A heating cable manufacturing device and its application method

A technology for manufacturing devices and heating cables, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuits, etc., which can solve problems such as inaccurate positioning, easy eccentricity, and easy contamination, and achieve the effect of fastening and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

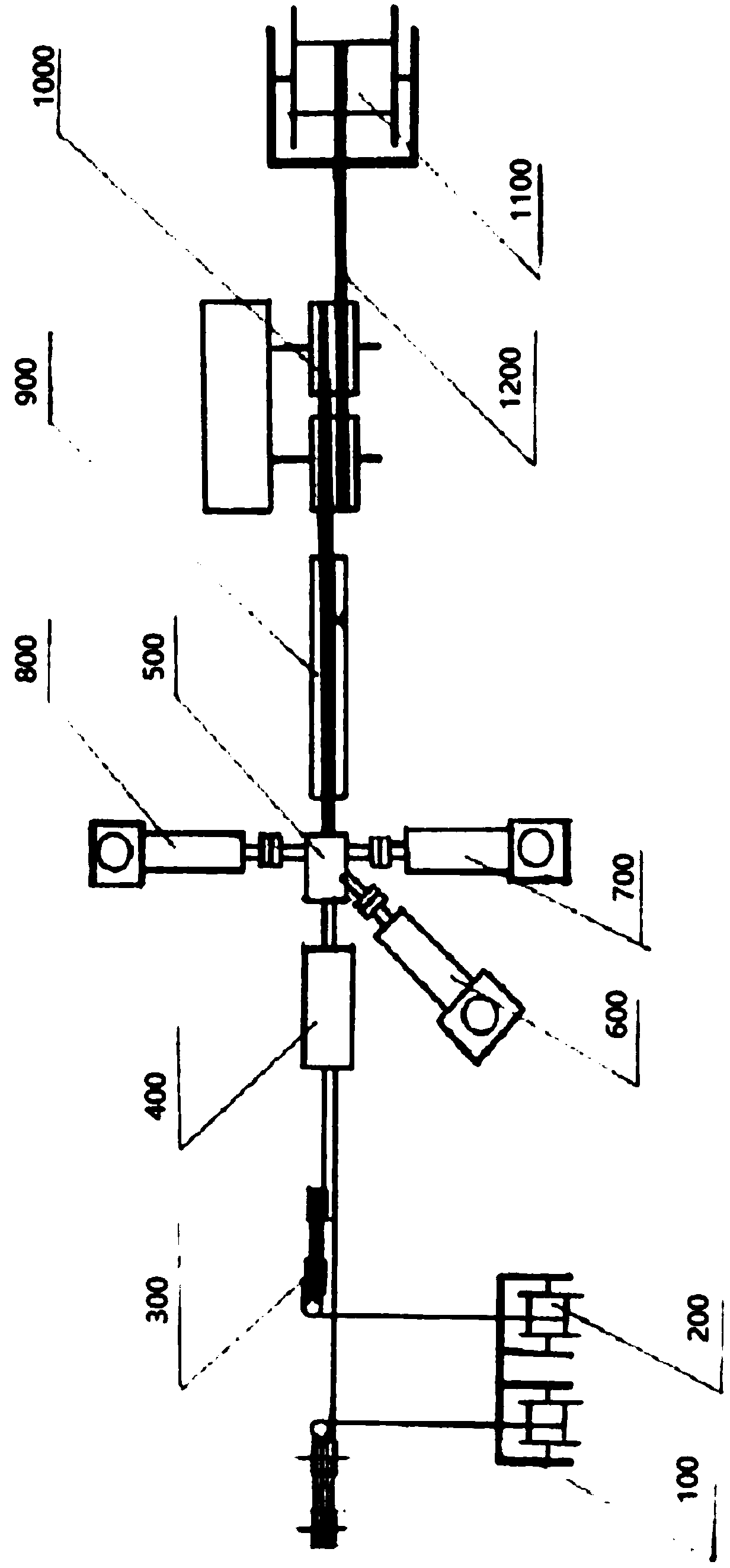

[0033] Such as figure 1 as shown, figure 1It is a schematic diagram of the overall structure of the present invention. The multi-layer co-extrusion device includes an active pay-off machine, a pay-off reel, a dancing wheel, a heater, a co-extrusion head, a plastic extruder, a constant temperature water tank, a traction device, and a take-up reel. . Two metal inner cores 1200 are actively released from the two active pay-off machines 100 and the two pay-off reels 200, and after being tensioned by the dance wheel 300 and heated by the heater 400, they enter three sets of the The co-extrusion head 500 between the plastic extruders is coated with the inner conductor layer, the PTC heating element layer, and the composite insulation layer at one time, and then cooled by the constant temperature water tank 900, and then cooled by the traction device 1000 and the take-up reel 1100 are put away. During the manufacturing process, the tension force of the two metal inner cores 1200 s...

