Organic fertilizer and preparation method thereof

A technology for organic fertilizers and raw materials, applied in the preparation of organic fertilizers, organic fertilizer equipment, organic fertilizers, etc., can solve the problems of inconvenient control of humidity, temperature and oxygen, affecting the normal fermentation of fermentation strains, and affecting the effect of fermentation, etc. The effect of ensuring fermentation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

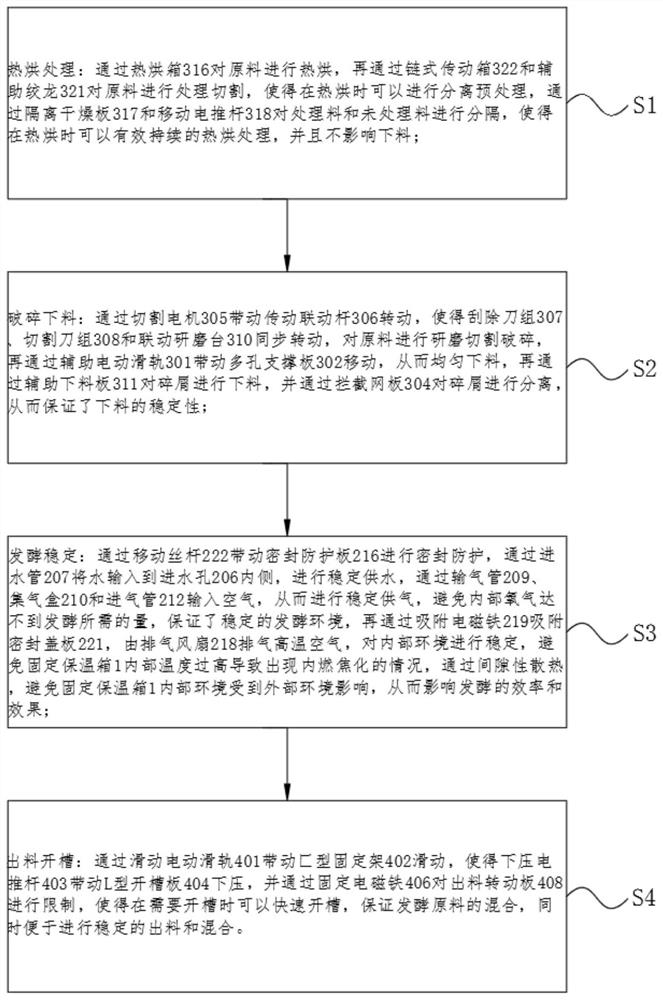

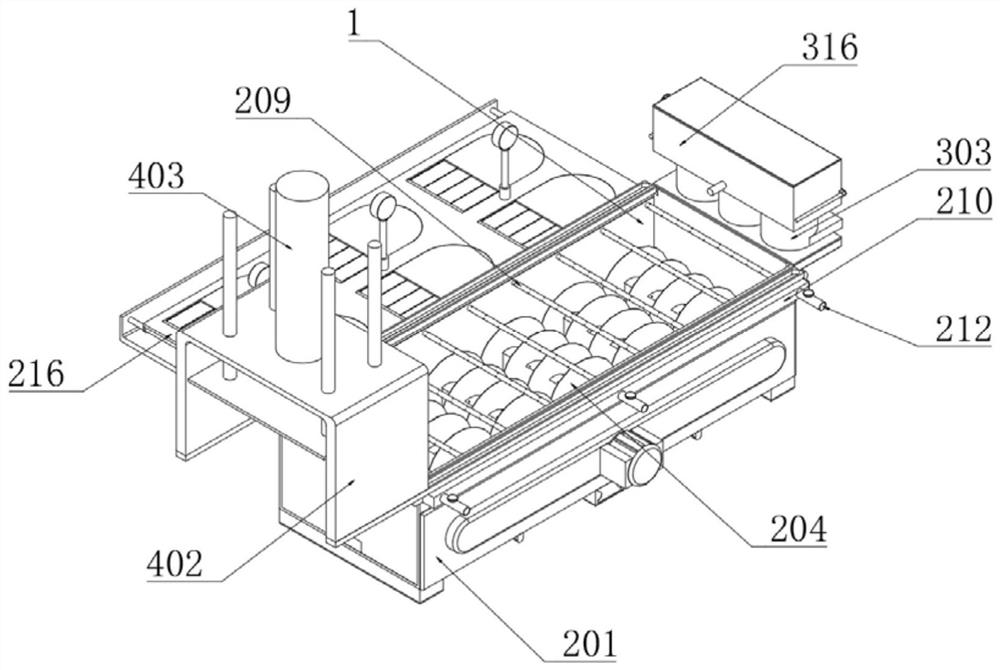

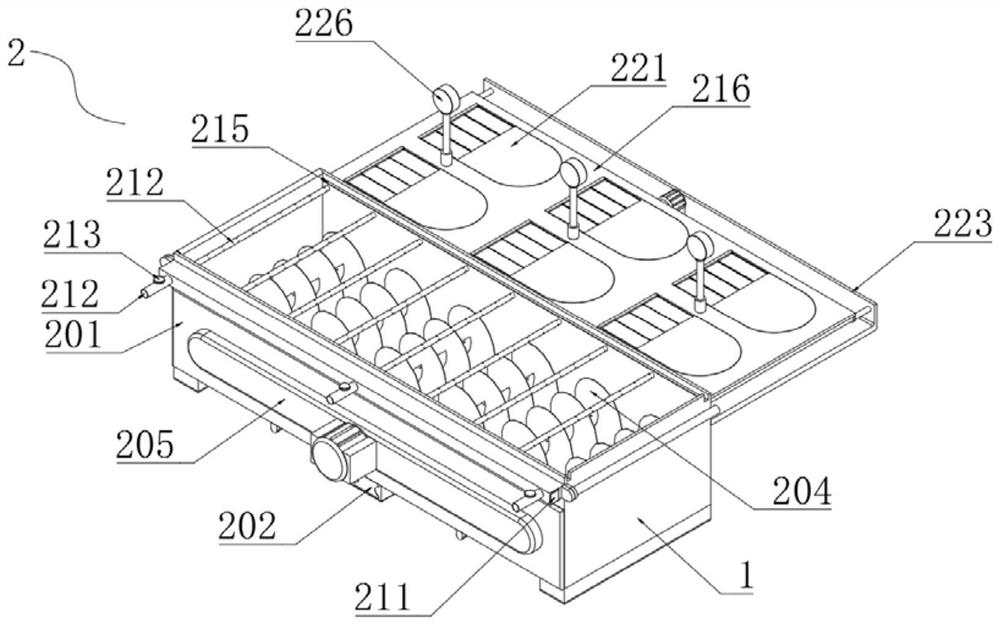

[0038] Example: such as Figure 1-12 As shown, the present invention provides a kind of technical scheme, a kind of organic fertilizer preparation method, comprises the steps:

[0039] S1: heat drying treatment: heat the raw materials through the heat oven 316, and then process and cut the raw materials through the chain transmission box 322 and the auxiliary auger 321, so that separation and pretreatment can be carried out during heat drying, and through the isolation drying plate 317 Separate the processed material and the untreated material with the mobile electric push rod 318, so that the heat drying process can be effectively and continuously performed during heat drying, and it does not affect the blanking;

[0040] S2: Crushing and blanking: the cutting motor 305 drives the transmission linkage rod 306 to rotate, so that the scraper knife group 307, the cutting knife group 308 and the linkage grinding table 310 rotate synchronously to grind, cut and crush the raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com