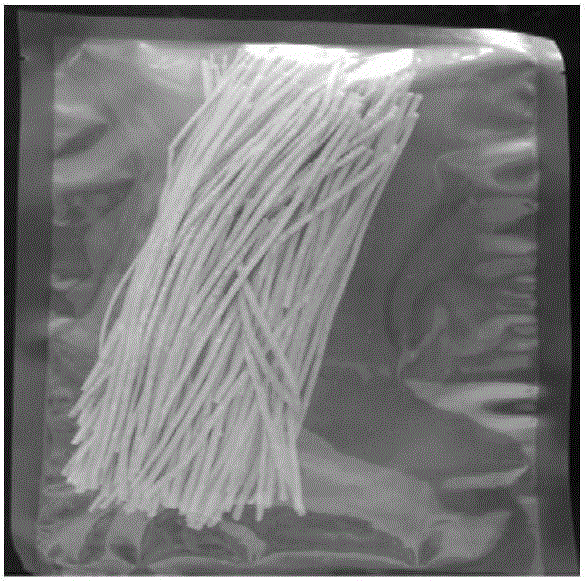

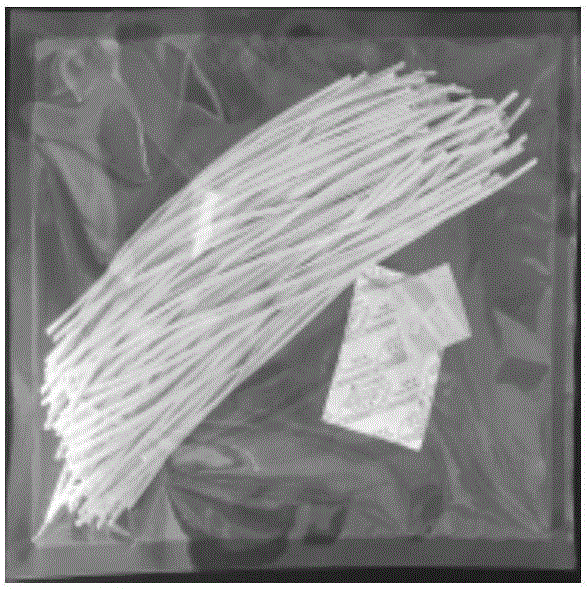

Semi-dry buckwheat noodles and processing and preservation methods thereof

A processing method and technology for semi-dry noodles, which are applied in chemical instruments and methods, food preservation, containers, etc., can solve the problems of complicated and cumbersome processing techniques, insufficient noodle aroma, poor taste and gluten strength, etc., and achieve simple production techniques and strong buckwheat aroma. , the taste is strong and smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

