Preparation method of soft hygroscopic composite alginate dressing

A compound alginate and soft technology, which is applied in the field of preparation of compound alginate dressings, can solve the problems of hardness and brittleness, low strength, and unsatisfactory moisture absorption performance, and achieve stability, enhance flexibility, The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

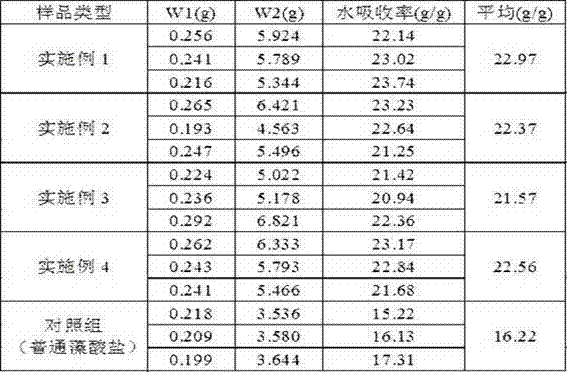

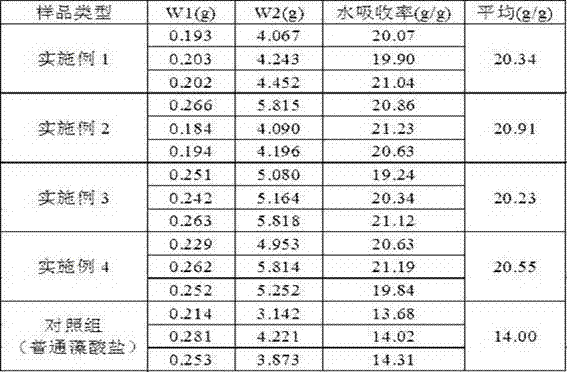

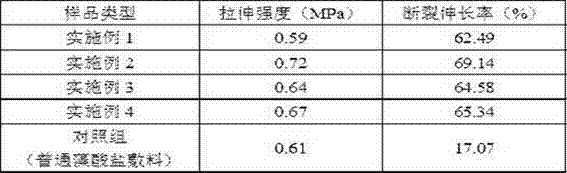

Examples

Embodiment 1

[0018] (1) Configure an aqueous solution of carboxymethyl chitosan with a mass fraction of 1%, which is designated as liquid A; configure a 5% aqueous solution of sodium alginate, which is designated as liquid B; configure a mass fraction of 0.5%, and the solutes are glutaraldehyde and The aqueous solution of genipin mixed according to the weight ratio of 1:2 is recorded as crosslinking agent C liquid.

[0019] (2) Mix liquid A and liquid B at a weight ratio of 1:3 in a hot water bath at 50°C. After stirring evenly, add a certain amount of liquid C so that the concentration of the crosslinking agent in the entire mixed liquid system is 0.6mmol / L, stir quickly, and heat at the same water bath temperature for 1 hour to fully react to obtain crosslinked carboxymethyl chitosan / sodium alginate mixed solution D.

[0020] (3) Add 30% propylene glycol alginate with the weight of liquid D, stir and mix thoroughly in a hot water bath at 50°C to obtain spinning dope E liquid.

[0021] (...

Embodiment 2

[0025] (1) Configure an aqueous solution of carboxymethyl chitosan with a mass fraction of 10%, which is designated as liquid A; configure a 10% aqueous solution of sodium alginate, which is designated as liquid B; configure a mass fraction of 0.1%, and a weight ratio of 1: 4 The mixed solution of glutaraldehyde and genipin is recorded as crosslinking agent C solution.

[0026] (2) Mix liquid A and liquid B at a ratio of 1:2 by weight in a hot water bath at 40°C. After stirring evenly, add a certain amount of liquid C so that the concentration of the crosslinking agent in the entire mixed liquid system is 0.5mmol / L, stir quickly, and heat at the same water bath temperature for 2 hours to fully react to obtain cross-linked carboxymethyl chitosan / sodium alginate mixed solution D.

[0027] (3) Add 20% propylene glycol alginate with the weight of liquid D, stir and mix thoroughly in a hot water bath at 40°C to obtain spinning dope E liquid.

[0028] (4) Spinning: The spinning sto...

Embodiment 3

[0032] (1) Configure an aqueous solution of carboxymethyl chitosan with a mass fraction of 5%, which is designated as liquid A; configure a 6% aqueous solution of sodium alginate, which is designated as liquid B; configure a mass fraction of 0.6%, and a weight ratio of 1: The mixed solution of glutaraldehyde and genipin in 3 is recorded as crosslinking agent C solution.

[0033] (2) Mix liquid A and liquid B at a ratio of 2:3 by weight in a hot water bath at 60°C. After stirring evenly, add a certain amount of liquid C so that the concentration of the crosslinking agent in the entire mixed liquid system is 1mmol / L, stir quickly, and heat at the same water bath temperature for 3 hours to fully react to obtain cross-linked carboxymethyl chitosan / sodium alginate mixed liquid D.

[0034] (3) Add 5% propylene glycol alginate with the weight of liquid D, stir and mix thoroughly in a hot water bath at 60°C to obtain spinning stock solution E.

[0035] (4) Spinning: The spinning stoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com