Manufacturing process of ultrahigh-pressure coarse-cereal noodles

A miscellaneous grain noodle and manufacturing process technology, which is applied in food preparation, food preservation, food science, etc., can solve the problems of high fiber taste loss, long dough making time, and non-compliance requirements, etc., to improve viscosity and gelatinization degree, Effect of inhibiting fat oxidation and improving molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

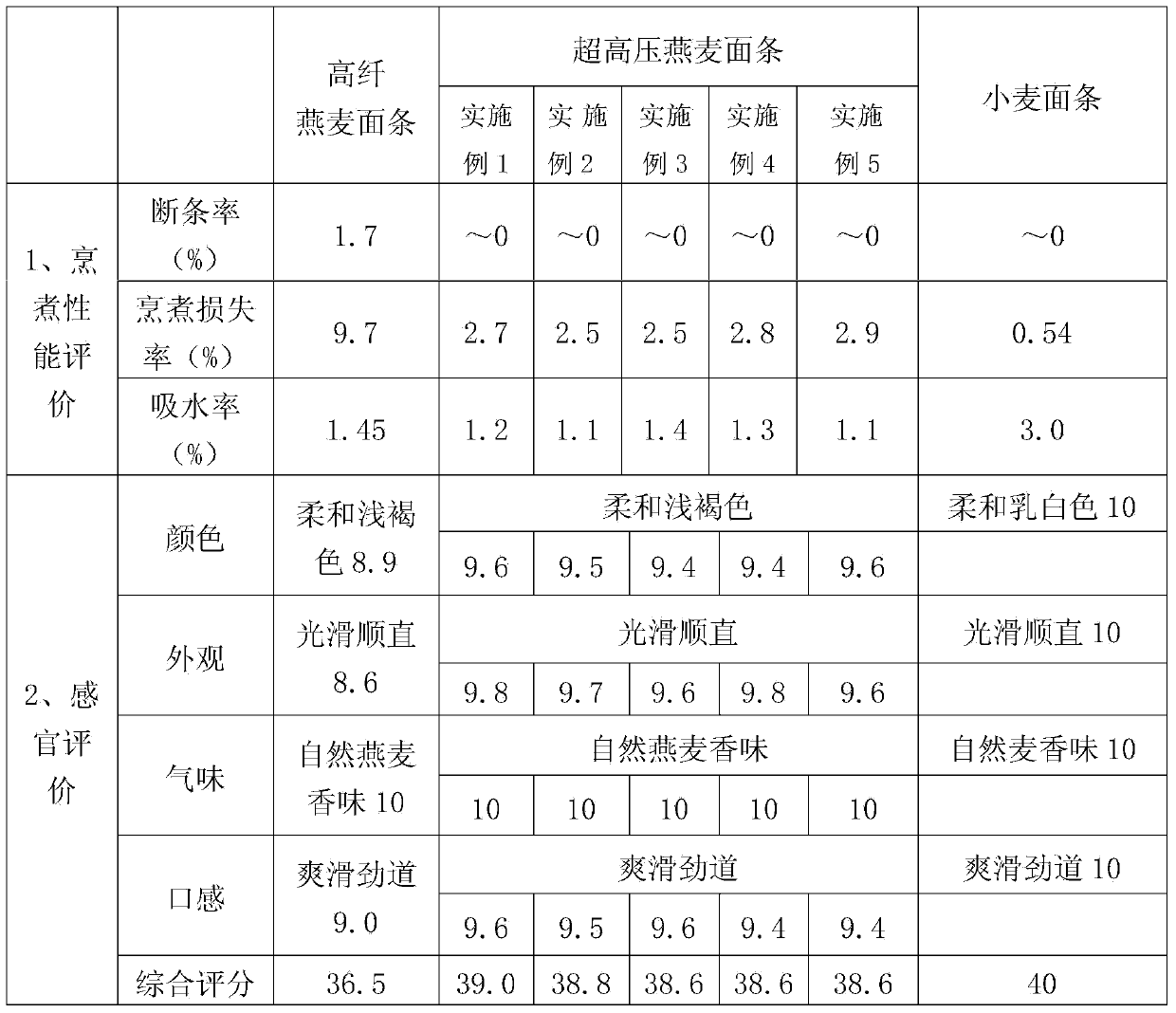

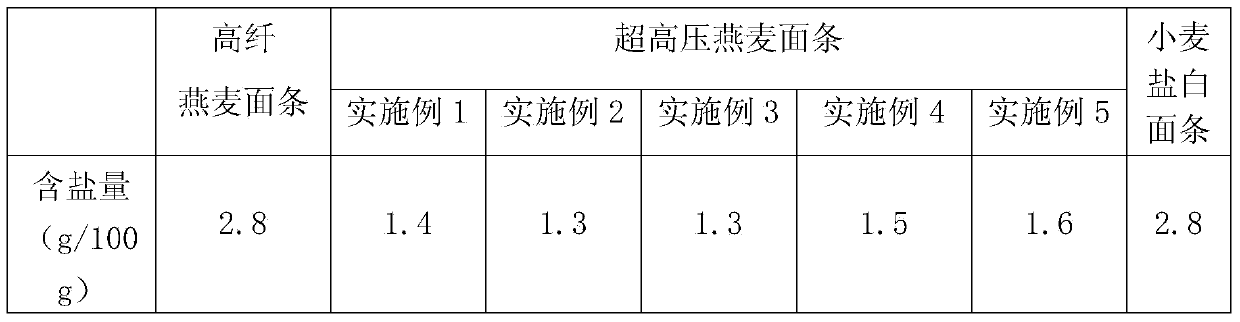

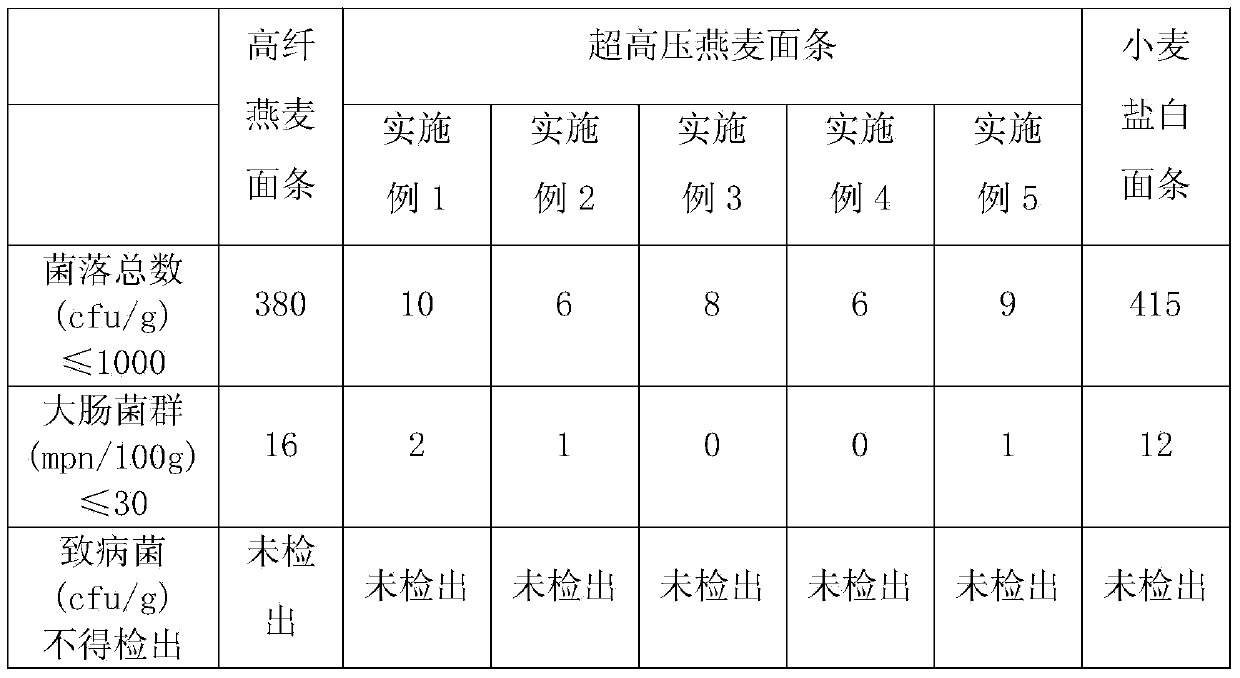

[0035] 2.85kg of oat flour, 45g of wheat flour, 45g of tapioca starch, and 60g of gluten powder are fully mixed and then added to the hopper of the vacuum dough mixing machine, and 2.55kg of 3wt% salt solution is added to the liquid inlet tank; Knead the dough for 15min at 30kpa and rotate at 150r / min, and knead it into a smooth dough; vacuum pack the dough, put it into the pressure chamber of an ultra-high pressure testing machine (SSYH6SP-30), pressurize at 600MPa, hold the pressure for 15min, and release Remove the dough after pressing. The sterilized calender is pressed step by step into noodle strips with a thickness of 0.2 cm; cut into 0.2 cm noodles; put the noodles at 4°C and 70% humidity for aging for 24 hours. Vacuum nitrogen-filled packaging, namely to obtain oatmeal fresh noodles, noodle performance table, salt content measurement results and hygienic index measurement results are shown in Table 1, Table 2, Table 3.

Embodiment 2

