Set yoghurt and preparation method thereof

A yogurt and milk technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of coagulated yogurt, such as rough texture, large space occupation, and slow turnover, so as to retain nutritional value, improve digestibility, and smooth taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

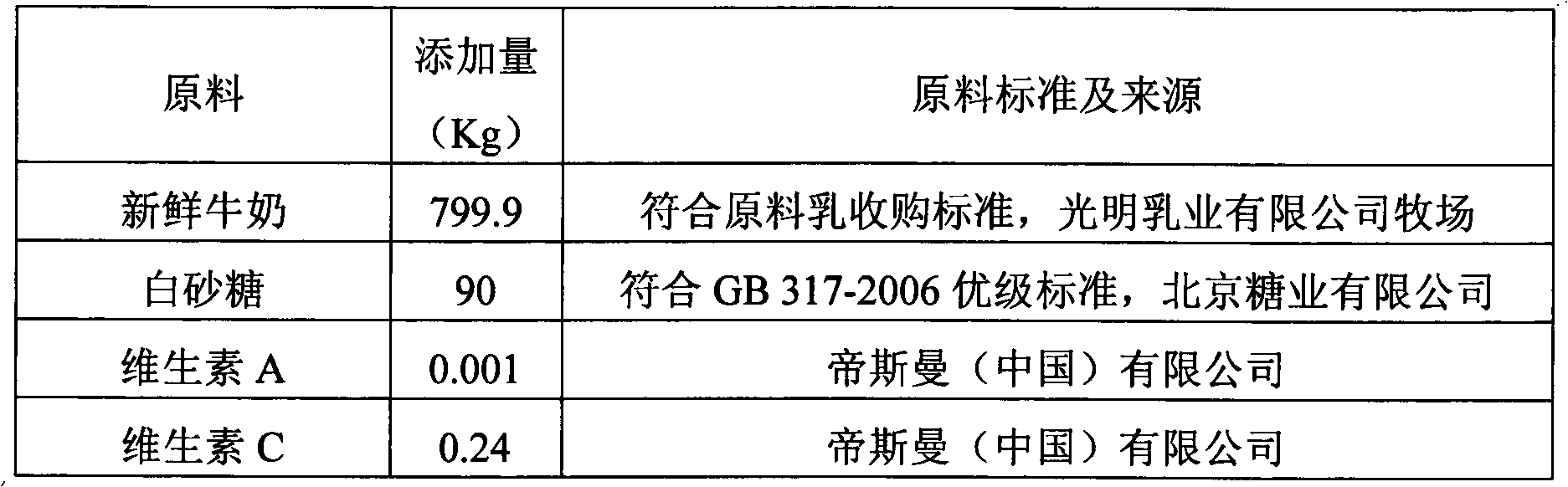

[0049] 1. Raw material formula (see Table 1):

[0050] Table 1 Raw materials, additions, standards and their sources (calculated on the basis of 1 ton of product)

[0051]

[0052]

[0053] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0054] 2. Preparation process:

[0055] 1) Mix white sugar, whey protein concentrate WPC-80, gelatin, pectin and modified starch with fresh milk preheated to 50°C, stir for 20 minutes, and mix the feed liquid with vitamin A, Mix vitamin C and vitamin E evenly;

[0056] 2) After the semi-finished product is qualified, homogenize at 70°C and 18MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool to 42°C, inoculate the starter, and ferment for 6 hours until the acidity reaches 70-80°T;

[0057] 3) When the temperature drops to 15-20°C, add yellow peach essence and yellow peach fruit granules, carry out aseptic filling, cool to 2...

