Four-wheel reclamation machine

A four-wheel drive and walking mechanism technology, applied in the field of agricultural and forestry machinery, can solve problems such as high labor intensity, increased production costs, and low efficiency of manual excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

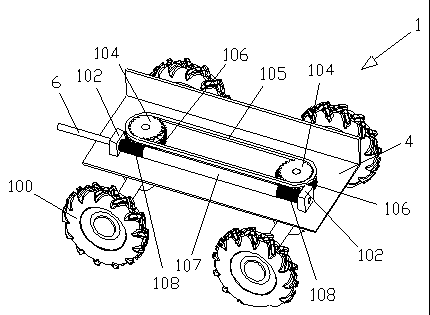

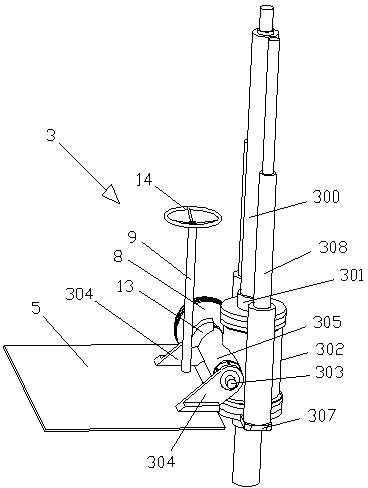

Embodiment 1

[0055] When the groove needs to be opened, the angle adjustment worm 9 is driven by the adjustment plate 14 on the angle adjustment worm 9, and the fan-shaped worm wheel 13 is driven by the angle adjustment worm 9. Meanwhile, the worm housing 305 and the main power head shell 302 are also followed to adjust the inclination angle of the end milling screw cutter 300. At this time, the diesel engine 200 is used to drive the travel sprocket 104 to rotate by the travel hydraulic motor 201, so that the wheel 100 travels, and the pulley 8 is also driven to rotate at the same time. The driving head screw 303 rotates to drive the rotating worm gear 312 on the rotating sleeve 30301. At this time, the end milling screw 300 also rotates accordingly to perform groove opening.

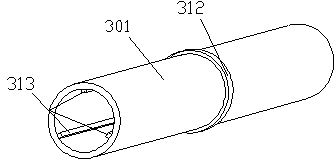

Embodiment 2

[0057] When the ground hole needs to be drilled, the angle adjustment worm 9 is driven by the adjustment disk 14 on the angle adjustment worm 9, and the fan-shaped worm wheel 13 is driven by the angle adjustment worm 9. Meanwhile, the worm housing 305 and the main power head housing 302 also follow and adjust the end mill screw cutter 300 to a vertical angle, start the diesel engine 200, and at the same time the pulley 8 will also be driven to rotate, so that the main power head screw 303 rotates to drive the rotating worm gear 312 on the rotating sleeve 301. At this time, the end milling screw cutter 300 also rotates accordingly. When it is necessary to give the ground hole a depth, the hydraulic lifting rod 308 is controlled to descend through the hydraulic pump station, and drives the milling screw cutter 300 to descend in the rotating sleeve 301, thereby Reach the depth required for the ground hole.

Embodiment 3

[0059] When it is necessary to dig trees and transplant seedlings, when the bottom end of the end milling helical cutter 300 is aligned near the base of the tree or seedlings, the angle adjustment worm 9 is driven by the adjustment disc 14 on the angle adjustment worm 9, and the angle adjustment worm 9 is used to adjust the angle. Drive the fan-shaped worm gear 13, and at the same time, the worm housing 305 and the main power head housing 302 also move accordingly, thereby adjusting the inclination angle of the end milling screw cutter 300, and driving the vertical direction rod 10 by rotating the direction rotating disc 12 , and then through the bevel gear b 11 at the bottom of the vertical direction rod 10, and the bevel gear a 7 is driven by the bevel gear b 11 to drive the direction linkage rod 6 to rotate. At this time, the worm 107 will also rotate thereupon, because the worm The worm gears 108 at both ends of the 107 are arranged in opposite directions, so that the worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com