Quality-improved frozen cooked noodles and processing method thereof

A technology of quality improvement and processing method, which is applied in the field of food processing, can solve the problems of failing to meet the essential requirements of improving the frozen storage quality of frozen cooked noodles, unable to overcome the stability of frozen cooked noodles frozen storage, and unable to meet people's consumption needs, etc., to achieve The taste is chewy and elastic, the quality of frozen storage is stable, and the effect of improving taste and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

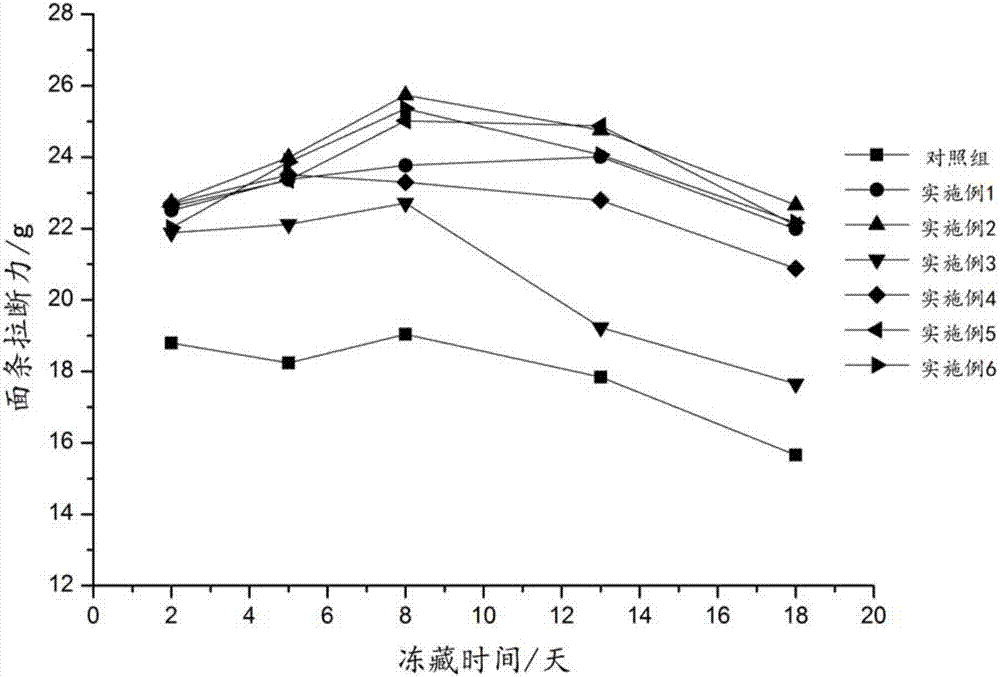

Embodiment 1

[0072] 1. The quality-improved frozen cooked noodles formula of the present embodiment is: wheat flour 600g, mixed soybean milk 288g (the mass ratio of soybean, mung bean, red bean is 6:3:1), salt 6.0g, egg white powder 6.0g, seaweed Propylene glycol 1.2g, DATEM 0.9g, complex phosphate 1.2g, modified starch 3.0g.

[0073] 2. The processing method of the quality-improved frozen cooked noodles of the present embodiment comprises the following steps:

[0074] Measure 288g of the filtered mixed mixed soybean milk, dissolve the above ingredients in the formula for use, then mix it with 600g wheat flour into a vacuum dough mixer and stir for 445s, take out the dough and place it at room temperature for 15min, then roll it to 2.0mm dough pieces in turn, cut them into pieces. Strips, weighed, steamed for 1min, rinsed, boiled for 4min, cooled, sprayed with 1.5% soybean salad oil, quick-frozen, packaged, stored at -18°C, and the following indicators were regularly measured.

[0075] Te...

Embodiment 2

[0079] 1. The quality-improved frozen cooked noodles formula of this embodiment is: wheat flour 600g, mixed soybean milk 288g (the mass ratio of soybean, mung bean, red bean is 6:2:2), salt 6.0g, egg white powder 6.0g, seaweed Propylene glycol 1.2g, DATEM 0.9g, complex phosphate 1.2g, modified starch 3.0g.

[0080] 2. The processing method of the quality-improved frozen cooked noodles of the present embodiment comprises the following steps:

[0081] Measure 288g of the filtered mixed mixed soybean milk, dissolve the above ingredients in the formula for use, then mix it with 600g wheat flour into a vacuum dough mixer and stir for 445s, take out the dough and place it at room temperature for 15min, then roll it to 2.0mm dough pieces in turn, cut them into pieces. Strips, weighed, steamed for 1min, rinsed, boiled for 4min, cooled, sprayed with 1.5% soybean salad oil, quick-frozen, packaged, stored at -18°C, and the following indicators were regularly measured.

[0082] Texture i...

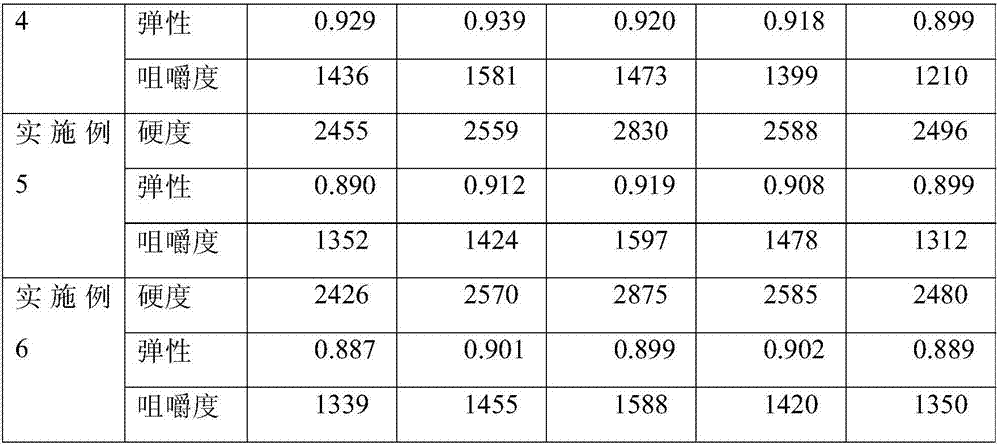

Embodiment 3

[0086]1. The quality-improved frozen cooked noodles formula of this embodiment is: wheat flour 600g, mixed soybean milk 300g (the mass ratio of soybean, mung bean, red bean is 4:3:3), salt 6.0g, egg white powder 6.0g, seaweed Propylene glycol 1.2g, DATEM 0.9g, complex phosphate 1.2g, modified starch 3.0g.

[0087] 2. The processing method of the quality-improved frozen cooked noodles of the present embodiment comprises the following steps:

[0088] Measure 300g of filtered mixed mixed soybean milk, dissolve all the above ingredients in the formula for use, and then mix with 600g wheat flour into a vacuum kneader and stir for 445s, take out the dough and place it at room temperature for 15min, then roll it to 2.0mm dough pieces in turn, cut them into pieces. Strips, weighed, steamed for 1min, rinsed, boiled for 4min, cooled, sprayed with 1.5% soybean salad oil, quick-frozen, packaged, stored at -18°C, and the following indicators were regularly measured.

[0089] Texture index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com