Patents

Literature

32results about How to "Taste is smooth and strong" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing tasty instant rice noodles from broken rice

The invention discloses a method for producing tasty instant rice noodles from broken rice. The formula of the starch raw material of the tasty instant rice noodles comprises 72-84% of rice meal prepared from broken rice, 4-7% of potato starch, and corn starch of which the amount is 3 times that of the potato starch, and a polysaccharide thickener and an emulsifier are added. The production process comprises the following steps: making the starch raw material into starch dough; adjusting the extrusion parameters and temperature in the process of preparing wavy noodle blocks on an instant rice noodles production line; aging and re-steaming the noodle blocks, and drying by a three-section hot air circular drying method; and finally cooling, inspecting and packing. The instant rice noodles produced by the method disclosed by the invention can not cause paste soup, seasonings in the soup can enter the rice noodles, so that the rice noodles have good taste and toughness and is easy to cook; the soaking time is long that the rice noodles are not broken after being soaked for 12 hours, and the rice noodles have smooth and tough mouthfeel, good taste, unique flavor and rich nutrition; and moreover, the comprehensive utilization rate of the broken rice is improved, the production cost is reduced, and relatively high economic and social benefits are gained.

Owner:LOUDI TONGXING RICE

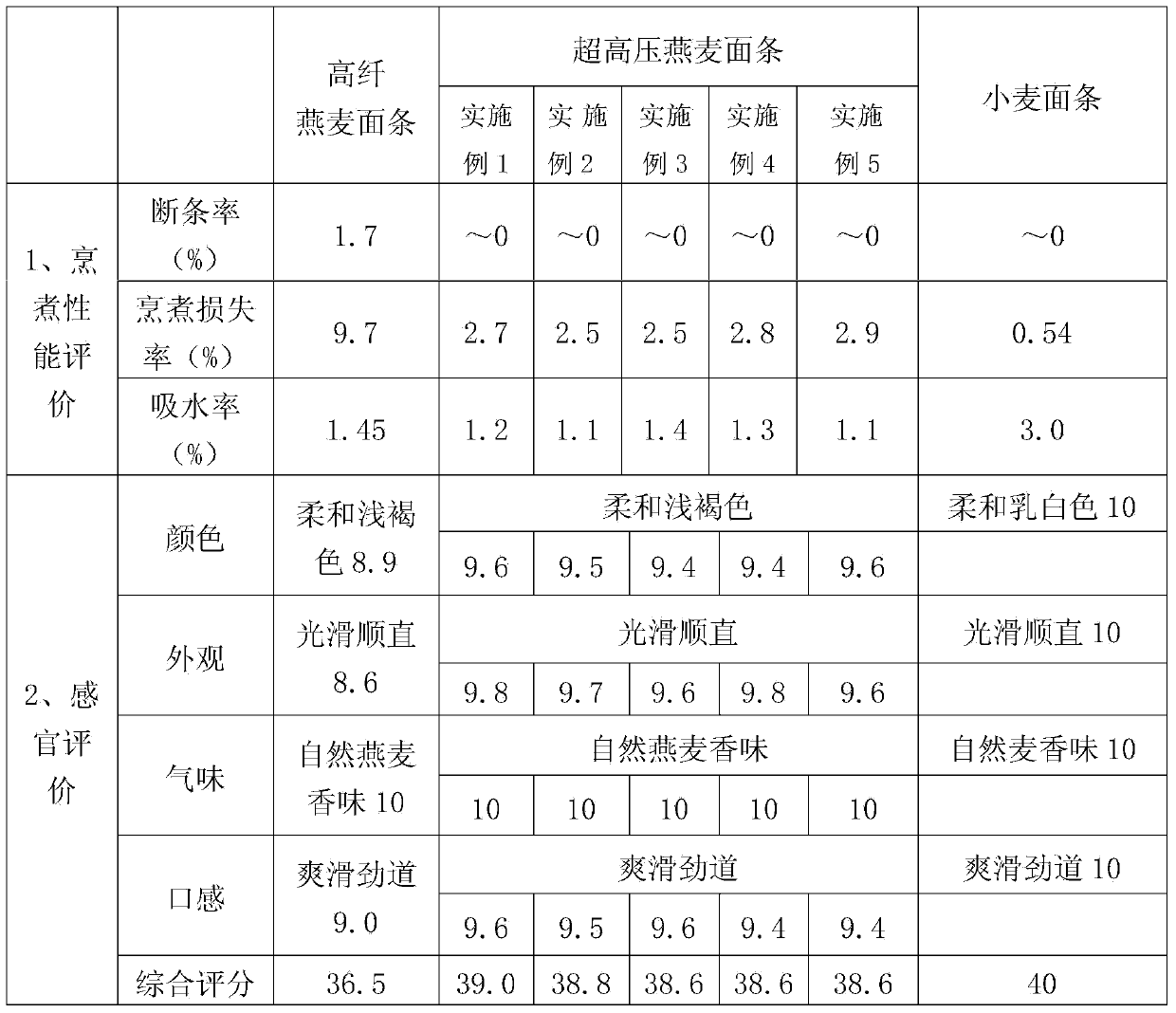

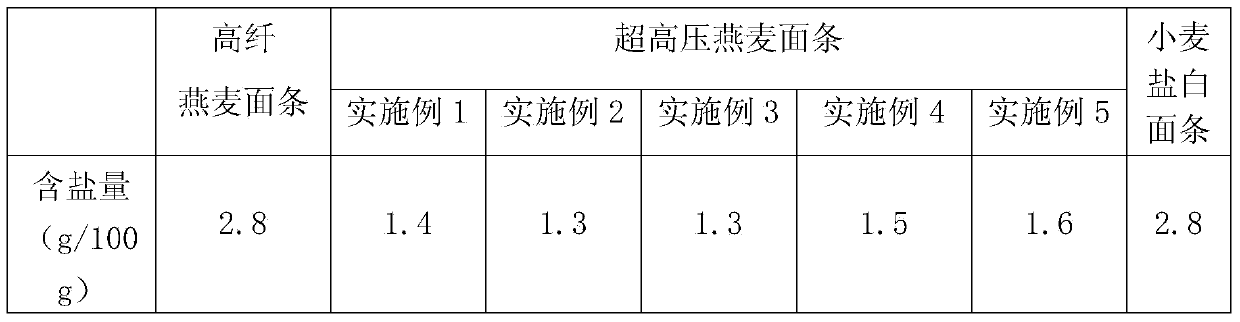

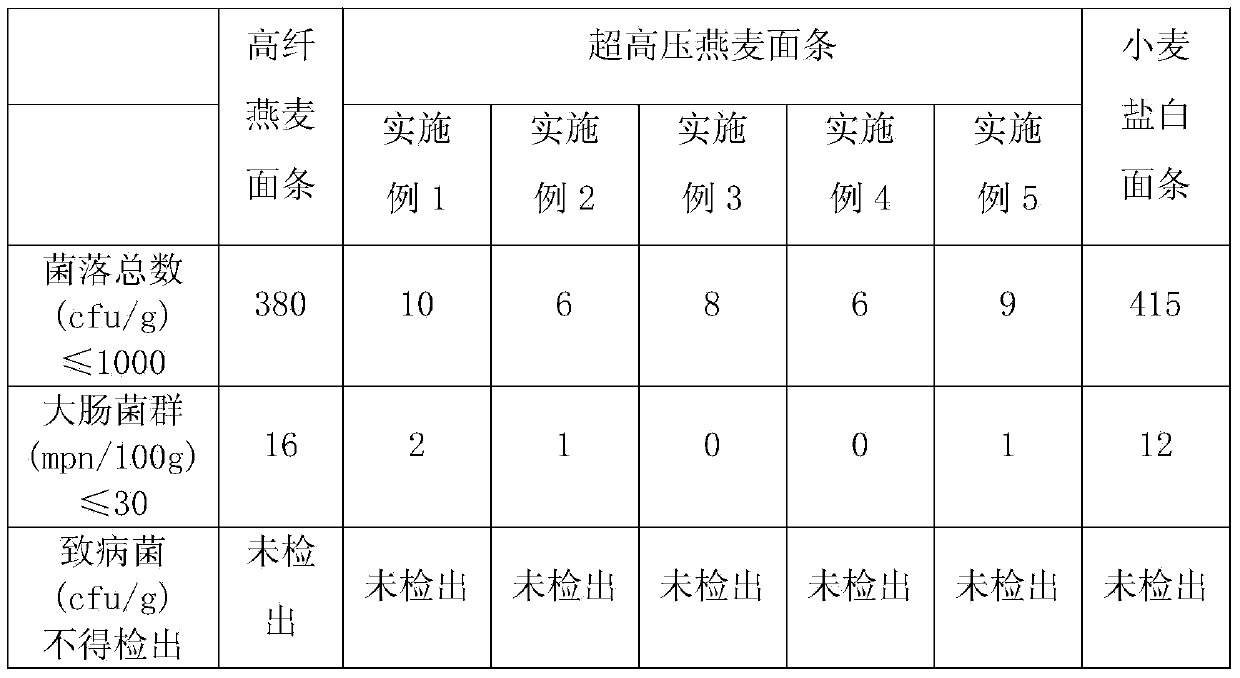

Manufacturing process of ultrahigh-pressure coarse-cereal noodles

InactiveCN104171906AGood molding effectImprove the molding effect and increase the proportion of miscellaneous grainsFood preservationFood preparationUltra high pressureSalt solution

The invention discloses a manufacturing process of ultrahigh-pressure coarse-cereal noodles. The manufacturing process comprises the steps: after fully mixing coarse-cereal flour, wheat flour, starch and a gluten fortifier solid matter, adding a hopper of a vacuum dough maker, adding a salt solution, vacuum-stirring and kneading into a smooth dough; and vacuum-packaging, placing in an ultra-high pressure testing machine pressure cavity, pressurizing for 400-600 MPa, cutting into noodles with required width after the pressure is maintained for 1-30min, ageing, and vacuum-packaging to obtain the coarse-cereal noodles. The coarse-cereal noodles have the advantages of chewy mouth feel, low salt content and long expiration date. The content of the coarse-cereal noodles which can be produced in a large scale is 90-95wt percent.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

