A kind of dumpling powder and preparation method thereof

A dumpling powder and flour technology, applied in food science and other fields, can solve problems such as easy water loss, unsatisfactory, cracking, etc., and achieve the effect of improving extensibility and water retention, and reducing the cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 dumpling powder

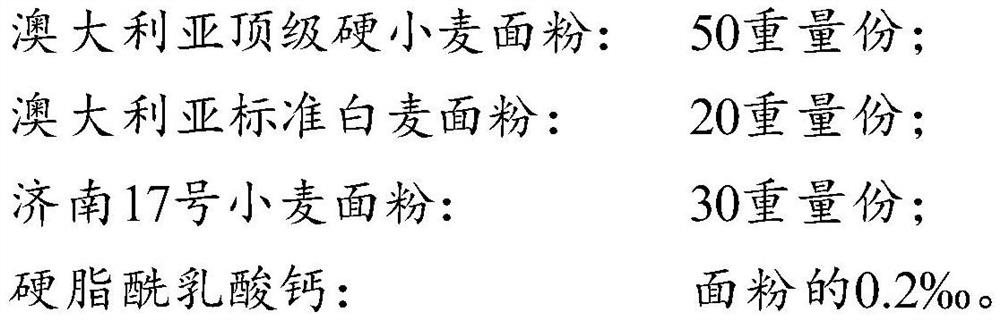

[0030] The formula of dumpling powder in the present embodiment is as follows:

[0031]

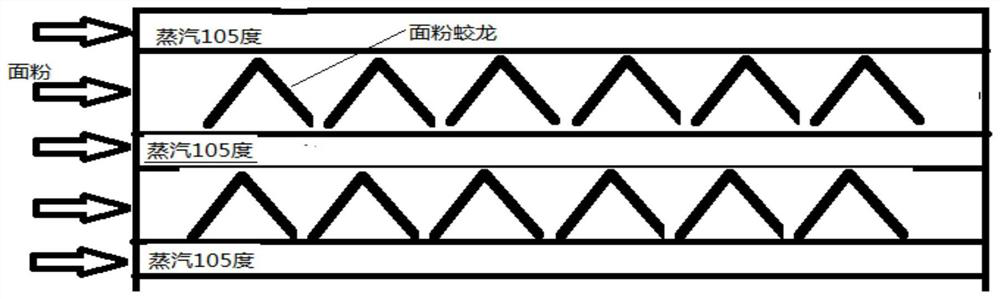

[0032] The preparation method is as follows: the Australian top hard wheat flour, the Australian standard white wheat flour and the Jinan No. 17 wheat flour are transported to the flour Jiaolong respectively, and treated with hot and humid steam at 105°C for 20 minutes. During the whole process, the flour is completely separated from the hot and humid steam. picture see figure 1 . Then the moisture content of the flour is reduced below 14% by a dehumidification device, pulverized, dried, mixed with the formula amount of each raw material flour, added with the formula amount of calcium stearoyl lactylate, and formulated into dumpling special powder.

Embodiment 2

[0033] The preparation of embodiment 2 dumpling flour

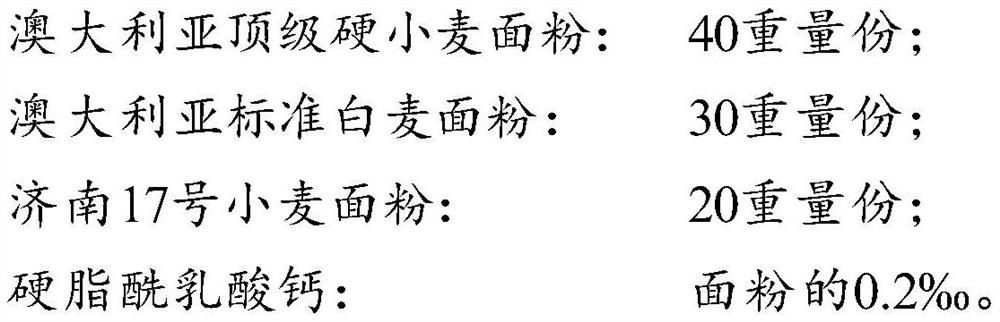

[0034] The formula of dumpling powder in the present embodiment is as follows:

[0035]

[0036] The preparation method is as follows: the Australian top hard wheat flour, the Australian standard white wheat flour and the Jinan No. 17 wheat flour are respectively transported into the flour Jiaolong, and treated with hot and humid steam at 105°C for 20 minutes. During the whole process, the flour is completely separated from the hot and humid steam. Then the moisture content of the flour is reduced below 14% by a dehumidification device, pulverized, dried, mixed with the formula amount of each raw material flour, added with the formula amount of calcium stearoyl lactylate, and formulated into dumpling special powder.

Embodiment 3

[0037] The preparation of embodiment 3 dumpling flour

[0038] The formula of dumpling powder in the present embodiment is as follows:

[0039]

[0040] The preparation method is as follows: the Australian top hard wheat flour, the Australian standard white wheat flour and the Jinan No. 17 wheat flour are respectively transported into the flour Jiaolong, and treated with hot and humid steam at 105°C for 20 minutes. During the whole process, the flour is completely separated from the hot and humid steam. Then the moisture content of the flour is reduced below 14% by a dehumidification device, pulverized, dried, mixed with the formula amount of each raw material flour, added with the formula amount of calcium stearoyl lactylate, and formulated into dumpling special powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com