A kind of tomato vermicelli, its processing method and the application of tomato paste in the production of vermicelli

A processing method and a technology for tomato paste, applied in the field of tomato dried noodles, can solve the problems of lack of nutrition, single flavor, long cooking time of tomato dried noodles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

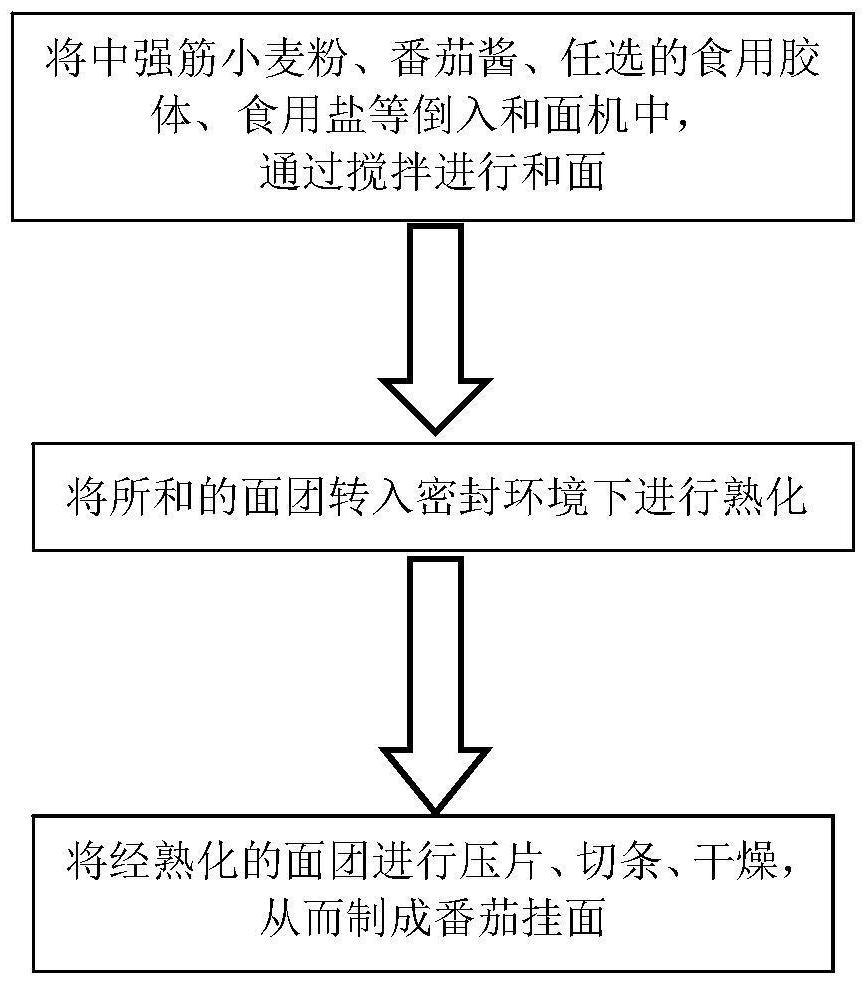

Method used

Image

Examples

Embodiment 1

[0064] The following raw materials for preparing tomato dried noodles were weighed: 100 kg of medium-strength gluten wheat flour sieved through a 70-mesh sieve, 49 kg of tomato paste, and 3 kg of edible salt. Tomato vermicelli is prepared by the following processing method:

[0065] Step 1: Pour the medium-strength gluten wheat flour, tomato paste, and edible salt into the noodle mixer, and knead the noodles by stirring. The kneading time is 16 minutes, and the stirring speed is 128 rpm for 5 minutes, followed by stirring at 63 rpm. Slow play for 11min;

[0066] Step 2, transfer the dough to a sealed environment, and ripen at room temperature for 45 minutes;

[0067] Step 3, the cured dough is pressed into the pressing roller for 10 times in an environment with a humidity of 65% (wherein, the matured dough is pressed 5 times with a rolling distance of 2 mm, including direct pressing 2 times, 2 times of tri-folding and pressing, 1 time of folding and pressing in half; and pre...

Embodiment 2

[0069] Weigh the following raw materials for preparing tomato dried noodles: 100kg of medium-strength gluten wheat flour, 50kg of tomato paste, 1kg of edible salt, 0.05kg of artemisia gum, 0.01kg of guar gum, 0.07kg of konjac gum, which are screened through a 100-mesh sieve kg. Tomato vermicelli is prepared by the following processing method:

[0070] Step 1. Pour the medium-strength wheat flour, tomato paste, edible colloids (artemisia gum, guar gum, konjac gum) and edible salt into the dough mixer, and mix the dough by stirring, and the dough mixing time is 15 minutes. Wherein, beat fast for 4min at a stirring speed of 126rpm, then beat slowly for 11min at a stirring speed of 61rpm;

[0071] Step 2, transfer the mixed dough into a sealed environment, and ripen at room temperature for 45min;

[0072]Step 3, making the matured dough enter the pressing roller for sheeting 10 times under an environment of 65% humidity (wherein, making the cooked dough sheeting 5 times with a p...

Embodiment 3

[0074] Weigh the following raw materials for preparing tomato noodles: 100kg of medium-strength wheat flour, 49kg of tomato sauce, 2kg of edible salt, 0.08kg of artemisia gum, 0.08kg of guar gum, and 0.08kg of konjac gum sifted through a 70-mesh sieve. kg. Prepare tomato vermicelli by following processing method:

[0075] Step 1, pour medium-strength gluten wheat flour, tomato paste, edible colloids (artemisia gum, guar gum, konjac gum) and edible salt into the dough mixer, and knead the dough by stirring. The dough kneading time is 15 minutes. Among them, beating fast for 5 minutes at a stirring speed of 128rpm, and then beating slowly for 10 minutes at a stirring speed of 63rpm;

[0076] Step 2, transfer the mixed dough into a sealed environment, and ripen at room temperature for 40 minutes;

[0077] Step 3, making the matured dough enter the pressing roller for sheeting 10 times under an environment of 65% humidity (wherein, making the cooked dough sheeting 5 times with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com