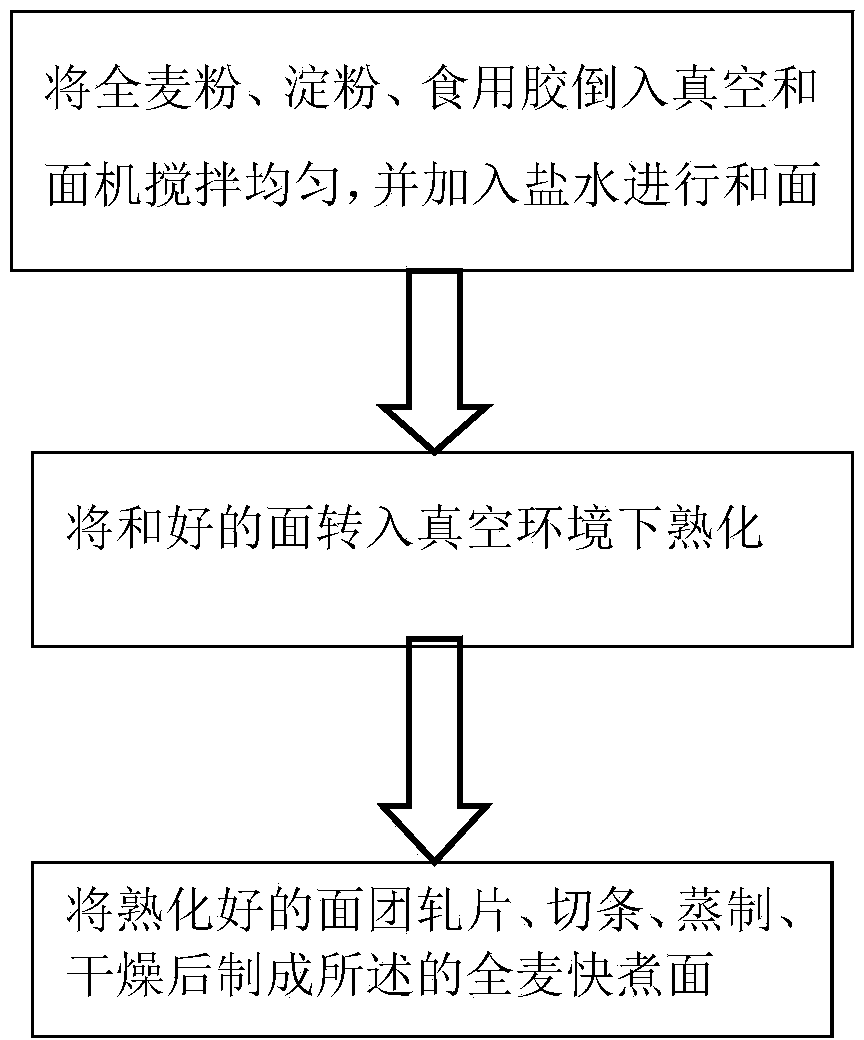

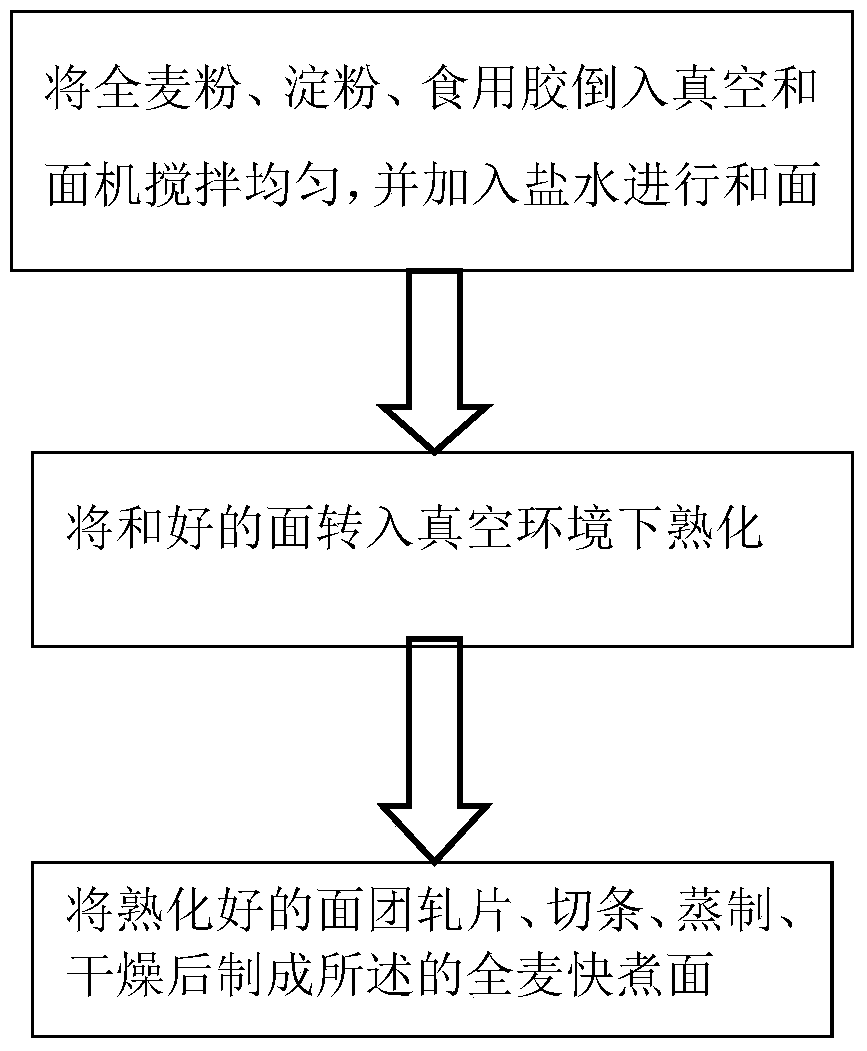

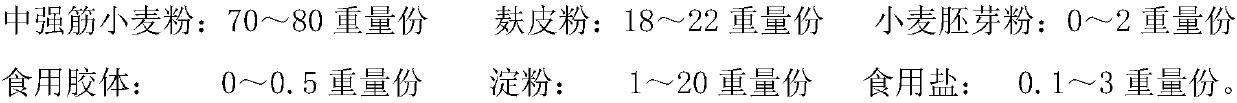

Wholewheat quick-cooking noodles and processing method thereof

The invention belongs to the technical field of food processing and manufacturing, and discloses instant non-fried wholewheat quick-cooking noodles and a processing method thereof. The wholewheat quick-cooking noodles are prepared from the following raw materials in parts by weight: 70 to 80 parts of moderate and strong gluten wheat flour, 18 to 22 parts of bran flour, 0 to 2 parts of wheat germ flour, 0 to 0.5 part of edible gel, 1 to 20 parts of starch, and 0.1 to 3 parts of edible salt. The wholewheat flour, the starch and the edible gel serve as the main raw materials, and mixing, vacuum dough kneading, vacuum curing, compound calendering, noodle cutting, steaming, high-temperature drying and other procedures are carried out to prepare the wholewheat quick-cooking noodles. The produced non-fried quick-cooking noodles have delicate and smooth taste, can be cooked within a short time, have good reconstitution property, and are nutritive, healthy and delicious.

Owner:COFCO NUTRITION & HEALTH RES INST +1

High-content buckwheat half-dried noodles and making method thereof

InactiveCN106923176AImprove qualityStrong and smooth tasteFood ingredient functionsPotassium carbonateWheat flour

The invention discloses high-content buckwheat half-dried noodles and a making method thereof. The high-content buckwheat half-dried noodles comprise main materials and auxiliary materials, wherein the main materials comprise buckwheat flour, wheat flour, vital wheat gluten, egg white powder and the like, and the auxiliary materials comprise resistance dextrin, konjaku flour, edible salt, sorbitol liquid, sodium carbonate, potassium carbonate, edible alcohol, sterile water and the like. The making method comprises the following steps of premixing the main raw materials according to a set proportion, uniformly mixing the premixed main raw materials to obtain a mixture, placing the mixture into a vacuum dough mixer, then adding the auxiliary materials and the sterile water, performing vacuum dough mixing, then ageing the dough, extruding the aged dough, performing moderate dehydration on the extruded dough, performing tempering treatment on the dehydrated dough, finally performing packaging, and performing warehousing. According to the method disclosed by the invention, a vacuum extrusion technique is adopted, so that the addition amount of the buckwheat flour can be greatly increased, the mouth feel is smooth, and nutrient components are reserved. The buckwheat half-dried noodles disclosed by the invention are smooth in surface, smooth and tenacious in mouth feel and rich in nutrition, have unique fragrance of buckwheat, are high in content of dietary fibers, and are healthy staple food products.

Owner:河北今旭面业有限公司 +1

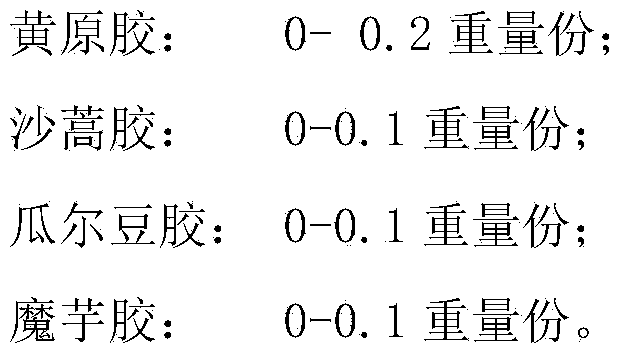

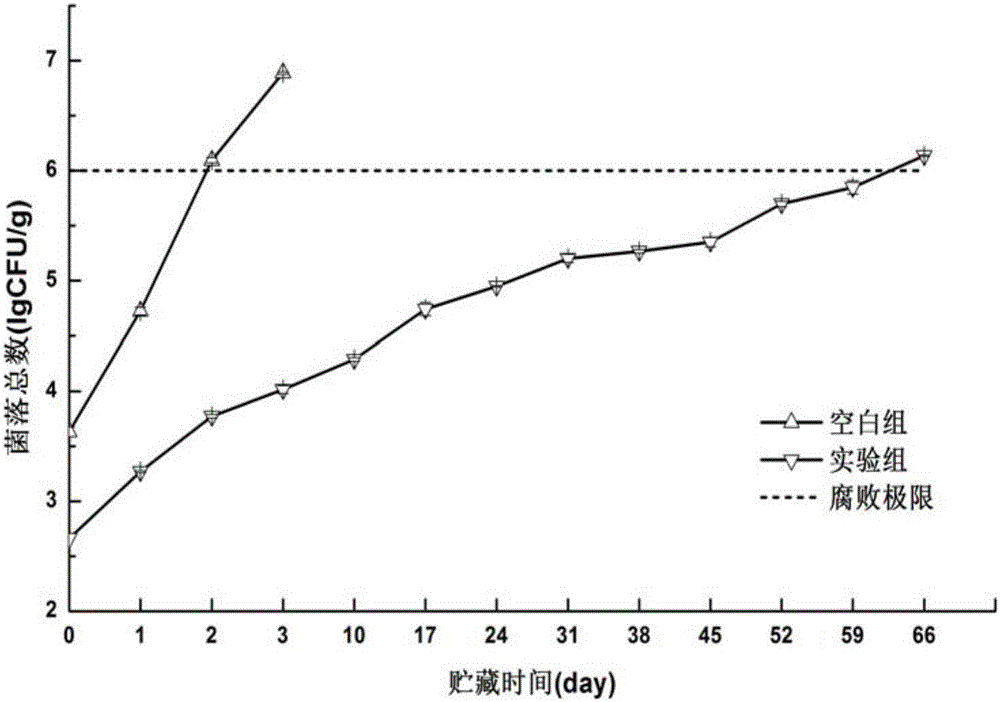

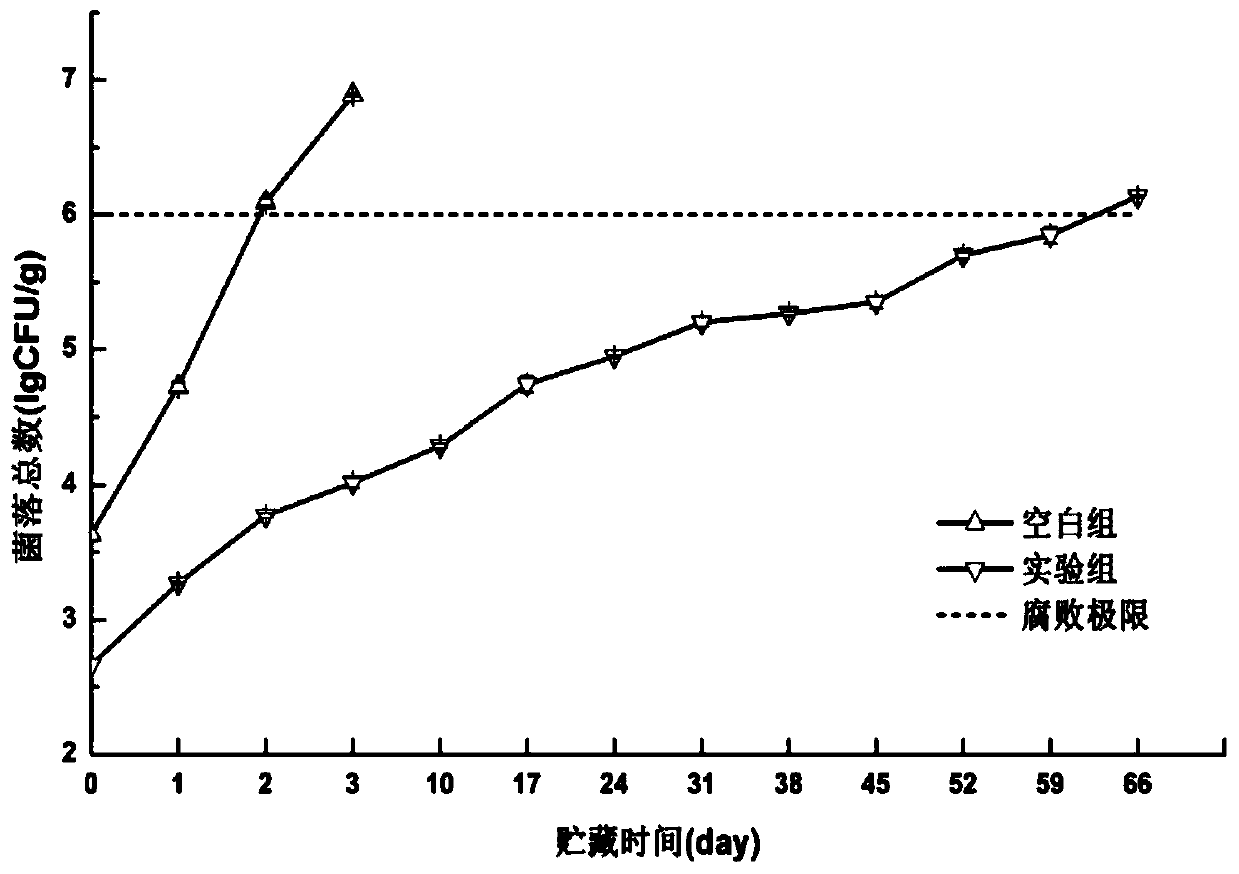

Semi-dry buckwheat noodles and processing and preservation methods thereof

ActiveCN106562205AFull of nutritionStrong flavor of buckwheatSynthetic resin layered productsFood preservationAlcoholPositive pressure

The present invention discloses semi-dry buckwheat noodles and processing and preservation methods thereof. The processing and preservation methods comprise the following steps: main materials of the semi-dry buckwheat noodles are mixed evenly, the mixture is subjected to dynamic circulation bacterium number reducing treatment by using cold source plasma, then the treated mixture is sent into a vacuum dough kneading machine by using a positive pressure pneumatic conveying device, then auxiliary materials of the semi-dry buckwheat noodles are added into the vacuum dough kneading machine, then the vacuum dough kneading machine is turned on to conduct dough kneading, then first leavening, rolling, second leavening, rolling, noodle cutting, moderate dehydrating, tempering and packaging are conducted to prepare dough pieces and dough into semi-dry buckwheat noodle finished products. By using the bacterium number reducing treatment of the raw materials of the semi-dry buckwheat noodles, the specific preservation packaging, processing, preserving, etc. the method enables the prepared semi-dry buckwheat noodles to be convenient in cooking, mellow in buckwheat fragrance, and chewy and refreshing in mouthfeel under the premise of not adding alcohol and chemical preservatives, and is moderate in means and obvious in effects. Besides, the semi-dry buckwheat noodle products have a shelf life of 2 months or more at room temperature and have a refrigerated shelf life of up to 6 months.

