Top opening type dual-power washing machine

A washing machine and dual-power technology, applied in the field of top-loading dual-power washing machines, can solve the problems of uneven washing effect of clothes, uneven stirring effect of water body, etc., and achieve the advantages of miniaturized design, simple structure, and improved washing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

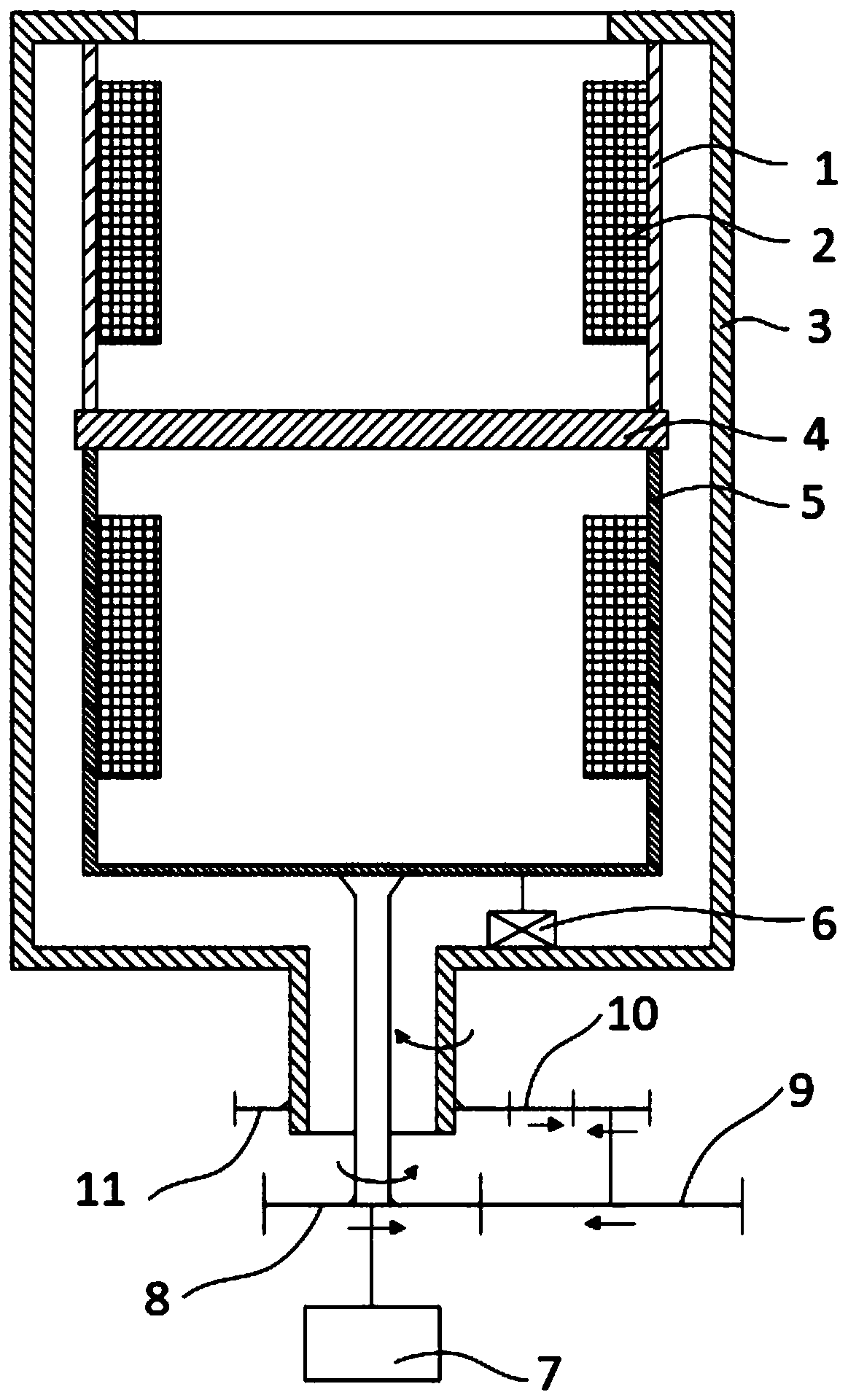

[0056] In this embodiment, the transmission mechanism is a gear transmission mechanism, and the gear transmission mechanism includes an input gear 8 , a transmission gear 9 , a reversing gear 10 and an output gear 11 . refer to figure 1 As shown, the input gear 8 is simultaneously used as an input member and a first output member, that is, the input gear 8 is simultaneously connected with the output shaft of the motor 7 and the rod-shaped connector extending from the lower barrel body 5. It should be noted that the connected The input gear 8 can be movably arranged on the axis where the output shaft of the motor 7 and the rod-shaped connector are located, so as to facilitate the separation of the input gear 8 and the transmission gear 9 during the drying process to disconnect the input gear 8 and the output gear 11. transmission path between them. For example, the motor 7 outputs a clockwise driving force, and through the connection of the input gear 8, the power is transmitt...