[0037] With 2.85kg tartary buckwheat flour, 45g wheat flour, 45g sweet potato starch, 60g konjac powder, after fully mixing, add to the hopper of the vacuum dough mixing machine, add 2.25kg3% salt solution to the liquid inlet tank; -30kpa, speed 120r / min. Knead the dough for 12min., and knead it into a smooth dough; vacuum pack the dough, put it into the pressure chamber of the ultra-high pressure testing machine, pressurize 500MPa, keep the pressure for 12min., take out the dough after releasing the pressure . The sterilized calender is pressed step by step into noodle strips with a thickness of 0.2 cm; cut into 0.4 cm noodles; and the noodles are aged at 4°C and 70% humidity for 24 hours. Vacuum nitrogen-filled packaging, tartary buckwheat fresh noodles are obtained, and the properties of the noodles are shown in Table 1, Table 2, and Table 3.

Embodiment 3

[0039] 2.76kg of sweet buckwheat flour, 115.5g of wheat flour, 115.5g of potato starch, and 9g of Artemisia gum are fully mixed and then added to the hopper of the vacuum dough mixing machine, and 2.1kg of 2% salt solution is added to the liquid inlet tank; Vacuum degree -28kpa, rotating speed 80r / min. Knead the dough for 10min., and knead it into a smooth dough; vacuum pack the dough, put it into the pressure chamber of the ultra-high pressure testing machine, pressurize 400MPa, hold the pressure for 5min., and release the pressure Take out the dough. The sterilized calender is pressed step by step into noodle strips with a thickness of 0.3cm; cut into 0.4cm noodles; put the noodles at 4°C and 65% humidity for aging for 15h. Vacuum nitrogen-filled packaging, namely to obtain sweet buckwheat fresh noodles, noodle performance table, salt content measurement results and hygienic index measurement results are shown in Table 1, Table 2, Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com