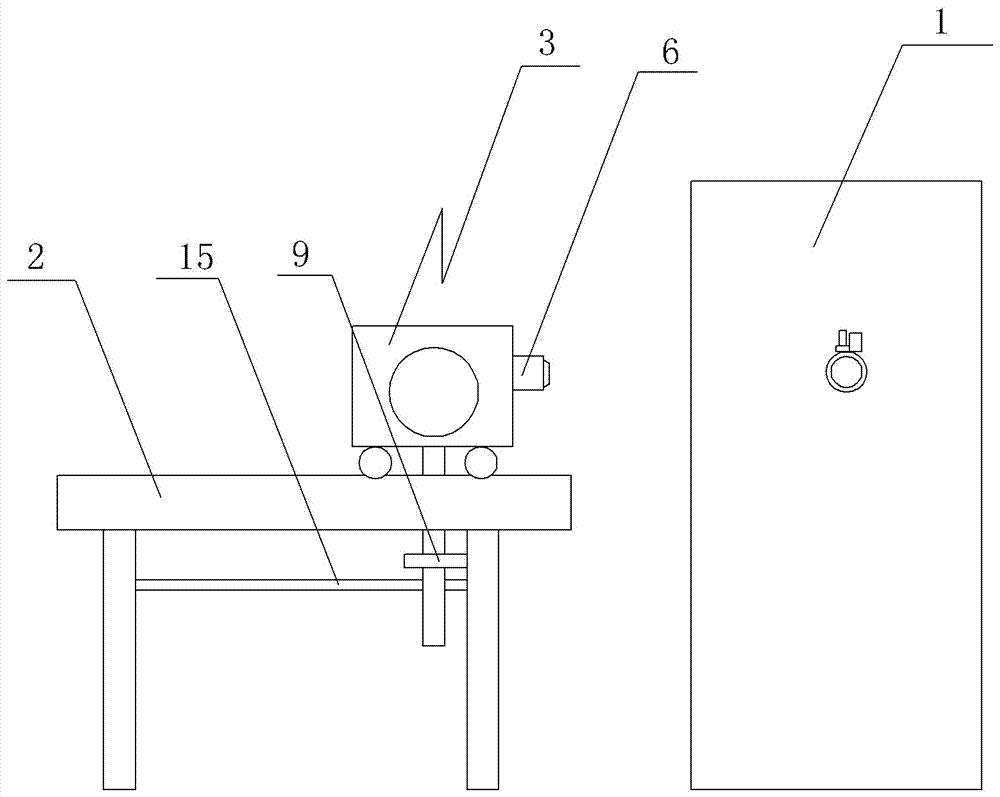

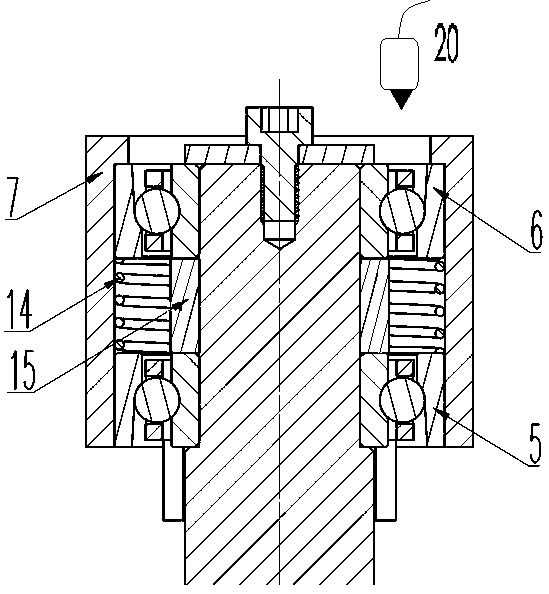

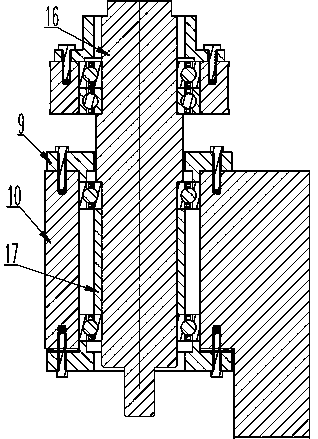

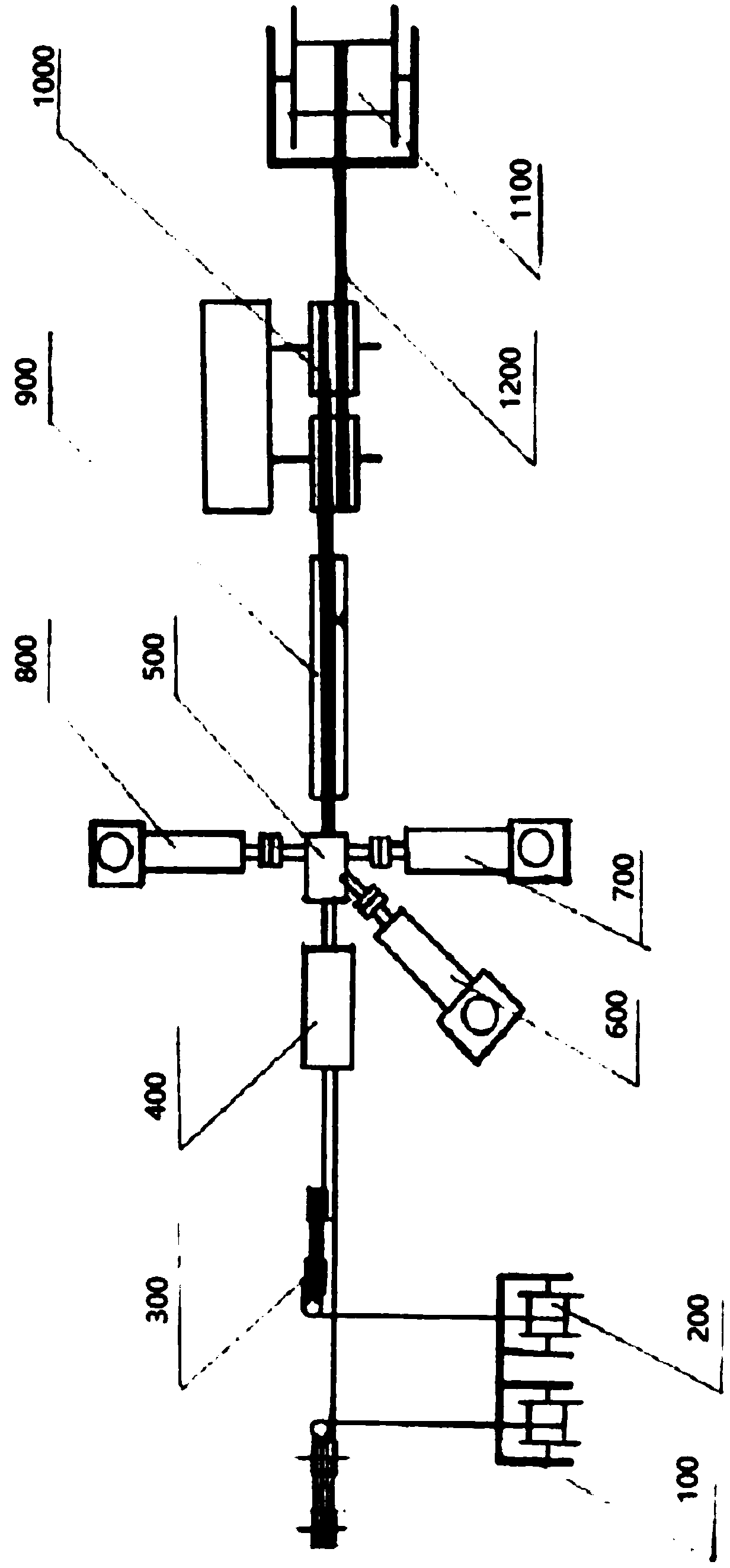

Paired bearing differential motion holder dynamic characteristic test device

ActiveCN106840672AAchieve reverse rotationGuaranteed coaxialityMachine bearings testingElectricityLaser

The invention discloses a paired bearing differential motion holder dynamic characteristic test device. Inner rings and outer rings of paired bearings are connected respectively and rotate synchronously, and an electric spindle drives the inner rings to rotate and controls the rotation speed of a holder of the bearings, so that the inner rings drive the outer rings through friction between a ball and a roller path to rotate, and differential motion of the inner rings and the outer rings of the tested bearings and controlling over the holder rotation speed are achieved; a corresponding tooth-embed type high-precision holder rotation speed control driving mechanism is arranged, a holder connecting sleeve is connected with the holder of the bearings in an embedded mode and connected with a toothed synchronous belt wheel, and a stepping motor controls the rotation speed of the holder through toothed synchronous belt transmission. A loading part is located between the outer rings of the paired bearings and achieves axial constant pressure loading through a compression spring, and in a measuring part, a laser vibrometer is placed in the axial direction of the tested bearings to measure the swing vibration and vortex motion conditions of the holder. The device is ingenious in structure, no special processing needs to be conducted on the tested bearing, and when the differential motion of the inner rings and the outer rings of the tested bearings exists, the holder dynamic characteristic measurement is achieved.

Owner:SHANGHAI UNIV +1

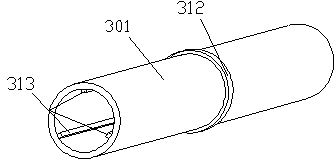

Spiral cable back twist machine

ActiveCN103489533AAchieve reverse rotationReduce the labor intensity of back twistingCable/conductor manufactureEngineeringMechanical engineering

The invention provides a spiral cable back twist machine. The spiral cable back twist machine greatly reduces spiral cable back twist labor intensity, improves production efficiency, comprises a cable winding device, and is characterized in that a machine frame corresponding to the cable winding device is arranged and is provided with a movable rotating device, and a clamping head is arranged on the rotating device.