Embodiment 2

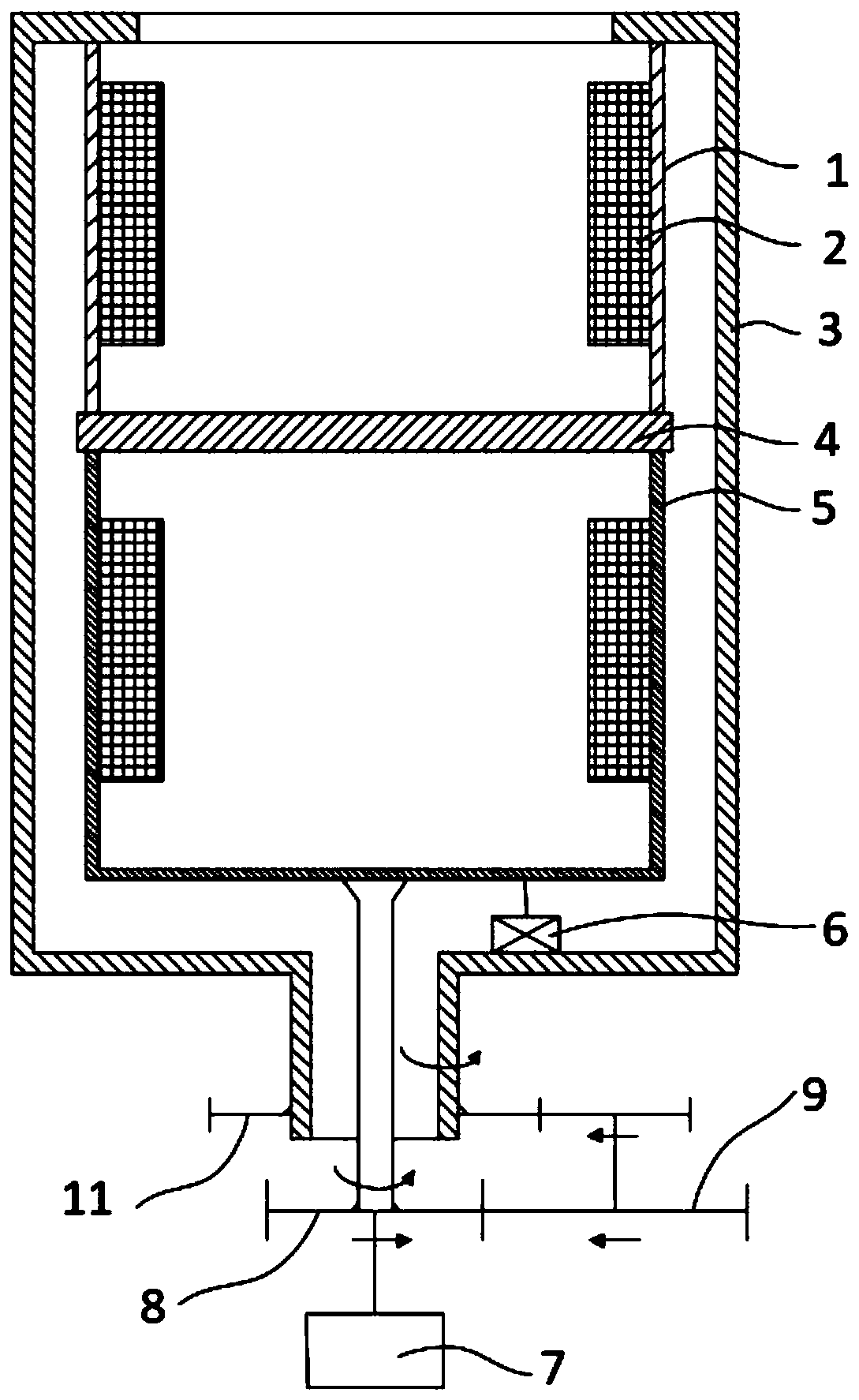

[0058] The transmission mechanism of the dual-power washing machine provided in this embodiment is a gear transmission mechanism, and the gear transmission mechanism in this embodiment includes an input gear 8 , a transmission gear 9 and an output gear 11 . refer to figure 2 , the input gear 8 is simultaneously used as an input member and a first output member, that is, the input gear 8 is simultaneously connected with the output shaft of the motor 7 and the rod-shaped connector extending from the lower barrel body 5. It should be noted that the connected input gear 8 is movable on the axis where the output shaft of the motor 7 and the rod-shaped connecting piece are located, so as to facilitate the disengagement of the input gear 8 and the transmission gear 9 during the drying process to disconnect the input gear 8 and the output gear 11. transmission path. The output gear 11 is used as the second output member. One end of the transmission gear 9 meshes with the input gear ...