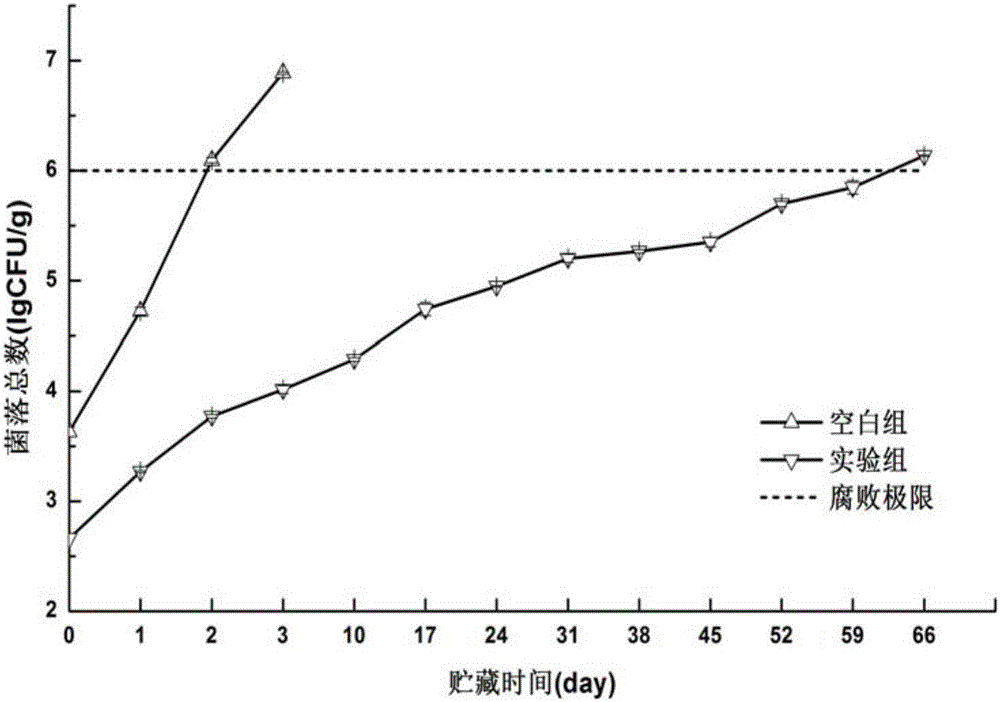

Examples

Embodiment 1

[0109] Embodiment 1: the formula of a kind of buckwheat semi-dry noodles of the present embodiment: high-quality wheat flour 51kg, whole buckwheat flour 40kg and gluten powder 9kg, sorbitol 5kg, sodium lactate 0.3kg, propylene glycol 0.25kg, compound phosphate 0.8kg, Salt 2kg.

[0110] The processing and fresh-keeping methods of the buckwheat semi-dry noodles include:

[0111] (1) Bacteria-reducing treatment of main ingredients: Pre-mix 51kg of high-quality wheat flour, 40kg of whole buckwheat flour and 9kg of gluten powder. The power is 1000W, the processing time is 120min, and the number of cycles is 6 times. The material is subjected to dynamic cycle plasma sterilization treatment, and then the treated material is sent to the vacuum dough mixing machine through a positive pressure pneumatic conveying device.

[0112] (2) Mixing of auxiliary materials: first add 25.3L sterile water to the stirring mixer, start the stirring device, and then slowly add 5 kg of sorbitol, 0.3 k...

Embodiment 2

[0121] Embodiment 2: the formula of a kind of buckwheat semi-dry noodles of the present embodiment: high-quality wheat flour 57kg, whole buckwheat flour 35kg and gluten powder 7kg, sorbitol 4kg, sodium lactate 0.25kg, propylene glycol 0.2kg, compound phosphate 0.6kg, Salt 2kg.

[0122] The processing and fresh-keeping methods of the buckwheat semi-dry noodles include:

[0123] (1) Bacteria reduction treatment of main ingredients: Pre-mix 57kg of high-quality wheat flour, 35kg of whole buckwheat flour and 7kg of gluten powder. The power is 900W, the processing time is 100min, and the number of cycles is 5 times. The material is subjected to dynamic cycle plasma sterilization treatment, and then the treated material is sent to the vacuum dough mixing machine through a positive pressure pneumatic conveying device.

[0124] (2) Mixing of auxiliary materials: first add 23.3L sterile water to the stirring mixer, start the stirring device, and then slowly add 4 kg of sorbitol, 0.25 ...

Embodiment 3

[0133] Embodiment 3: the formula of a kind of buckwheat semi-dry noodles of the present embodiment: high-quality wheat flour 65kg, whole buckwheat flour 30kg and gluten powder 5kg, sorbitol 3kg, sodium lactate 0.2kg, propylene glycol 0.15kg, compound phosphate 0.4kg, Salt 1.5kg.

[0134] The processing and fresh-keeping methods of the buckwheat semi-dry noodles include:

[0135] (1) Bacteria-reducing treatment of main ingredients: Pre-mix 65kg of high-quality wheat flour, 30kg of whole buckwheat flour and 5kg of gluten powder. The power is 800W, the processing time is 80min, and the number of cycles is 4 times. The material is subjected to dynamic cycle plasma sterilization treatment, and then the treated material is sent to the vacuum dough mixing machine through a positive pressure pneumatic conveying device.

[0136] (2) Mixing of auxiliary materials: first add 21.3L sterile water to the stirring mixer, start the stirring device, and then slowly add 3kg of sorbitol, 0.2kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com