Owner:河北鲜邦食品有限公司

Cooked instant noodles and making method thereof

InactiveCN109363082ATaste is smooth and strongGreat tasteFood ingredient as mouthfeel improving agentPhosphateDeep frying

The invention relates to cooked instant noodles. The cooked instant noodles comprise the components in parts by weight of 45-65 parts of wheat flour, 15-30 parts of acetate modified starch, 3-10 partsof vital wheat gluten, 0.2-0.5 part of sodium alginate, 1-2 parts of table salt, 0.1-0.25 part of sodium carbonate, 0.3-0.6 part of composite phosphate, 0.1-0.2 part of propylene glycol alginate, 20-30 parts of water, and 0.0005-0.0015 part of edible pigment. The noodles disclosed by the invention are nutritive, healthy, free from deep frying, and smooth and chewy in mouth feel, and have the mouth feel of cooked noodles, after being soaked. Common instant noodles are large in differences in the eating manner of soaking and cooking due to secondary gelatinizing in the cooking process. A steaming manner and a cooking manner are combined for use, and the cooking process is favorable for absorption of moisture by wrappers, so that the gelatinizing degree is increased. The technique breaks through and reduces the mouth feel differences between different eating methods. The instant noodles disclosed by the invention have the advantages of being convenient, quick, and good in mouth feel.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Method of manufacturing corn dumpling powder

InactiveCN101108369AStrong and smooth tasteGolden colorGrain treatmentsFood preparationTegmenGround corn

The invention discloses a preparation method of core powder, which is characterized in that: the techinics procedure is as follows: the tegmen of core is extracted by dehuller; crash the corn power after extracting tegmen to 20 to 40 items; add the broken corn into the water of 2 to 5 per cent to process swelling by a bulking machine when the temperature is between 120 to 180 DEG C.; the swelled corn powder is crashed into 80 items; put the broken swelling corn into the 1 to 1.3 times corn powder of 80 items. The corn dumpling powder with forceful and smooth mouthfeel and has nature fragrance of the corn. The production techinics are simple and easy to practice with low cost, which is suitable for mass consumption.

Owner:冯家彪

Method for making drawn noodles by lactic acid bacteria fermentation

The invention relates to a method for making drawn noodles by lactic acid bacteria fermentation, which relates to a noodle processing technology in the technical field of food processing. In view of the problems in the existing drawn noodle processing technology, by combining with a traditional hand-extended noodle making process, the drawn noodles are prepared by lactic acid bacteria fermentation. The specific preparation method comprises the following steps: dough kneading, dough fermentation, big-strips cutting, strips fermentation, small-strips kneading, strips fermentation, strip-windingon rod, final fermentation, drawing, and strips cutting. The fermented drawn noodles prepared by the method have good tensile properties, unique flavor, high nutritional value, and smooth and good taste.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

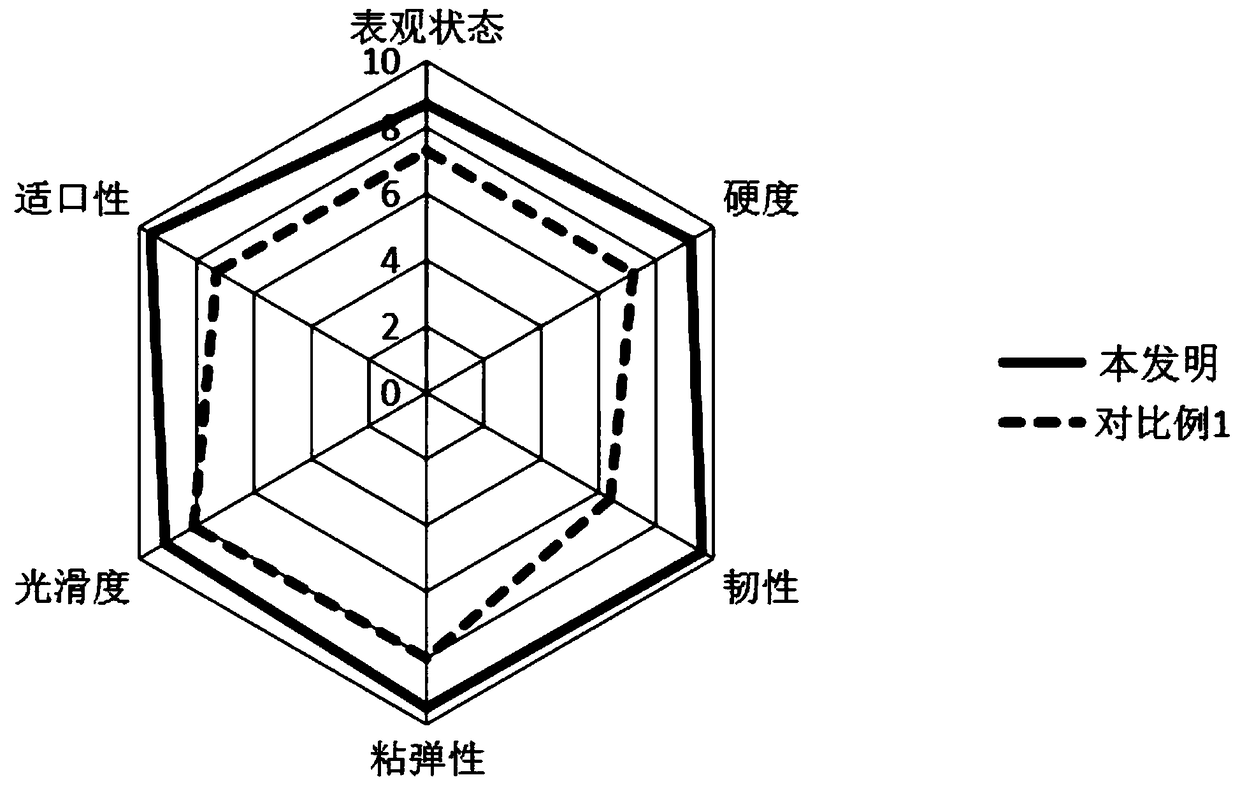

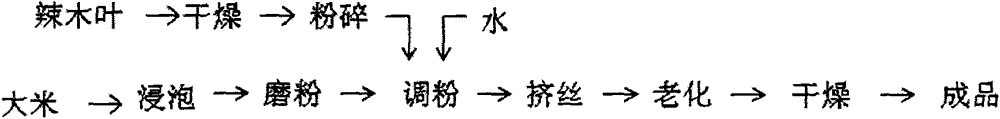

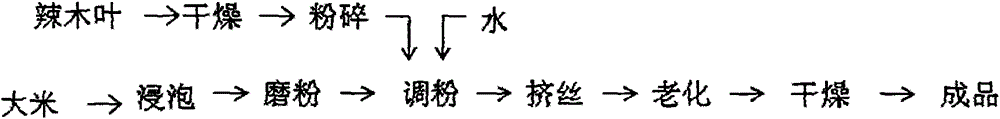

Moringa oleifera rice noodles and production process thereof

InactiveCN106260845APromote new city metabolismTaste is smooth and strongFood preparationNutrient contentAdditive ingredient

The invention discloses moringa oleifera rice noodles and a production process thereof and relates to rice food, in particular to moringa oleifera rice noodles. The moringa oleifera rice noodles are prepared from polished round-grained rice, indica rice and moringa oleifera powder, wherein in components of the moringa oleifera rice noodles, on the basis of rice (100%), the proportion of the polished round-grained rice to the indica rice is 5:1, and 30%-40% of water and 0-5% of the moringa oleifera powder are used; the rice is uniformly mixed with the treated moringa oleifera powder after being soaked and ground, the water is added to the mixture, the mixture is blended and extruded to form noodles on a machine for processing rice noodles, the moringa oleifera rice noodles are prepared through ageing, drying and other procedures, rich nutritional ingredients of moringa oleifera are blended in the moringa oleifera rice noodles, demands of eight amino acids necessary to human bodies can be met, besides, the moringa oleifera rice noodles contain rich Ca, Fe, Zn and other components, have unique flavor and taste chewy and smooth. The taste of the rice noodles is improved, and nutritional ingredients of the rice noodles are greatly enriched; no additives are added in the preparation process, the prepared moringa oleifera rice noodles are safe and high in nutritional value, and the process is simple and high in operability.

Owner:YUNNAN DEHONG TROPICAL AGRI RES INST

Making method of hulless barley, pitaya and potato fine dried noodles

InactiveCN108740758AReduce viscosityIncrease the juice yieldFood thermal treatmentFood ingredient as pH modification agentFruit juiceDietary fiber

The invention discloses a making method of hulless barley, pitaya and potato fine dried noodles. According to the making method disclosed by the invention, medium-gluten flour, hulless barley powder and pitayas are used as main raw materials, mashed potatoes are used as auxiliary materials, based on a formula and processing technology of traditional noodles, pitaya juice and the mashed potatoes are sufficiently crushed through a colloid mill to obtain a mixture, and then the mixture and dough are completely combined, so that finished products of the noodles are fine and smooth in tissue, and smooth and chewy in mouth feel, a new way is provided for transition of traditional flour products to functional health-care nutrient flour products, the flavor and the mouth feel of traditional handmade noodles are improved, health-care functions and nutrient value of products are strengthened, and the products have unique color, have the effects of resisting cancer, reducing blood lipid and reducing blood sugar, are rich in dietary fibers, and also have definite auxiliary treatment effects on diabetes and constipation.

Owner:汤广顺

Fermented brown rice powder and preparation method thereof

PendingCN111000128AIncrease productivityFit for consumptionFood ingredient functionsBiotechnologyBotany

The invention belongs to the field of rice products, relates to fermented brown rice powder, and particularly relates to fermented brown rice powder and a preparation method thereof. The fermented brown rice powder comprises brown rice, early indica rice, water and mixed zymophyte. The fermented brown rice powder which is rich in dietary fiber, rich in nutrition and chewy and smooth in taste is prepared through the following eight steps: washing rice and removing sand; soaking rice and fermenting rice; grinding rice into thick liquid; spreading thick liquid, steaming the thick liquid into powder, and carrying out quick re-steaming; pre-drying and aging the powder; carrying out shredding and forming; carrying out cyclic baking at low temperature in sections; and carrying out packaging and warehousing.

Owner:HUNAN YUXIANG FOODS

Preparation method of undaria pinnatifida dumpling

InactiveCN104642820AEasy to set upPromote digestion and absorptionFood ingredient functionsFood preparationCerebral ThrombusCholesterol

The invention discloses a preparation method of undaria pinnatifida dumpling. The preparation method comprises the following steps of blending processed undaria pinnatifida powder, flour and egg, processing the mixture to obtain dough, processing the dough to obtain a dumpling wrapper and preparing dumpling stuffing from the processed undaria pinnatifida as a raw material. Undaria pinnatifida as a raw material has a good taste, a high nutrition value and effects of reducing cholesterol in blood, promoting discharge of superfluous sodions in human body, preventing cerebral thrombus, improving and reinforcing blood vessels, preventing arteriosclerosis and reducing hypertension. Through organic combination of undaria pinnatifida, dumpling wrapper and dumpling stuffing, the preparation method has a very great practical value and economic significance.

