Special whole-grain noodle for diabetics and making method thereof

A technology for diabetics and a production method, applied in the food field, can solve the problems of difficulty in crushing, unfavorable formation of gluten, low addition amount, etc., and achieve the effects of controlling glycemic index and body weight, long calorie release time, and smooth and smooth taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

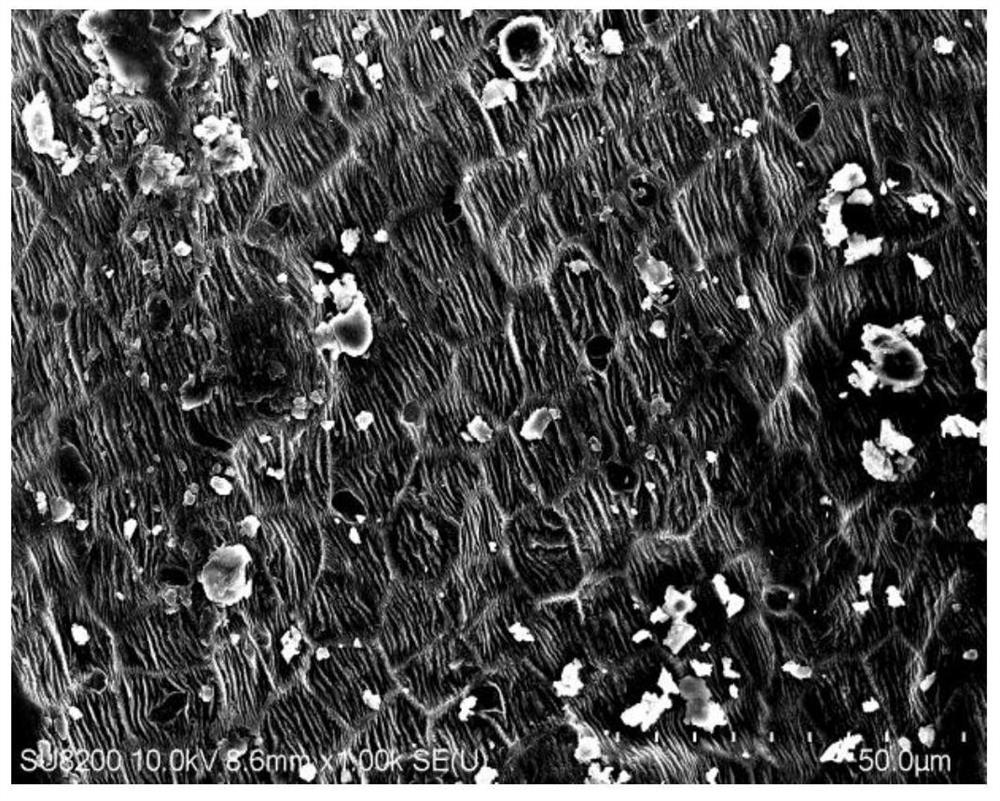

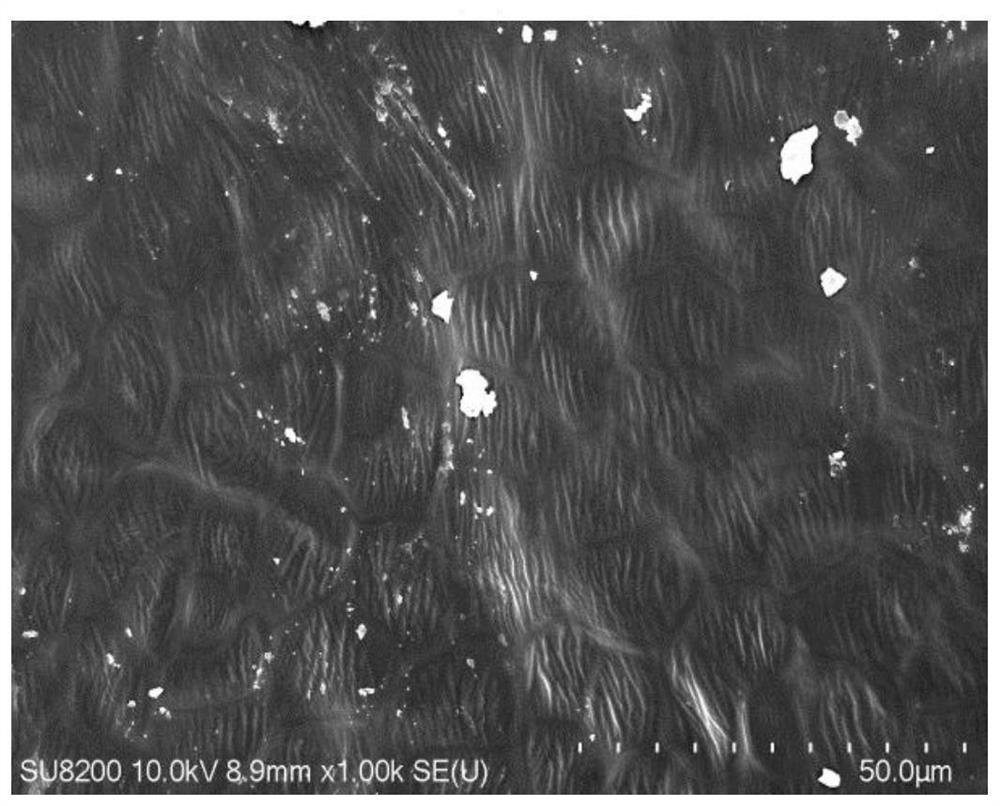

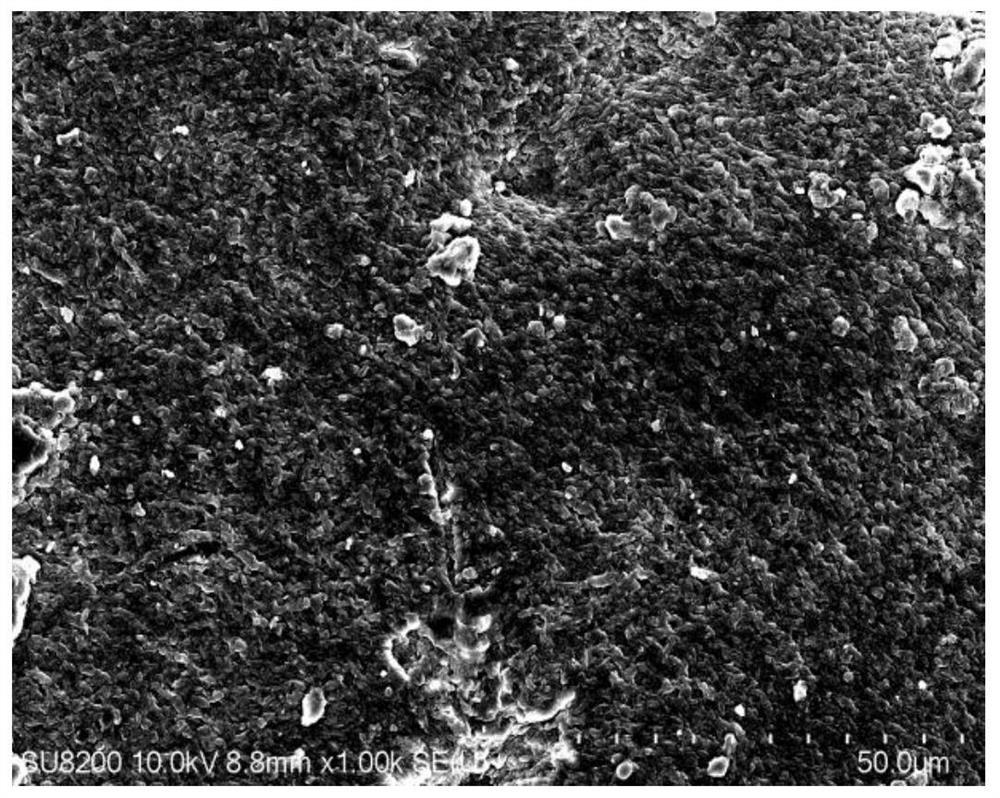

Image

Examples

Embodiment 1

[0065] A method for making whole grain noodles for diabetics, comprising the following steps:

[0066] S1:

[0067] (1) Put the whole tartary buckwheat grain material in a precision heat flow roasting machine for grains, and process it for 7 minutes at a temperature of 150°C and a wind speed of 12m / s to obtain vitrified whole tartary buckwheat grains, and then pass it through an ultrafine pulverizer Pulverize to 120 mesh, obtain tartary buckwheat whole grain powder;

[0068] (2) 70kg of wheat flour and 30kg of tartary buckwheat whole grain flour were mixed and stirred, stirred for 20min, and placed in a dough mixer at normal pressure for subsequent use;

[0069] S2:

[0070] Add 5kg of drinking water into the mixing mixer, start the mixer, add 1kg of edible salt, then add 15kg of drinking water, stir for 20min, put it in the normal pressure noodle mixer and mix it with the main ingredients in S1, start the normal pressure Dough mixer, processed under atmospheric pressure fo...

Embodiment 2

[0081] A method for making whole grain noodles for diabetics, comprising the following steps:

[0082] S1:

[0083] (1) Put the whole highland barley grain material in a grain precision heat flow roasting machine, and process it for 7 minutes at a temperature of 150°C and a wind speed of 12m / s to obtain vitrified whole highland barley grains, which are then pulverized by an ultrafine pulverizer to 120 meshes to obtain highland barley whole grain flour;

[0084] (2) 49kg of wheat flour and 51kg of highland barley whole grain flour were mixed and stirred, stirred for 20min, and placed in a vacuum kneading machine for subsequent use;

[0085] S2:

[0086] Add 5kg of drinking water to the stirring mixer, start the mixer, add 1kg of edible salt, then add 20kg of drinking water, stir for 20min, put it in the vacuum dough mixing machine and mix it with the main ingredients in S1, start the vacuum mixing of dough machine, the vacuum degree of kneading dough is 0.08MPa, and it is pr...

Embodiment 3

[0097] A method for making whole grain noodles for diabetics, comprising the following steps:

[0098] S1:

[0099] (1) Put whole tartary buckwheat grain materials and highland barley whole grain materials in a precision heat flow roasting machine for grains, and process them for 7 minutes at a temperature of 150°C and a wind speed of 12m / s to obtain vitrified whole grains, which are then subjected to ultra- The pulverizer is pulverized to 120 meshes to obtain whole grain powder of tartary buckwheat and whole grain powder of highland barley;

[0100] (2) 70kg of wheat flour, 15kg of tartary buckwheat whole grain powder, 15kg of highland barley whole grain powder, and 10kg of wheat whole grain seed coat powder were mixed and stirred, stirred for 20 min, and placed in a dough mixer at normal pressure for subsequent use;

[0101] S2:

[0102] Add 5kg of drinking water into the mixing mixer, start the mixer, add 1kg of edible salt, then add 25kg of drinking water, stir for 20min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com