Owner:WUXI HUAHAO ELECTRIC

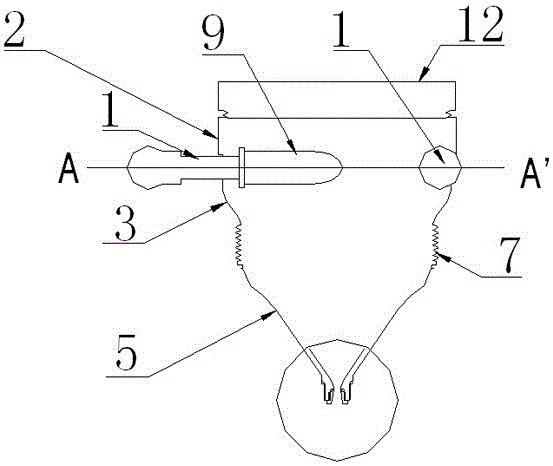

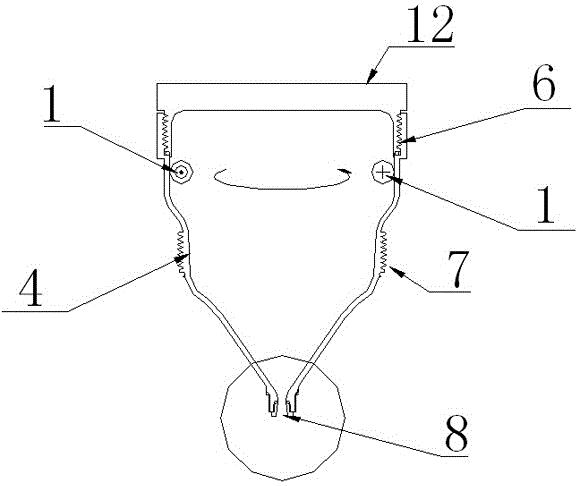

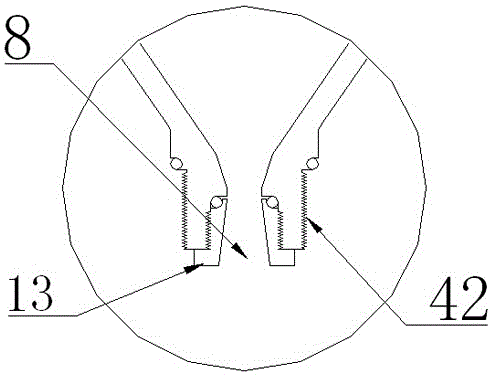

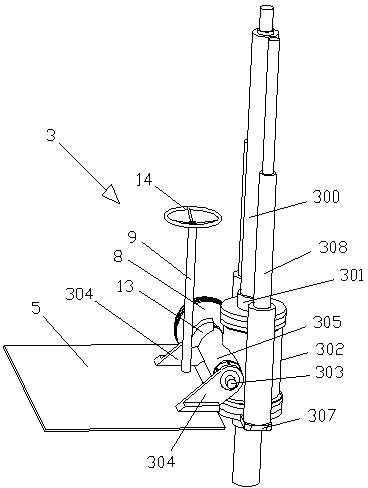

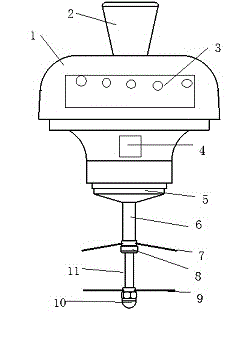

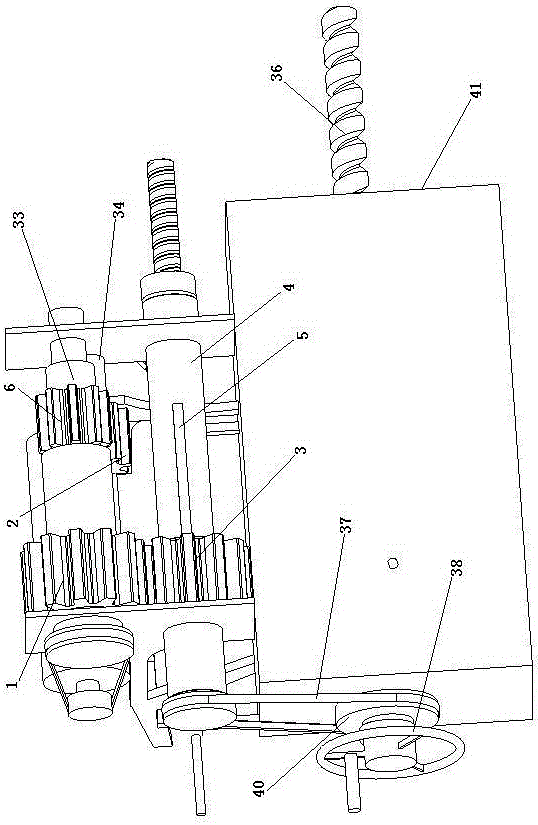

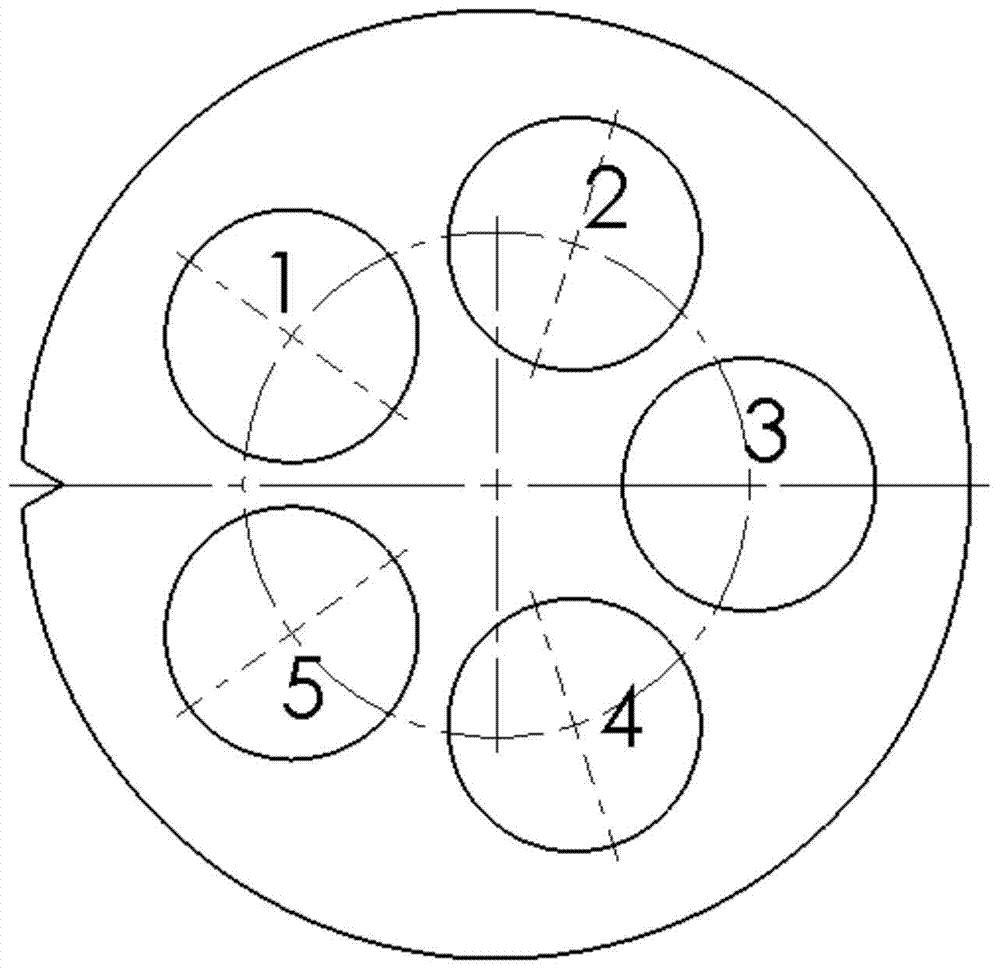

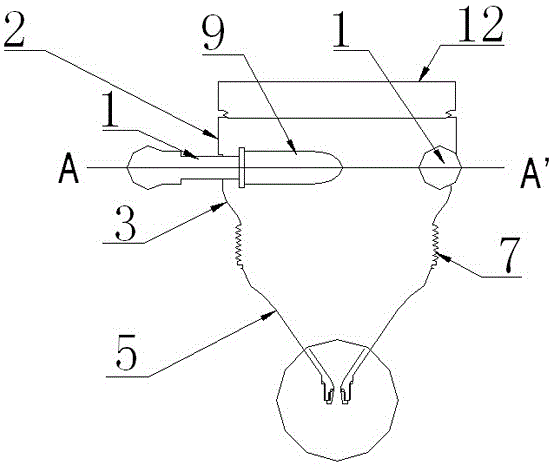

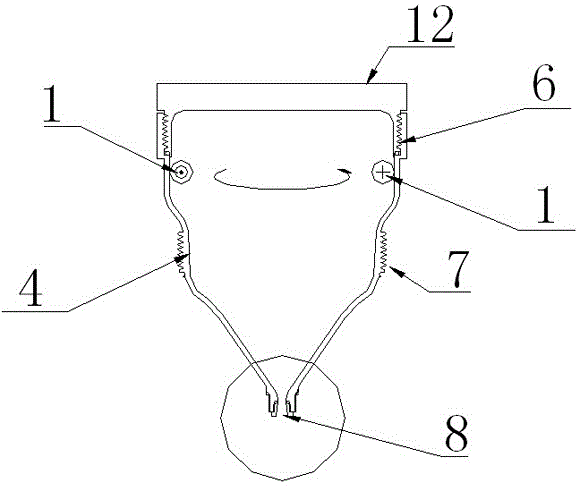

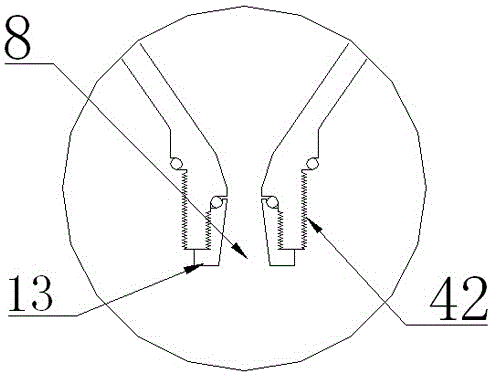

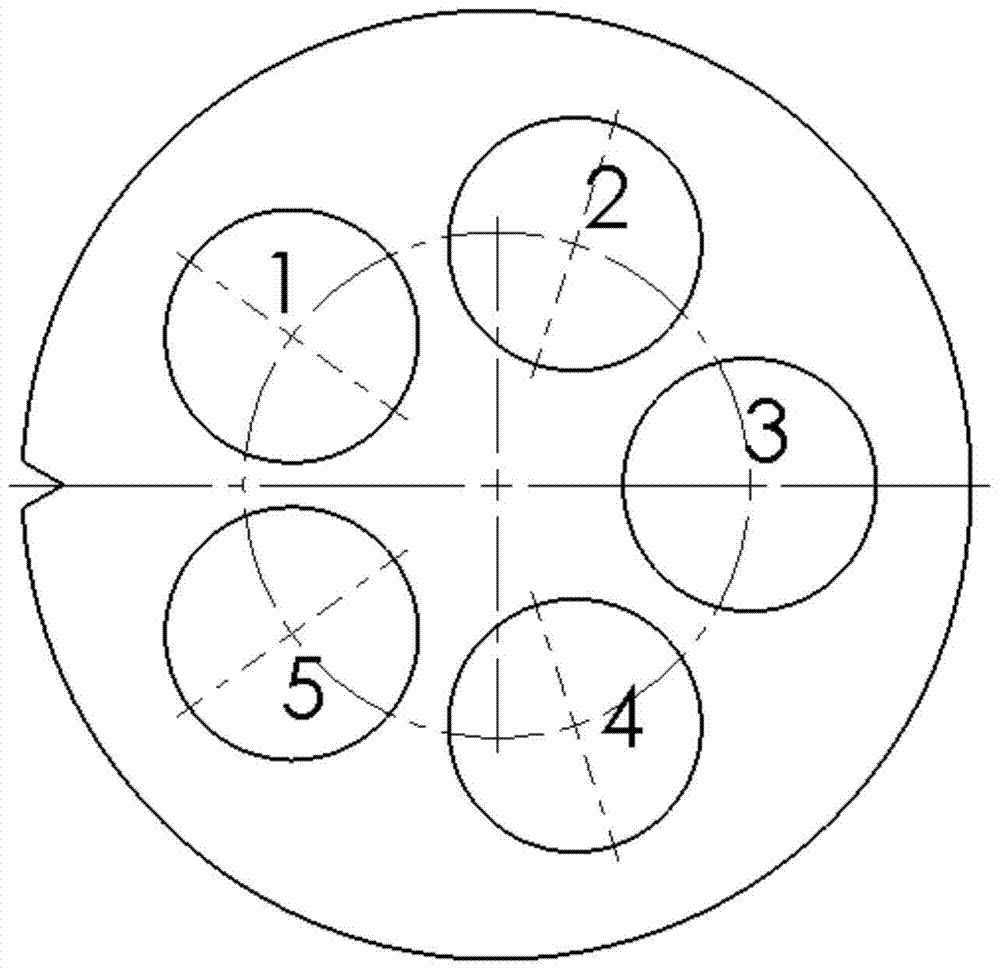

Coaxial dual-spiral domestic soybean milk machine head

InactiveCN104305873AAvoid enteringHelp defoamBeverage vesselsMilk substitutesControl systemDrive shaft

The invention belongs to the field of domestic soybean milk machine equipment, and particularly relates to a coaxial dual-spiral domestic soybean milk machine head. The coaxial dual-spiral domestic soybean milk machine head comprises that a handle is fixed above the soybean milk machine head, a control system is arranged in the soybean milk machine head, a motor is connected with a transmission shaft, a reverse transmission device is arranged in the soybean milk machine head, a sleeve is arranged on the reverse transmission device, the lower end of the sleeve is provided with a lip-shaped seal ring, a reverse blade is fixed at the lower end of the sleeve, and a forward blade is fixed at the lower end of the transmission shaft and is fixed by a locknut. The coaxial dual-spiral domestic soybean milk machine head is simple in structure and high in pertinence, dual-direction rotation of two blades can be realized on the same motor transmission shaft, the shearing effect of beans is improved, the milk making effect of the soybean milk is improved and the coaxial dual-spiral domestic soybean milk machine head has wide market application value.