Embodiment 2

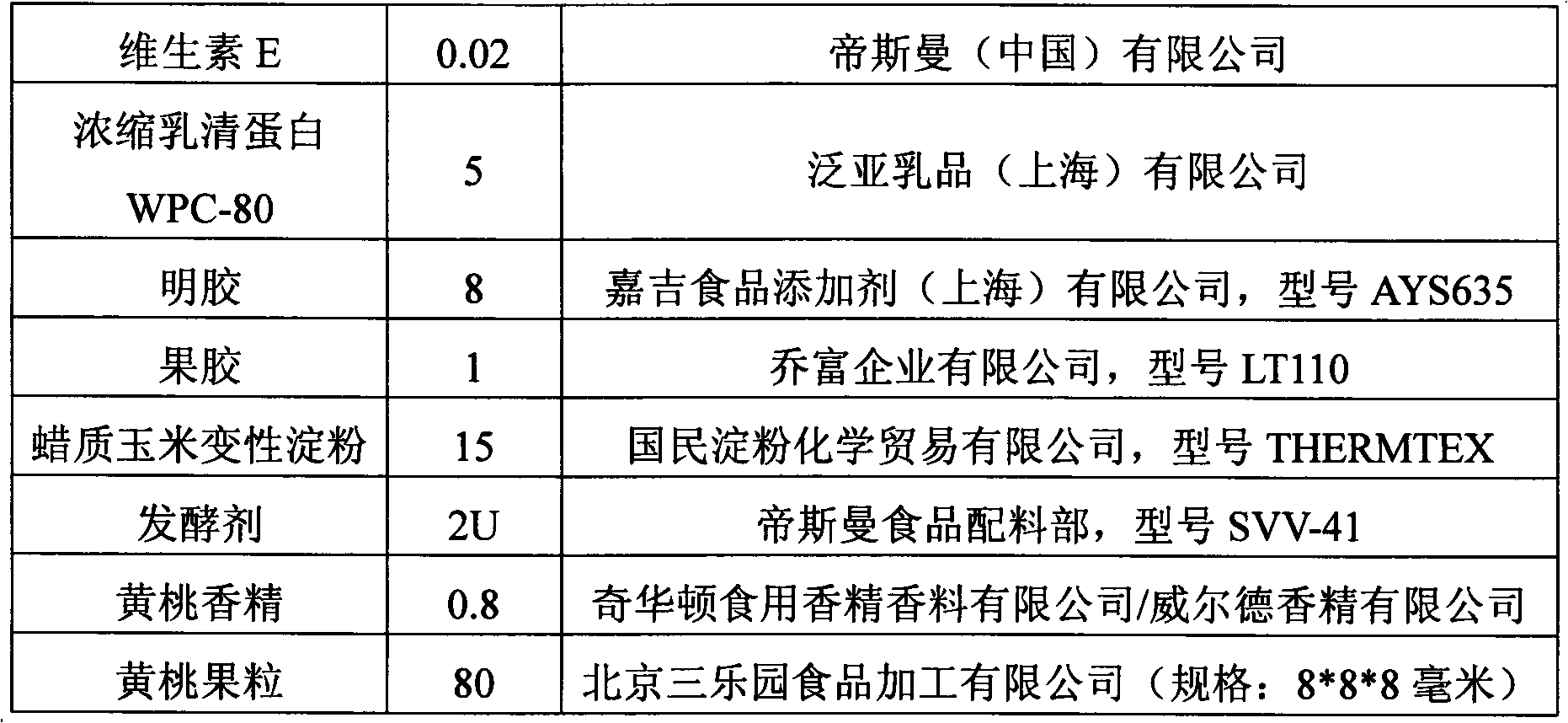

[0059] 1. Raw material formula (see Table 2):

[0060] Table 2 Raw materials, addition amount, standard and source (calculated on the basis of 1 ton of product)

[0061]

[0062]

[0063] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0064] 2. Preparation process:

[0065] 1) Mix white sugar, whey protein concentrate WPC-34, agar, gelatin and modified starch with fresh milk preheated to 68°C, and stir for 18 minutes;

[0066] 2) After the semi-finished product is qualified, homogenize at 60°C and 20MPa, sterilize at 95°C for 360 seconds, put the sterilized material into a milk buffer tank and cool to 38°C, inoculate with starter, and ferment for 6.5 hours until the acidity reaches 70-80°T;

[0067] 3) When the temperature drops to 15-20°C, add orange essence and granules of orange fruit, carry out aseptic filling, cool to 2-6°C, and ferment for 24 hours.

Embodiment 3

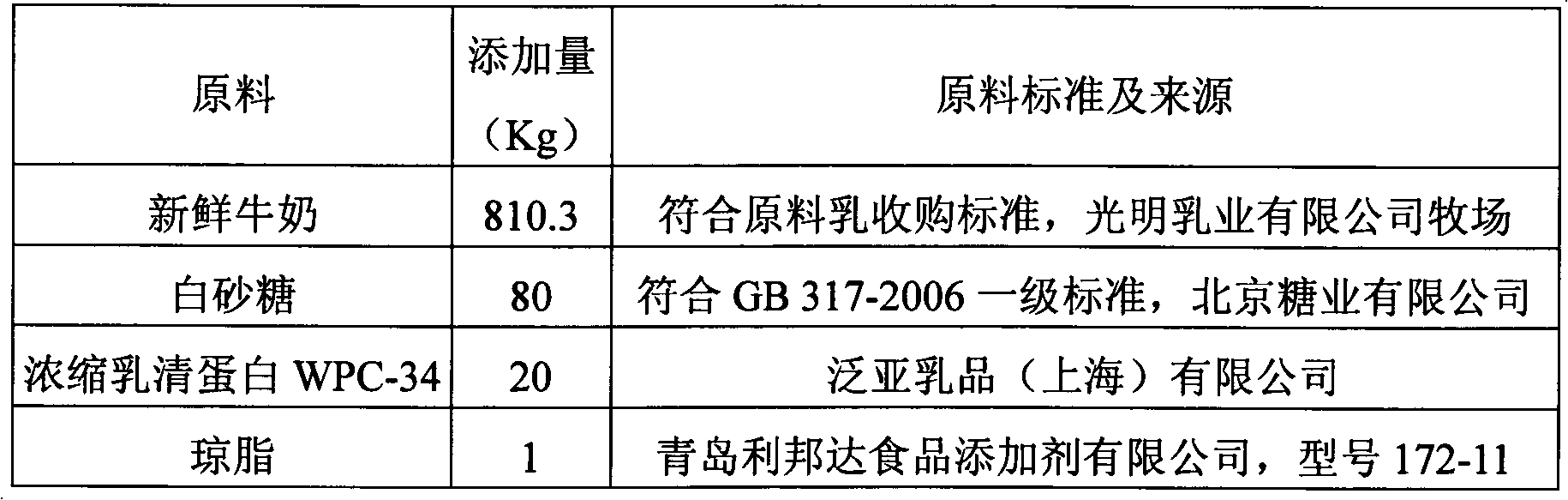

[0069] 1. Raw material formula (see Table 3):

[0070] Table 3 Raw materials, addition amount, standards and their sources (calculated on the basis of 1 ton of product)

[0071]

[0072]

[0073] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0074] 2. Preparation process:

[0075] 1) Mix acesulfame K, aspartame, whey protein concentrate WPC-34, gelatin, PGA and modified starch with fresh milk preheated to 70°C, and stir for 20 minutes;

[0076] 2) After the semi-finished product is qualified, homogenize at 80°C and 16MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool it to 44°C, inoculate the starter, and ferment for 5 hours until the acidity reaches 70-80°T;

[0077] 3) When the temperature drops to 15-20°C, add mango essence and mango fruit granules, carry out aseptic filling, cool to 2-6°C, and ferment for 24 hours to obtain the product, and leave the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com