Lactobacillus beverage contains probiotic fermented fruits and vegetables and preparation method of lactobacillus beverage

A technology of lactic acid bacteria drinks and probiotics, applied in dairy products, milk preparations, applications, etc., can solve the problem of less addition of fruit and vegetable juices, and achieve the effect of easy acceptance, uniform tissue state, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

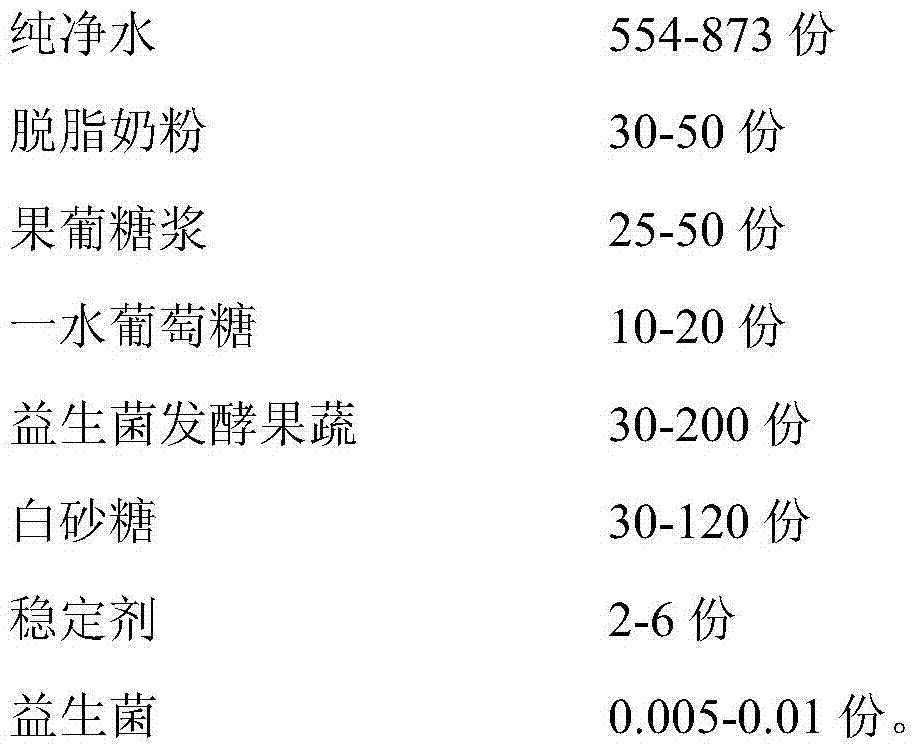

Method used

Image

Examples

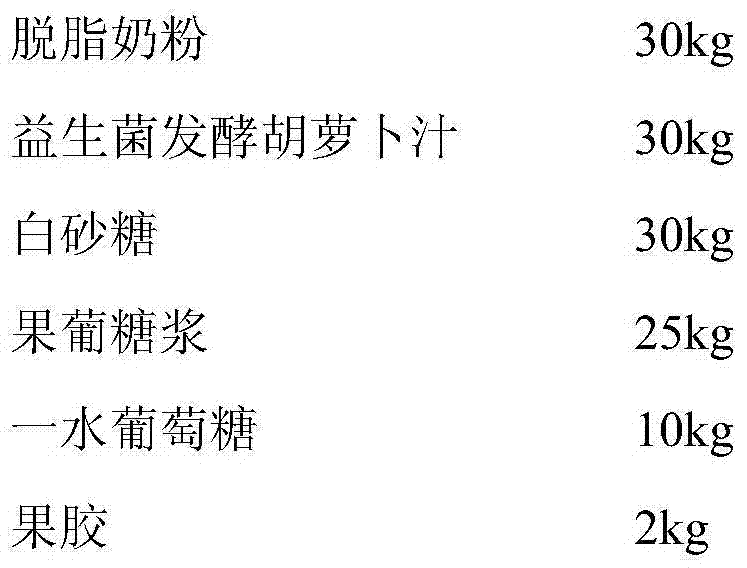

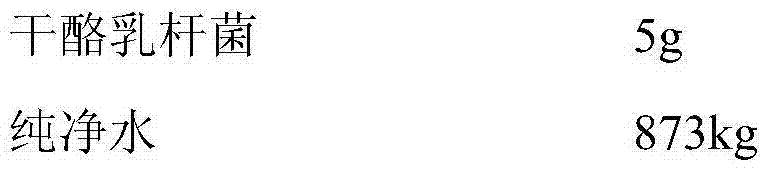

Embodiment 1

[0049]

[0050]

[0051] (1) Fermented milk ingredients: heat up the purified water to 40°C, dissolve skimmed milk powder, glucose monohydrate, and 12.5kg fructose syrup in purified water, and dilute to 250 parts;

[0052] (2) Hydration: The prepared fermented milk feed solution was hydrated at 40°C for 30 minutes;

[0053] (3) Homogenization: raise the temperature of the hydrated feed liquid to 55°C for homogenization, and the homogenization pressure is 18MPa;

[0054] (4) Browning: Keep the homogenized feed liquid at 95°C for 2 hours for browning;

[0055] (5) Sterilization: Sterilize the feed liquid at the same time during the browning process;

[0056] (6) Inoculation: Cool down the sterilized material liquid to the inoculation temperature of 36°C, and inoculate. The inoculation amount is adjusted according to the selected strain;

[0057] (7) Fermentation: According to the pH value to be achieved by the fermented milk, ferment at 36°C for 70 hours, and the ferment...

Embodiment 2

[0065]

[0066](1) Ingredients for fermented milk: heat up purified water to 50°C, dissolve skimmed milk powder, glucose monohydrate, and 15kg fructose syrup in purified water, and dilute to 250 parts;

[0067] (2) Hydration: the prepared fermented milk feed solution was hydrated at 50°C for 50 minutes;

[0068] (3) Homogenization: raise the temperature of the hydrated feed liquid to 60°C for homogenization, and the homogenization pressure is 20MPa;

[0069] (4) Browning: Keep the homogenized feed liquid at 98°C for 3 hours for browning;

[0070] (5) Sterilization: Sterilize the feed liquid at the same time during the browning process;

[0071] (6) Inoculation: Cool the sterilized feed liquid to the inoculation temperature of 39°C, and inoculate. The inoculation amount is adjusted according to the selected strain;

[0072] (7) Fermentation: According to the pH value to be achieved by the fermented milk, ferment at 39°C for 120 hours, and the fermentation can be terminated...

Embodiment 3

[0080]

[0081] (1) Fermented milk ingredients: heat up the purified water to 45°C, dissolve skimmed milk powder, glucose monohydrate, and 25kg fructose syrup in purified water, and dilute to 250 parts;

[0082] (2) Hydration: The prepared fermented milk feed solution was hydrated at 45°C for 40 minutes;

[0083] (3) Homogenization: raise the temperature of the hydrated feed liquid to 57°C for homogenization, and the homogenization pressure is 19MPa;

[0084] (4) Browning: Keep the homogenized feed liquid at 96°C for 2.5 hours for browning;

[0085] (5) Sterilization: Sterilize the feed liquid at the same time during the browning process;

[0086] (6) Inoculation: Cool down the sterilized material liquid to the inoculation temperature of 37°C, and then inoculate. The inoculation amount is adjusted according to the selected strain;

[0087] (7) Fermentation: According to the pH value to be achieved by the fermented milk, ferment at 37°C for 100 hours, and the fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com