Owner:UNIV OF JINAN

Grinding device for outer wall of petroleum screen pipe

ActiveCN108044423AImplement auto-rotationRealize repeated polishingGrinding carriagesRevolution surface grinding machinesCamPetroleum

The invention discloses a grinding device for the outer wall of a petroleum screen pipe, and specifically relates to the technical field of casting. Support columns are arranged under the support frame, the support frame is slidably connected with a grinding mechanism, two ends of wedge plates are provided with limiting columns, the wedge plates are slidably connected with working vehicles, firstsprings are connected between the working vehicles and abutting blocks, connecting frames are rotatably connected with connecting rods which are provided with second springs, and the second springs are connected with grinding blocks which are rotatably connected with grinding plates; and the abutting blocks penetrates through a fixed block, a second motor is provided with a cam, a wedge rod is provided with a fixed plate and a friction portion, third springs are arranged between the fixed plate and the support frame, a through-hole is formed in a support rod, a rotating shaft is provided withan external thread and is connected with a through hole threaded mode, and the rotating shaft is provided with blades. The technical scheme overcomes the problem that screen holes adsorb mental dust during petroleum screen pipe grinding, and can be used for grinding the outer surface of the petroleum screen pipe and screen holes.

Owner:东方光源集团有限公司

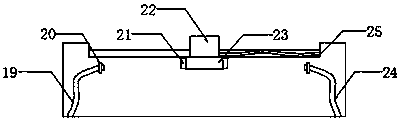

Patient posture adjusting device for magnetic resonance detection

InactiveCN111685767AEasy to moveSmooth transmissionDiagnostic recording/measuringSensorsHead fixationBody posture

The invention discloses a patient posture adjusting device for magnetic resonance detection, and relates to the field of magnetic resonance detection equipment. The following scheme is provided for solving the problems that an existing magnetic resonance examination device is not provided with a posture fixing and adjusting mechanism, and normal examination is inconvenient for patients who do notcooperate or cannot be completely automatically controlled. The device comprises a detection machine, a detection cavity is formed in the detection machine, a horizontally-arranged supporting plate isfixedly installed at the bottom of the detection cavity, a bed body is installed on the supporting plate in a sliding mode, a head pillow plate is installed on the upper surface of one end of the bedbody, and side plates are fixedly installed at the two ends of the head pillow plate. The bed body is accurate to move and position, the body postures of patients of different shapes and ages can befixed through a head fixing structure and hand and leg fixing mechanisms, and the device is easy to operate, high in comfort level, beneficial to normal detection, high in accuracy of detection results and convenient for doctors to make accurate diagnosis.

Owner:李光辉

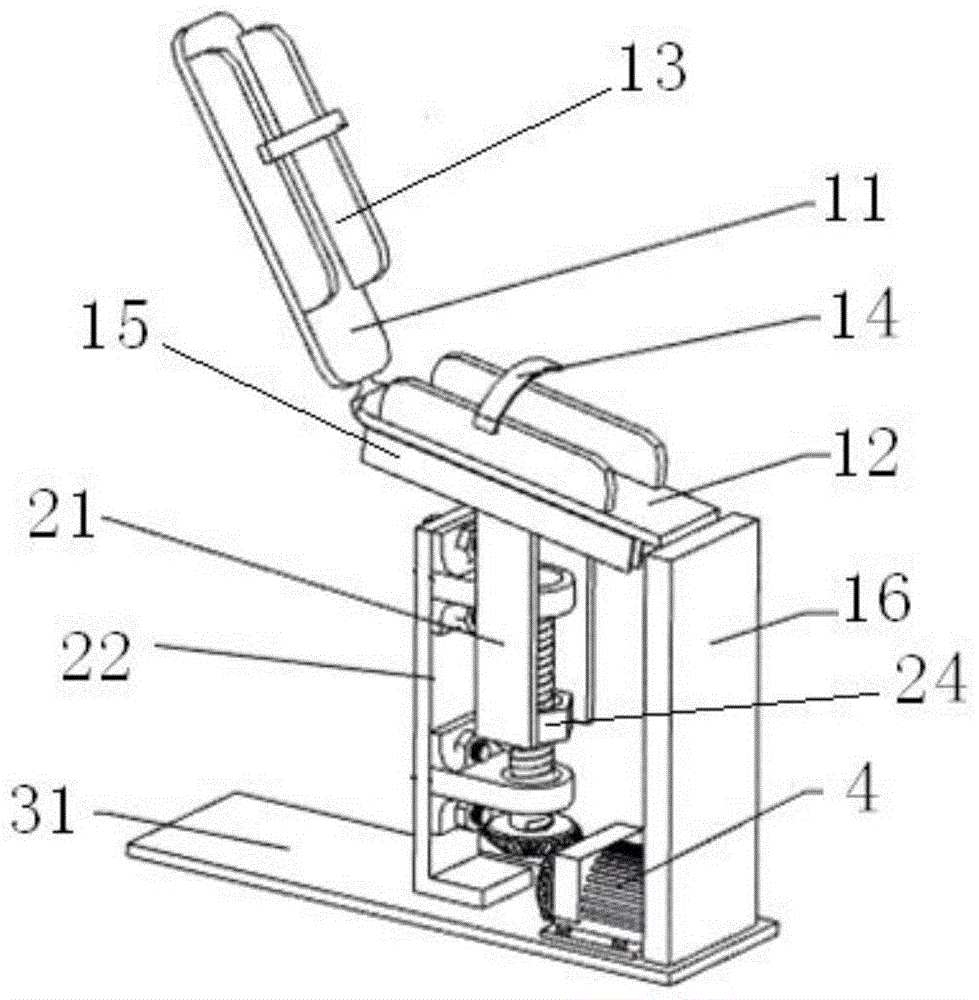

Arm thinning rocking arm device

InactiveCN106474673AAchieving any comfortable postureIncrease coefficient of frictionGymnastic exercisingMulti degree of freedomEngineering

An arm thinning rocking arm device is provided. One end of a front arm supporting rack of the device is connected with one end of a back arm supporting rack via a spherical hinge chain; the other end of the back arm supporting rack is hinged on the upper end of a first fixing supporting leg via a hinge chain; the lower end of the first supporting leg is fixed on a work bench; a first positioning tightening belt is arranged on the front arm supporting rack; a second positioning tightening belt is arranged on the back arm supporting rack; the lower end of a second fixing supporting leg is fixed on the work bench; a lead screw of the lead screw nut pair is fixed on the second fixing supporting leg via a first bearing and a bearing seat, a second bearing and a bearing seat; the lower end of a connection rod is fixed on a nut of the lead screw nut pair; and the upper end of the connection rod is fixed on the base surface of the back arm supporting rack. Multi-degree of freedom can be achieved and various arm postures can be achieved; the user can complete a series of reciprocating up-down actions via comfortable postures; and the arm thinning rocking arm device can be used at home or offices, and can be simply operated and independently operated.