Embodiment 2

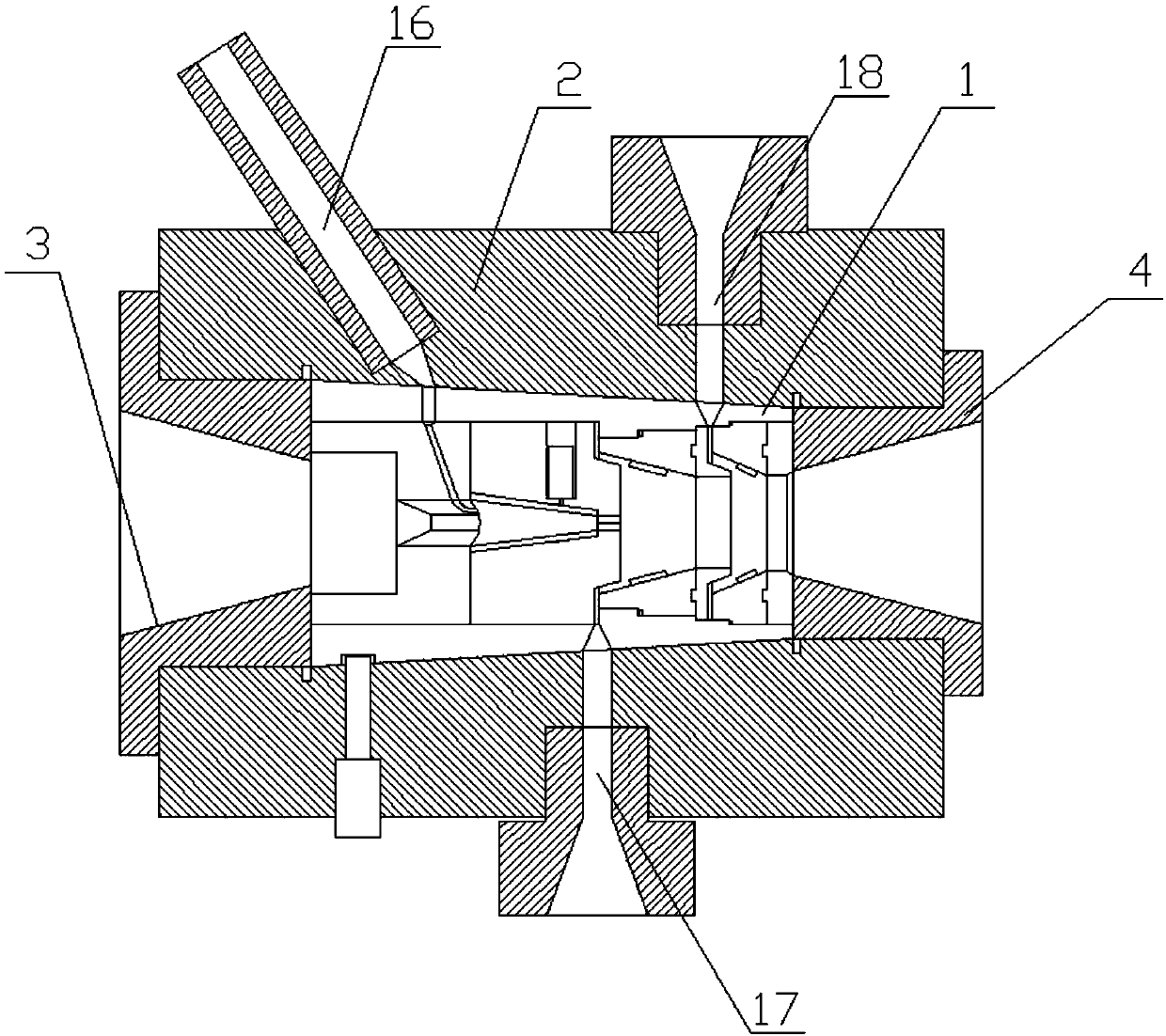

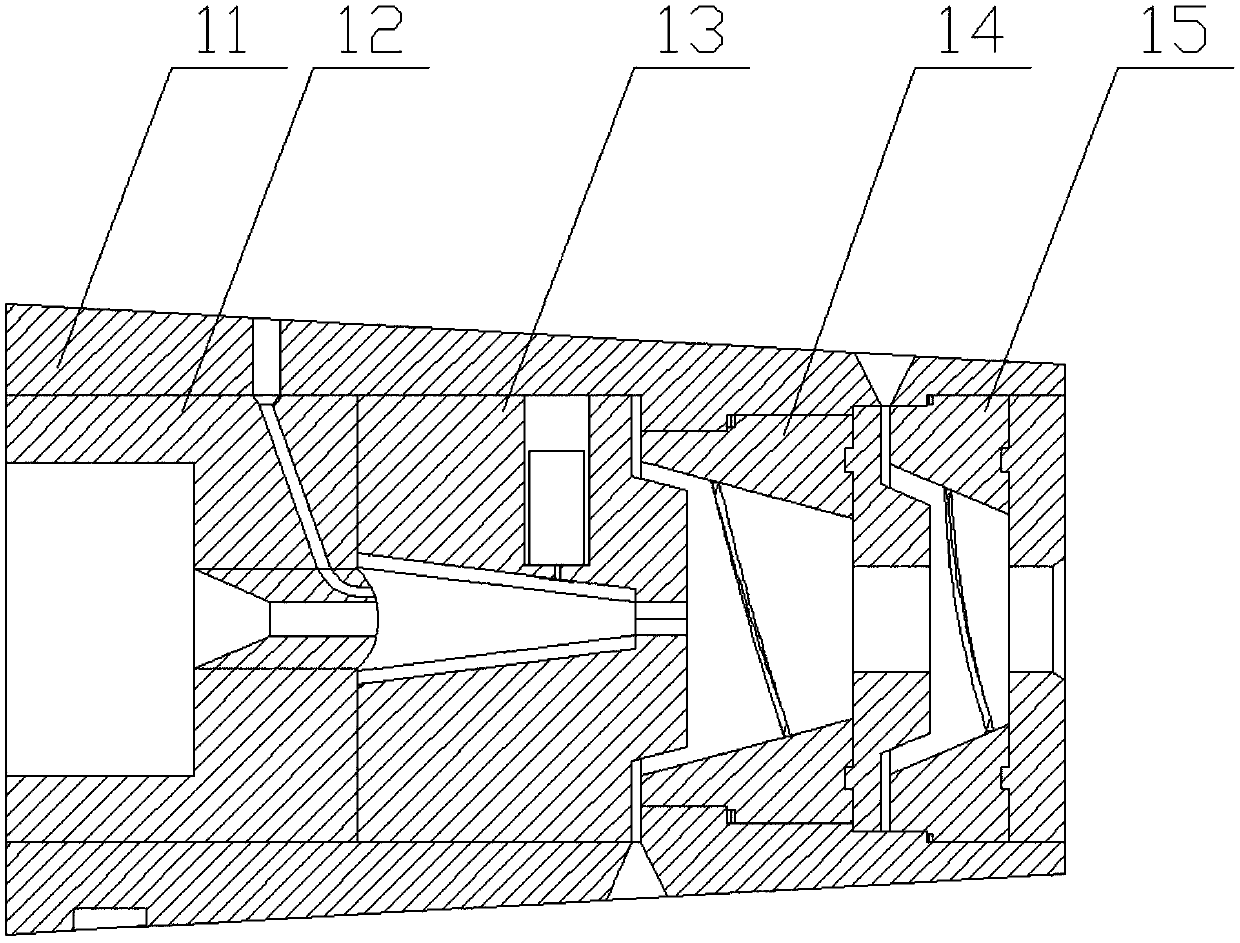

[0040] Such as image 3 as shown, image 3 It is a structural view (front view) of the composite module of the present invention, the wire inlet positioning module 12 includes a wire inlet mold 121 and a positioning mold 122 .

[0041] The wire inlet die 121 is arranged at the feeding end of the core support sleeve 11, and the wire inlet die 121 is provided with a number of through holes according to the number of inner cores of the heating cable, two of which are provided in this embodiment, and the positioning die 122 is provided with In the through hole, the positioning die 122 is preferably set as a cylinder, and a positioning hole is arranged in the positioning die 122, and the metal inner core is arranged in the positioning hole, and the positioning die 122 and the advancing The wire mold 121 is fixedly connected by pins or bolts, etc., and the wire inlet positioning module 12 can be adapted to make different heating cables by replacing the positioning mold 122 with pos...

Embodiment 3

[0043] The third embodiment improves the inner conductor layer module, specifically, the inner conductor layer module 13 includes a fixed mold 131 and a rotating mold 132.

[0044] Such as Figure 4 as shown, Figure 4 It is a structural view (top view) of the composite module group; the fixed mold 131 is fixed in the core support sleeve 11 through fixed connections such as pins or bolts, and several holes are set in the fixed mold 131 according to the number of through holes. The first molding cavity, the first molding cavity includes a rotating part 133 and a molding part 134, the rotating part 133 is configured as a cone, the rotating mold 132 is arranged in the rotating part 133, and the rotating The mold 132 can freely rotate in the rotating part 133; the rotating mold 132 is a hollow conical tubular structure, and the outer surface of the rotating mold 132 and the inner surface of the rotating part 133 are set in size to realize the rotation of the rotating mold. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com