Owner:WEIHAI XINYI BIOLOGICAL TECH

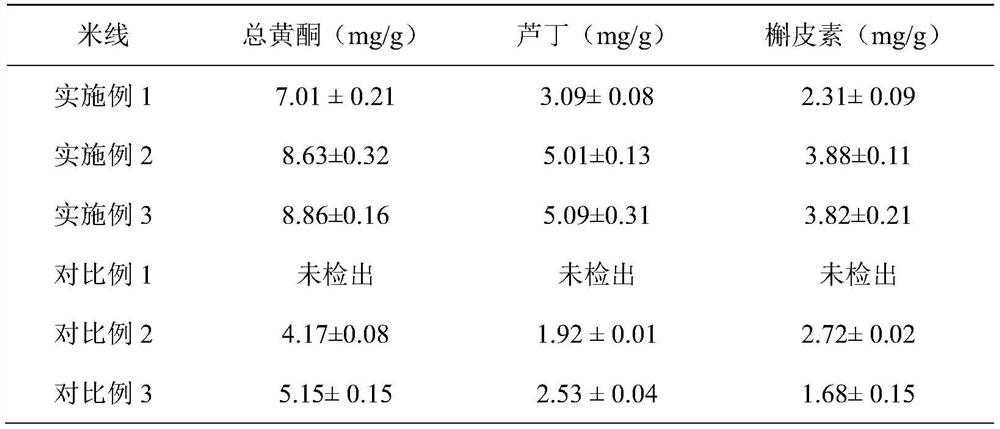

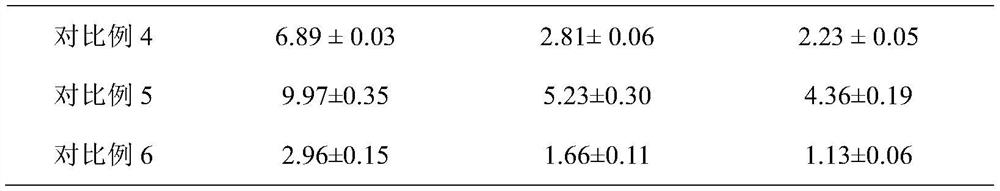

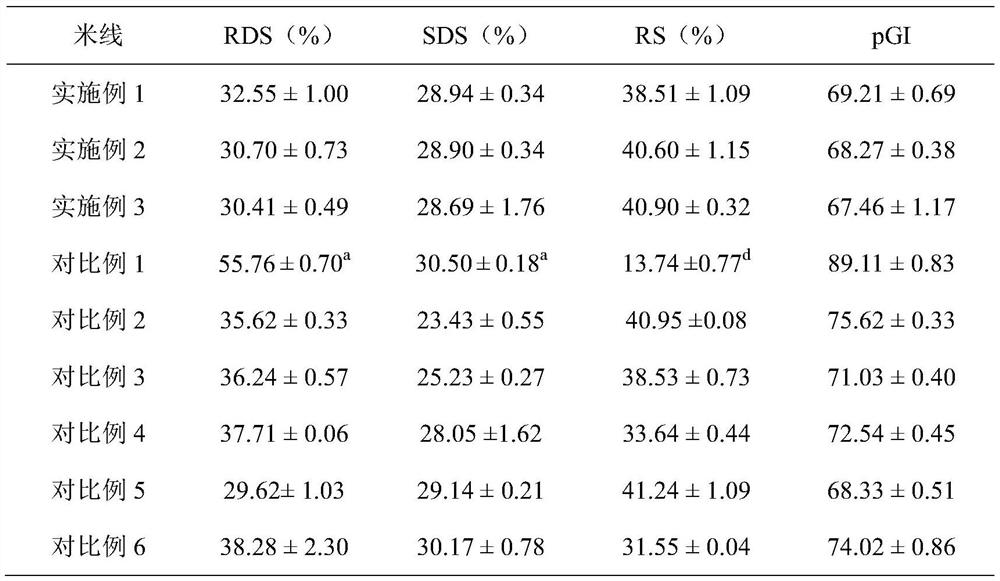

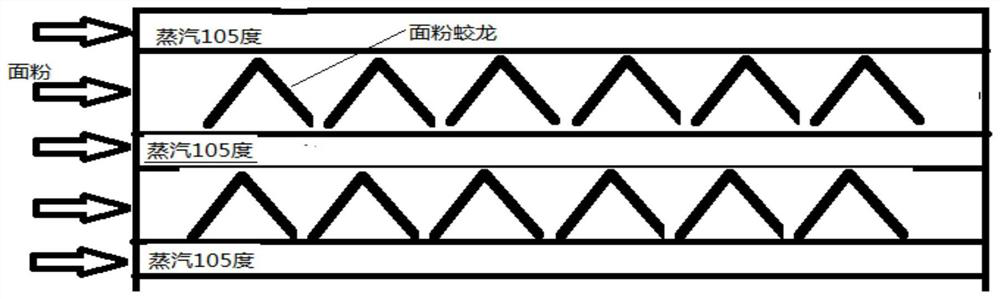

Preparation method and application of instant rice noodles suitable for people with hyperglycemia and people wanting to lose weight

InactiveCN111789218ASlow down digestionReduce lossesNatural extract food ingredientsFood ingredient as mouthfeel improving agentBiotechnologyDigestible starch

The invention discloses a preparation method and application of instant rice noodles suitable for people with hyperglycemia and people wanting to lose weight, and belongs to the technical field of deep processing of agricultural products. The loss of active ingredients such as flavones in crushing and extrusion gelatinization processes is reduced by flexibly crushing through a semi-dry method andadding konjaku flour. Germinated tartary buckwheat, white kidney bean extract, the konjaku flour, mulberry leaf extract and the like are compounded to change the composition of starch, so that the content of resistant starch is remarkably increased, the content of rapidly digestible starch is reduced, and thus a starch digestion rate is favorably reduced. By adding the white kidney bean extract and the mulberry leaf extract, the activity of amylase is remarkably inhibited, and starch digestion is delayed. The germinated tartary buckwheat, the white kidney bean extract, the konjaku flour and the mulberry leaf extract are combined to achieve a synergistic interaction effect in the aspects of improving the content of resistant starch, reducing the activity of amylase and the like, the instantrice noodles prepared through the method are good in taste, smooth and chewy, the digestion rate of starch in the rice noodles is low, a glycemic index is remarkably lower than that of fresh wet polished rice noodles, and the product is suitable for people with hyperglycemia and people wanting to lose weight, and has a wide application prospect.