Owner:GUANGXI UNIV

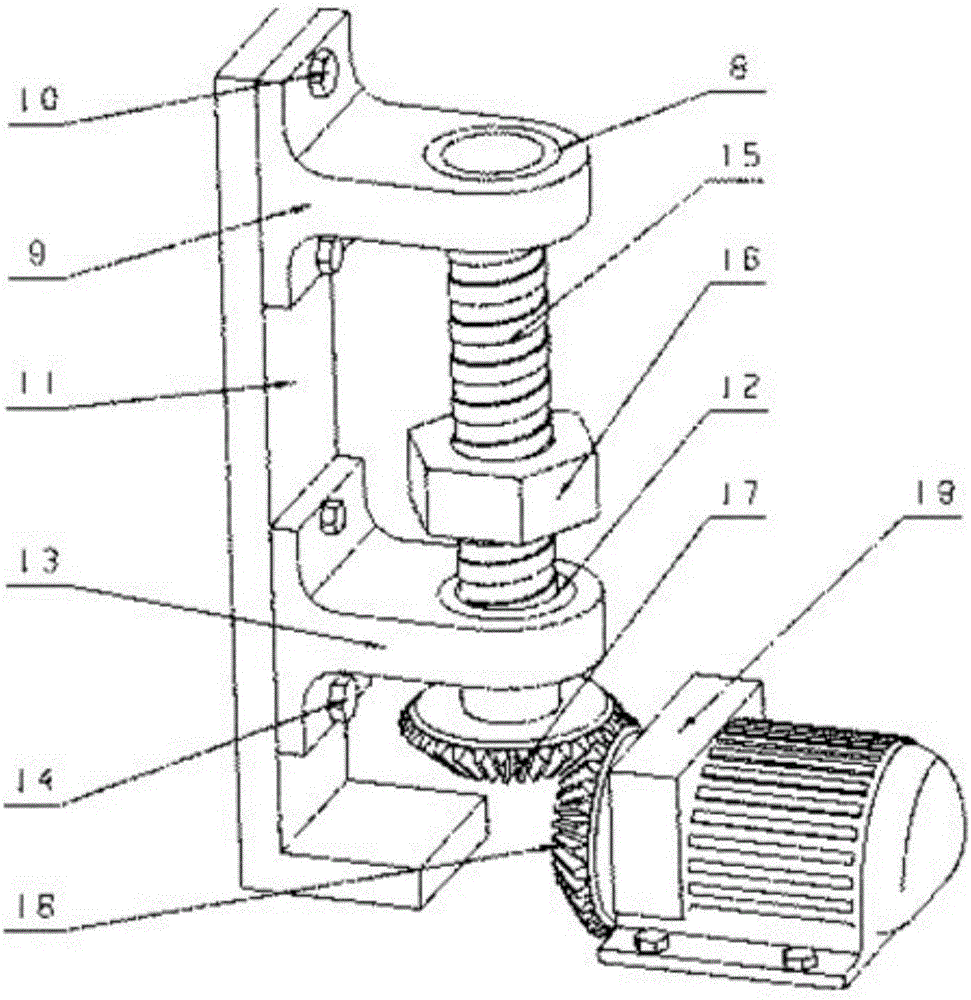

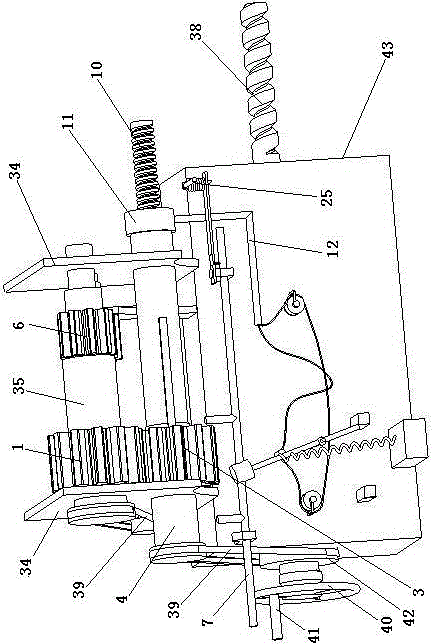

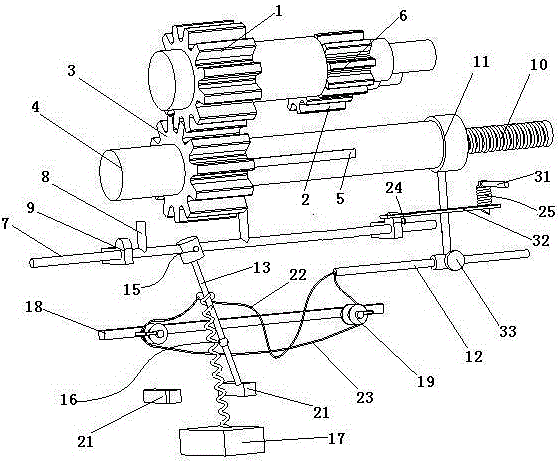

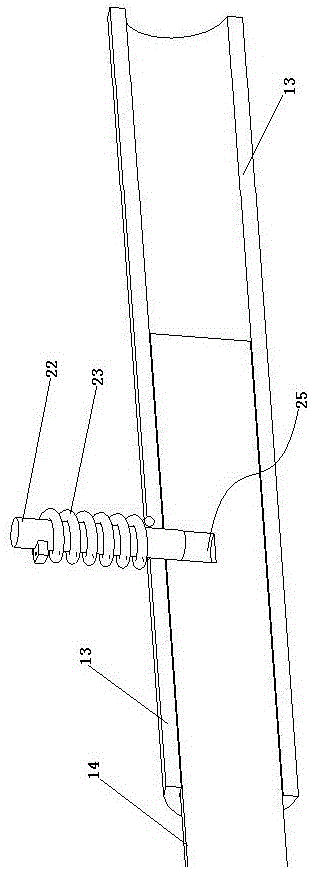

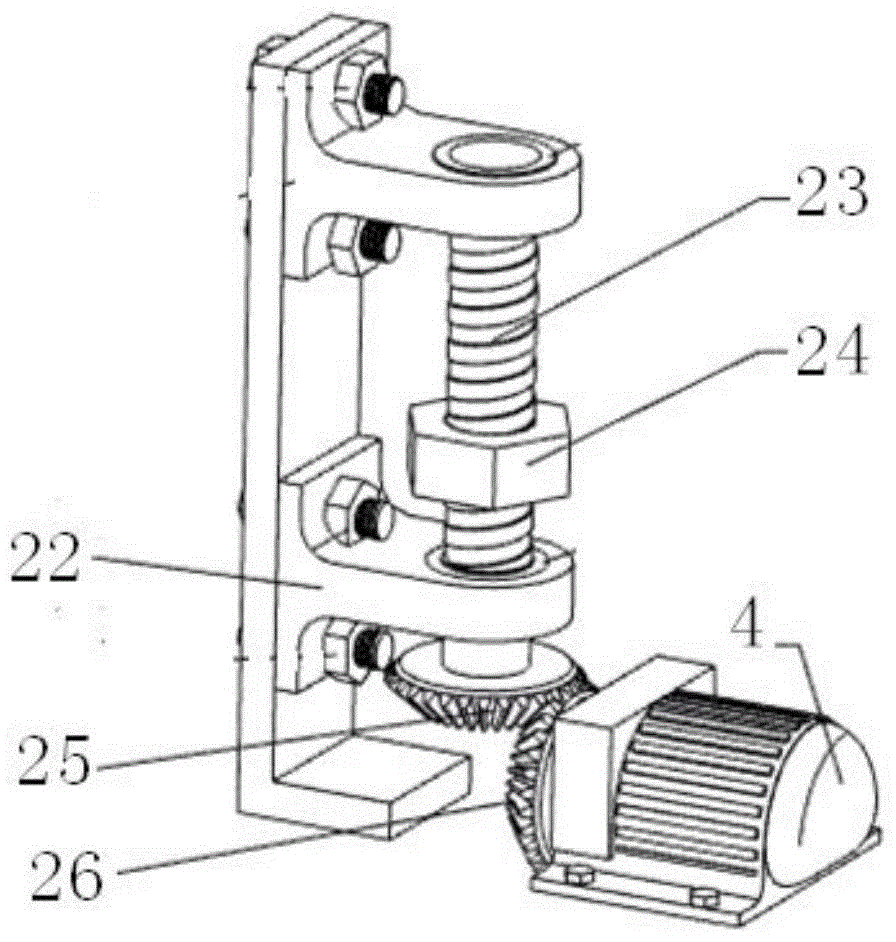

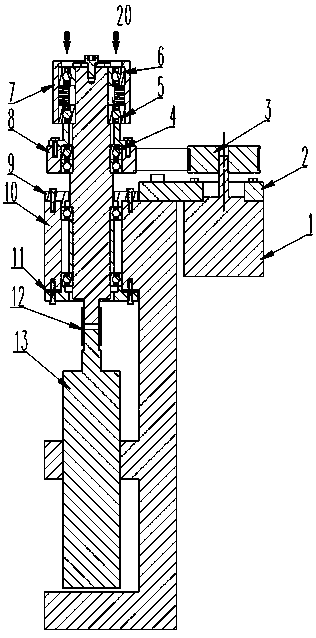

Automatic-feeding lathe tailstock mechanism

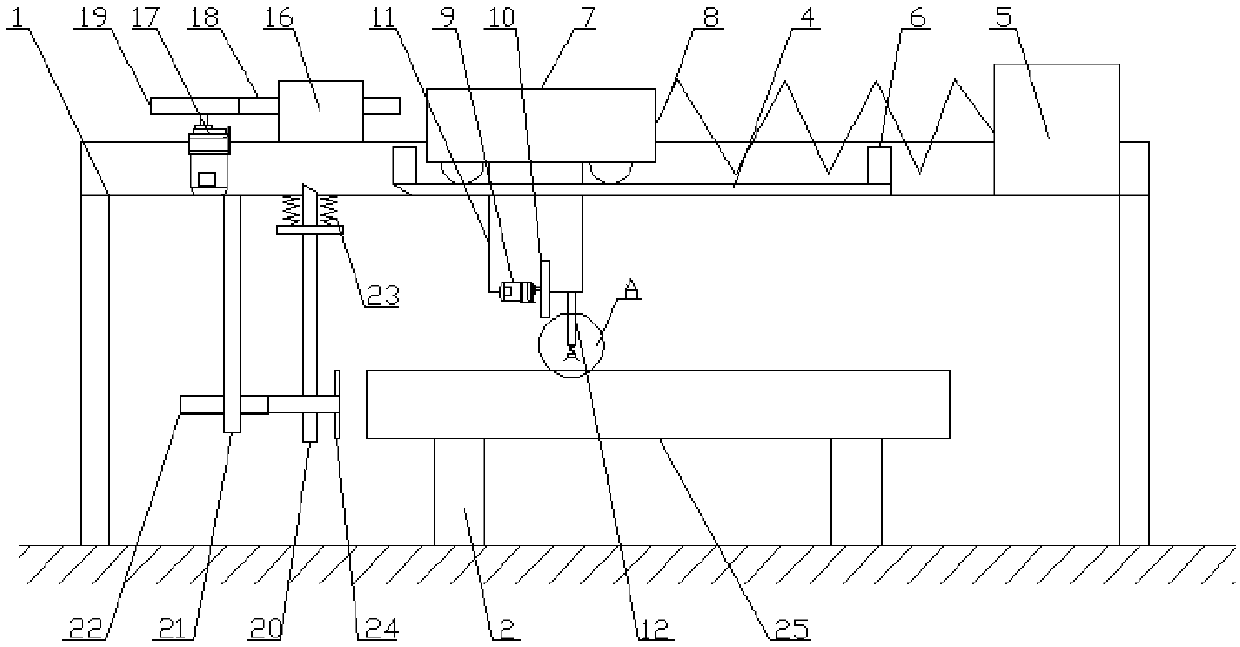

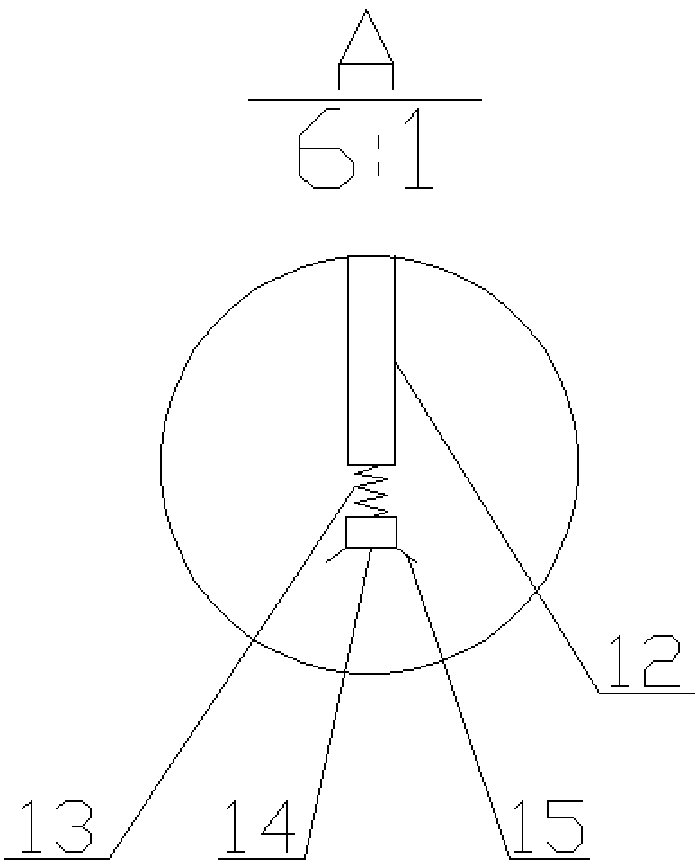

ActiveCN105057714APlay the role of meshing objectGuaranteed normal movementTailstocks/centresDrive shaftTailstock

The invention relates to an automatic-feeding lathe tailstock mechanism. The automatic-feeding lathe tailstock mechanism comprises a frame body and a driving mechanism and a pushing mechanism which are installed on the frame body; the driving mechanism and the pushing mechanism are linked through pushing fork rods, the driving mechanism is driven by a power device and drives a drill bit to act, and the driving mechanism can drive a driving gear to conduct forward rotation and reverse rotation; the pushing mechanism comprises a pushing rod which is arranged in a sliding mode, and the two pushing fork rods are located on the out sides of the two ends of the driving gear respectively; one end of a driving shaft is provided with a screw, and a thread sleeve connected with a curved rod is connected to the screw in a sleeving mode; an oscillating rod is connected with the pushing rod through a first rotating shaft and connected with a chain rod through a second rotating shaft, and the oscillating rod rotates through a third rotating shaft; the two ends of a chain are connected with the free end of the chain rod and the free end of the curved rod, and the free end of the chain rod and the free end of the curved rod can be in butt joint; one end of a first spring is fixedly connected to the portion, located on the position of the second rotating shaft, of the oscillating rod, and the other end of the first spring is fixedly connected to a fixing block; the pushing rod is further provided with a protruding block, and the protruding block is linked with a stopping mechanism.

