Paper pressing roller transmission device

A transmission device and paper pressing roller technology, which is used in transportation and packaging, thin material handling, object supply, etc., can solve the problems of inability to transport paper, high pressure, and different rotational speeds of the upper and lower paper pressing rollers. Ensure equipment stability and service life, simple control logic, and reduce paper scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

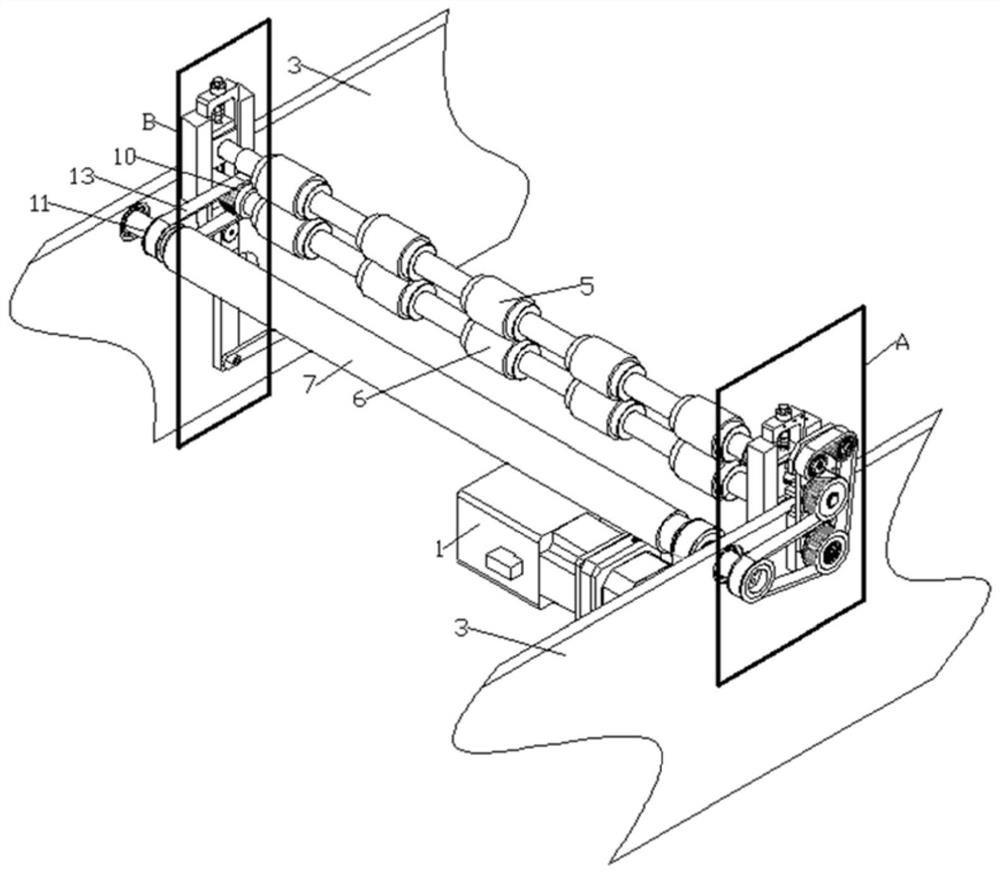

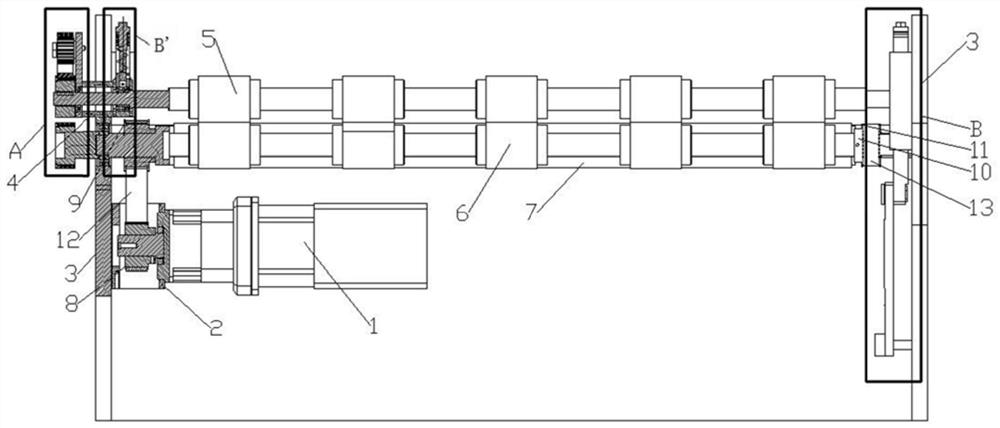

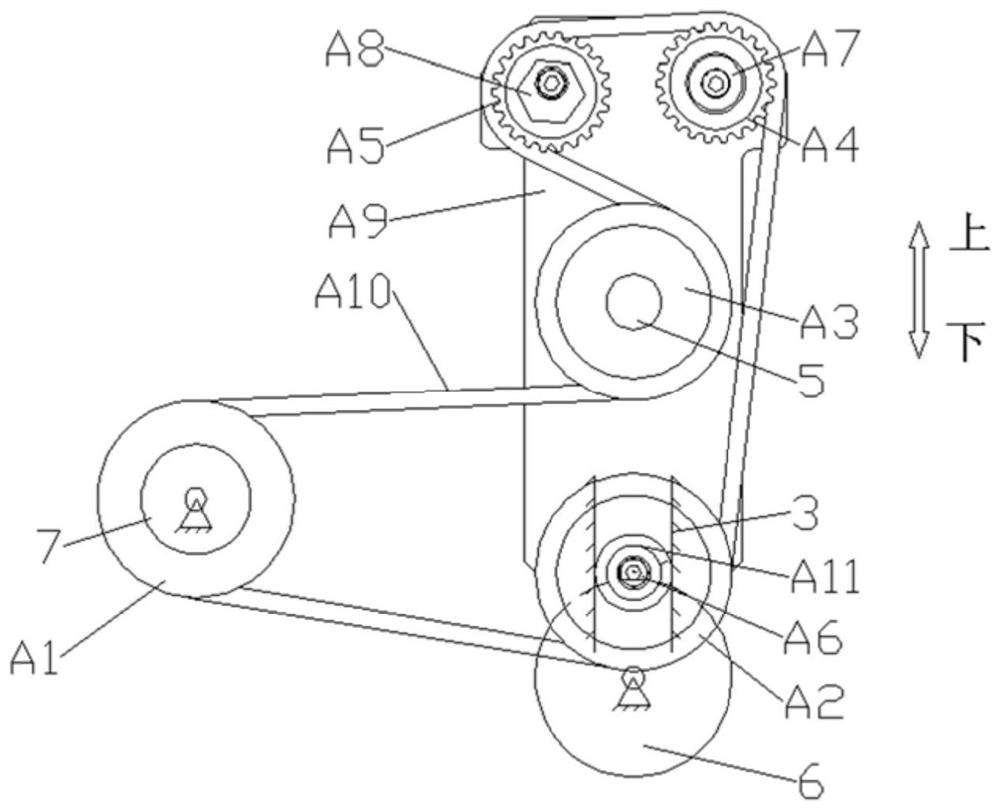

[0037] Figure 1-4 and the following descriptions describe alternative embodiments of the invention to teach those skilled in the art how to implement and reproduce the invention. In order to teach the technical solutions of the present invention, some conventional aspects have been simplified or omitted. Those skilled in the art will appreciate that modifications or substitutions derived from these embodiments will fall within the scope of the present invention. Those skilled in the art will appreciate that the following features can be combined in various ways to form various variations of the invention. Thus, the present invention is not limited to the alternative embodiments described below, but only by the claims and their equivalents.

[0038] like figure 1 As shown, it is a schematic diagram of the structure of the paper platen roller transmission device of the present invention, figure 2 It is the front view of the paper pressing roller transmission device of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com