Owner:苏州谷润上膳生物科技有限公司

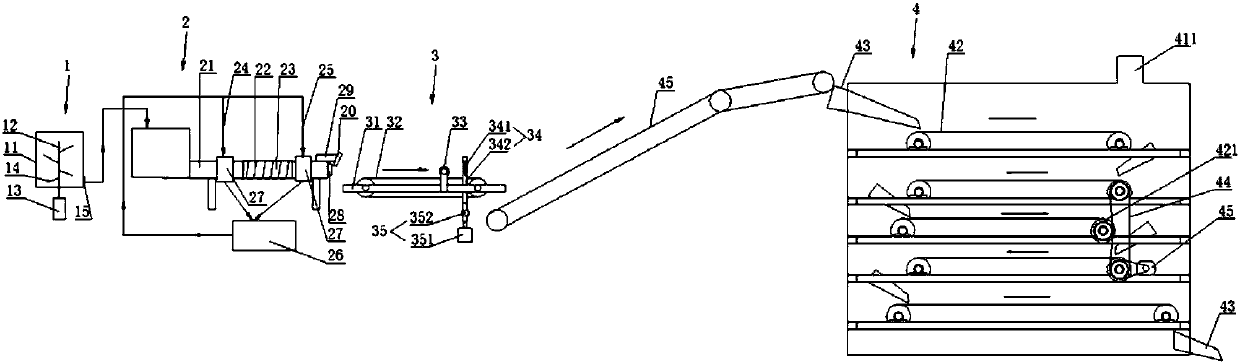

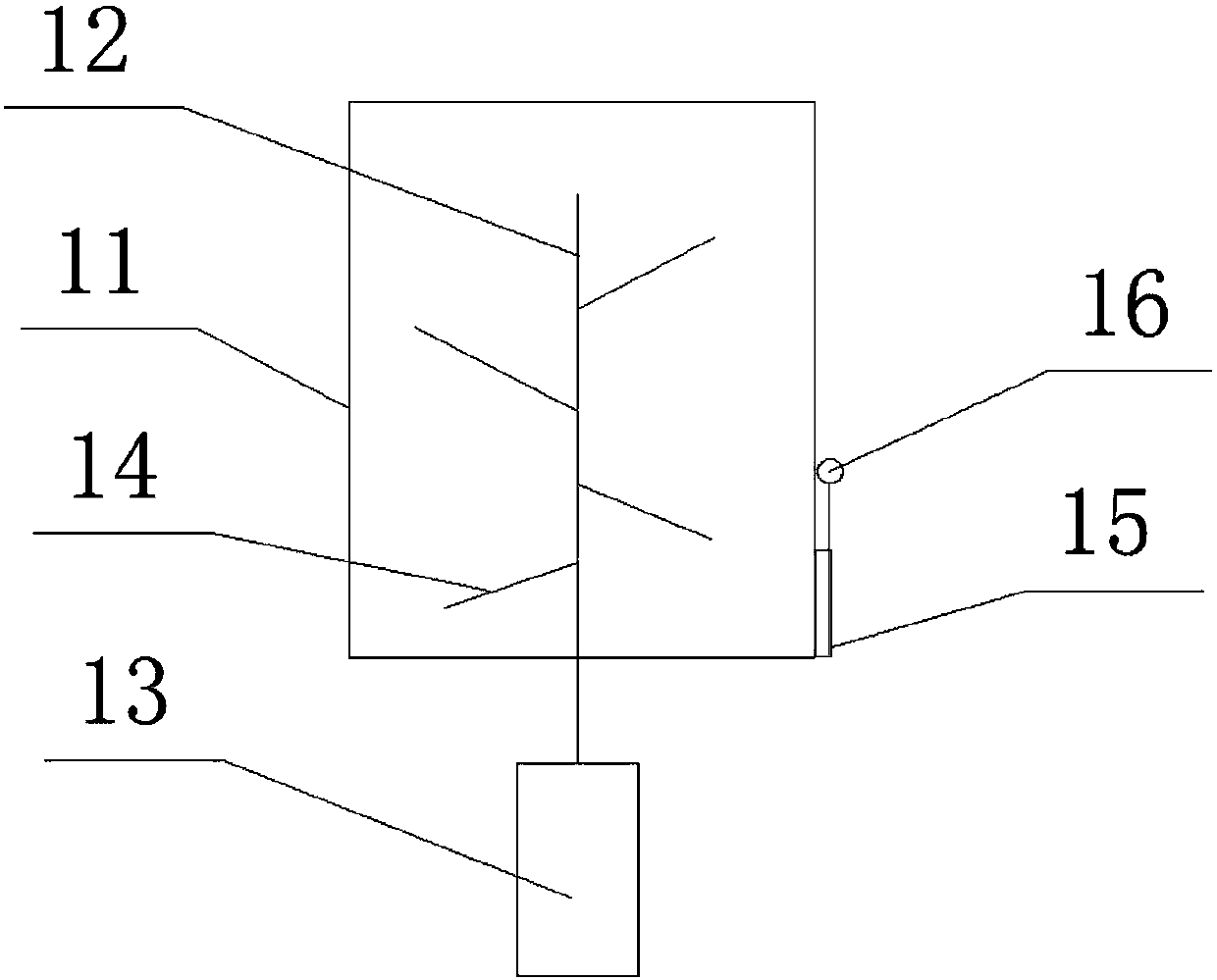

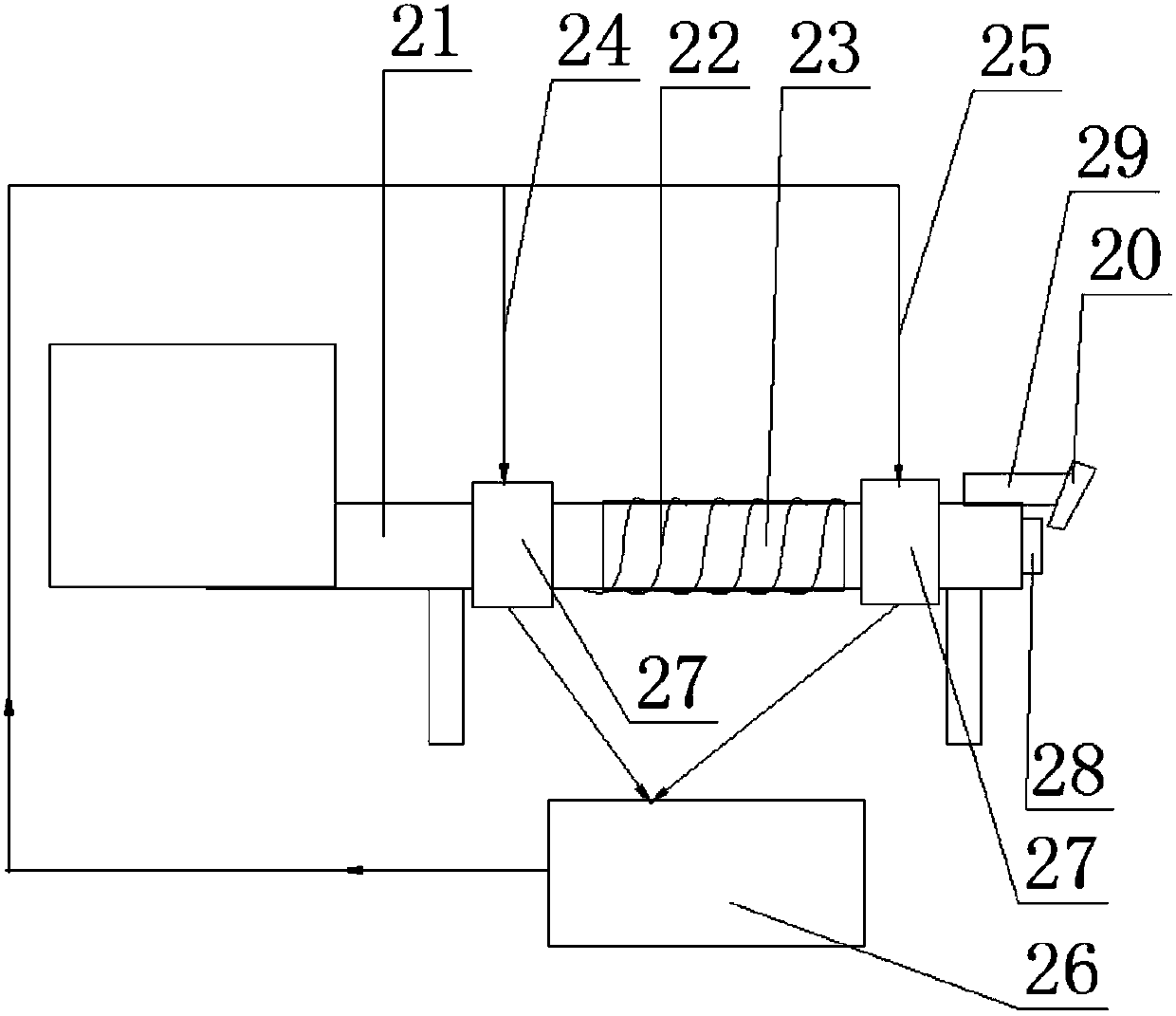

Flatted rice noodles, production method of flatted rice noodles and flatted rice noodle shaping machine

The invention discloses flatted rice noodles. The flatted rice noodles are prepared from the following raw materials in parts by weight: 100 parts of rice flour, 5-40 parts of soybean flour, 5-30 parts of mung bean flour and 5-30 parts of corn flour. By improvement on the raw material formula of the rice flour, soybean flour, mung bean flour and corn flour and improvement on the production process, the produced new flatted rice noodles can be boiled, stir-fried or eaten cold and dressed with sauce. The flatted rice noodles after being baked can be stored for a long term, and also can be deeplyprocessed into instant flatted rice noodles in cups, i.e. the flatted rice noodles are instant when infused with boiled water. In the production process, the flatted rice noodles are not added with any additives and are not fried. The flatted rice noodles are rich in dietary fibers, comprehensive in nutrition and chewy and smooth in mouthfeel, and are green health food. The flatted rice noodles after being baked are convenient to boil, the boiling method of the flatted rice noodles is similar to a boiling method of noodles, and the flatted rice noodles can be boiled by consumers without richboiling experience.

Owner:合肥市禅仁食品有限公司

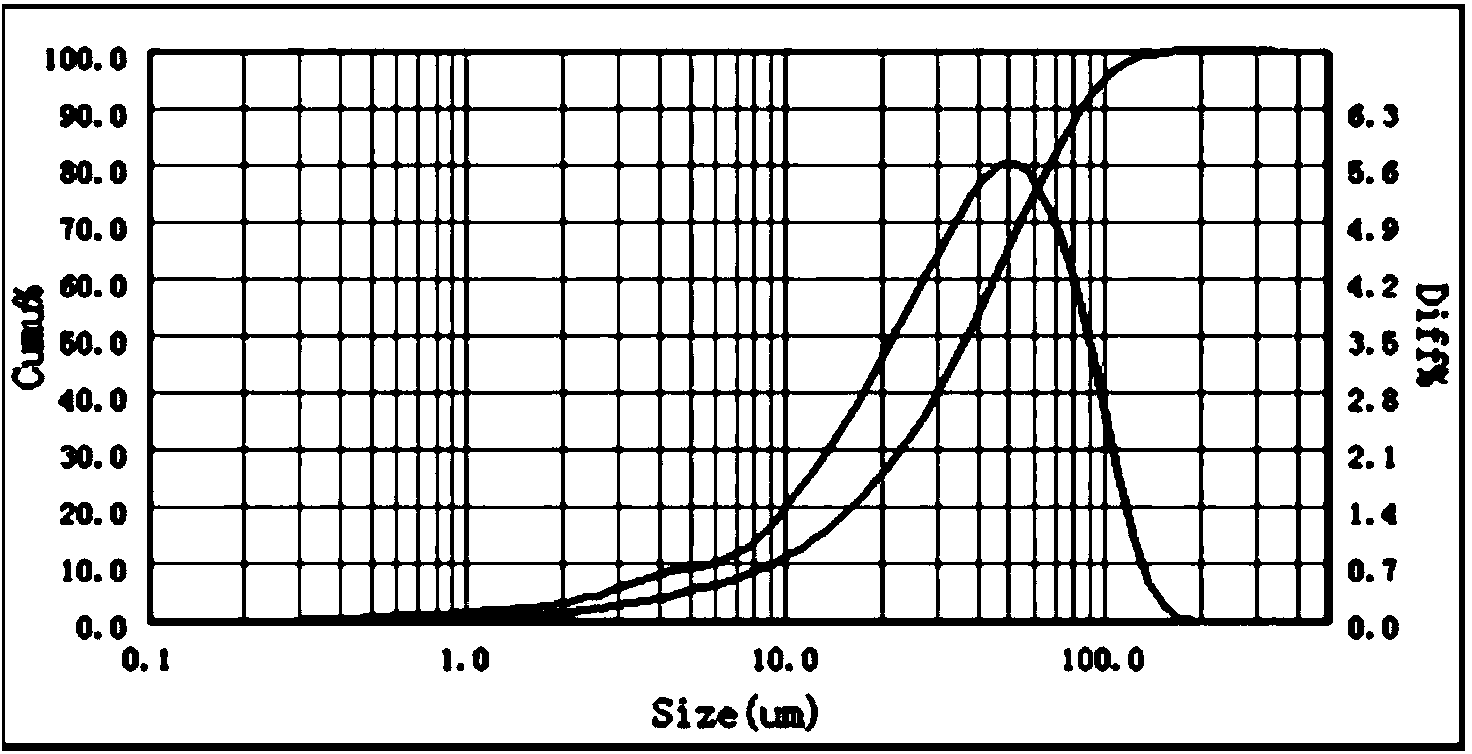

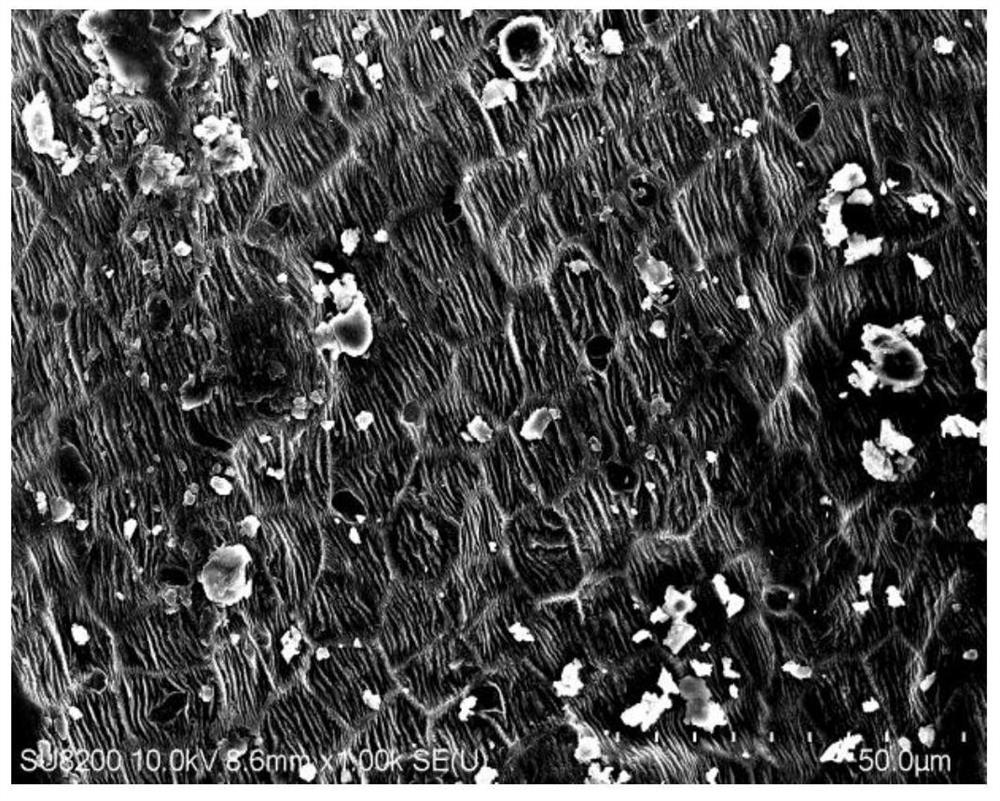

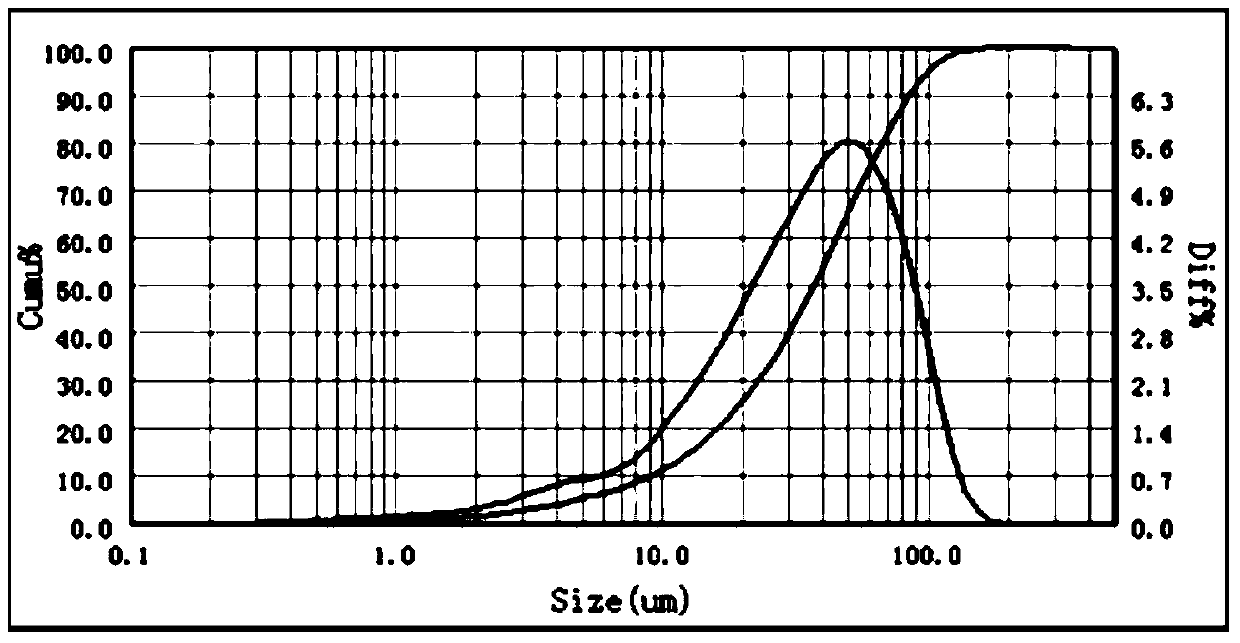

Special whole-grain noodle for diabetics and making method thereof

ActiveCN112841516AImprove qualityStrong and smooth tasteFood ingredient functionsBiotechnologyAmylase

The invention discloses a special whole-grain noodle for diabetics and a preparation method thereof. The noodle comprises main materials and auxiliary materials, the main materials comprise wheat flour and whole grain flour, and the auxiliary materials comprise edible salt and drinking water. After the whole-grain raw materials are treated by a precise heat flow technology, grain seed coats are physically treated into small particles with the particle size of less than 50 microns, the particles are in a weak link state, the particles are added into the wheat flour through superfine grinding and are uniformly dispersed in dough, and the whole-grain endosperm powder is in a glassy state, and the opportunity that gastrointestinal tract amylase is in contact with wheat starch is reduced. The content of dietary fibers in the noodle is as high as 10% or above, so that the blood glucose response is low, the slow release of sugar in the digestion process is realized, the heat release time is long, and the glycemic index and the body weight are remarkably controlled. Therefore, the blood sugar level cannot be increased when the prepared noodle is eaten by diabetics.