Owner:扬州高力机械有限公司

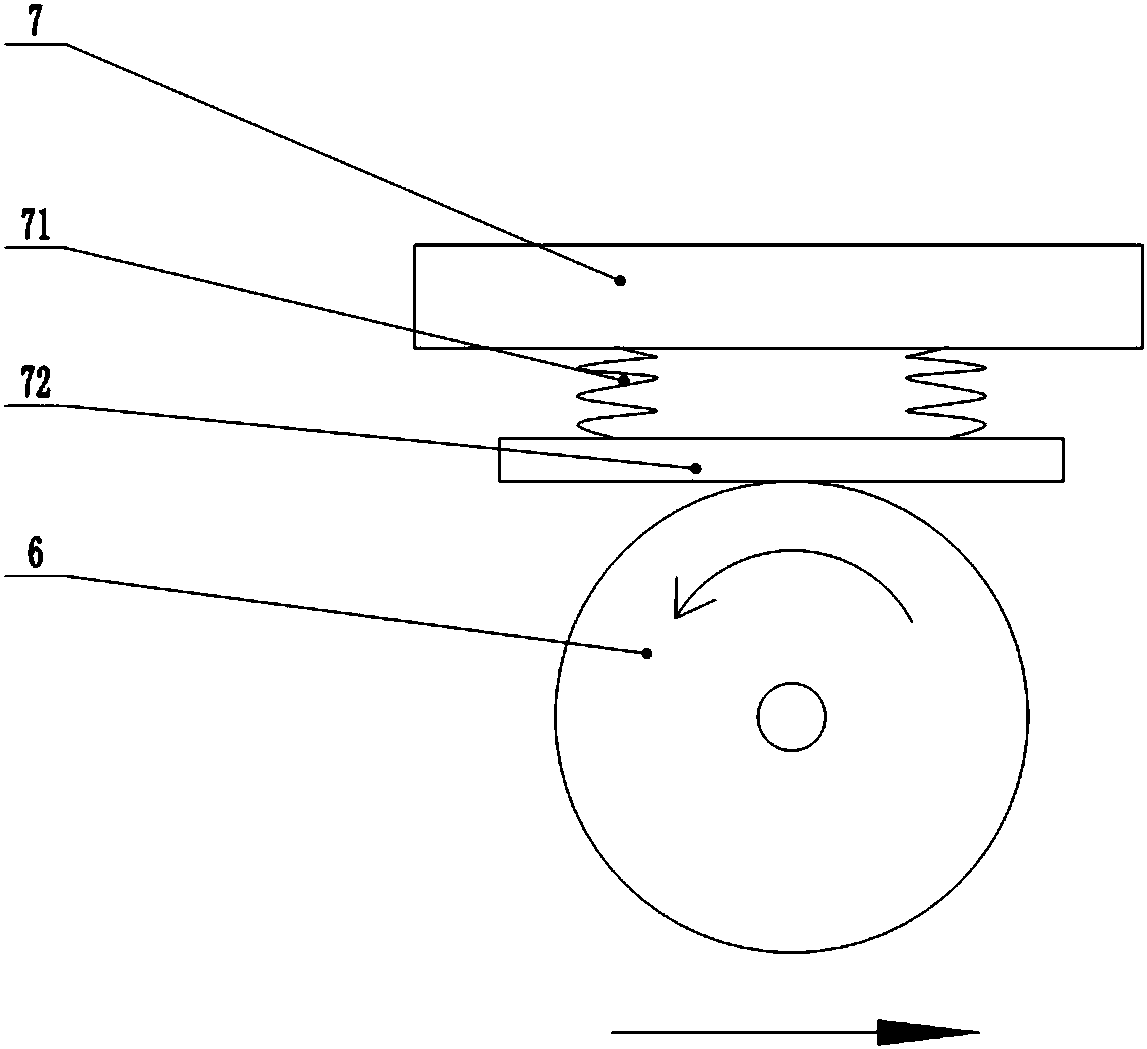

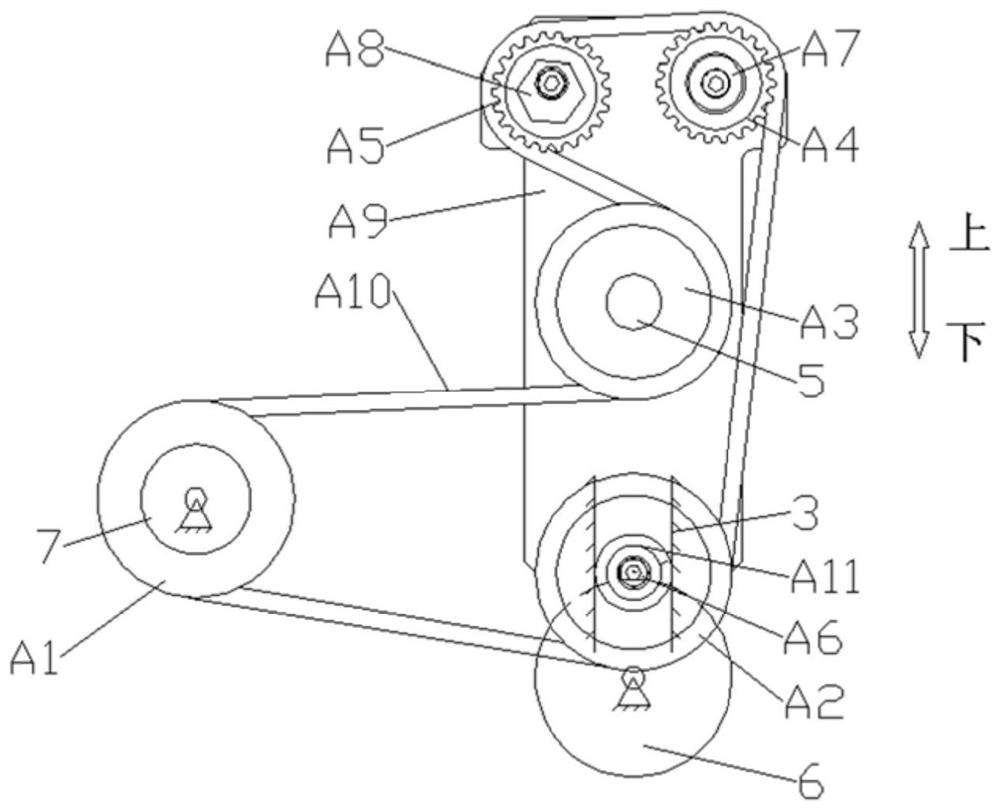

Friction false twisting device and operation method thereof

The invention discloses a friction false twisting device and an operation method of the device. The friction false twisting device comprises two sets of shafts which are parallel to each other and keep synchronous. Each shaft is provided with a friction disk. A friction wheel is arranged on a transmission shaft in each shaft. Nylon belts penetrate through the portion between the friction wheels to drive the two sets of shafts to rotate in the different directions. The two sets of shafts can rotate in the same direction through a synchronous mechanism. Incongruous twisting of the two sets of friction disks is achieved by means of the friction wheels and the nylon belts on the two sets of shafts, concurrent twisting is achieved through the other synchronous mechanism, setting can be carried out according to the requirement of the process, and use is flexible and convenient. When the twisting direction is changed, the nylon belts keep transmission in the same direction, the direction does not need to be changed, reverse rotating of the false twisting device is achieved through a connecting mode of the friction wheels and the shafts, and the false twisting device is suitable for producing filaments, stranded or not stranded, of yarn twisted in the same direction or yarn twisted in the different directions in the next processing procedure.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

Working feed fast backward refitting mechanism suitable for common vehicles

ActiveCN105033316APlay the role of meshing objectGuaranteed normal movementAttachable boring/drilling devicesGear wheelDrive shaft

The invention relates to a working feed fast backward refitting mechanism suitable for common vehicles. The working feed fast backward refitting mechanism comprises a rack body, a driving mechanism and a stirring mechanism both installed on the rack body, wherein the driving mechanism and the stirring mechanism are joined with each other via a shifting fork rod; the driving mechanism is driven by a power device; the driving mechanism drives a drill bit to act; the driving mechanism can also drive a driving gear to rotate forward and backward; the stirring mechanism is formed by a stirring rod slideably arranged; two shifting fork rods are mounted on the stirring rod; the two shifting fork rods are respectively arranged on external sides of the two ends of the driving gear; one end of a driving shaft is provided with a screw rod; a screw sleeve thread of a connection soft rope covers the screw rod; a swinging rod is connected with the stirring rod via a first rotating shaft; the swinging rod is connected with a pulley rod via a second rotating shaft; the first and second soft ropes are respective connected with the swinging rod along two side directions of the swinging rod between the first and second rotating shaft; the first soft rope is connected with the swinging rod along a near side; the second soft rope is guided by at least one pulley on the pulley rod to be connected with the swinging rod from the other side; the stirring rod is provided with a projecting block; and the projecting block is joined with a stop mechanism.

Owner:惠州市新菱实业有限公司

Gravity-driven reciprocating mechanism

ActiveCN105065606APlay the role of meshing objectGuaranteed normal movementGearingTransmission elementsDrive shaftEngineering

