Friction false twisting device and operation method thereof

An operating method and false twisting technology, applied in textiles and papermaking, etc., can solve the problems of halving the production capacity, twisting direction can only be reversed, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

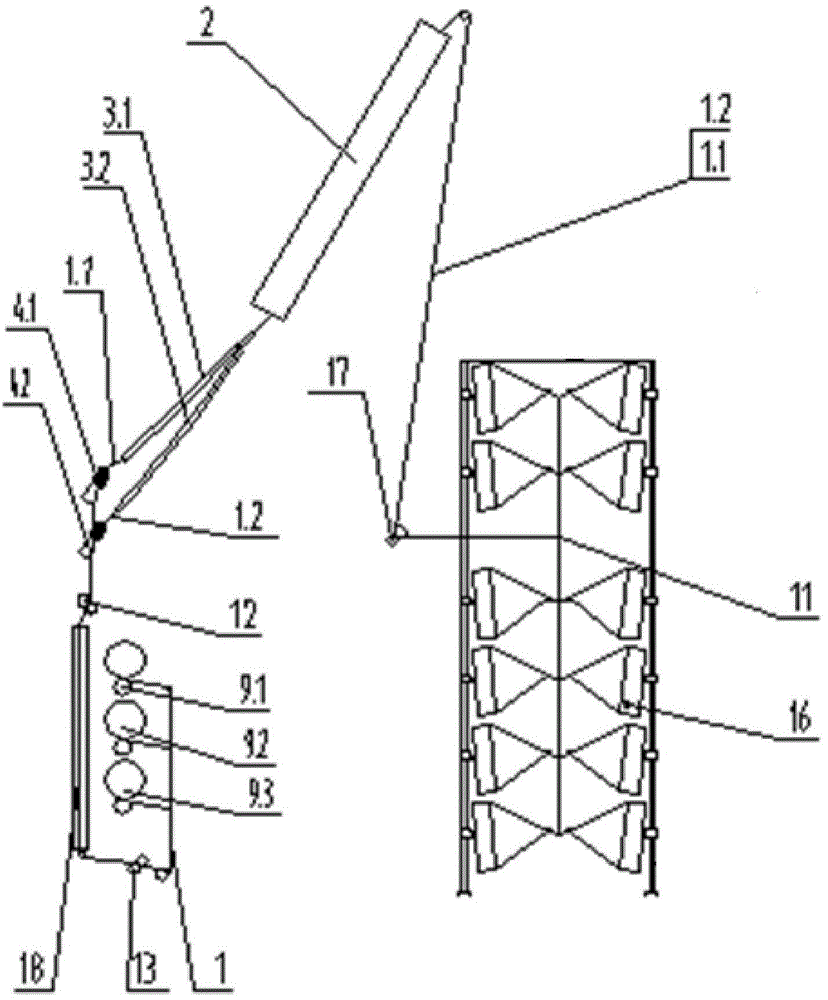

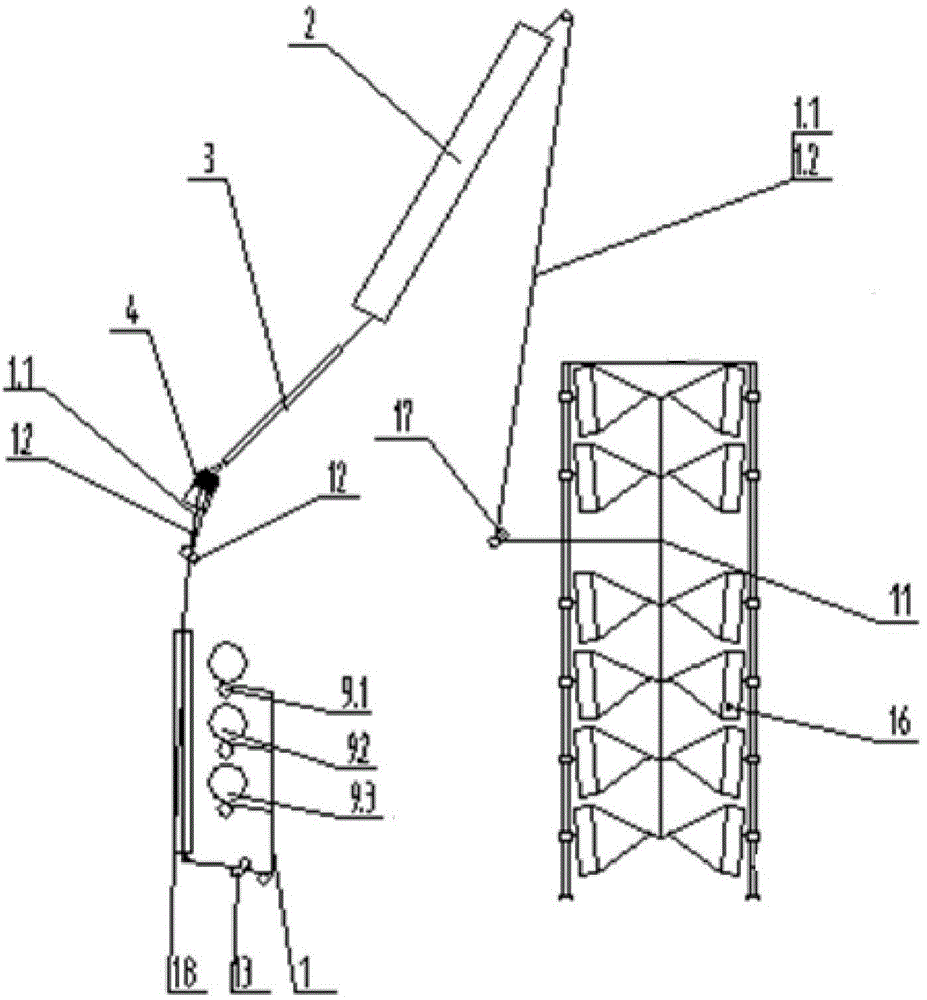

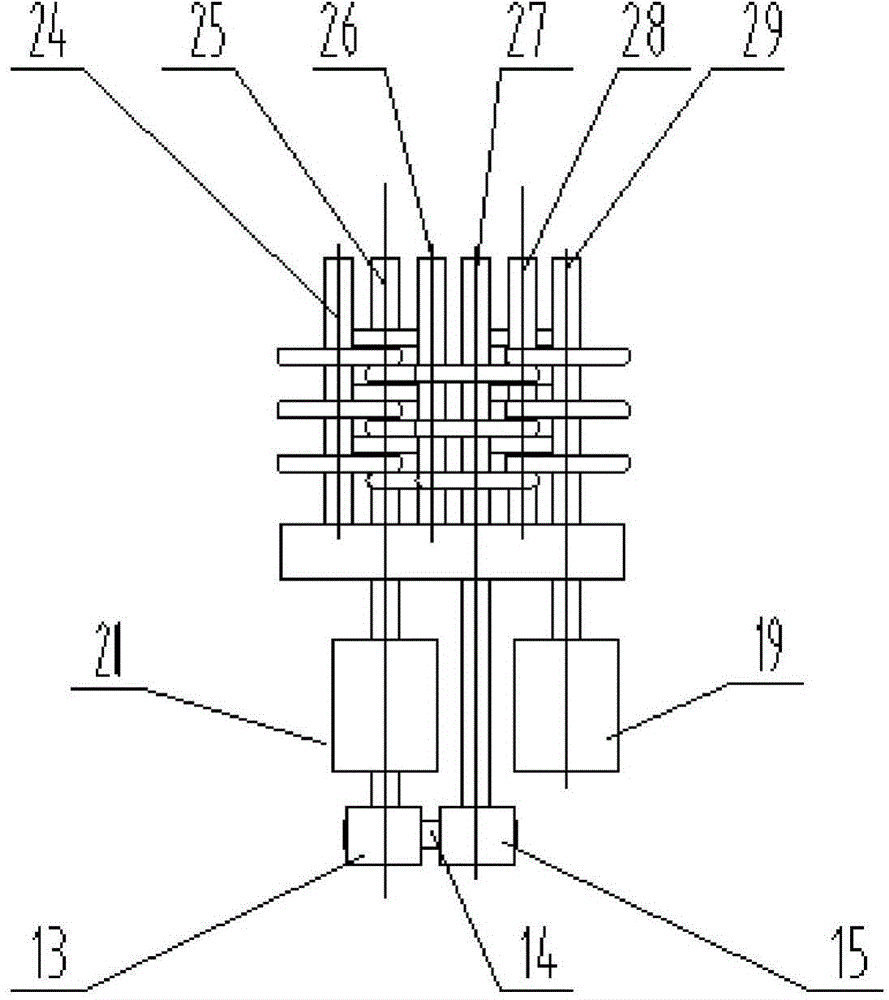

[0024] Example :like image 3 , 4 As shown, a friction false twisting device includes six parallel shafts 24, 25, 26; ; 27, 28, 29 are kept synchronously by a belt around its periphery that is an equilateral triangle. Each shaft 24, 25, 26; 27, 28, 29 is equipped with a plurality of friction discs that twist the silk thread, and they overlap each other and are arranged axially, and each group of shafts 24, 25, 26; 27, 28, 29 The friction disc on the top rotates in the same direction to twist one silk thread (S twist or Z twist), and the two groups correspond to twist two silk threads respectively, and the twist direction can be the same or different. One of each group of shafts 24, 25, 26, 27, 28, 29 is used as a transmission shaft 25, 29, and the two transmission shafts 25, 29 are respectively eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com