A kind of processing method of nutritional noodles

ActiveCN108522971BEasy cookingEasy to operateFood preservationFood dryingBiotechnologyAnimal science

The invention provides a processing method of nutritional noodles, comprising the following steps: (A) After stirring the noodles and edible oil, drying is carried out in a plurality of variable temperature gradient intervals, and the temperature of each gradient is controlled at 35-50°C between, and the temperature of the previous gradient and the subsequent gradient alternates back and forth, and the difference between two adjacent gradients is 4-5°C; (B) After the above steps, the surface of the gnocchi is coated with a layer of egg white- Dry the water mixture for 15-20 minutes, and then sterilize it by microwave for 4-5 minutes after packaging. This processing method has formed a whole set of processing methods with standardized operations after a large number of practical explorations of the drying, sterilization and antiseptic processes in the entire technological process. It is convenient, improves the shelf life, and tastes strong and smooth.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Method for processing fresh instant hot and sour rice noodles

The invention discloses a method for processing fresh instant hot and sour rice noodles, which comprises the following main steps of: immersing crude silk noodles in water for maceration, fishing the macerated silk noodles out, airing, boiling the aired silk noodles until the silk noodles are cooked, adding vegetable oil while the silk noodles are hot, and stirring uniformly; cooling, adding seasoners into the silk noodles; and finally vacuum-packaging the silk noodles into heat resisting vacuum bags, performing high-temperature sterilization and cooling. Compared with the conventional processing method for instant hot and sour rice noodles, the processing method has the advantages of simple and reasonable processing steps and obviously low production cost, and the processed instant hot and sour rice noodles are convenient to eat and have authentic taste and chewy and smooth mouthfeel.

Owner:温泽平

A kind of special whole grain noodles for diabetics and its preparation method

ActiveCN112841516BImprove qualityTaste is smooth and strongFood ingredient functionsBiotechnologyAmylase

The invention discloses a special whole grain noodle for diabetics and a preparation method thereof. The components include main materials and auxiliary materials, the main materials include wheat flour and whole grain flour, and the auxiliary materials include edible salt and drinking water. After the whole grain raw material is processed by precise heat flow technology, the grain seed coat is physically processed into small particles below 50 microns, and these particles are in a weak link state. They are added to the wheat flour after superfine grinding, and they are evenly dispersed in the dough. And the whole grain endosperm powder presents a glassy state, which reduces the chance of gastrointestinal amylase contacting wheat starch. The dietary fiber in noodles is as high as 10%, which can make the blood sugar response low, realize the slow release of sugar in the digestion process, make the heat release time longer, and significantly control the blood sugar index and body weight. Therefore, eating the noodles prepared by the present invention will not increase the blood sugar level for diabetics.

Owner:瑞德智能科技(淮安)有限公司

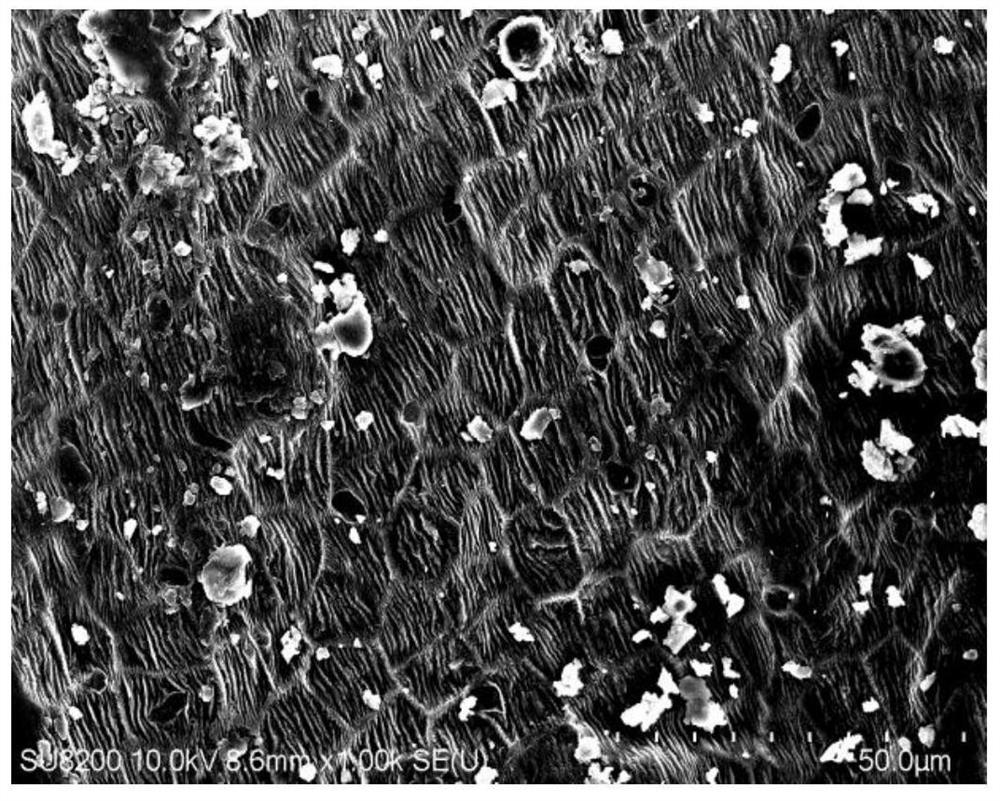

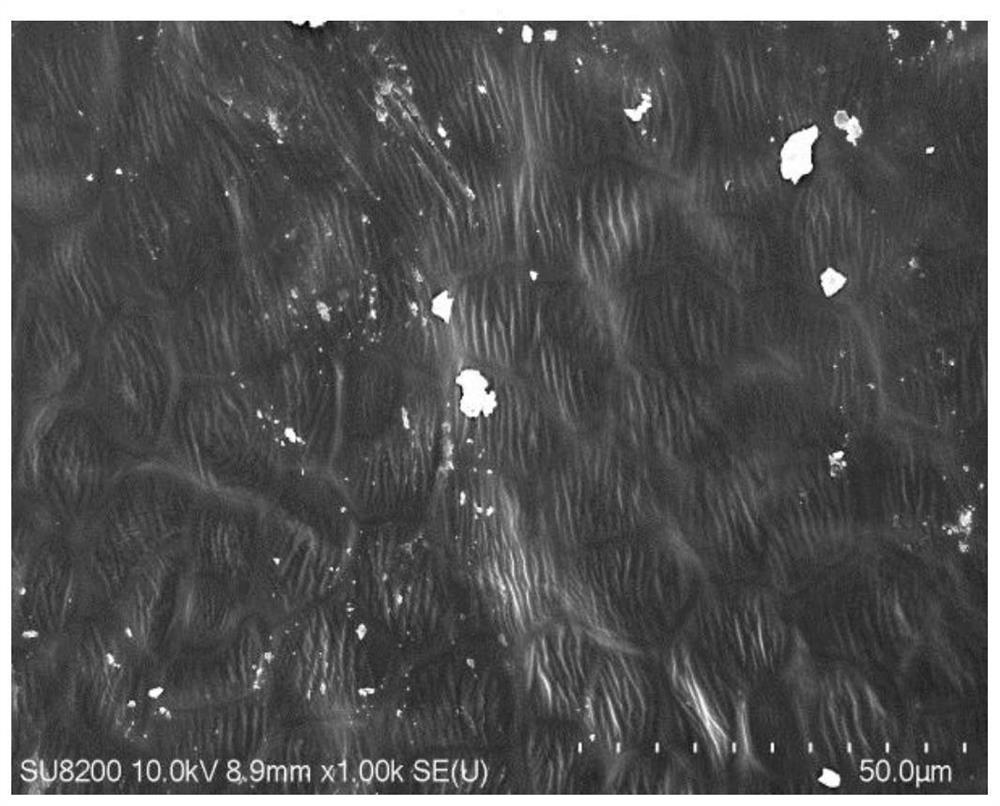

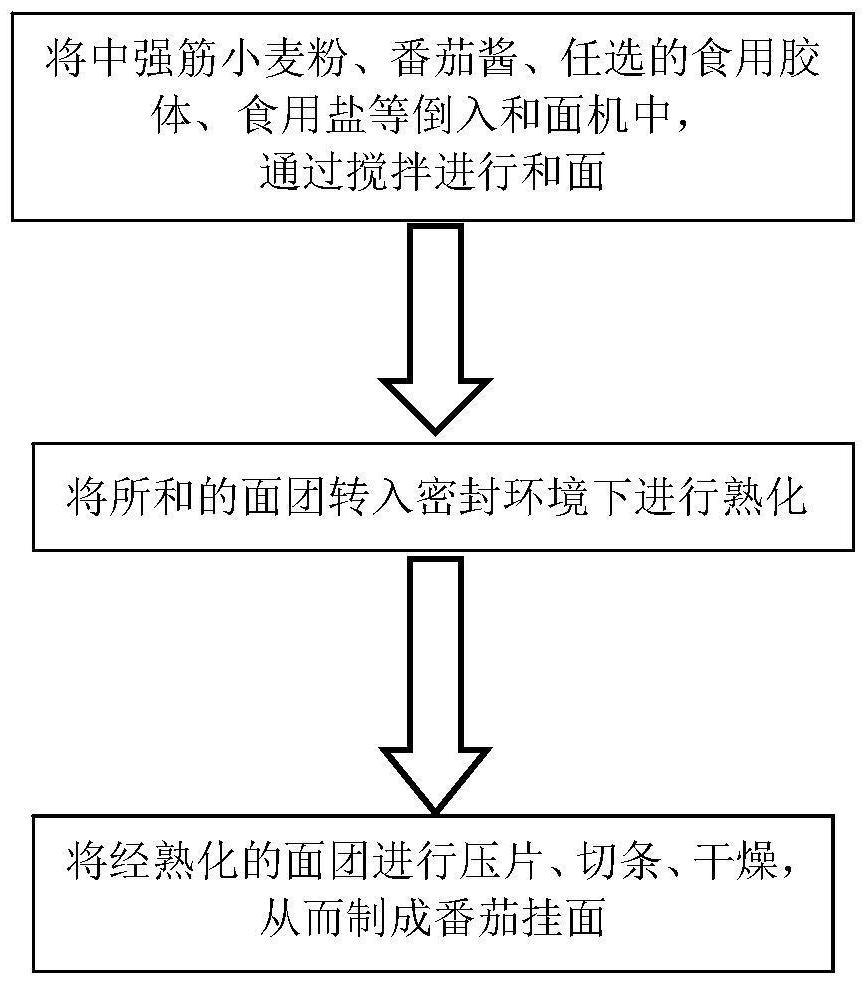

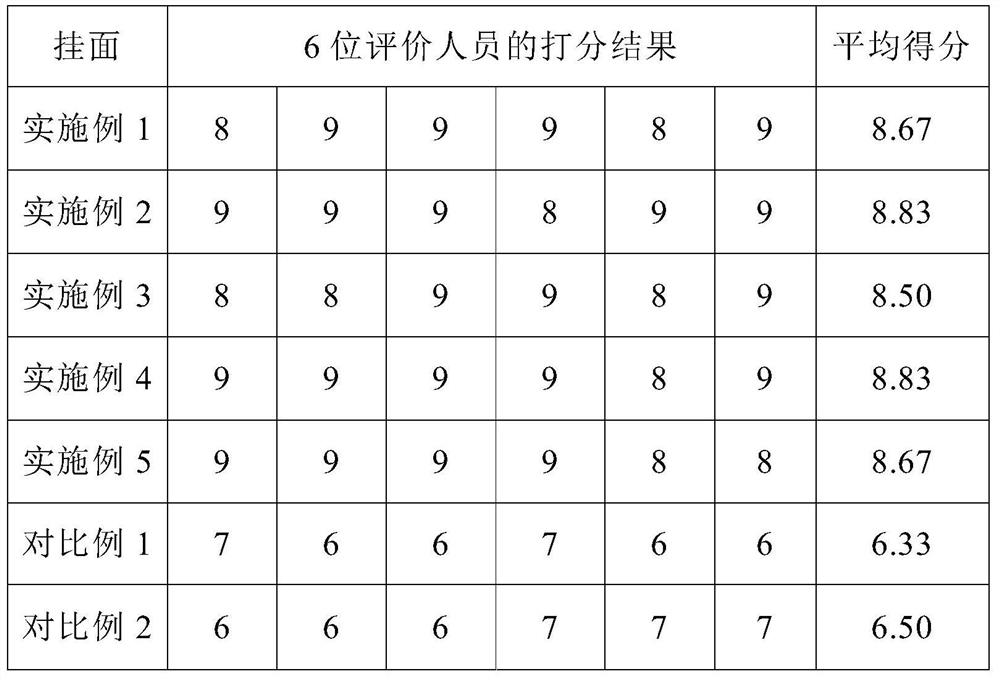

A kind of tomato vermicelli, its processing method and the application of tomato paste in the production of vermicelli

ActiveCN106962776BImprove qualityTaste is smooth and strongFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentBiotechnologyGluten

The present invention discloses tomato fine dried noodles, which are prepared from the following raw materials by weight: 100 parts of medium gluten wheat powder, 49-50 parts of tomato sauce, 0-0.3 part of edible colloid, and 1-3 parts of edible salt. The invention further discloses a processing method of the tomato fine dried noodles, wherein the processing method comprises: carrying out doughmaking on various raw materials, carrying out sealing agent, pressing into sheets, cutting into strips, drying, and other steps so as to prepare the finished product fine dried noodles. According to the present invention, the tomato fine dried noodles have characteristics of delicate in taste, rich tomato aroma, short cooking time and good rehydration, and integrate the instant food, the nutrition health, and the delicious taste.