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

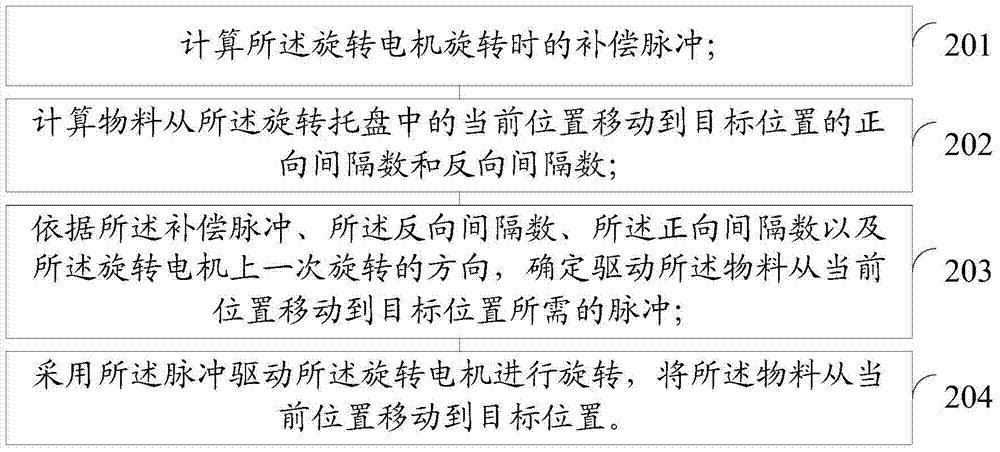

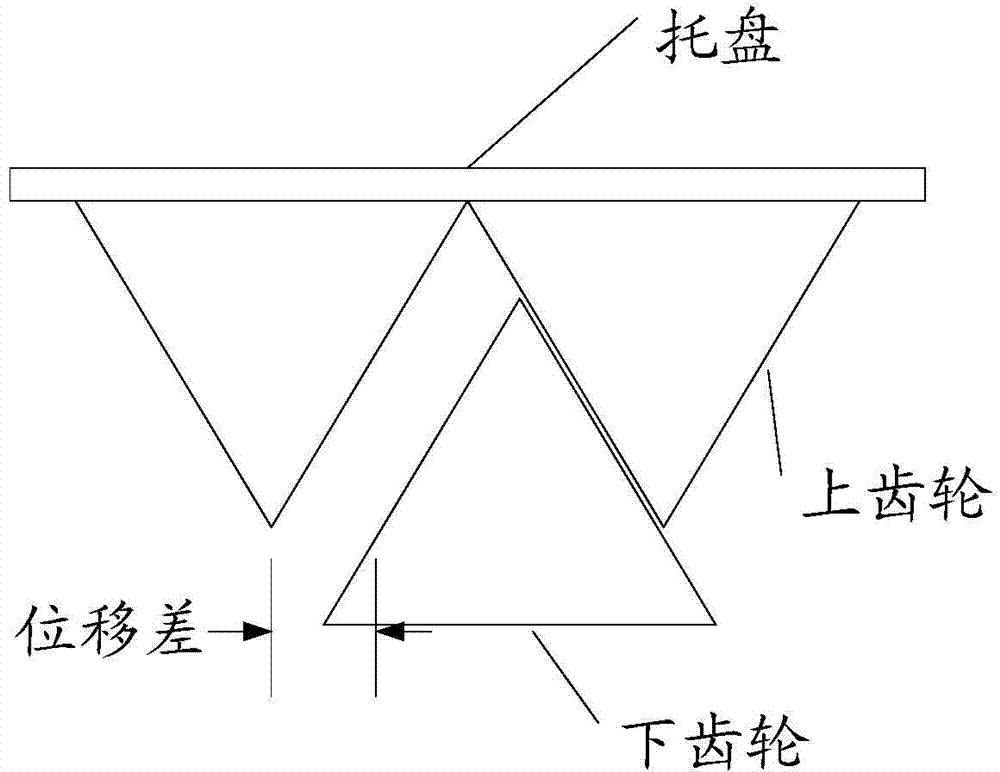

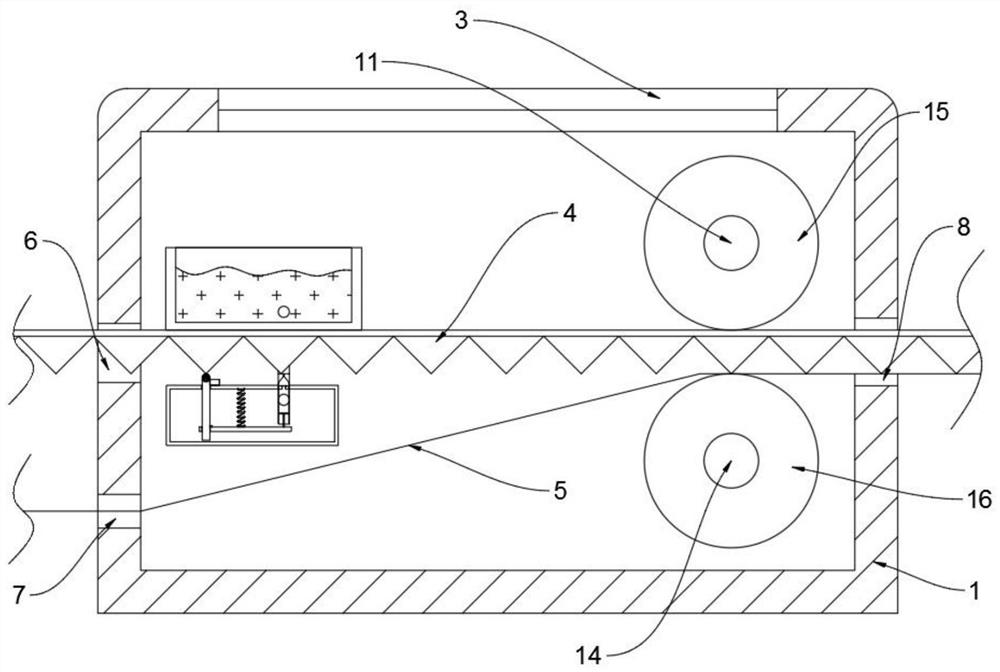

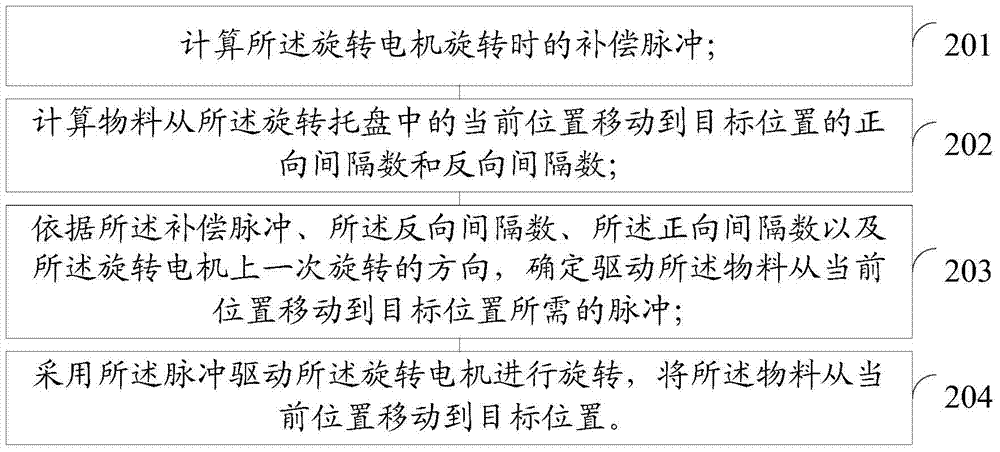

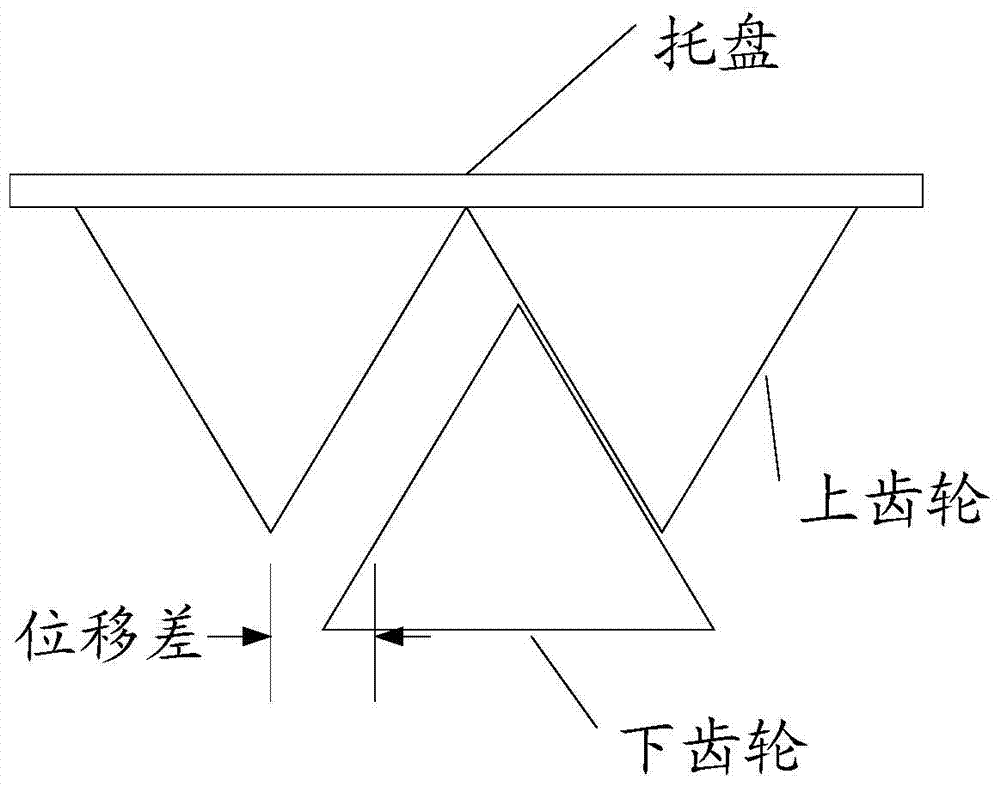

Rotating motor operation control method and device

ActiveCN104753401AOvercoming the effects of voidsImprove transmission efficiencyPolyphase induction motor starterMotor driveEngineering

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Corrugated paper gluing equipment

InactiveCN112318943AAvoid wastingSpray evenlyMechanical working/deformationPaperboardStructural engineering

The invention discloses corrugated paper gluing equipment which comprises a box body and a servo motor; a box door is rotatably connected to the top of the box body, a corrugated paper inlet is formedin the outer side wall of the box body in a penetrating mode, corrugated paper is slidably connected to the inner side wall of the corrugated paper inlet, a paperboard inlet is formed in the outer side wall of the box body in a penetrating mode, and a a paperboard is slidably connected to the inner side wall of the a paperboard inlet; and the outer side wall of the box body is provided with an outlet in a penetrating mode, and the inner side wall of the box body is fixedly connected with a glue storage box. According to the corrugated paper gluing equipment, glue can be sprayed on the bondingportions between the corrugated paper and the paperboard through movement of the corrugated paper, waste of glue is reduced, and the utilization rate of the glue is increased; and through rotation ofthe servo motor, same-speed reverse rotation of a first pressing roller and a second pressing roller is realized, the bonding portions between the paperboard and the corrugated paper are well pressed, meanwhile, pulling of the corrugated paper and the paperboard is also realized, the work efficiency is improved, and the resource waste is reduced.