Embodiment 3

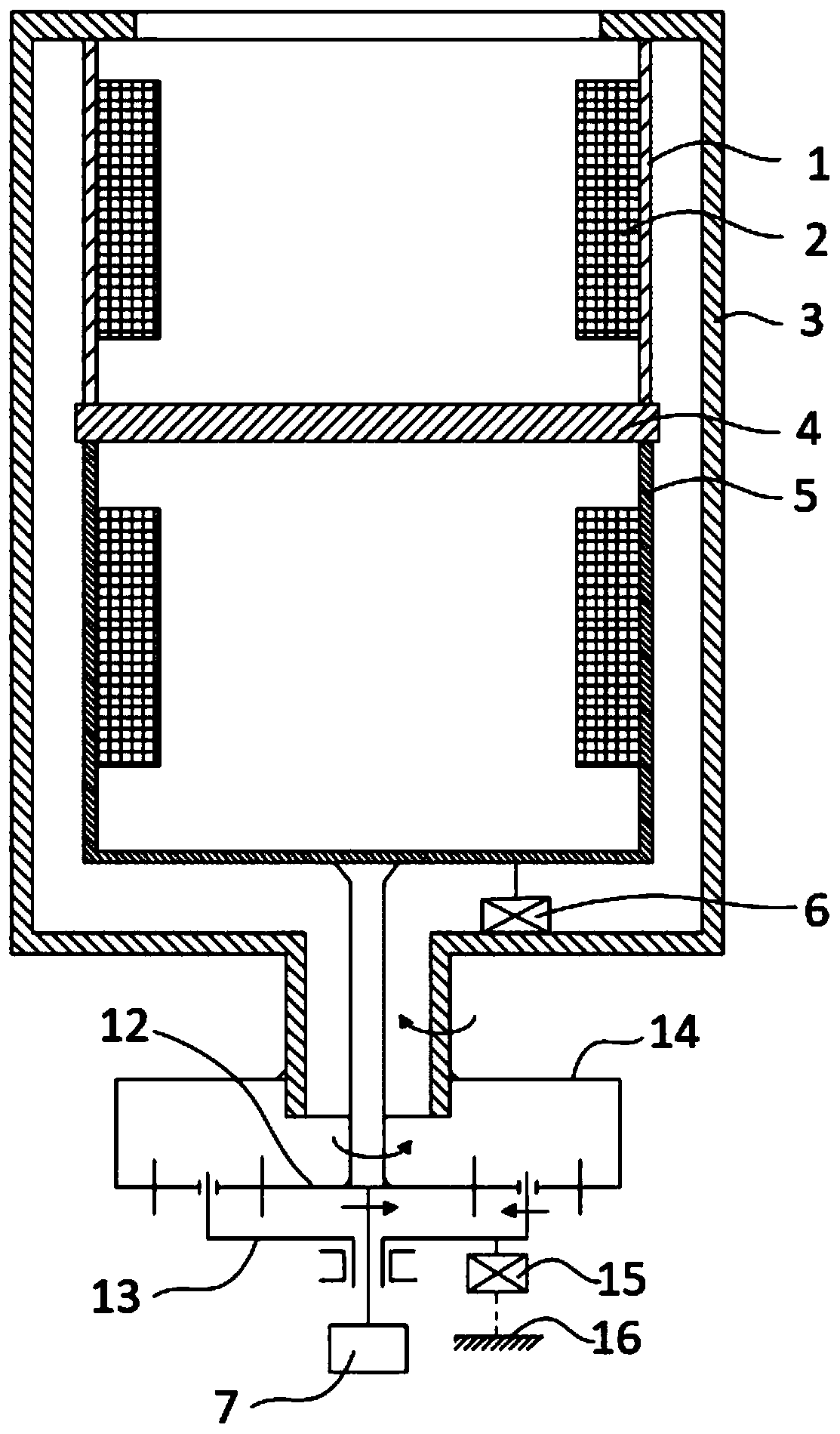

[0060] In this embodiment, the dual-power driving device further includes a first brake 15, and the first brake 15 mainly functions to brake the running components. The transmission mechanism in this embodiment is a planetary gear mechanism, and the planetary gear mechanism includes a sun gear 12 , a planetary gear, a planet carrier 13 and a ring gear 14 . refer to image 3 , the planetary carrier 13 is selectively connected to the casing 16 of the washing machine through the first brake 15, that is, the planetary carrier 13 can be fixed relative to the casing 16 or rotate relative to the casing 16 during operation. There are various forms of the first brake 15 for fixing the planetary carrier 13 , for example, restricting the movement of the planetary carrier 13 through a lever, or restricting the movement of the planetary carrier 13 through a movable positioning pin, and so on. The sun gear 12 serves as both an input member and a first output member, and the ring gear 14 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com