Owner:COFCO NUTRITION & HEALTH RES INST +1

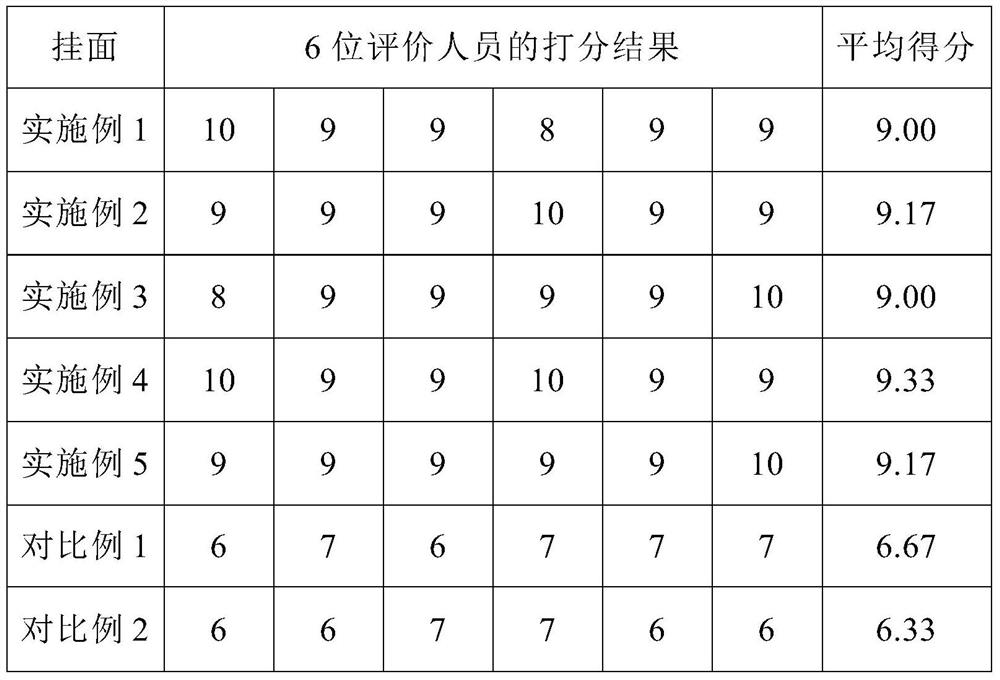

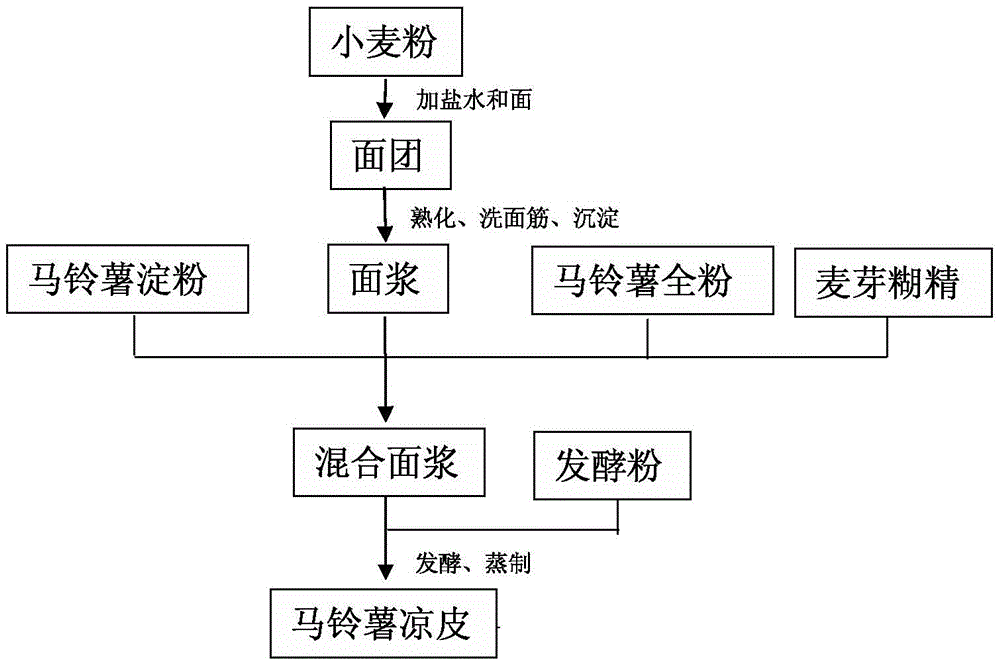

A kind of potato cold skin and processing method thereof

ActiveCN104664233BTaste is smooth and strongThe taste is strong, strong and smoothFood ingredientsYeastPotato starch

The invention discloses a potato cold noodle and a processing method thereof. The potato cold noodle is prepared from the following components in parts by weight: 28-54 parts of wheat flour, 18-42 parts of whole potato powder, 8-32 parts of potato starch and 8-12 parts of maltodextrin. The processing method comprises the following steps: mixing the wheat flour with an appropriate amount of water and kneading to obtain dough, aging the dough at 18-33 DEG C for 1-2 hours and then washing out the gluten, standing the obtained paste water for 6-8 hours for layering, taking the lower-layer precipitate to obtain paste, mixing the whole potato powder, the potato starch and the maltodextrin with the obtained paste to obtain mixed paste, adding 0.5-5% of yeast powder to the mixed paste and fermenting at 30-40 DEG C for 5-8 hours; and spreading the fermented mixed paste and steaming for 2-5 minutes until the mixed paste is transparent, thereby obtaining the potato cold noodle.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Corn noodle production process

The invention relates to a corn noodle production process. The production process is characterized by comprising the following steps: 1) preparing materials, wherein the raw material components comprise corn flour, drinking water and edible oil; 2) burdening: putting the corn flour into a flour mixer, adding drinking water and edible oil into the flour mixer, and uniformly stirring; 3) curing andpressing into strips: feeding the uniformly stirred corn flour into a curing barrel for curing, controlling the curing temperature to be 120-160 DEG C, and feeding the cured corn flour into a pressingbarrel for pressing into strips; 4) packaging: cooling by air cooling, weighing, cutting off, putting into a packaging bag, and then vacuumizing and sealing; and (5) scattering: putting the packagedcorn noodles into a freezing chamber, and setting the freezing temperature to be -14 DEG C to -20 DEG C and the freezing time to be 96-120 hours so as to finish scattering. The preparation process hasthe advantages that the prepared corn noodles do not contain food additives and pigments, are smooth and chewy in taste, firm and flexible, are not easy to break when being cooked, can adapt to various cooking methods, completely retain the inherent nutritional ingredients of corn, and are free of heavy metal residues.

Owner:王彦恒

Buckwheat semi-dry noodles and its processing and preservation method

ActiveCN106562205BFull of nutritionStrong flavor of buckwheatSynthetic resin layered productsFood preservationBiotechnologyEngineering

The present invention discloses semi-dry buckwheat noodles and processing and preservation methods thereof. The processing and preservation methods comprise the following steps: main materials of the semi-dry buckwheat noodles are mixed evenly, the mixture is subjected to dynamic circulation bacterium number reducing treatment by using cold source plasma, then the treated mixture is sent into a vacuum dough kneading machine by using a positive pressure pneumatic conveying device, then auxiliary materials of the semi-dry buckwheat noodles are added into the vacuum dough kneading machine, then the vacuum dough kneading machine is turned on to conduct dough kneading, then first leavening, rolling, second leavening, rolling, noodle cutting, moderate dehydrating, tempering and packaging are conducted to prepare dough pieces and dough into semi-dry buckwheat noodle finished products. By using the bacterium number reducing treatment of the raw materials of the semi-dry buckwheat noodles, the specific preservation packaging, processing, preserving, etc. the method enables the prepared semi-dry buckwheat noodles to be convenient in cooking, mellow in buckwheat fragrance, and chewy and refreshing in mouthfeel under the premise of not adding alcohol and chemical preservatives, and is moderate in means and obvious in effects. Besides, the semi-dry buckwheat noodle products have a shelf life of 2 months or more at room temperature and have a refrigerated shelf life of up to 6 months.

Owner:河北鲜邦食品有限公司

Tremella noodles and preparation method thereof

InactiveCN112869005ATaste is smooth and strongHas health effectsFood scienceBiotechnologyNutritive values

The invention provides tremella noodles and a preparation method thereof, and relates to the technical field of food. The tremella noodles comprise the following raw materials: flour, tremella, Chinese honeylocust fruits and peach gum, the flour is plain flour, and the tremella is freshly picked tremella and is high in nutritional value, smooth and chewy in taste and delicious in taste when eaten. In addition, the invention further provides a preparation method of the tremella noodles, the preparation method comprises the following steps of raw material pretreatment, raw material steaming and noodle pressing, the method is simple in process and beneficial to cost reduction, and the prepared noodles are high in nutritive value and good in eating taste.

Owner:山东北耳菌业有限公司

Processing method of nutritive doughballs

ActiveCN108522971AEasy to operateMild operating conditionsFood preservationFood dryingNutrientChemistry

The invention provides a processing method of nutritive doughballs. The processing method comprises the following steps of (A) stirring doughballs with edible oil, and perform drying in a plurality oftemperature alternating gradient regions, wherein the temperature of each gradient is controlled between 35-50 DEG C, the temperature of the previous gradient and the temperature of the next gradientare in an alternating trend, and the difference between every two adjacent gradients is 4-5 DEG C; and (B) coating a layer of egg white-water mixing liquid onto the surfaces of the processed doughballs, performing drying operation for 15-20min, performing packaging, and performing microwave sterilization for 4-5min, so as to obtain the nutritive doughballs. According to the processing method disclosed by the invention, massive practical exploration is performed on technological processes of drying, sterilizing and preservation in the whole technological process, a complete set of processing method adopting standard operation is formed; the operation is convenient; and the processed nutritive doughballs food are rich in food nutrients, convenient to cook and chewy and smooth in mouth feel,and the quality guarantee period is prolonged

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Corn noodle pre-blend powder

InactiveCN110122754AStrong fragranceGolden colorFood ingredient as colourFood ingredient as taste affecting agentFood additiveWarm water

The invention provides a corn noodle pre-blend powder, wherein the pre-blend powder comprises wheat flour, expanded corn flour, corn starch, pre-gelatinized corn starch, acetate cassava denaturated starch and wheat gluten. The pre-blend powder also has addition of an improver, wherein the improver comprises sodium alginate, guar gum, xylanase, sodium hexametaphosphate, gardenia yellow and curcumin. The noodles prepared by the noodle flour have corn taste, strong fragrance, golden yellow color, chewy and smooth taste, boiling resistance and soaking resistance. All the ingredients of used food additives are poisonless and harmless. After being cooked thoroughly, the noodles can also be placed for a long time without swelling or strip breaking or other phenomena, and the thoroughly cooked noodles can be soaked in warm water for up to 72 hours while still maintaining the taste of just cooked noodles.