Owner:黄丹

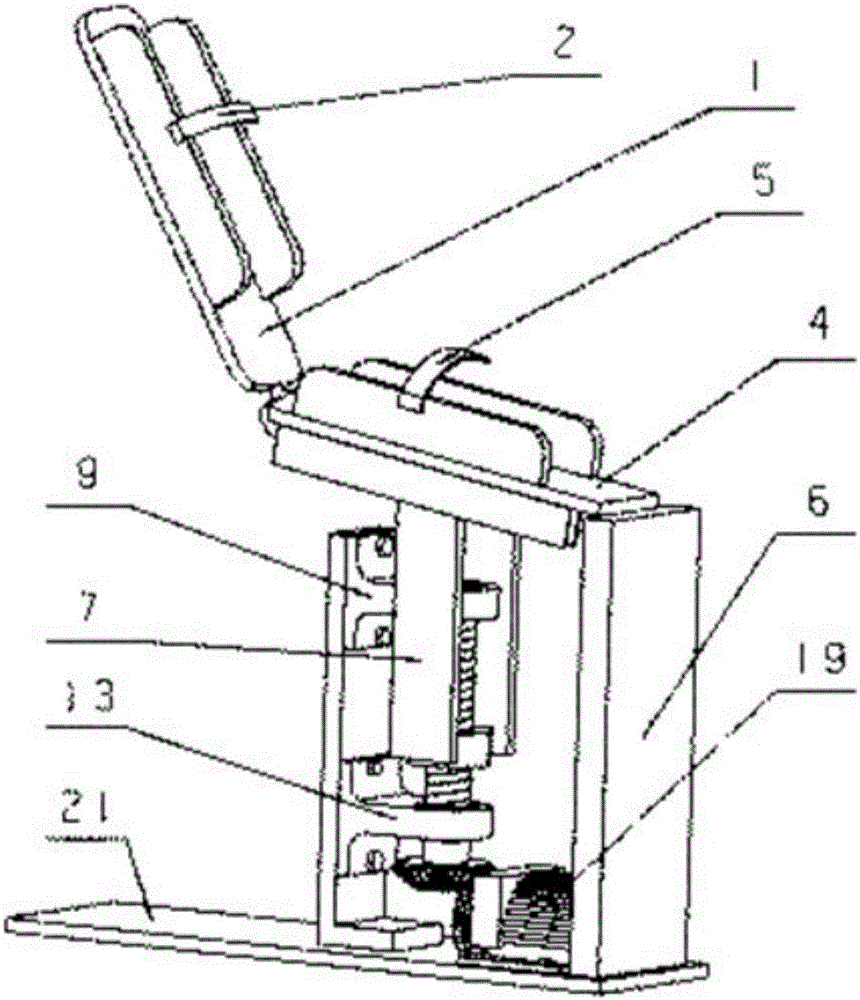

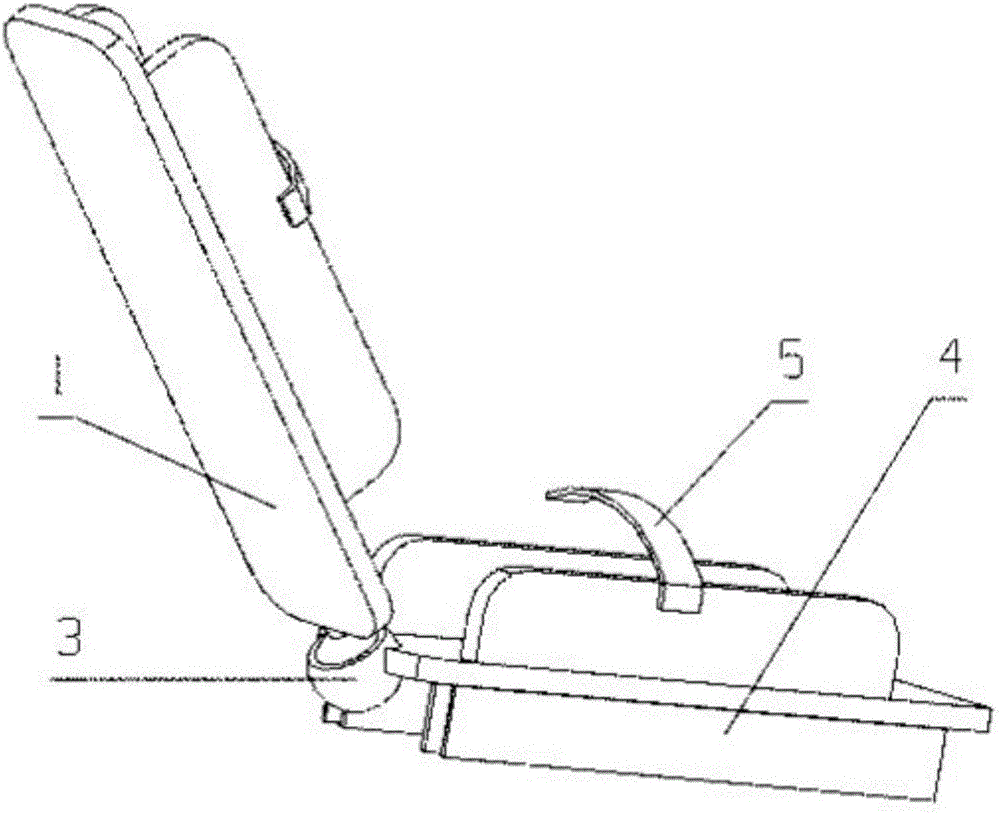

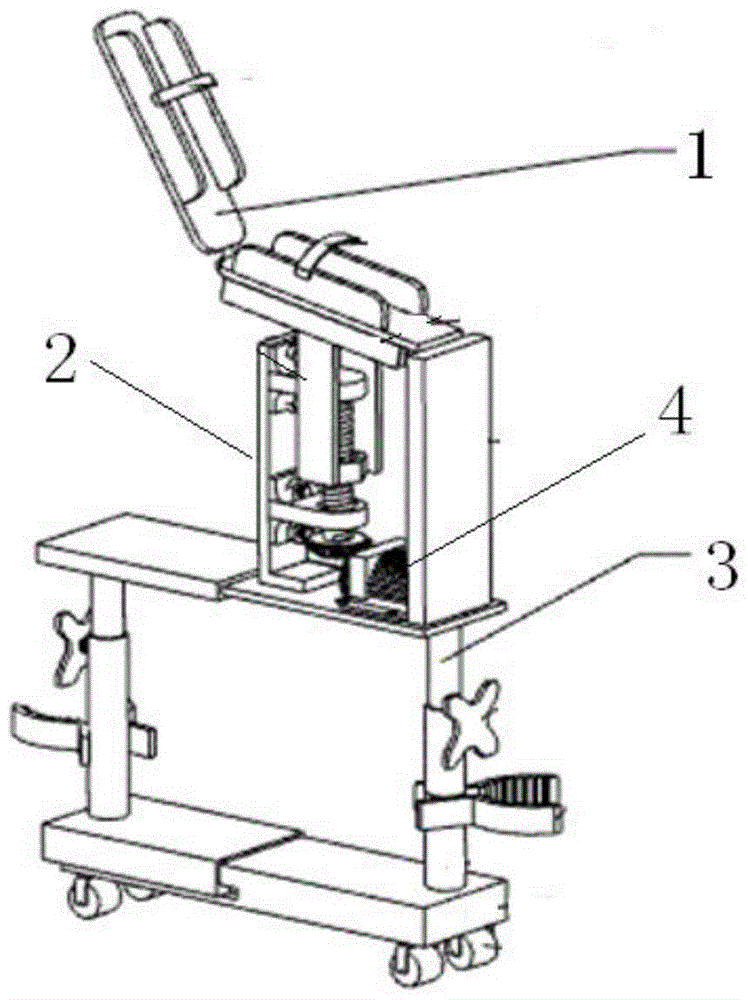

Sitting type arm slimming device

InactiveCN105031890ARun smoothlyIncrease coefficient of frictionGymnastic exercisingFastenerEngineering

The invention discloses a sitting type arm slimming device. The sitting type arm slimming device comprises an arm supporting mechanism, a lifting mechanism and a base. The arm supporting mechanism comprises a front arm supporting frame and a rear arm supporting frame connected with the front arm supporting frame. The front arm supporting frame and the rear arm supporting frame are both provided with a containing groove capable of containing the corresponding portion of an arm, a fastener used for fastening the corresponding portion of the arm is arranged on each containing groove, and the bottom of the rear arm supporting frame is provided with a sliding groove and is movably connected with a support frame plate. The lifting mechanism comprises a lifting slider which is correspondingly arranged in the sliding groove in a sliding mode and slides in the sliding groove so that the rear arm supporting frame can be driven to move up and down around the support plate. The arm supporting mechanism and the lifting mechanism are arranged on the base. When the sitting type arm slimming device is used for body building, the arm is placed in the containing grooves of the arm supporting mechanisms, the lifting slider slides in the sliding groove, the rear arm supporting frame is driven to swing up and down around the support plate so that the arm can swing up and down and be exercised, and then the effect of slimming the arm can be achieved.

