Corn noodle pre-blend powder

A technology of corn noodles and pre-mixed powder, which is applied in food science, food ingredients as color, food ingredients as taste improver, etc. It can solve the problems of easy breaking of noodles, single taste, dull color, etc., and achieve a strong and refreshing taste Smooth, golden color, strong fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

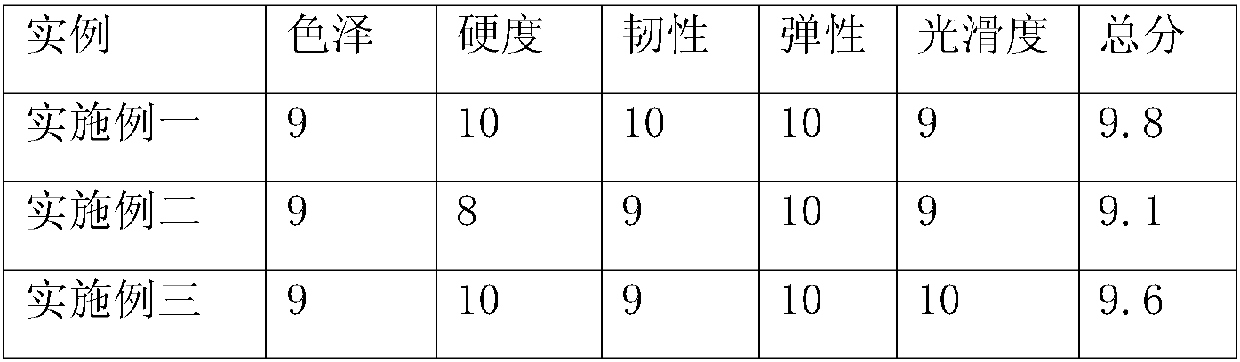

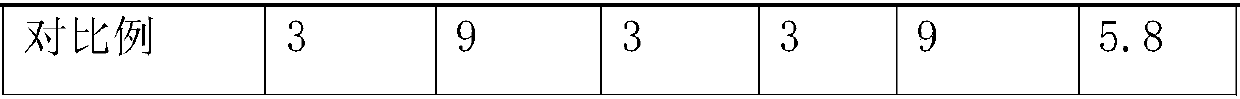

Embodiment 1

[0042] The corn noodle premix powder of present embodiment, its component content by mass percentage is: wheat flour 40%, puffed corn flour 30%, cornstarch 20%, pregelatinized cornstarch 5%, acetate tapioca modified starch 4% , Gluten 1%.

[0043] The above-mentioned premixed powder is also added with an improving agent, and the improving agent includes sodium alginate, guar gum, xylanase, sodium hexametaphosphate, gardenia yellow, and curcumin. Wherein, sodium alginate accounts for 100 ppm by mass of the premixed powder, guar gum accounts for 100 ppm by mass of the premixed powder, and xylanase accounts for 100 ppm by mass of the premixed powder. Content is 5ppm, sodium hexametaphosphate accounts for 200ppm in mass percent of said premixed powder, gardenia yellow accounts for 100ppm in mass percent of said premixed powder, and curcumin accounts for the mass percent of said premixed powder The percentage content is 100ppm.

[0044] The corn noodles premixed powder is kneaded...

Embodiment 2

[0046] The corn noodle premix of present embodiment, its component content by mass percentage is: wheat flour 35%, puffed corn flour 25%, cornstarch 25%, pregelatinized cornstarch 10%, acetate tapioca modified starch 3% , Gluten 2%.

[0047] The above-mentioned premixed powder is also added with an improving agent, and the improving agent includes sodium alginate, guar gum, xylanase, sodium hexametaphosphate, gardenia yellow, and curcumin. Wherein, sodium alginate accounts for 110 ppm by mass of the premixed powder, guar gum accounts for 110 ppm by mass of the premixed powder, and xylanase accounts for 110 ppm by mass of the premixed powder. Content is 6ppm, sodium hexametaphosphate accounts for 210ppm in mass percent of said premixed powder, gardenia yellow accounts for 110ppm in mass percent of said premixed powder, and curcumin accounts for the mass percent of said premixed powder The percentage content is 110ppm.

[0048] The above corn noodle premix powder is kneaded, r...

Embodiment 3

[0050] The corn noodle premix powder of present embodiment, its component content by mass percentage is: wheat flour 45%, puffed corn flour 35%, cornstarch 10%, pregelatinized cornstarch 5%, acetate tapioca modified starch 4% , Gluten 1%.

[0051] The above-mentioned premixed powder is also added with an improving agent, and the improving agent includes sodium alginate, guar gum, xylanase, sodium hexametaphosphate, gardenia yellow, and curcumin. Wherein, sodium alginate accounts for 90 ppm by mass of the premixed powder, guar gum accounts for 90 ppm by mass of the premixed powder, and xylanase accounts for 90 ppm by mass of the premixed powder. Content is 4ppm, sodium hexametaphosphate accounts for 190ppm in mass percent of said premixed powder, gardenia yellow accounts for 90ppm in mass percent of said premixed powder, and curcumin accounts for the mass percent of said premixed powder The percentage content is 90ppm.

[0052] The above corn noodle premix powder is kneaded, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com