Owner:青岛品品好食品发展有限公司

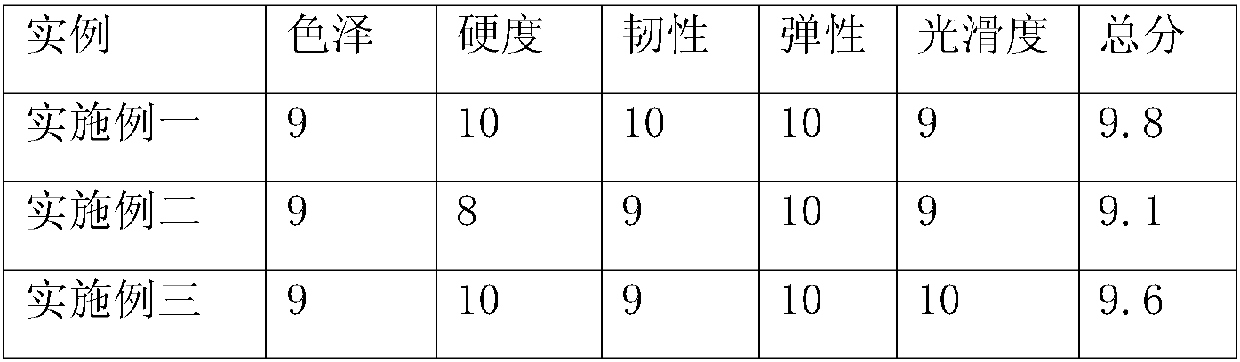

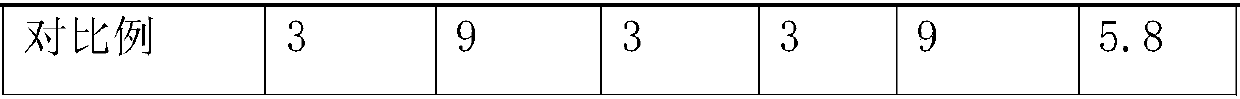

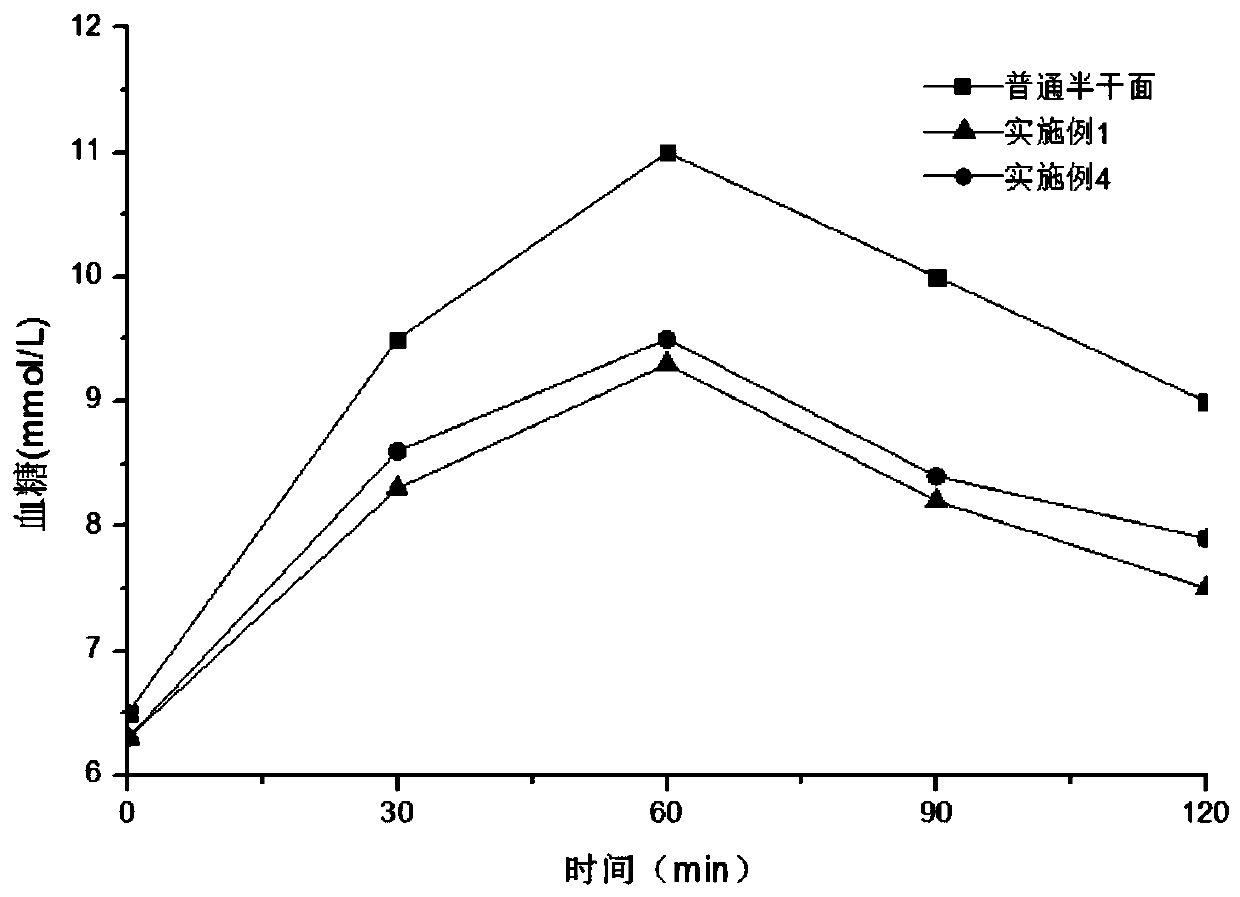

Semi-dry noodles for diabetics and its preparation method

Owner:河北今旭面业有限公司 +1

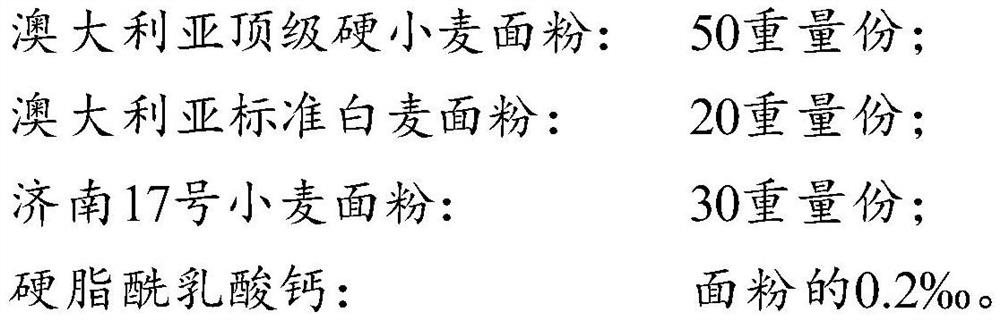

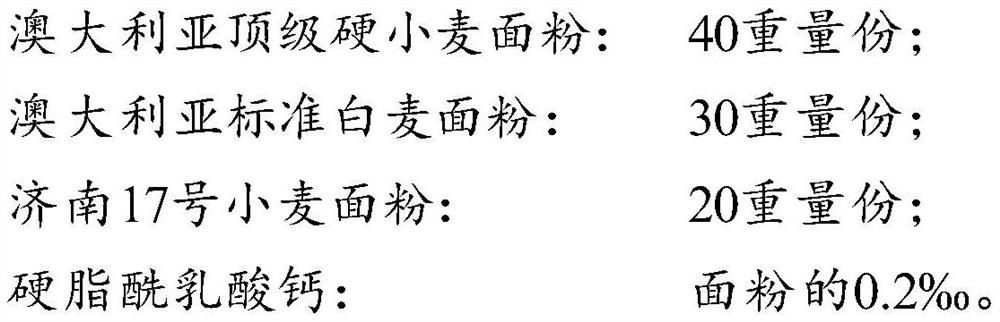

A kind of dumpling powder and preparation method thereof

The invention relates to the technical field of food and particularly relates to dumpling flour and a preparation method thereof. The dumpling flour contains flour and an additive, wherein the flour is produced from top-level Australian hard wheat, standard Australian white wheat and Jinan 17# wheat. By mixing the top-level Australian hard wheat, the standard Australian white wheat and the Jinan 17# wheat in proportion for use, the extensibility and water-retaining property of a wrapper can be remarkably improved, and the breakage rate of a dumpling during the freezing is reduced; and meanwhile, the dumpling wrapper prepared from the dumpling flour has smooth and chewy taste and sufficient elasticity, is pure white and transparent and can completely meet the requirements of top-grade wrappers.

Owner:青岛品品好粮油集团有限公司

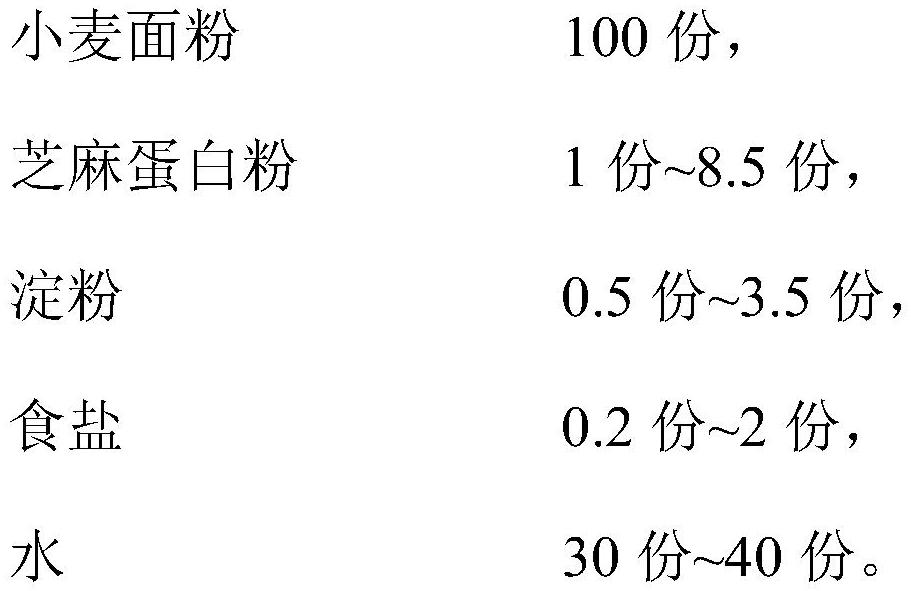

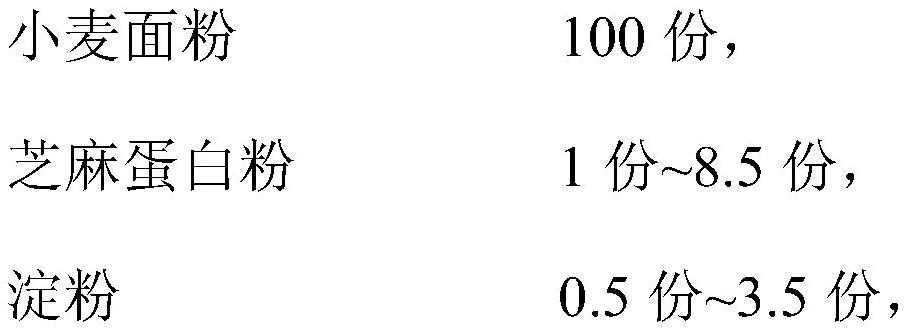

Sesame protein noodles and preparation method thereof

PendingCN114431408AHigh hardnessIncrease elasticityFood ingredient functionsBiotechnologyWheat flour

The invention relates to the technical field of food processing, in particular to sesame protein noodles and a preparation method thereof. The sesame protein noodles are prepared from the following raw materials in parts by weight: 100 parts of wheat flour, 1 to 8.5 parts of sesame protein powder, 0.5 to 3.5 parts of starch, 0.2 to 2 parts of table salt and 30 to 40 parts of water. The sesame protein noodles provided by the invention are chewy and smooth in mouth feel, high in edible safety and richer in nutrition.

Owner:代代田(武汉)食品集团有限公司 +1

Quick-frozen laminaria japonica dumpling

InactiveCN105519856AAbundant resourcesImprove use valueFood preparationChinese ChiveAllium schoenoprasum

The present invention discloses a quick-frozen laminaria japonica dumpling which is characterized in that laminaria japonica powder and flour are mixed to prepare a dough and the dough is prepared dumpling skins, and the diced laminaria japonica, Chinese chives, pork, fresh ginger, minced green onion, refined salt and accessory materials are processed into dumpling fillings step by step. The laminaria japonica and cooked wheaten food are organically combined and the quick-frozen dumplings are prepared by an organic combination of the dumpling skins and the meat and vegetable dumpling fillings. The quick-frozen laminaria japonica dumpling will be deeply loved by people in today when people pay a widespread attention on nutrition and health.

Owner:WEIHAI HONGYIN FOOD TECH CO LTD

A kind of whole wheat instant noodles and processing method thereof

The invention belongs to the technical field of food processing and manufacturing, and discloses instant non-fried wholewheat quick-cooking noodles and a processing method thereof. The wholewheat quick-cooking noodles are prepared from the following raw materials in parts by weight: 70 to 80 parts of moderate and strong gluten wheat flour, 18 to 22 parts of bran flour, 0 to 2 parts of wheat germ flour, 0 to 0.5 part of edible gel, 1 to 20 parts of starch, and 0.1 to 3 parts of edible salt. The wholewheat flour, the starch and the edible gel serve as the main raw materials, and mixing, vacuum dough kneading, vacuum curing, compound calendering, noodle cutting, steaming, high-temperature drying and other procedures are carried out to prepare the wholewheat quick-cooking noodles. The produced non-fried quick-cooking noodles have delicate and smooth taste, can be cooked within a short time, have good reconstitution property, and are nutritive, healthy and delicious.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com