Owner:GUANGXI UNIV

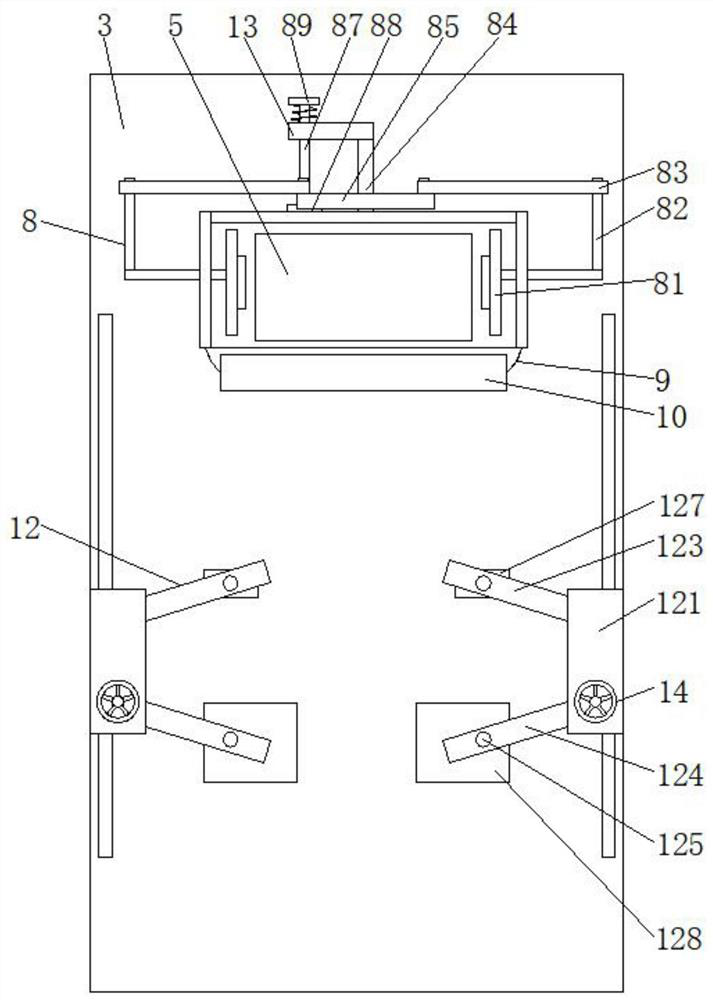

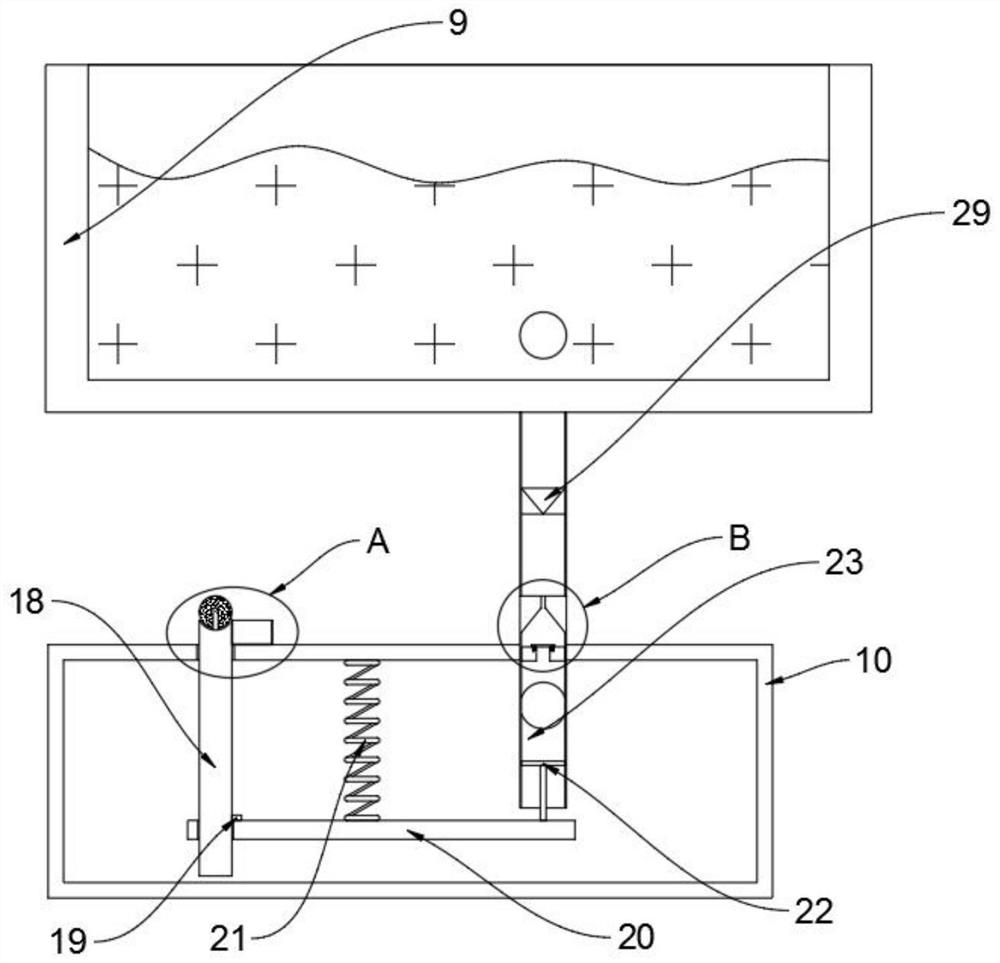

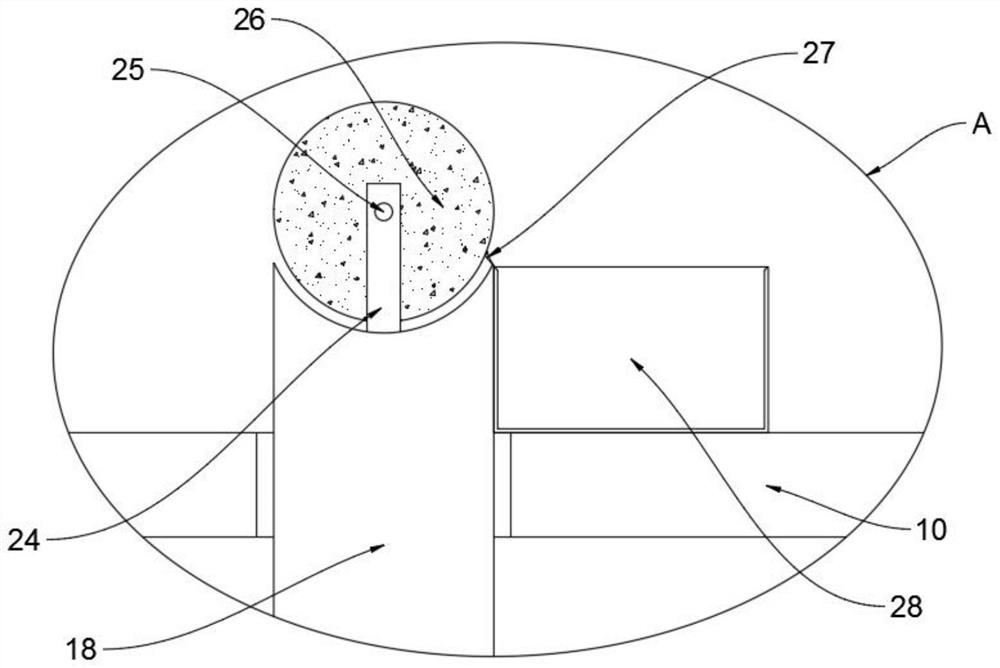

Top opening type dual-power washing machine

PendingCN110835827ASimple structureConducive to miniaturization designOther washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention relates to the technical field of washing machines, aims to solve the problem that an existing pulsator washing machine is uneven in clothes cleaning effect due to the fact that the pulsator washing machine is uneven in water stirring effect, and provides a top opening type dual-power washing machine. The top opening type dual-power washing machine comprises an inner drum component,a dual-power drive device and a connecting component, wherein the inner drum component comprises an upper drum and a lower drum which are connected with each other in a relatively rotatable manner; the first power output end of the dual-power drive device is connected with the lower drum and used for driving the lower drum to rotate; the first end of the connecting component is connected with theupper drum, and the second end of the connecting component is connected with the second power output end of the dual-power drive device to allow the upper drum and the lower drum to be driven by the dual-power drive device to rotate independently. The top opening type dual-power washing machine has the advantages that the problem of uneven clothes cleaning effect caused by uneven water stirring can be avoided effectively, a pulsator can be omitted, washing machine structure simplification is achieved, production cost is saved, and washing machine miniaturization design is benefited.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Labor-saving wrench

PendingCN107717800AAchieve disassemblyRealize the assemblySpannersWrenchesControl engineeringElectric power equipment

The invention discloses a labor-saving wrench. The labor-saving wrench comprises a spline shaft and a sleeve, wherein the two ends of the spline shaft are separately in sleeving connection with a first connecting device and a second connecting device; the first connecting device can move up and down along the axis of the spline shaft; the second connecting device is fixedly connected with the spline shaft; the sleeve is arranged between the first connecting device and the second connecting device; one end, away from the spline shaft, of the first connecting device is equipped with a nut-shapedsleeve hole; and a reversing gear box is further arranged between the sleeve and the second connecting device. Compared with the prior art, the labor-saving wrench has the advantages that an existingdouble-hand one-way stressed operation mode is changed into a single-hand two-way stressed mode, so that operating and maintaining efficiency can be improved, operation labor intensity is relieved, and maintaining power-failure time of electric equipment is shortened.

Owner:STATE GRID CORP OF CHINA +1

Plastic product trimming device

ActiveCN114734566AAchieve cullingIncrease resistancePlastic recyclingStructural engineeringCentrifugal force

The invention discloses a plastic product trimming device which comprises longitudinal limiting plates, the position between the top ends of the two longitudinal limiting plates passes through an adjusting positioning rod, a transverse trimming mechanism is fixedly connected to the middle position of the lower longitudinal limiting plate, and a positioning inner groove is formed in the middle position of a mounting frame. A positioning transverse toothed rod is fixedly connected to the transverse position in the positioning inner groove, a driving sliding block is slidably connected to the transverse position in the positioning inner groove, a driving carrier plate is fixedly connected to the end, located outside the positioning inner groove, of the driving sliding block, and a contact scraper is fixedly connected to the right side of the front face of the driving carrier plate. According to the plastic product trimming device, reverse rotation of the driving gear shaft is achieved, centrifugal force generated by rotation enables the structure of the reverse scraping cutter piece to extend outwards and make contact with the side edge of a plastic product for scraping, reverse scraping is achieved, burrs in different directions are eradicated, and the trimming efficiency is improved.

Owner:南通市通州区锦都拉链有限公司

Electromagnetic motor capable of rotating reversely

InactiveCN107947490AAchieve reverse rotationChange magnetismAssociation with control/drive circuitsEngineeringPower flow

The invention discloses a reversibly rotating electromagnetic motor, which comprises a motor body, a protection frame and a linkage shaft are arranged at the left end of the motor body, and the linkage shaft is arranged through the motor body. The right end is equipped with a heat sink and a heat dissipation port, and the heat dissipation port is embedded in the heat sink. The top of the motor body is provided with a controller. By moving the handle on the controller, the current flows in the reverse direction and the magnetism of the positive electrode plate is changed to realize the reverse rotation of the motor. The process is easy to operate and can be realized without any post-processing by the staff, making this Electromagnetic motors can be more widely used and recognized in the market, and this type of motor can also help the type of motor to change direction and rotate by turning to the magnetic pole, and there will be no confusion that makes the type of motor unable to operate normally.

Owner:常永江

Paper pressing roller transmission device

PendingCN114684638AAchieve reverse rotationPrevent slippingArticle feedersWebs handlingElectric machineryCounter rotation

The invention provides a paper pressing roller transmission device. The paper pressing roller transmission device comprises a motor, a rack, an upper paper pressing roller, a lower paper pressing roller, a paper conveying table driving shaft and a guide block device. The upper paper pressing roller, the lower paper pressing roller and the paper conveying table driving shaft are arranged on the rack in parallel and can rotate relative to the rack, and the motor is arranged on the rack and used for providing power for rotation of the upper paper pressing roller, the lower paper pressing roller and the paper conveying table driving shaft; the guide block device is arranged on the machine frame, connected with the upper paper pressing roller and used for driving the upper paper pressing roller to vertically slide along the machine frame. According to the device, real-time constant-speed reverse rotation of the upper paper pressing roller and the lower paper pressing roller can be achieved, paper slipping is avoided, and paper scratching caused by paper slipping is reduced; the paper squeezing pressure of the upper paper pressing roller and the lower paper pressing roller is adjustable, and the problems that the paper is damaged due to overlarge pressure of the upper paper pressing roller and the lower paper pressing roller or the paper cannot be conveyed due to oversmall pressure are solved; the upper paper pressing roller, the lower paper pressing roller and the paper conveying table driving shaft share the same power source, and the motion law can be kept consistent.

Owner:MASTERWORK GROUP CO LTD

A spiral cable untwisting machine

ActiveCN103489533BAchieve reverse rotationReduce the labor intensity of back twistingCable/conductor manufactureEngineeringUltimate tensile strength

The invention provides a spiral cable untwisting machine, which greatly reduces the labor intensity of cable spiral untwisting and improves production efficiency. A movable rotating device is arranged on the frame, and a clamping head is arranged on the rotating device.

Owner:WUXI HUAHAO ELECTRIC

Dynamic characteristic test device of paired bearing differential cage

ActiveCN106840672BAchieve reverse rotationGuaranteed coaxialityMachine bearings testingElectricityThrust bearing

Owner:SHANGHAI UNIV +1

Method and device for measuring light beam orbit angular momentum spectrum

InactiveCN101334315BImprove parallelismImprove coaxialityOptical measurementsPhotometryBeam splittingPower detector

The invention relates to a method for realizing beam orbital angular momentum spectrometry, which belongs to the technical field of laser application. The invention consists of a light source to be tested, two polarization dispersion prisms, 1 / 2 wave plate, two parallel optical flats, two pieces of 1 / 4 wave plates, a total reflector, a rectangular prism, a Porro prism, a Pi / 2 phase delay piece anda power detector. The invention adopts the two parallel optical flats and the rectangular prism to realize the beam splitting and the beam combining of the beams, ensure the good parallelism of beamsplitting light and the coaxiality of beam combining light, and realize the complete identical optical paths and attenuation of the two bunches of light. The invention adopts the polarization dispersion prism, the total reflector, the Porro prism and the two 1 / 4 wave plates to realize the beam splitting, and the two bunches of light obtained by the beam splitting rotate coaxially to further realize the coaxial superimposition of the beam and a rotating mirror image thereof. The orbital angular momentum spectrum of an incident beam can be analyzed by measuring the relation between the power ofthe beam combining light and the rotation of the Porro prism. The method of the invention has application value in the laser intelligence processing field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A spray drying device

InactiveCN105750111BAchieve reverse rotationAchieve hybridMachine part testingLiquid spraying apparatusSide effectSprayer

Owner:李依真

Operation control method and device for a rotating electrical machine

ActiveCN104753401BOvercoming the effects of voidsImprove transmission efficiencyPolyphase induction motor starterMotor driveFeed drive

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A heating cable manufacturing device and its application method

ActiveCN107967970BAchieve reverse rotationFixed tightlyInsulating conductors/cablesElectrical conductorEngineering

The invention discloses a heat tracing cable manufacturing device and a using method thereof. The heat tracing cable manufacturing device comprises a machine head, an active pay-off machine, a conductor pay-off reel, a dancing wheel, a heater, a co-extrusion head, a constant-temperature water tank, a traction device and a take-up reel. The co-extrusion head comprises a composite die set, a shell body, a front pressure cover and a rear pressure cover. The composite die set comprises a die core supporting sleeve, an incoming wire positioning die set, and an inner conductor layer die set, a PTC layer die set and an insulating layer die set. The inner conductor layer die set comprises a fixed die, a rotary die and a first brake assembly. The composite die set further comprises a second brake assembly. The heat tracing cable manufacturing device realizes the one-step coating of metal inner cores with an inner conductor layer, a PTC heating body layer and a composite insulating layer by means of the composite die set, and drives the rotation of fusion coating materials by means of the braking effects of a first linkage portion and a second linkage portion, so that the coating materials are tightly adhered.

Owner:ANHUI HUANRUI ELECTROTHERMAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com