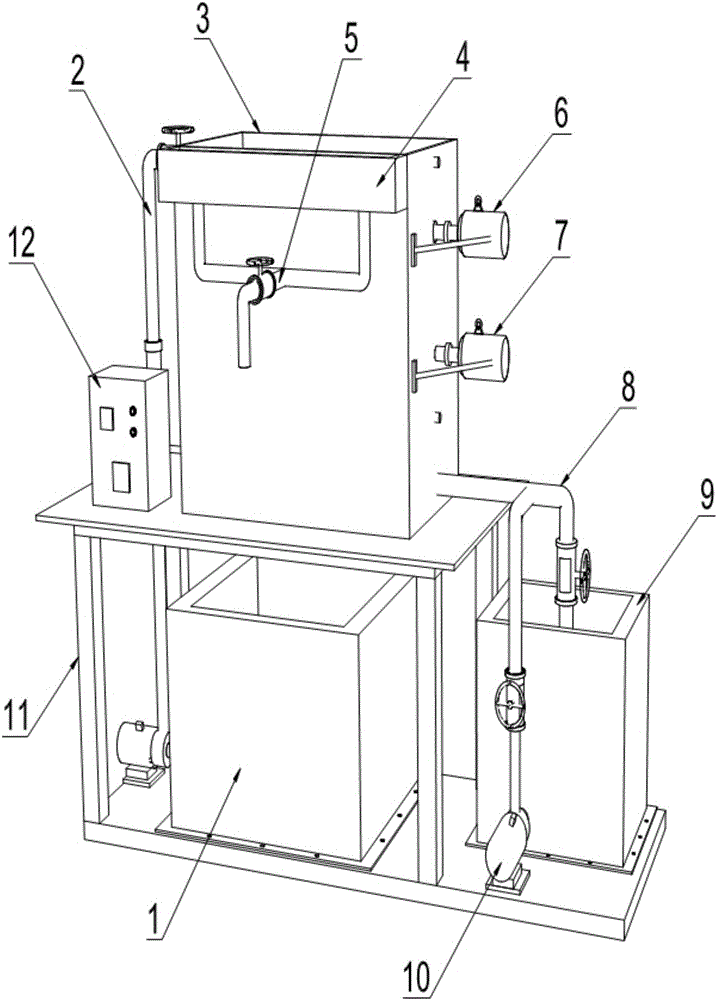

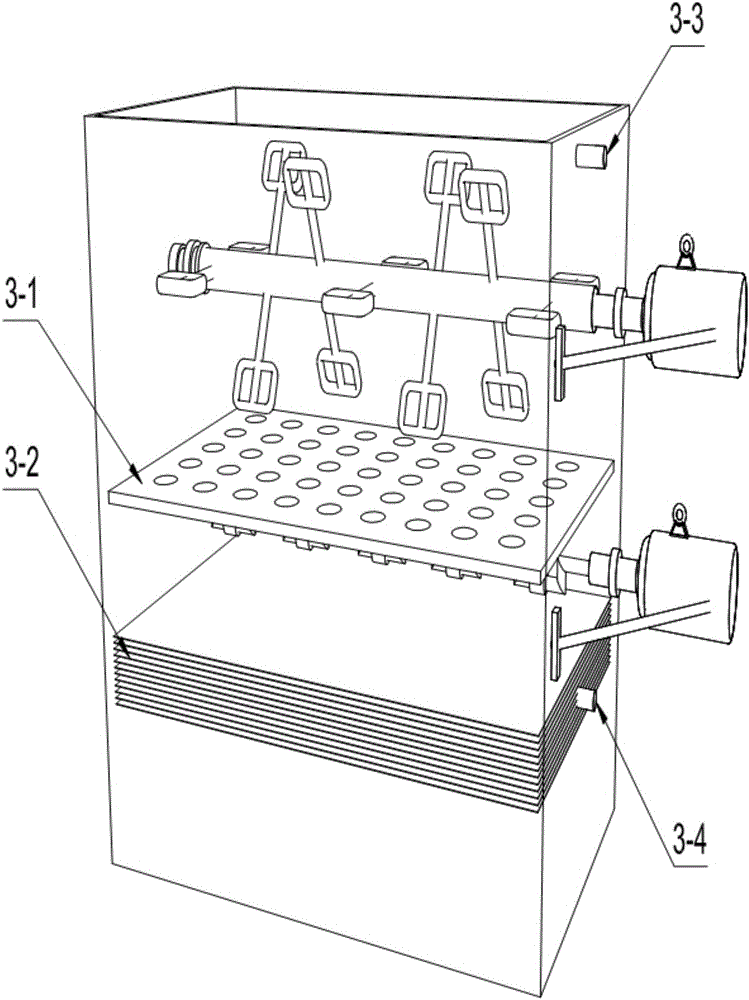

Stirring and vibrating water purifying device and working method thereof

A water purification device, stirring vibration technology, applied in chemical instruments and methods, water treatment parameter control, adsorption water/sewage treatment, etc., can solve the problems of long process flow, high treatment cost, complicated control, etc., and achieve uniform stirring effect , high sewage purification rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

