Method for continuous esterification of waste oil and fat

A waste oil and esterification technology, which is applied in the production of fatty acids, esterification of fatty acids, chemical modification of fatty acids, etc., can solve the problems of low level of automation control, high labor intensity, high energy consumption of high-power compressors, and improve the level of automation control. , The effect of reducing labor intensity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

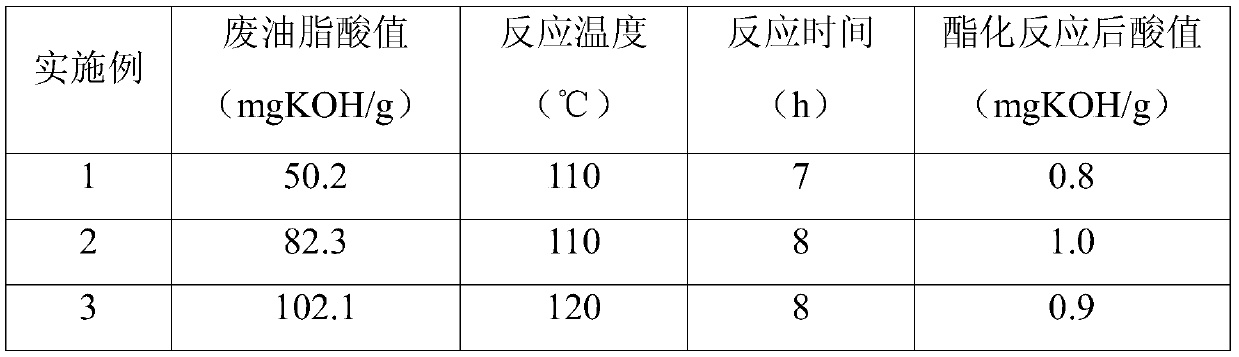

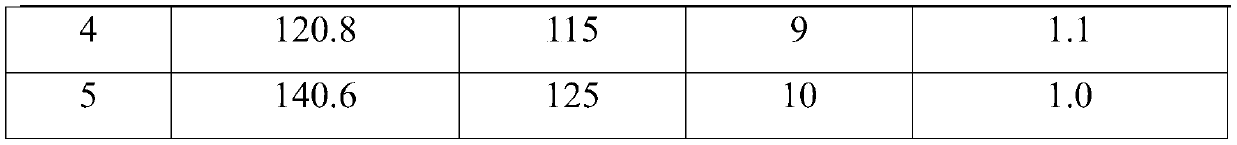

Examples

Embodiment Construction

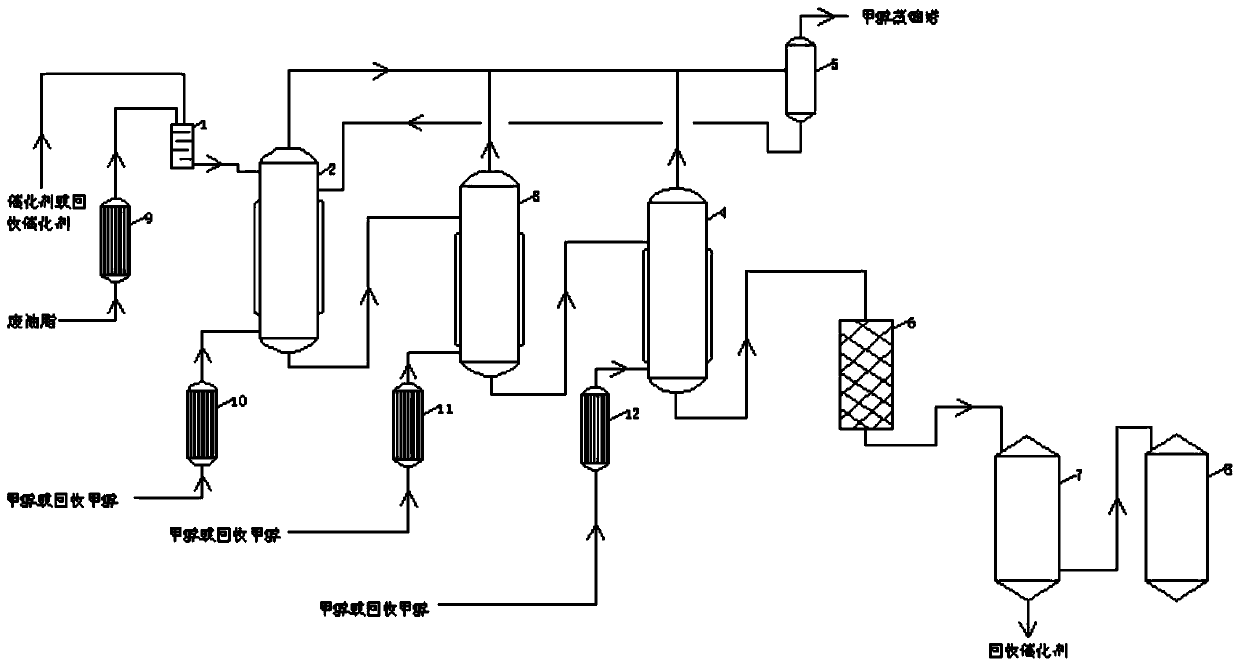

[0019] The method for continuous esterification production of waste oil and fat of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0020] figure 1 As shown, the operation steps of the method for continuous esterification production of a kind of waste grease of the present invention are as follows:

[0021] (1) Mixing of waste grease and catalyst: The purified waste grease is heated by 1# heater 9 and sent to mixer 1, and the prepared catalyst or recovered catalyst is also sent to mixer 1, and in mixer 1 The waste grease is mixed with the catalyst;

[0022] (2) the mixed material enters the tower from the upper side of the 1# reaction tower 2, and methanol or recovered methanol is heated and gasified by the 2# heater 10 and enters the tower from the bottom side of the 1# reaction tower 2, keeping 1# The reaction temperature in the reaction tower 2 is 110-130 ° C, and the introduction of ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com