Semi-dry noodles for diabetics and its preparation method

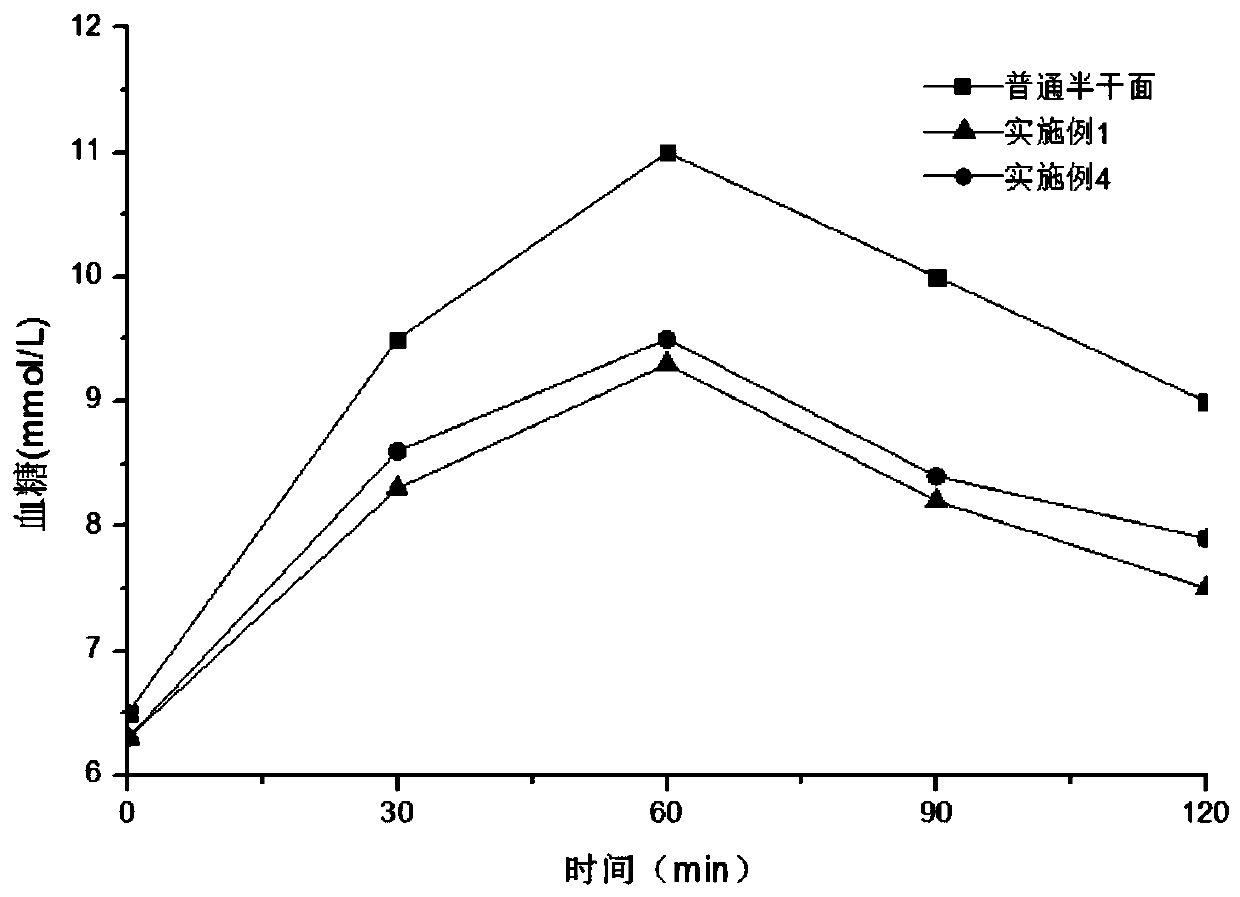

A production method and technology for diabetics, applied in the field of flour product processing, can solve the problems of regulating blood sugar function and low dietary fiber content, difficult to control the growth and reproduction of microorganisms, affecting the shelf life of products, etc., so as to inhibit the reproduction of microorganisms and release heat for a long time. , better quality of noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Semi-dry noodle formula: 30kg wheat flour, 55kg tartary buckwheat flour, 0.5kg sweet buckwheat flour, 4kg wheat bran powder, 0.5kg resistant dextrin, 10kg gluten powder, 4kg sorbitol liquid, 2kg edible salt, 0.2 propylene glycol kg, sodium carbonate 0.2kg, potassium carbonate 0.1kg, edible alcohol 5kg.

[0069] 2. Production method:

[0070] (1) Main material processing: mix 30kg of wheat flour, 55kg of tartary buckwheat flour, 0.5kg of sweet buckwheat flour, 4kg of wheat bran powder, 0.5kg of resistant dextrin and 10kg of gluten powder according to the formula, and then send it into the vibrating machine through air conveying equipment Sieve and carry out bacteria reduction treatment, control the ozone concentration in the vibrating sieve to 120mg / L, the mixed powder stays in the vibrating sieve for 5min, and transports it to the vacuum dough mixing machine;

[0071] (2) Mixing of auxiliary materials: add 23.3ml of sterile water to the stirring mixer, start the sti...

Embodiment 2

[0081] 1. Semi-dry noodle formula: 40kg of wheat flour, 35kg of tartary buckwheat flour, 8kg of sweet buckwheat flour, 7kg of wheat bran powder, 2kg of inulin and 8kg of gluten powder, 3kg of sorbitol liquid, 1.5kg of edible salt, 0.18kg of propylene glycol, carbonic acid Sodium 0.18kg, potassium carbonate 0.2kg, edible alcohol 4kg.

[0082] 2. Production method:

[0083] (1) Processing of main ingredients: Mix 40kg of wheat flour, 35kg of tartary buckwheat powder, 8kg of sweet buckwheat flour, 7kg of wheat bran powder, 2kg of inulin and 8kg of gluten powder according to the formula, and then send them to the vibrating screen through air conveying equipment and reduce them. Bacteria treatment, control the ozone concentration in the vibrating sieve to 110mg / L, the mixed powder stays in the vibrating sieve for 6 minutes, and transports it to the vacuum dough mixing machine;

[0084] (2) Mixing of auxiliary materials: add 21.3ml of sterile water into the stirring mixer, start th...

Embodiment 3

[0094] 1. Semi-dry noodle formula: 50kg of wheat flour, 25kg of tartary buckwheat flour, 4kg of sweet buckwheat flour, 12kg of wheat bran powder, 3kg of resistant dextrin, 6kg of gluten powder, 2kg of sorbitol liquid, 1kg of edible salt, 0.15kg of propylene glycol, Sodium carbonate 0.15kg, potassium carbonate 0.02kg, edible alcohol 3.5kg.

[0095] 2. Production method:

[0096] (1) Main material processing: mix 50kg of wheat flour, 25kg of tartary buckwheat flour, 4kg of sweet buckwheat flour, 12kg of wheat bran powder, 3kg of resistant dextrin and 6kg of gluten powder according to the formula, and then send them to the vibrating screen through air conveying equipment and Carry out bacteria reduction treatment, control the ozone concentration in the vibrating sieve to 100mg / L, and the mixed powder stays in the vibrating sieve for 8 minutes, and transports it to the vacuum dough mixing machine;

[0097] (2) Mixing of auxiliary materials: add 20.0ml of sterile water into the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com