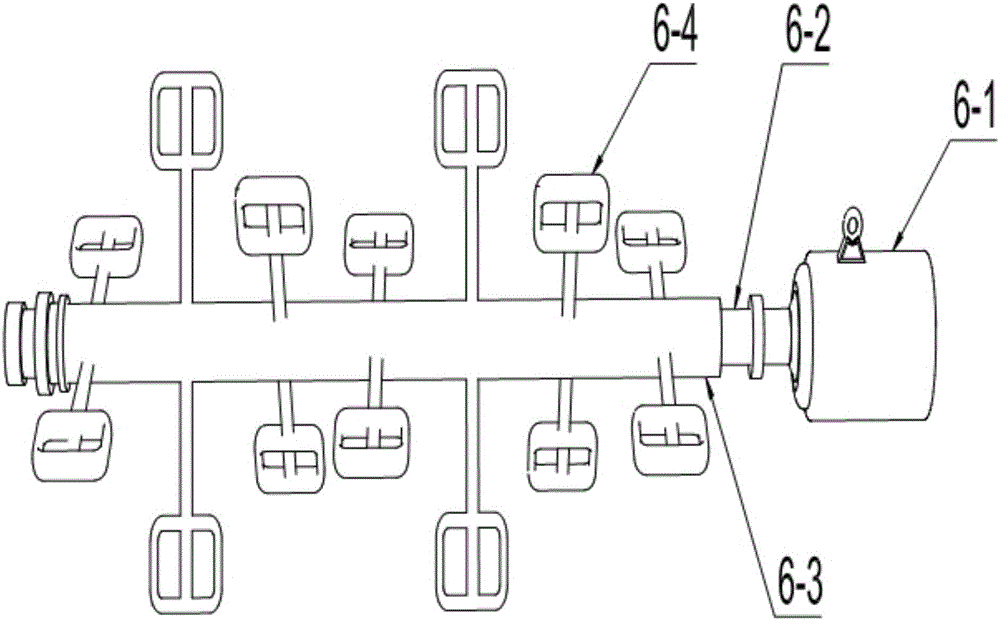

[0054] Make stirring blade 6-4 of the present invention according to the following steps, and by weight fraction:

[0055]Step 1: Add 900 parts of ultrapure water with a conductivity of 0.02μS / cm into the reactor, start the stirrer in the reactor at a speed of 111rpm, start the heating pump, and raise the temperature in the reactor to 47°C; add in order 8-bromocyclic adenosine monophosphate, tri-n-octyl triazine, p-methoxyphenyl isocyanate, stir until completely dissolved, adjust the pH value to 2.4, adjust the stirrer speed to 56rpm, and the temperature is 32°C, esterification Reaction for 8 hours;

[0056] Step 2: take levosalbutamol hydrochloride and methylthioxime ether and pulverize, the powder particle size is 520 mesh; 23 minutes of α-ray irradiation with an energy of 3.65 MeV;

[0057] Step 3: Dissolve the mixed powder treated in step 2 in sodium ethoxide ethanol solution, add it to the reactor, the stirrer speed is 67rpm, the temperature is 85°C, start the vacuum pu...

Embodiment 2

[0061] Make stirring blade 6-4 of the present invention according to the following steps, and by weight fraction:

[0062] Step 1: Add 2,800 parts of ultrapure water with a conductivity of 0.15μS / cm into the reactor, start the stirrer in the reactor at a speed of 151rpm, start the heating pump, and raise the temperature in the reactor to 69°C; add in sequence 8-Bromocyclic adenosine monophosphate, tri-n-octyl triazine, and p-methoxyphenylisocyanate were stirred until they were completely dissolved, and the pH value was adjusted to 5.2. 19 hours of reaction;

[0063] Step 2: take levosalbutamol hydrochloride and methylthioxime ether and pulverize, the particle size of the powder is 820 mesh; α-ray irradiation with an energy of 9.85 MeV for 58 minutes;

[0064] Step 3: Dissolve the mixed powder treated in step 2 in sodium ethoxide ethanol solution, add it to the reactor, the stirrer speed is 83rpm, the temperature is 112°C, start the vacuum pump to make the vacuum degree of th...

Embodiment 3

[0068] Make stirring blade 6-4 of the present invention according to the following steps, and by weight fraction:

[0069] Step 1: Add 1800 parts of ultrapure water with a conductivity of 0.09μS / cm into the reactor, start the stirrer in the reactor at a speed of 131rpm, start the heating pump, and raise the temperature in the reactor to 58°C; add in sequence 8-bromocyclic adenosine monophosphate, tri-n-octyl triazine, p-methoxyphenyl isocyanate, stir until completely dissolved, adjust the pH value to 3.2, adjust the stirrer speed to 76rpm, and the temperature is 46°C, esterification Reaction for 13 hours;

[0070] Step 2: take levosalbutamol hydrochloride and methylthioxime ether and pulverize, the powder particle size is 620 mesh; 48 minutes of α-ray irradiation with an energy of 6.85 MeV;

[0071] Step 3: Dissolve the mixed powder treated in step 2 in sodium ethoxide ethanol solution, add it to the reaction kettle, the stirrer speed is 73rpm, the temperature is 96°C, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com